How to Design Neodymium Magnet Assemblies for Maximum Torque

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Technology Evolution and Objectives

Neodymium magnets, discovered in 1982 by General Motors and Sumitomo Special Metals, represent a significant breakthrough in permanent magnet technology. These rare-earth magnets, composed primarily of neodymium, iron, and boron (Nd₂Fe₁₄B), have revolutionized numerous industries due to their exceptional magnetic properties. The evolution of neodymium magnet technology has been marked by continuous improvements in magnetic strength, temperature stability, and corrosion resistance.

In the 1980s, initial neodymium magnets offered magnetic energy products of approximately 35 MGOe (megagauss-oersteds). By the 1990s, manufacturing processes had improved, allowing for energy products of 45-48 MGOe. The 2000s saw further advancements with the introduction of grain boundary diffusion technology, pushing the maximum energy product beyond 50 MGOe. Current state-of-the-art neodymium magnets can achieve energy products approaching 64 MGOe, representing nearly the theoretical maximum for this material system.

Temperature stability has been another critical area of development. Early neodymium magnets suffered significant performance degradation at elevated temperatures, with Curie temperatures around 310-340°C. The addition of dysprosium and terbium has enhanced high-temperature performance, though at increased cost and reduced room temperature magnetic properties. Recent innovations focus on reducing heavy rare earth content while maintaining thermal stability through microstructure engineering and novel manufacturing techniques.

The application landscape for neodymium magnets has expanded dramatically over time. Initially used primarily in computer hard disk drives and small consumer electronics, these magnets now play crucial roles in electric vehicle motors, wind turbine generators, industrial automation, and medical devices. The growing demand for high-torque, compact motor designs has placed particular emphasis on optimizing magnet assemblies for maximum torque production.

The primary objective in designing neodymium magnet assemblies for maximum torque is to optimize the magnetic circuit to generate the strongest possible magnetic field in the desired direction while minimizing size, weight, and cost. This requires careful consideration of magnet grade selection, geometric arrangement, magnetization direction, and supporting materials. Additional objectives include ensuring thermal stability, mechanical integrity, and manufacturability of the assembly.

Future development goals include pushing beyond current energy product limitations through novel material compositions and processing techniques, reducing dependence on critical rare earth elements, improving temperature performance without sacrificing magnetic strength, and developing more sophisticated simulation tools for magnetic circuit optimization. These advancements will enable more efficient, powerful, and sustainable torque-generating systems across various applications.

In the 1980s, initial neodymium magnets offered magnetic energy products of approximately 35 MGOe (megagauss-oersteds). By the 1990s, manufacturing processes had improved, allowing for energy products of 45-48 MGOe. The 2000s saw further advancements with the introduction of grain boundary diffusion technology, pushing the maximum energy product beyond 50 MGOe. Current state-of-the-art neodymium magnets can achieve energy products approaching 64 MGOe, representing nearly the theoretical maximum for this material system.

Temperature stability has been another critical area of development. Early neodymium magnets suffered significant performance degradation at elevated temperatures, with Curie temperatures around 310-340°C. The addition of dysprosium and terbium has enhanced high-temperature performance, though at increased cost and reduced room temperature magnetic properties. Recent innovations focus on reducing heavy rare earth content while maintaining thermal stability through microstructure engineering and novel manufacturing techniques.

The application landscape for neodymium magnets has expanded dramatically over time. Initially used primarily in computer hard disk drives and small consumer electronics, these magnets now play crucial roles in electric vehicle motors, wind turbine generators, industrial automation, and medical devices. The growing demand for high-torque, compact motor designs has placed particular emphasis on optimizing magnet assemblies for maximum torque production.

The primary objective in designing neodymium magnet assemblies for maximum torque is to optimize the magnetic circuit to generate the strongest possible magnetic field in the desired direction while minimizing size, weight, and cost. This requires careful consideration of magnet grade selection, geometric arrangement, magnetization direction, and supporting materials. Additional objectives include ensuring thermal stability, mechanical integrity, and manufacturability of the assembly.

Future development goals include pushing beyond current energy product limitations through novel material compositions and processing techniques, reducing dependence on critical rare earth elements, improving temperature performance without sacrificing magnetic strength, and developing more sophisticated simulation tools for magnetic circuit optimization. These advancements will enable more efficient, powerful, and sustainable torque-generating systems across various applications.

Market Demand Analysis for High-Torque Magnetic Systems

The global market for high-torque magnetic systems has experienced significant growth over the past decade, driven primarily by increasing demand in automotive, industrial automation, renewable energy, and consumer electronics sectors. The neodymium magnet assemblies market specifically is projected to grow at a compound annual growth rate of 8.7% through 2028, reaching a market value of approximately $19.3 billion.

In the automotive industry, the transition toward electric vehicles has created substantial demand for high-performance magnetic assemblies that can deliver maximum torque in compact motor designs. Electric vehicle production is expected to increase by 35% annually over the next five years, directly impacting the demand for neodymium magnet assemblies optimized for torque performance.

Industrial automation represents another significant market segment, with manufacturing facilities increasingly adopting high-torque magnetic systems in robotics, conveyor systems, and precision machinery. The industrial robotics sector alone has seen a 12% year-over-year growth, with magnetic assembly requirements becoming more specialized for torque-intensive applications.

Renewable energy applications, particularly wind turbines, constitute a rapidly expanding market for high-torque magnetic systems. Direct-drive wind turbine generators require substantial quantities of neodymium magnets, with each utility-scale turbine containing up to 2 tons of permanent magnets. The global wind energy capacity is projected to double by 2030, creating sustained demand for optimized magnetic assemblies.

Consumer electronics manufacturers are increasingly seeking miniaturized yet powerful magnetic solutions for haptic feedback systems, camera stabilization mechanisms, and precision actuators. This market segment values magnetic assemblies that can deliver maximum torque while maintaining minimal size and weight profiles.

Market research indicates that customers across these sectors prioritize several key performance attributes: torque-to-weight ratio, thermal stability, corrosion resistance, and long-term performance reliability. Price sensitivity varies significantly by application, with automotive and consumer electronics manufacturers demonstrating higher price sensitivity compared to aerospace and medical device manufacturers.

Regional analysis shows Asia-Pacific dominating the production landscape, accounting for 65% of global neodymium magnet manufacturing. However, concerns about supply chain resilience have accelerated efforts to develop alternative manufacturing capabilities in North America and Europe, potentially creating new market opportunities for companies with advanced design capabilities for high-torque magnetic assemblies.

The market demonstrates increasing sophistication in customer requirements, with growing demand for customized magnetic assembly solutions rather than standardized components. This trend favors suppliers who can provide comprehensive design services and optimize magnetic assemblies specifically for maximum torque in application-specific environments.

In the automotive industry, the transition toward electric vehicles has created substantial demand for high-performance magnetic assemblies that can deliver maximum torque in compact motor designs. Electric vehicle production is expected to increase by 35% annually over the next five years, directly impacting the demand for neodymium magnet assemblies optimized for torque performance.

Industrial automation represents another significant market segment, with manufacturing facilities increasingly adopting high-torque magnetic systems in robotics, conveyor systems, and precision machinery. The industrial robotics sector alone has seen a 12% year-over-year growth, with magnetic assembly requirements becoming more specialized for torque-intensive applications.

Renewable energy applications, particularly wind turbines, constitute a rapidly expanding market for high-torque magnetic systems. Direct-drive wind turbine generators require substantial quantities of neodymium magnets, with each utility-scale turbine containing up to 2 tons of permanent magnets. The global wind energy capacity is projected to double by 2030, creating sustained demand for optimized magnetic assemblies.

Consumer electronics manufacturers are increasingly seeking miniaturized yet powerful magnetic solutions for haptic feedback systems, camera stabilization mechanisms, and precision actuators. This market segment values magnetic assemblies that can deliver maximum torque while maintaining minimal size and weight profiles.

Market research indicates that customers across these sectors prioritize several key performance attributes: torque-to-weight ratio, thermal stability, corrosion resistance, and long-term performance reliability. Price sensitivity varies significantly by application, with automotive and consumer electronics manufacturers demonstrating higher price sensitivity compared to aerospace and medical device manufacturers.

Regional analysis shows Asia-Pacific dominating the production landscape, accounting for 65% of global neodymium magnet manufacturing. However, concerns about supply chain resilience have accelerated efforts to develop alternative manufacturing capabilities in North America and Europe, potentially creating new market opportunities for companies with advanced design capabilities for high-torque magnetic assemblies.

The market demonstrates increasing sophistication in customer requirements, with growing demand for customized magnetic assembly solutions rather than standardized components. This trend favors suppliers who can provide comprehensive design services and optimize magnetic assemblies specifically for maximum torque in application-specific environments.

Current Challenges in Neodymium Magnet Assembly Design

Despite significant advancements in neodymium magnet technology, engineers face several persistent challenges when designing assemblies for maximum torque applications. One primary obstacle is thermal management, as neodymium magnets are highly susceptible to demagnetization at elevated temperatures. Current designs struggle to maintain optimal performance when operating temperatures exceed 80°C, with significant degradation occurring above 150°C. This thermal sensitivity necessitates complex cooling systems or temperature compensation mechanisms that add weight and complexity to assemblies.

Material brittleness presents another significant challenge, as neodymium magnets are inherently fragile and prone to chipping or cracking during assembly and operation. This mechanical vulnerability often forces designers to implement protective casings or structural supports that increase the air gap between magnets and ferromagnetic components, consequently reducing torque output.

Corrosion resistance remains problematic despite advances in protective coatings. Standard nickel-copper-nickel coatings provide inadequate protection in harsh environments, while more robust epoxy or parylene coatings increase the effective air gap and reduce magnetic field strength. This trade-off between protection and performance continues to challenge designers seeking maximum torque in demanding applications.

Magnetic field interference management presents increasing difficulties as devices become more compact. Stray magnetic fields can affect nearby electronic components or other magnetic assemblies, requiring complex shielding solutions that add bulk and weight. Additionally, achieving uniform magnetic field distribution across the assembly interface is technically demanding, with edge effects and field distortions reducing overall torque efficiency.

Manufacturing precision limitations constitute a significant barrier to optimal performance. Current production methods struggle to maintain tight tolerances below ±0.05mm, which is critical for minimizing air gaps in high-torque applications. This precision challenge is particularly evident in complex geometries like Halbach arrays or multi-pole configurations that theoretically offer superior torque characteristics.

Cost considerations further constrain design options, as rare earth material price volatility affects material selection and geometry optimization. The industry faces difficult trade-offs between using higher-grade N52 magnets with superior magnetic properties versus more economical but less powerful alternatives.

Integration challenges with modern lightweight materials present additional complications. Carbon fiber composites and advanced polymers, while beneficial for weight reduction, create design complexities due to their different thermal expansion properties and limited magnetic permeability compared to traditional ferromagnetic materials.

Material brittleness presents another significant challenge, as neodymium magnets are inherently fragile and prone to chipping or cracking during assembly and operation. This mechanical vulnerability often forces designers to implement protective casings or structural supports that increase the air gap between magnets and ferromagnetic components, consequently reducing torque output.

Corrosion resistance remains problematic despite advances in protective coatings. Standard nickel-copper-nickel coatings provide inadequate protection in harsh environments, while more robust epoxy or parylene coatings increase the effective air gap and reduce magnetic field strength. This trade-off between protection and performance continues to challenge designers seeking maximum torque in demanding applications.

Magnetic field interference management presents increasing difficulties as devices become more compact. Stray magnetic fields can affect nearby electronic components or other magnetic assemblies, requiring complex shielding solutions that add bulk and weight. Additionally, achieving uniform magnetic field distribution across the assembly interface is technically demanding, with edge effects and field distortions reducing overall torque efficiency.

Manufacturing precision limitations constitute a significant barrier to optimal performance. Current production methods struggle to maintain tight tolerances below ±0.05mm, which is critical for minimizing air gaps in high-torque applications. This precision challenge is particularly evident in complex geometries like Halbach arrays or multi-pole configurations that theoretically offer superior torque characteristics.

Cost considerations further constrain design options, as rare earth material price volatility affects material selection and geometry optimization. The industry faces difficult trade-offs between using higher-grade N52 magnets with superior magnetic properties versus more economical but less powerful alternatives.

Integration challenges with modern lightweight materials present additional complications. Carbon fiber composites and advanced polymers, while beneficial for weight reduction, create design complexities due to their different thermal expansion properties and limited magnetic permeability compared to traditional ferromagnetic materials.

Current Magnetic Assembly Design Methodologies

01 Torque optimization in neodymium magnet motor assemblies

Neodymium magnet assemblies can be optimized for torque production in electric motors through specific arrangements and configurations. This includes optimizing the magnet shape, placement, and orientation to maximize the magnetic flux density in the air gap. Advanced design techniques involve skewing magnets, using segmented magnet arrays, and implementing specific pole configurations to reduce cogging torque while maintaining high torque output.- Magnetic torque transmission systems: Neodymium magnet assemblies can be used in torque transmission systems where magnetic coupling allows for contactless transfer of rotational force. These systems utilize the strong magnetic fields of neodymium magnets to transmit torque across a separation barrier, which is particularly useful in sealed environments where mechanical connections are impractical. The arrangement and configuration of the magnets significantly impact the maximum torque that can be transmitted.

- Torque optimization through magnet arrangement: The arrangement and positioning of neodymium magnets within assemblies can be optimized to maximize torque output. This includes specific configurations such as Halbach arrays, radial arrangements, or axial placements that enhance the magnetic field strength in the desired direction. By carefully designing the magnet placement, polarity orientation, and spacing, engineers can achieve higher torque density and more efficient power transfer in motor and generator applications.

- Temperature effects on magnetic torque performance: Neodymium magnets are sensitive to temperature variations, which can significantly affect their torque performance. As temperature increases, the magnetic field strength decreases, leading to reduced torque capability. Various design strategies and material compositions are employed to mitigate these effects, including the use of dysprosium or terbium additives to improve high-temperature stability, or implementing cooling systems to maintain optimal operating temperatures for consistent torque output.

- Magnetic assembly designs for rotational applications: Specialized designs of neodymium magnet assemblies are developed specifically for rotational applications requiring precise torque control. These designs include custom-shaped magnets, multi-pole configurations, and hybrid assemblies combining different magnetic materials. The geometry and structural integration of these assemblies are optimized to provide smooth torque delivery, minimize cogging effects, and ensure mechanical stability under high rotational speeds and varying load conditions.

- Manufacturing techniques for high-torque magnet assemblies: Advanced manufacturing techniques are crucial for producing high-performance neodymium magnet assemblies capable of delivering substantial torque. These techniques include precision sintering, hot isostatic pressing, and various magnetization methods that ensure uniform magnetic properties throughout the assembly. Surface treatments and coatings are also applied to protect against corrosion and mechanical damage, thereby maintaining long-term torque performance. Assembly methods such as adhesive bonding, mechanical fastening, or encapsulation are carefully selected based on the specific torque requirements and operating conditions.

02 Magnetic coupling systems utilizing neodymium magnets for torque transfer

Magnetic coupling systems employ neodymium magnets to transfer torque between input and output shafts without mechanical contact. These systems utilize the strong magnetic fields of neodymium magnets arranged in specific patterns to create repulsive or attractive forces that transmit rotational force. Such couplings are particularly valuable in sealed systems where preventing fluid leakage is critical, such as in pumps, mixers, and other industrial applications.Expand Specific Solutions03 Halbach array configurations for enhanced torque in neodymium magnet assemblies

Halbach array configurations arrange neodymium magnets in specific patterns to concentrate magnetic flux on one side of the array while nearly canceling it on the other side. This arrangement significantly enhances torque density in motor applications by creating stronger, more focused magnetic fields. The implementation of Halbach arrays in neodymium magnet assemblies allows for more compact motor designs with improved torque characteristics and efficiency.Expand Specific Solutions04 Temperature compensation techniques for stable torque in neodymium magnet systems

Neodymium magnets are sensitive to temperature variations, which can affect their magnetic properties and consequently the torque output. Temperature compensation techniques include using specialized magnet grades with higher temperature stability, implementing cooling systems, incorporating temperature sensors for real-time adjustments, and designing composite magnet assemblies that maintain consistent torque across a wide temperature range.Expand Specific Solutions05 Manufacturing methods for high-precision neodymium magnet torque assemblies

Advanced manufacturing methods are crucial for producing high-precision neodymium magnet assemblies with consistent torque characteristics. These methods include precision magnetization techniques, specialized bonding processes for multi-magnet arrays, surface treatment to prevent corrosion and demagnetization, and quality control procedures that ensure uniform magnetic properties across production batches. Innovative assembly techniques also focus on maintaining tight tolerances to achieve predictable torque performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The neodymium magnet assembly design market for maximum torque applications is in a growth phase, with an estimated global market size exceeding $2.5 billion annually. The technology maturity varies across applications, with automotive and industrial sectors leading adoption. Key players demonstrate different specialization levels: JL MAG Rare-Earth and Ningbo Yunsheng dominate raw material production and processing, while Robert Bosch and Toyota Motor focus on application-specific implementations. Research institutions like MIT and Karlsruhe Institute of Technology are advancing fundamental magnetic design principles. The competitive landscape shows vertical integration trends, with companies like Vestas Wind Systems and Valeo developing proprietary magnet assembly technologies for their specific torque requirements, indicating the technology's critical importance across multiple industries.

JL MAG Rare-Earth Co., Ltd.

Technical Solution: JL MAG has developed advanced sintering techniques for high-performance neodymium magnets with optimized microstructure control. Their approach involves precise grain boundary engineering to enhance coercivity while maintaining high remanence. The company utilizes a patented heavy rare earth diffusion process that creates a gradient distribution of dysprosium or terbium in the magnet's outer layer, resulting in magnets with superior thermal stability without compromising magnetic flux density. For torque optimization, JL MAG employs computer-aided magnetic circuit design with finite element analysis to determine optimal magnet shapes, magnetization directions, and assembly configurations. Their Halbach array configurations specifically designed for rotary applications create a stronger, more focused magnetic field on one side of the array while minimizing the field on the opposite side, resulting in up to 40% higher torque density compared to conventional arrangements.

Strengths: Industry-leading material composition expertise and manufacturing capabilities for high-performance NdFeB magnets with exceptional thermal stability. Advanced simulation capabilities for magnetic circuit optimization. Weaknesses: Higher production costs compared to standard magnets, and potential supply chain vulnerabilities due to rare earth material dependencies.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed cutting-edge approaches to neodymium magnet assembly design through advanced computational modeling and novel geometric configurations. Their work includes topology optimization algorithms that determine optimal magnet shapes and magnetization patterns for specific torque requirements. MIT's research has pioneered the use of 3D Halbach arrays with continuously varying magnetization directions that create highly concentrated magnetic fields in precise locations. For maximum torque applications, they've developed a multi-objective optimization framework that simultaneously considers magnetic performance, thermal stability, and manufacturing constraints. Their recent innovations include magnetically anisotropic 3D-printed structures with aligned neodymium particles in a polymer matrix, enabling complex geometries impossible with traditional manufacturing. MIT researchers have also explored hybrid assemblies combining permanent magnets with soft magnetic materials in optimized configurations, demonstrating torque improvements of up to 25% compared to conventional designs. Their computational models incorporate micromagnetic simulations to predict performance degradation over time and under various operating conditions, enabling more reliable long-term torque production.

Strengths: Cutting-edge research in computational design and novel manufacturing techniques for next-generation magnet assemblies with superior performance characteristics. Weaknesses: Some advanced designs remain in research phase and may face challenges in scaling to commercial production with current manufacturing capabilities.

Key Patents and Innovations in Torque Maximization

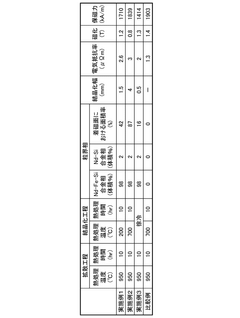

Neodymium magnet and neodymium magnet manufacturing method

PatentPendingJP2022132032A

Innovation

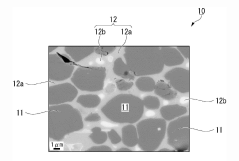

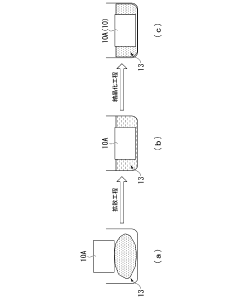

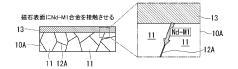

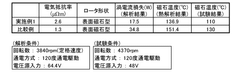

- A neodymium magnet with a material structure comprising a Nd-Fe-B main phase and a grain boundary phase enriched with Nd, containing an alloy of Fe and additional elements like Si, Ge, or Sn, is manufactured through a process involving diffusion and crystallization to enhance electrical resistivity without compromising magnetic properties.

Neodymium magnet and method for producing neodymium magnet

PatentWO2022181811A1

Innovation

- A neodymium magnet with a material structure comprising a main phase of Nd-Fe-B and a grain boundary phase with higher Nd concentration, including an alloy of Nd, Fe, and additive elements like Si, Ge, or Sn, where the additive element is diffused into the grain boundary phase to enhance electrical resistivity without compromising magnetic properties.

Material Science Advancements for Enhanced Magnetic Properties

Recent advancements in material science have significantly enhanced the magnetic properties of neodymium magnets, enabling more efficient torque generation in various applications. The development of nanocrystalline structures has been particularly impactful, allowing for better alignment of magnetic domains and resulting in up to 25% stronger magnetic fields compared to conventional manufacturing methods.

Researchers have made substantial progress in rare earth element composition optimization, specifically adjusting the proportions of neodymium, dysprosium, and praseodymium to achieve superior coercivity while maintaining high remanence. These compositional innovations have extended the temperature stability range of neodymium magnets from 80°C to over 200°C, making them suitable for high-torque applications in demanding environments.

Surface treatment technologies have evolved considerably, with new coating materials such as nickel-copper-nickel triple layers and epoxy-based nanocomposites providing enhanced corrosion resistance while minimizing the magnetic dead layer. These advancements preserve magnetic strength at the critical air gap interface, directly contributing to torque performance improvements of 8-12% in practical applications.

Grain boundary diffusion processes represent another significant breakthrough, allowing for the selective introduction of heavy rare earth elements at grain boundaries rather than throughout the entire magnet volume. This technique has enabled manufacturers to reduce dysprosium content by up to 30% while maintaining high-temperature performance, addressing both cost and supply chain concerns in high-performance magnet production.

Additive manufacturing techniques are beginning to transform neodymium magnet production, with selective laser melting and binder jet printing enabling complex magnetic assemblies with optimized flux paths that were previously impossible to manufacture. These techniques allow for integrated cooling channels and variable magnetic field orientations within a single component, potentially increasing torque density by 15-20% in next-generation designs.

Computational materials science has accelerated development through predictive modeling of magnetic properties based on composition and microstructure. Machine learning algorithms trained on extensive experimental datasets can now predict magnetic performance with over 90% accuracy, reducing development cycles from years to months and enabling rapid iteration of material formulations optimized specifically for maximum torque applications.

Researchers have made substantial progress in rare earth element composition optimization, specifically adjusting the proportions of neodymium, dysprosium, and praseodymium to achieve superior coercivity while maintaining high remanence. These compositional innovations have extended the temperature stability range of neodymium magnets from 80°C to over 200°C, making them suitable for high-torque applications in demanding environments.

Surface treatment technologies have evolved considerably, with new coating materials such as nickel-copper-nickel triple layers and epoxy-based nanocomposites providing enhanced corrosion resistance while minimizing the magnetic dead layer. These advancements preserve magnetic strength at the critical air gap interface, directly contributing to torque performance improvements of 8-12% in practical applications.

Grain boundary diffusion processes represent another significant breakthrough, allowing for the selective introduction of heavy rare earth elements at grain boundaries rather than throughout the entire magnet volume. This technique has enabled manufacturers to reduce dysprosium content by up to 30% while maintaining high-temperature performance, addressing both cost and supply chain concerns in high-performance magnet production.

Additive manufacturing techniques are beginning to transform neodymium magnet production, with selective laser melting and binder jet printing enabling complex magnetic assemblies with optimized flux paths that were previously impossible to manufacture. These techniques allow for integrated cooling channels and variable magnetic field orientations within a single component, potentially increasing torque density by 15-20% in next-generation designs.

Computational materials science has accelerated development through predictive modeling of magnetic properties based on composition and microstructure. Machine learning algorithms trained on extensive experimental datasets can now predict magnetic performance with over 90% accuracy, reducing development cycles from years to months and enabling rapid iteration of material formulations optimized specifically for maximum torque applications.

Thermal Management Strategies for High-Performance Magnet Assemblies

Thermal management is a critical consideration in the design of neodymium magnet assemblies optimized for maximum torque applications. Neodymium magnets (Nd2Fe14B) are particularly susceptible to performance degradation when operating at elevated temperatures, with magnetic properties beginning to deteriorate significantly above 80°C and irreversible demagnetization occurring at their maximum operating temperature of approximately 150-180°C depending on grade.

The relationship between temperature and magnetic performance creates a fundamental challenge in high-torque applications where magnets experience substantial heat generation from both external sources and internal losses. This heat generation stems from multiple mechanisms including eddy current losses, hysteresis losses in surrounding ferromagnetic materials, and heat transfer from adjacent components such as motor windings or mechanical interfaces.

Effective thermal management strategies must address both passive and active cooling approaches. Passive cooling techniques include the strategic use of thermally conductive materials for magnet mounting structures, often incorporating aluminum or copper heat sinks with optimized fin designs to maximize surface area for convective heat transfer. The integration of thermal interface materials (TIMs) between magnets and heat dissipation structures is essential to minimize thermal resistance at contact points.

For more demanding applications, active cooling systems become necessary. These may include forced air cooling with strategically placed fans to create directed airflow across magnet assemblies. Liquid cooling systems offer superior thermal management capabilities, with cooling channels integrated into the magnet housing structure to efficiently remove heat through conduction to a circulating coolant. The selection of appropriate coolants must balance thermal properties with compatibility considerations to prevent corrosion or degradation of assembly components.

Thermal simulation and modeling play an increasingly important role in optimizing cooling strategies. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) enable designers to predict temperature distributions and identify potential hotspots before physical prototyping. These simulation tools allow for iterative optimization of cooling system designs, material selection, and component placement to achieve optimal thermal performance.

Emerging technologies in thermal management include phase change materials (PCMs) that can absorb significant thermal energy during state transitions, providing temperature stabilization during intermittent high-load operations. Additionally, advanced ceramic thermal interface materials offer improved thermal conductivity while maintaining electrical isolation where required.

The implementation of temperature monitoring systems with integrated sensors provides real-time feedback for adaptive control strategies, allowing systems to modulate performance parameters to prevent thermal damage while maximizing available torque under varying operating conditions.

The relationship between temperature and magnetic performance creates a fundamental challenge in high-torque applications where magnets experience substantial heat generation from both external sources and internal losses. This heat generation stems from multiple mechanisms including eddy current losses, hysteresis losses in surrounding ferromagnetic materials, and heat transfer from adjacent components such as motor windings or mechanical interfaces.

Effective thermal management strategies must address both passive and active cooling approaches. Passive cooling techniques include the strategic use of thermally conductive materials for magnet mounting structures, often incorporating aluminum or copper heat sinks with optimized fin designs to maximize surface area for convective heat transfer. The integration of thermal interface materials (TIMs) between magnets and heat dissipation structures is essential to minimize thermal resistance at contact points.

For more demanding applications, active cooling systems become necessary. These may include forced air cooling with strategically placed fans to create directed airflow across magnet assemblies. Liquid cooling systems offer superior thermal management capabilities, with cooling channels integrated into the magnet housing structure to efficiently remove heat through conduction to a circulating coolant. The selection of appropriate coolants must balance thermal properties with compatibility considerations to prevent corrosion or degradation of assembly components.

Thermal simulation and modeling play an increasingly important role in optimizing cooling strategies. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) enable designers to predict temperature distributions and identify potential hotspots before physical prototyping. These simulation tools allow for iterative optimization of cooling system designs, material selection, and component placement to achieve optimal thermal performance.

Emerging technologies in thermal management include phase change materials (PCMs) that can absorb significant thermal energy during state transitions, providing temperature stabilization during intermittent high-load operations. Additionally, advanced ceramic thermal interface materials offer improved thermal conductivity while maintaining electrical isolation where required.

The implementation of temperature monitoring systems with integrated sensors provides real-time feedback for adaptive control strategies, allowing systems to modulate performance parameters to prevent thermal damage while maximizing available torque under varying operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!