How to Employ Data Analytics in Heat Exchanger Optimization

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Analytics Background and Objectives

Heat exchangers have evolved significantly since their inception in the early 20th century, transitioning from simple shell-and-tube designs to complex multi-channel configurations with enhanced heat transfer capabilities. The technological progression has been driven by increasing demands for energy efficiency, space optimization, and cost reduction across various industries including power generation, chemical processing, HVAC systems, and automotive applications. Recent advancements in materials science and manufacturing techniques have further accelerated innovation in this field.

Data analytics represents a transformative approach to heat exchanger optimization, offering unprecedented insights into performance parameters that were previously difficult to measure or predict. The convergence of IoT sensors, cloud computing, and machine learning algorithms has created new possibilities for real-time monitoring, predictive maintenance, and design optimization of heat exchange systems. This technological synergy marks a significant departure from traditional empirical methods that often relied on conservative design margins and periodic manual inspections.

The primary objective of employing data analytics in heat exchanger optimization is to maximize thermal efficiency while minimizing operational costs and environmental impact. This involves developing comprehensive data collection frameworks that capture critical parameters such as temperature distributions, pressure drops, flow rates, and fouling factors across different operating conditions. These data points serve as the foundation for building predictive models that can optimize design parameters and operational strategies.

Another key goal is to establish digital twin capabilities for heat exchangers, enabling virtual simulation and testing of various scenarios before physical implementation. This approach significantly reduces development cycles and allows engineers to explore innovative designs without the constraints of physical prototyping. The digital twin concept also facilitates continuous improvement through iterative optimization based on real-world performance data.

From a sustainability perspective, data analytics aims to reduce the carbon footprint of heat exchange processes by minimizing energy consumption and extending equipment lifespan. Advanced analytics can identify optimal cleaning schedules, detect early signs of performance degradation, and recommend precise adjustments to operating parameters that maximize efficiency under varying conditions. These capabilities align with global initiatives to reduce industrial energy consumption and greenhouse gas emissions.

The integration of data analytics into heat exchanger technology also seeks to democratize expertise by codifying specialized knowledge into algorithms and decision support systems. This transformation enables organizations to maintain optimal performance even with limited access to specialized human expertise, particularly important in remote operations or during periods of workforce transition.

Data analytics represents a transformative approach to heat exchanger optimization, offering unprecedented insights into performance parameters that were previously difficult to measure or predict. The convergence of IoT sensors, cloud computing, and machine learning algorithms has created new possibilities for real-time monitoring, predictive maintenance, and design optimization of heat exchange systems. This technological synergy marks a significant departure from traditional empirical methods that often relied on conservative design margins and periodic manual inspections.

The primary objective of employing data analytics in heat exchanger optimization is to maximize thermal efficiency while minimizing operational costs and environmental impact. This involves developing comprehensive data collection frameworks that capture critical parameters such as temperature distributions, pressure drops, flow rates, and fouling factors across different operating conditions. These data points serve as the foundation for building predictive models that can optimize design parameters and operational strategies.

Another key goal is to establish digital twin capabilities for heat exchangers, enabling virtual simulation and testing of various scenarios before physical implementation. This approach significantly reduces development cycles and allows engineers to explore innovative designs without the constraints of physical prototyping. The digital twin concept also facilitates continuous improvement through iterative optimization based on real-world performance data.

From a sustainability perspective, data analytics aims to reduce the carbon footprint of heat exchange processes by minimizing energy consumption and extending equipment lifespan. Advanced analytics can identify optimal cleaning schedules, detect early signs of performance degradation, and recommend precise adjustments to operating parameters that maximize efficiency under varying conditions. These capabilities align with global initiatives to reduce industrial energy consumption and greenhouse gas emissions.

The integration of data analytics into heat exchanger technology also seeks to democratize expertise by codifying specialized knowledge into algorithms and decision support systems. This transformation enables organizations to maintain optimal performance even with limited access to specialized human expertise, particularly important in remote operations or during periods of workforce transition.

Market Demand for Data-Driven Heat Exchanger Solutions

The global market for data-driven heat exchanger solutions is experiencing significant growth, driven by increasing demands for energy efficiency and operational cost reduction across multiple industries. Heat exchangers, as critical components in various industrial processes, represent a substantial portion of energy consumption in sectors such as oil and gas, chemical processing, power generation, and HVAC systems. The optimization of these systems through data analytics presents a compelling value proposition for businesses seeking to enhance performance while reducing operational expenses.

Recent market research indicates that the industrial heat exchanger market is expanding at a compound annual growth rate of approximately 6%, with the smart heat exchanger segment growing even faster. This acceleration is primarily fueled by the integration of IoT sensors, advanced analytics, and machine learning capabilities that enable real-time monitoring and optimization of heat transfer processes.

Energy-intensive industries are particularly motivated to adopt data-driven solutions due to rising energy costs and increasingly stringent environmental regulations. For instance, petroleum refineries, which operate numerous heat exchangers in their processes, can achieve energy savings of 3-8% through advanced analytics-based optimization, translating to millions in annual cost reductions for large facilities.

The market demand is further strengthened by the growing emphasis on predictive maintenance capabilities. Traditional reactive maintenance approaches for heat exchangers result in unplanned downtime, production losses, and increased maintenance costs. Data analytics solutions that can predict fouling, scaling, and performance degradation before they cause operational issues are highly valued, with studies showing potential maintenance cost reductions of 15-25%.

Sustainability initiatives and carbon footprint reduction goals are also driving demand for more efficient heat exchanger operations. As organizations face pressure to meet environmental targets, the ability to optimize heat transfer efficiency through data analytics becomes increasingly attractive. This is particularly evident in regions with carbon pricing mechanisms or strict emissions regulations.

Geographically, North America and Europe currently lead in adoption of data-driven heat exchanger solutions, primarily due to their mature industrial bases and stronger regulatory pressures for energy efficiency. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, driven by rapid industrialization and increasing awareness of energy conservation benefits.

Customer expectations are evolving beyond simple monitoring solutions toward comprehensive platforms that integrate data collection, advanced analytics, visualization tools, and actionable recommendations. End users increasingly demand solutions that not only identify optimization opportunities but also quantify potential savings and provide clear implementation pathways with minimal disruption to operations.

Recent market research indicates that the industrial heat exchanger market is expanding at a compound annual growth rate of approximately 6%, with the smart heat exchanger segment growing even faster. This acceleration is primarily fueled by the integration of IoT sensors, advanced analytics, and machine learning capabilities that enable real-time monitoring and optimization of heat transfer processes.

Energy-intensive industries are particularly motivated to adopt data-driven solutions due to rising energy costs and increasingly stringent environmental regulations. For instance, petroleum refineries, which operate numerous heat exchangers in their processes, can achieve energy savings of 3-8% through advanced analytics-based optimization, translating to millions in annual cost reductions for large facilities.

The market demand is further strengthened by the growing emphasis on predictive maintenance capabilities. Traditional reactive maintenance approaches for heat exchangers result in unplanned downtime, production losses, and increased maintenance costs. Data analytics solutions that can predict fouling, scaling, and performance degradation before they cause operational issues are highly valued, with studies showing potential maintenance cost reductions of 15-25%.

Sustainability initiatives and carbon footprint reduction goals are also driving demand for more efficient heat exchanger operations. As organizations face pressure to meet environmental targets, the ability to optimize heat transfer efficiency through data analytics becomes increasingly attractive. This is particularly evident in regions with carbon pricing mechanisms or strict emissions regulations.

Geographically, North America and Europe currently lead in adoption of data-driven heat exchanger solutions, primarily due to their mature industrial bases and stronger regulatory pressures for energy efficiency. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, driven by rapid industrialization and increasing awareness of energy conservation benefits.

Customer expectations are evolving beyond simple monitoring solutions toward comprehensive platforms that integrate data collection, advanced analytics, visualization tools, and actionable recommendations. End users increasingly demand solutions that not only identify optimization opportunities but also quantify potential savings and provide clear implementation pathways with minimal disruption to operations.

Current State and Challenges in Heat Exchanger Analytics

The global heat exchanger market is currently experiencing significant technological transformation driven by data analytics integration. Traditional heat exchanger design and operation have relied primarily on theoretical models and empirical correlations, often resulting in conservative designs with efficiency gaps. Recent advancements in sensor technology, computational power, and machine learning algorithms have created new opportunities for optimization, yet implementation remains fragmented across industries.

In developed markets like North America and Europe, approximately 35-40% of industrial heat exchanger systems incorporate some level of data monitoring, though only 15-20% utilize advanced analytics for optimization. The Asia-Pacific region shows rapid adoption growth, particularly in China and South Korea, where government initiatives supporting industrial digitalization are accelerating implementation.

The primary technical challenges in heat exchanger analytics center around data acquisition, quality, and integration. Many existing heat exchanger installations lack sufficient instrumentation for comprehensive data collection, with temperature and pressure measurements often limited to inlet and outlet points rather than distributed throughout the system. This creates significant blind spots in understanding internal flow dynamics and fouling progression.

Data quality issues persist due to sensor drift, calibration inconsistencies, and environmental interference. Studies indicate measurement uncertainties of 2-5% are common in industrial settings, which can significantly impact model accuracy. Furthermore, the heterogeneous nature of industrial control systems creates integration barriers, with many facilities operating legacy equipment alongside modern systems, resulting in data silos and compatibility issues.

Computational challenges represent another significant hurdle. Real-time optimization of heat exchanger performance requires processing large volumes of multivariate data with complex interdependencies. Current computational methods often struggle to balance accuracy with processing speed, particularly for systems with phase changes or complex geometries. Most commercial solutions employ simplified models that sacrifice accuracy for computational efficiency.

The knowledge gap between data scientists and thermal engineers presents an organizational challenge. Effective heat exchanger optimization requires interdisciplinary expertise spanning thermodynamics, fluid dynamics, materials science, and data analytics. Few professionals possess this comprehensive skill set, creating communication barriers and implementation difficulties within organizations.

Regulatory frameworks and industry standards for data-driven heat exchanger optimization remain underdeveloped. This regulatory uncertainty creates hesitation among potential adopters, particularly in highly regulated industries like food processing, pharmaceuticals, and nuclear power generation, where changes to critical thermal management systems require extensive validation.

In developed markets like North America and Europe, approximately 35-40% of industrial heat exchanger systems incorporate some level of data monitoring, though only 15-20% utilize advanced analytics for optimization. The Asia-Pacific region shows rapid adoption growth, particularly in China and South Korea, where government initiatives supporting industrial digitalization are accelerating implementation.

The primary technical challenges in heat exchanger analytics center around data acquisition, quality, and integration. Many existing heat exchanger installations lack sufficient instrumentation for comprehensive data collection, with temperature and pressure measurements often limited to inlet and outlet points rather than distributed throughout the system. This creates significant blind spots in understanding internal flow dynamics and fouling progression.

Data quality issues persist due to sensor drift, calibration inconsistencies, and environmental interference. Studies indicate measurement uncertainties of 2-5% are common in industrial settings, which can significantly impact model accuracy. Furthermore, the heterogeneous nature of industrial control systems creates integration barriers, with many facilities operating legacy equipment alongside modern systems, resulting in data silos and compatibility issues.

Computational challenges represent another significant hurdle. Real-time optimization of heat exchanger performance requires processing large volumes of multivariate data with complex interdependencies. Current computational methods often struggle to balance accuracy with processing speed, particularly for systems with phase changes or complex geometries. Most commercial solutions employ simplified models that sacrifice accuracy for computational efficiency.

The knowledge gap between data scientists and thermal engineers presents an organizational challenge. Effective heat exchanger optimization requires interdisciplinary expertise spanning thermodynamics, fluid dynamics, materials science, and data analytics. Few professionals possess this comprehensive skill set, creating communication barriers and implementation difficulties within organizations.

Regulatory frameworks and industry standards for data-driven heat exchanger optimization remain underdeveloped. This regulatory uncertainty creates hesitation among potential adopters, particularly in highly regulated industries like food processing, pharmaceuticals, and nuclear power generation, where changes to critical thermal management systems require extensive validation.

Current Data Analytics Approaches for Heat Exchangers

01 Machine learning algorithms for heat exchanger design optimization

Machine learning techniques are applied to optimize heat exchanger designs by analyzing performance data and predicting optimal configurations. These algorithms can process large datasets of thermal performance metrics to identify patterns and correlations that human engineers might miss. By incorporating historical performance data, these systems can suggest design modifications that improve heat transfer efficiency, reduce pressure drop, and extend operational lifespan of heat exchangers.- Machine learning algorithms for heat exchanger performance prediction: Advanced machine learning algorithms can be applied to analyze operational data from heat exchangers to predict performance under various conditions. These algorithms can process historical data to identify patterns and correlations that affect efficiency. By implementing predictive models, engineers can anticipate performance degradation, optimize maintenance schedules, and adjust operational parameters to maintain optimal heat transfer rates.

- Real-time monitoring and data-driven control systems: Real-time monitoring systems collect continuous data streams from heat exchangers, enabling immediate analysis and response to changing conditions. These systems utilize sensors to measure temperature, pressure, flow rates, and other critical parameters. Data-driven control algorithms can automatically adjust operational settings based on current performance metrics, environmental conditions, and energy costs, leading to significant improvements in efficiency and reduced energy consumption.

- Computational fluid dynamics and digital twin technology: Computational fluid dynamics (CFD) simulations combined with digital twin technology create virtual models of heat exchangers that accurately represent physical behavior. These digital models can be used to test design modifications and operational strategies without disrupting actual operations. By analyzing fluid flow patterns, temperature distributions, and pressure drops, engineers can identify optimization opportunities and predict how modifications will affect overall system performance.

- Predictive maintenance through anomaly detection: Data analytics enables predictive maintenance strategies by identifying early signs of performance degradation or component failure. Anomaly detection algorithms can recognize subtle changes in operational patterns that indicate developing problems before they cause significant efficiency losses or system failures. This approach allows maintenance to be scheduled based on actual equipment condition rather than fixed time intervals, reducing downtime and extending equipment life.

- Multi-parameter optimization for energy efficiency: Multi-parameter optimization techniques analyze the complex interactions between various operational parameters to identify the most energy-efficient operating conditions. These methods consider factors such as flow rates, temperature differentials, fouling factors, and heat transfer coefficients simultaneously. By understanding how these parameters interact, optimization algorithms can determine the ideal settings that minimize energy consumption while maintaining required heat transfer performance across varying load conditions.

02 Real-time monitoring and predictive maintenance systems

Data analytics enables real-time monitoring of heat exchanger performance through sensor networks that collect operational data. Advanced analytics platforms process this information to detect performance degradation, predict potential failures, and recommend maintenance schedules. These systems analyze parameters such as temperature differentials, flow rates, and pressure drops to identify fouling, scaling, or other issues before they cause significant efficiency losses or system failures, thereby optimizing operational uptime and reducing maintenance costs.Expand Specific Solutions03 Computational fluid dynamics (CFD) simulation for performance prediction

CFD simulations combined with data analytics provide detailed insights into fluid flow and heat transfer within exchangers. These computational models analyze complex thermodynamic interactions to predict performance under various operating conditions. By simulating different geometries, flow rates, and thermal loads, engineers can optimize heat exchanger designs without costly physical prototyping. The integration of historical operational data enhances the accuracy of these simulations, allowing for more precise optimization of heat transfer surfaces and flow paths.Expand Specific Solutions04 Digital twin technology for heat exchanger optimization

Digital twin technology creates virtual replicas of physical heat exchangers that continuously update based on real-world performance data. These digital models enable engineers to test optimization strategies in a virtual environment before implementing them in actual systems. By integrating operational data with physics-based models, digital twins can simulate how modifications will affect performance across various operating conditions, facilitating more effective design iterations and operational adjustments to maximize efficiency and minimize energy consumption.Expand Specific Solutions05 Energy efficiency optimization through data-driven control systems

Data analytics enables the development of intelligent control systems that dynamically adjust heat exchanger operations based on real-time performance data and changing conditions. These systems analyze patterns in operational data to identify optimal setpoints for flow rates, temperatures, and other parameters. By continuously optimizing operating conditions in response to changing thermal loads, ambient conditions, and system requirements, these control systems can significantly reduce energy consumption while maintaining or improving heat transfer performance and extending equipment lifespan.Expand Specific Solutions

Key Industry Players in Heat Exchanger Optimization

The heat exchanger optimization analytics market is in a growth phase, with increasing adoption across industrial sectors. The market size is expanding rapidly as companies seek efficiency improvements and cost reductions through data-driven approaches. Technologically, the field is maturing with varying levels of sophistication among key players. Industry leaders like IBM, Siemens AG, and Carrier Corp. offer advanced analytics solutions with AI integration, while specialized firms like Energy Recovery and Baltimore Aircoil focus on industry-specific applications. Academic institutions including Xi'an Jiaotong University and Wuhan University contribute fundamental research. Oil and energy companies such as Suncor Energy and China National Petroleum are implementing these technologies to optimize large-scale heat exchange operations, driving further market development and standardization.

UOP LLC

Technical Solution: UOP (a Honeywell company) has developed specialized data analytics solutions for heat exchanger optimization in refining and petrochemical processes. Their approach combines process simulation tools with real-time monitoring systems to optimize heat integration networks. UOP's Connected Plant technology incorporates machine learning algorithms that analyze operational data to identify performance degradation patterns in heat exchangers. Their system uses thermodynamic models enhanced by actual plant data to optimize heat recovery and minimize energy consumption. UOP's analytics platform can detect fouling trends and predict cleaning cycles, optimizing maintenance schedules based on actual performance degradation rather than fixed time intervals. The solution includes specialized algorithms for different types of heat exchangers (shell and tube, plate, etc.) and can recommend operational adjustments to maximize thermal efficiency while maintaining process stability.

Strengths: Deep domain expertise in refining and petrochemical processes, specialized knowledge of industrial heat exchangers, and integration with broader plant optimization systems. Weaknesses: Solutions are highly specialized for specific industries and may not be easily adaptable to other applications.

Carrier Corp.

Technical Solution: Carrier has developed advanced data analytics solutions for HVAC heat exchanger optimization through their Carrier SMART Service platform. Their approach leverages IoT sensors and cloud computing to continuously monitor heat exchanger performance in commercial and industrial HVAC systems. Carrier's analytics system employs machine learning algorithms to establish performance baselines and detect deviations that indicate efficiency losses or potential failures. Their solution includes thermal modeling capabilities that can simulate different operating conditions and recommend optimal control parameters. Carrier's platform integrates weather data, building occupancy patterns, and energy pricing information to optimize heat exchanger operation in real-time. The system can identify specific fouling patterns and efficiency degradation, enabling targeted maintenance interventions and extending equipment life while maintaining optimal energy efficiency.

Strengths: Specialized expertise in HVAC systems, extensive installed base for data collection, and integration with building management systems. Weaknesses: Primary focus on HVAC applications may limit applicability in other industrial heat exchanger contexts.

Core Technologies in Heat Exchanger Performance Modeling

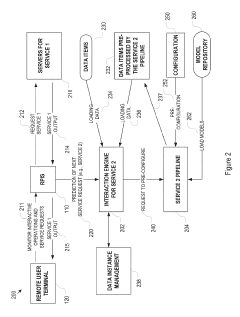

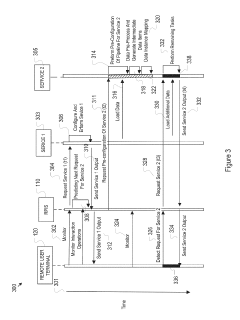

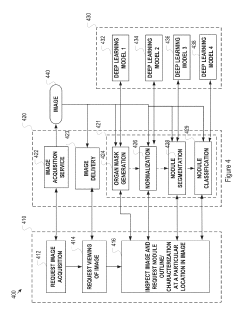

Enhancement of real-time response to request for detached data analytics

PatentInactiveUS10467142B1

Innovation

- A system and method that predictively pre-configure and pre-process data analytics pipelines based on user interactive operations, caching intermediate data for speedy access, allowing only real-time additional processing to complete the service upon actual request, thereby reducing user-perceived delay.

Energy Efficiency and Sustainability Considerations

The optimization of heat exchangers through data analytics presents significant opportunities for enhancing energy efficiency and sustainability across various industries. Energy consumption in heat exchange processes accounts for a substantial portion of industrial energy usage worldwide, making efficiency improvements critical for reducing carbon footprints and operational costs.

Data-driven optimization approaches enable real-time monitoring and adjustment of heat exchanger parameters to maintain optimal performance under varying conditions. This adaptive control significantly reduces unnecessary energy expenditure by ensuring that systems operate at their efficiency sweet spots rather than using conservative settings designed for worst-case scenarios.

Life cycle assessment (LCA) data integration with heat exchanger analytics provides a comprehensive view of environmental impacts beyond immediate energy consumption. By analyzing material selection, manufacturing processes, operational efficiency, and end-of-life considerations, organizations can make holistic decisions that minimize environmental footprint across the entire equipment lifecycle.

The implementation of predictive maintenance strategies through data analytics substantially extends equipment lifespan, reducing the resource-intensive manufacturing of replacement components. Studies indicate that predictive maintenance can extend heat exchanger service life by 15-30% compared to traditional maintenance approaches, representing significant material conservation and embodied energy savings.

Waste heat recovery optimization represents another critical sustainability dimension. Advanced analytics can identify previously overlooked opportunities for heat recovery and integration within industrial processes. Machine learning algorithms can continuously refine heat integration networks, potentially recovering up to 25-40% of energy that would otherwise be wasted in complex industrial systems.

Carbon footprint reduction metrics can be directly incorporated into heat exchanger optimization objectives. By assigning carbon costs to energy sources and quantifying emissions reductions from efficiency improvements, organizations can prioritize modifications that maximize climate impact mitigation while balancing economic considerations.

Water conservation also benefits from data-driven approaches, particularly in cooling applications. Analytics can optimize water usage in cooling towers and other water-intensive heat exchange systems, potentially reducing consumption by 10-20% through intelligent control strategies that adapt to ambient conditions and process requirements.

The integration of renewable energy sources with heat exchange systems becomes more viable through sophisticated data analytics. Dynamic optimization algorithms can adjust thermal processes to align with variable renewable energy availability, facilitating greater integration of sustainable energy sources into industrial thermal applications.

Data-driven optimization approaches enable real-time monitoring and adjustment of heat exchanger parameters to maintain optimal performance under varying conditions. This adaptive control significantly reduces unnecessary energy expenditure by ensuring that systems operate at their efficiency sweet spots rather than using conservative settings designed for worst-case scenarios.

Life cycle assessment (LCA) data integration with heat exchanger analytics provides a comprehensive view of environmental impacts beyond immediate energy consumption. By analyzing material selection, manufacturing processes, operational efficiency, and end-of-life considerations, organizations can make holistic decisions that minimize environmental footprint across the entire equipment lifecycle.

The implementation of predictive maintenance strategies through data analytics substantially extends equipment lifespan, reducing the resource-intensive manufacturing of replacement components. Studies indicate that predictive maintenance can extend heat exchanger service life by 15-30% compared to traditional maintenance approaches, representing significant material conservation and embodied energy savings.

Waste heat recovery optimization represents another critical sustainability dimension. Advanced analytics can identify previously overlooked opportunities for heat recovery and integration within industrial processes. Machine learning algorithms can continuously refine heat integration networks, potentially recovering up to 25-40% of energy that would otherwise be wasted in complex industrial systems.

Carbon footprint reduction metrics can be directly incorporated into heat exchanger optimization objectives. By assigning carbon costs to energy sources and quantifying emissions reductions from efficiency improvements, organizations can prioritize modifications that maximize climate impact mitigation while balancing economic considerations.

Water conservation also benefits from data-driven approaches, particularly in cooling applications. Analytics can optimize water usage in cooling towers and other water-intensive heat exchange systems, potentially reducing consumption by 10-20% through intelligent control strategies that adapt to ambient conditions and process requirements.

The integration of renewable energy sources with heat exchange systems becomes more viable through sophisticated data analytics. Dynamic optimization algorithms can adjust thermal processes to align with variable renewable energy availability, facilitating greater integration of sustainable energy sources into industrial thermal applications.

ROI Analysis of Analytics Implementation

Implementing data analytics solutions for heat exchanger optimization requires significant investment in technology, expertise, and organizational change. A comprehensive ROI analysis reveals that these investments typically yield returns within 12-24 months, with long-term benefits far exceeding initial costs. The average implementation cost ranges from $50,000 for basic analytics systems to $250,000+ for enterprise-wide solutions with advanced AI capabilities, depending on organization size and complexity of operations.

Energy savings represent the most immediate and quantifiable return, with organizations reporting 5-15% reduction in energy consumption through optimized heat exchanger operations. This translates to annual savings of $10,000-$500,000 depending on facility size and energy prices. Maintenance cost reduction provides another substantial benefit, with predictive maintenance approaches reducing unplanned downtime by 30-45% and extending equipment lifespan by 15-25%.

Operational efficiency improvements deliver additional value through increased throughput and production quality. Organizations implementing advanced analytics for heat exchanger optimization report 3-8% increases in production capacity without additional capital expenditure. The reduction in process variability also contributes to higher product quality and fewer rejections, with an estimated value of 2-5% of production costs.

Environmental compliance benefits, while harder to quantify directly, include reduced emissions, lower water usage, and decreased risk of regulatory penalties. Companies can expect to reduce their carbon footprint by 3-7% through optimized heat exchanger operations, potentially qualifying for carbon credits or avoiding carbon taxes in applicable jurisdictions.

The intangible benefits extend beyond direct financial returns. Organizations report accelerated innovation cycles as data-driven insights lead to process improvements beyond heat exchangers. Knowledge capture from retiring workers becomes systematized rather than lost, and cross-functional collaboration improves as operations, maintenance, and engineering teams share a common data platform.

For maximum ROI, implementation should follow a phased approach, beginning with pilot projects targeting high-value heat exchangers before expanding. Organizations achieving the highest returns typically allocate 15-20% of project budgets to change management and training, ensuring that analytical capabilities are fully utilized by operational staff. The most successful implementations integrate analytics into daily workflows rather than treating them as separate analytical exercises.

Energy savings represent the most immediate and quantifiable return, with organizations reporting 5-15% reduction in energy consumption through optimized heat exchanger operations. This translates to annual savings of $10,000-$500,000 depending on facility size and energy prices. Maintenance cost reduction provides another substantial benefit, with predictive maintenance approaches reducing unplanned downtime by 30-45% and extending equipment lifespan by 15-25%.

Operational efficiency improvements deliver additional value through increased throughput and production quality. Organizations implementing advanced analytics for heat exchanger optimization report 3-8% increases in production capacity without additional capital expenditure. The reduction in process variability also contributes to higher product quality and fewer rejections, with an estimated value of 2-5% of production costs.

Environmental compliance benefits, while harder to quantify directly, include reduced emissions, lower water usage, and decreased risk of regulatory penalties. Companies can expect to reduce their carbon footprint by 3-7% through optimized heat exchanger operations, potentially qualifying for carbon credits or avoiding carbon taxes in applicable jurisdictions.

The intangible benefits extend beyond direct financial returns. Organizations report accelerated innovation cycles as data-driven insights lead to process improvements beyond heat exchangers. Knowledge capture from retiring workers becomes systematized rather than lost, and cross-functional collaboration improves as operations, maintenance, and engineering teams share a common data platform.

For maximum ROI, implementation should follow a phased approach, beginning with pilot projects targeting high-value heat exchangers before expanding. Organizations achieving the highest returns typically allocate 15-20% of project budgets to change management and training, ensuring that analytical capabilities are fully utilized by operational staff. The most successful implementations integrate analytics into daily workflows rather than treating them as separate analytical exercises.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!