How to Enhance Lithium Bromide Absorption Chiller Efficiency

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiBr Absorption Chiller Technology Background and Objectives

Lithium Bromide (LiBr) absorption chillers represent a significant advancement in cooling technology, with their development dating back to the early 20th century. These systems have evolved from simple single-effect designs to sophisticated multi-effect configurations capable of achieving higher coefficients of performance (COP). The fundamental principle behind LiBr absorption chillers leverages the strong affinity between lithium bromide salt and water, where water serves as the refrigerant and LiBr solution acts as the absorbent.

The evolution of LiBr absorption chiller technology has been marked by continuous improvements in efficiency, reliability, and environmental compatibility. Early systems in the 1950s and 1960s achieved COPs of approximately 0.5-0.6, while modern double-effect systems can reach COPs of 1.2-1.4, with triple-effect designs pushing beyond 1.7. This progression demonstrates the technology's adaptability and potential for further enhancement.

Current technological trends in LiBr absorption chillers focus on addressing inherent limitations such as crystallization risk, corrosion issues, and heat transfer inefficiencies. Research directions include advanced heat exchanger designs, improved working fluid formulations, and integration with renewable energy sources. The industry is witnessing a shift toward more compact designs with reduced footprint requirements and enhanced part-load performance characteristics.

The primary technical objective in enhancing LiBr absorption chiller efficiency involves optimizing several key parameters: heat transfer coefficients in absorbers and generators, solution distribution systems, refrigerant flow patterns, and thermal insulation properties. Additionally, reducing parasitic energy consumption from pumps and auxiliary systems represents a critical goal for overall system efficiency improvement.

From a broader perspective, LiBr absorption chillers align with global sustainability initiatives by utilizing low-grade thermal energy sources such as waste heat, solar thermal energy, or geothermal resources. This capability positions them as valuable components in district cooling systems, combined heat and power (CHP) applications, and industrial waste heat recovery schemes.

The technology aims to overcome the efficiency gap with conventional vapor compression systems while capitalizing on unique advantages such as minimal electricity consumption, low noise operation, and reduced direct greenhouse gas emissions. Future development targets include achieving COPs exceeding 2.0 for next-generation systems, reducing manufacturing costs through standardized components, and expanding operational flexibility across varying load conditions and ambient environments.

As energy efficiency standards become increasingly stringent worldwide, enhancing LiBr absorption chiller performance represents not merely a technical challenge but a strategic imperative for sustainable cooling solutions in commercial, industrial, and institutional applications.

The evolution of LiBr absorption chiller technology has been marked by continuous improvements in efficiency, reliability, and environmental compatibility. Early systems in the 1950s and 1960s achieved COPs of approximately 0.5-0.6, while modern double-effect systems can reach COPs of 1.2-1.4, with triple-effect designs pushing beyond 1.7. This progression demonstrates the technology's adaptability and potential for further enhancement.

Current technological trends in LiBr absorption chillers focus on addressing inherent limitations such as crystallization risk, corrosion issues, and heat transfer inefficiencies. Research directions include advanced heat exchanger designs, improved working fluid formulations, and integration with renewable energy sources. The industry is witnessing a shift toward more compact designs with reduced footprint requirements and enhanced part-load performance characteristics.

The primary technical objective in enhancing LiBr absorption chiller efficiency involves optimizing several key parameters: heat transfer coefficients in absorbers and generators, solution distribution systems, refrigerant flow patterns, and thermal insulation properties. Additionally, reducing parasitic energy consumption from pumps and auxiliary systems represents a critical goal for overall system efficiency improvement.

From a broader perspective, LiBr absorption chillers align with global sustainability initiatives by utilizing low-grade thermal energy sources such as waste heat, solar thermal energy, or geothermal resources. This capability positions them as valuable components in district cooling systems, combined heat and power (CHP) applications, and industrial waste heat recovery schemes.

The technology aims to overcome the efficiency gap with conventional vapor compression systems while capitalizing on unique advantages such as minimal electricity consumption, low noise operation, and reduced direct greenhouse gas emissions. Future development targets include achieving COPs exceeding 2.0 for next-generation systems, reducing manufacturing costs through standardized components, and expanding operational flexibility across varying load conditions and ambient environments.

As energy efficiency standards become increasingly stringent worldwide, enhancing LiBr absorption chiller performance represents not merely a technical challenge but a strategic imperative for sustainable cooling solutions in commercial, industrial, and institutional applications.

Market Demand Analysis for High-Efficiency Cooling Systems

The global market for high-efficiency cooling systems has experienced significant growth in recent years, driven by increasing energy costs, environmental regulations, and growing awareness of sustainability issues. Lithium Bromide (LiBr) absorption chillers represent a critical segment within this market, particularly valued for their ability to utilize waste heat or renewable energy sources, thereby reducing primary energy consumption and associated carbon emissions.

Commercial and industrial sectors constitute the primary demand drivers, with particular strength in regions experiencing high electricity costs or implementing stringent emissions regulations. The hospitality industry, healthcare facilities, and large commercial complexes have emerged as key adopters, seeking to reduce operational expenses while meeting sustainability targets. Data centers, with their substantial cooling requirements and emphasis on energy efficiency, represent another rapidly expanding market segment.

Market research indicates that the global absorption chiller market was valued at approximately $1.2 billion in 2022, with projections suggesting a compound annual growth rate of 4.7% through 2030. The LiBr absorption chiller segment accounts for roughly 60% of this market, highlighting its dominance within the absorption cooling technology landscape.

Regional analysis reveals varying adoption patterns, with Asia-Pacific leading in market share due to industrial expansion in China and India, coupled with government initiatives promoting energy-efficient technologies. North America and Europe follow, driven primarily by replacement of aging cooling infrastructure and stringent energy efficiency regulations.

Customer demand increasingly focuses on three key performance indicators: higher coefficient of performance (COP), reduced physical footprint, and lower maintenance requirements. Market surveys indicate that end-users are willing to pay a premium of 15-20% for systems demonstrating a 20% improvement in energy efficiency compared to standard models.

The market landscape is further shaped by evolving regulatory frameworks. Several countries have implemented minimum energy performance standards (MEPS) for cooling systems, while others offer financial incentives for adoption of high-efficiency solutions. The phase-down of hydrofluorocarbons (HFCs) under the Kigali Amendment to the Montreal Protocol has further accelerated interest in absorption cooling technologies that utilize environmentally benign working fluids.

Industry forecasts suggest that technological innovations enhancing LiBr absorption chiller efficiency could unlock additional market segments currently dominated by conventional vapor compression systems, particularly in medium-capacity applications where absorption systems have traditionally been less competitive due to efficiency limitations.

Commercial and industrial sectors constitute the primary demand drivers, with particular strength in regions experiencing high electricity costs or implementing stringent emissions regulations. The hospitality industry, healthcare facilities, and large commercial complexes have emerged as key adopters, seeking to reduce operational expenses while meeting sustainability targets. Data centers, with their substantial cooling requirements and emphasis on energy efficiency, represent another rapidly expanding market segment.

Market research indicates that the global absorption chiller market was valued at approximately $1.2 billion in 2022, with projections suggesting a compound annual growth rate of 4.7% through 2030. The LiBr absorption chiller segment accounts for roughly 60% of this market, highlighting its dominance within the absorption cooling technology landscape.

Regional analysis reveals varying adoption patterns, with Asia-Pacific leading in market share due to industrial expansion in China and India, coupled with government initiatives promoting energy-efficient technologies. North America and Europe follow, driven primarily by replacement of aging cooling infrastructure and stringent energy efficiency regulations.

Customer demand increasingly focuses on three key performance indicators: higher coefficient of performance (COP), reduced physical footprint, and lower maintenance requirements. Market surveys indicate that end-users are willing to pay a premium of 15-20% for systems demonstrating a 20% improvement in energy efficiency compared to standard models.

The market landscape is further shaped by evolving regulatory frameworks. Several countries have implemented minimum energy performance standards (MEPS) for cooling systems, while others offer financial incentives for adoption of high-efficiency solutions. The phase-down of hydrofluorocarbons (HFCs) under the Kigali Amendment to the Montreal Protocol has further accelerated interest in absorption cooling technologies that utilize environmentally benign working fluids.

Industry forecasts suggest that technological innovations enhancing LiBr absorption chiller efficiency could unlock additional market segments currently dominated by conventional vapor compression systems, particularly in medium-capacity applications where absorption systems have traditionally been less competitive due to efficiency limitations.

Current State and Technical Challenges in LiBr Absorption Chillers

Lithium Bromide (LiBr) absorption chillers represent a significant advancement in sustainable cooling technology, utilizing thermal energy rather than mechanical compression to produce cooling effects. Currently, these systems are deployed globally in various capacities, from industrial cooling to commercial building air conditioning, with particular prominence in regions with abundant waste heat resources or solar thermal installations.

The global market has witnessed steady growth in LiBr absorption chiller adoption, particularly in Asia-Pacific regions where manufacturing capabilities have advanced significantly. Current commercial systems typically operate with Coefficients of Performance (COP) ranging from 0.7 to 1.2 for single-effect designs and up to 1.5 for double-effect configurations, representing substantial improvement over early models but still lagging behind conventional vapor compression systems.

Despite these advancements, LiBr absorption chillers face several critical technical challenges. Crystallization risk remains a primary concern, occurring when the LiBr solution concentration exceeds solubility limits, causing system blockages and operational failures. This phenomenon is particularly problematic during low-temperature operation or load fluctuations, necessitating complex control systems that often reduce overall efficiency.

Corrosion presents another significant challenge, as LiBr solutions are inherently corrosive to many conventional metals used in heat exchange equipment. While corrosion inhibitors and specialized materials have been developed, these solutions often increase system costs and may introduce additional maintenance requirements, limiting widespread adoption.

Heat and mass transfer inefficiencies within the absorber component represent perhaps the most significant barrier to performance enhancement. Current absorber designs struggle to achieve optimal solution distribution and vapor absorption rates, creating bottlenecks that constrain overall system performance. Research indicates that absorber performance improvements could potentially increase system COP by 20-30%.

Vacuum maintenance poses ongoing operational challenges, as even minor leaks can dramatically reduce system performance. Current sealing technologies and maintenance protocols have improved reliability but still require regular attention and specialized expertise, increasing operational costs and complexity.

From a geographical perspective, research and development efforts are concentrated primarily in China, Japan, South Korea, and Germany, with emerging contributions from research institutions in the United States and India. Chinese manufacturers have achieved significant cost reductions through manufacturing scale, while Japanese and German entities lead in high-efficiency innovations and system integration technologies.

Recent technological developments have focused on advanced heat exchanger designs, novel working fluid additives, and improved control algorithms, yet fundamental breakthroughs in core thermodynamic efficiency remain elusive. The theoretical maximum efficiency of these systems suggests significant room for improvement, with research indicating potential COP increases of up to 40% through comprehensive system optimization.

The global market has witnessed steady growth in LiBr absorption chiller adoption, particularly in Asia-Pacific regions where manufacturing capabilities have advanced significantly. Current commercial systems typically operate with Coefficients of Performance (COP) ranging from 0.7 to 1.2 for single-effect designs and up to 1.5 for double-effect configurations, representing substantial improvement over early models but still lagging behind conventional vapor compression systems.

Despite these advancements, LiBr absorption chillers face several critical technical challenges. Crystallization risk remains a primary concern, occurring when the LiBr solution concentration exceeds solubility limits, causing system blockages and operational failures. This phenomenon is particularly problematic during low-temperature operation or load fluctuations, necessitating complex control systems that often reduce overall efficiency.

Corrosion presents another significant challenge, as LiBr solutions are inherently corrosive to many conventional metals used in heat exchange equipment. While corrosion inhibitors and specialized materials have been developed, these solutions often increase system costs and may introduce additional maintenance requirements, limiting widespread adoption.

Heat and mass transfer inefficiencies within the absorber component represent perhaps the most significant barrier to performance enhancement. Current absorber designs struggle to achieve optimal solution distribution and vapor absorption rates, creating bottlenecks that constrain overall system performance. Research indicates that absorber performance improvements could potentially increase system COP by 20-30%.

Vacuum maintenance poses ongoing operational challenges, as even minor leaks can dramatically reduce system performance. Current sealing technologies and maintenance protocols have improved reliability but still require regular attention and specialized expertise, increasing operational costs and complexity.

From a geographical perspective, research and development efforts are concentrated primarily in China, Japan, South Korea, and Germany, with emerging contributions from research institutions in the United States and India. Chinese manufacturers have achieved significant cost reductions through manufacturing scale, while Japanese and German entities lead in high-efficiency innovations and system integration technologies.

Recent technological developments have focused on advanced heat exchanger designs, novel working fluid additives, and improved control algorithms, yet fundamental breakthroughs in core thermodynamic efficiency remain elusive. The theoretical maximum efficiency of these systems suggests significant room for improvement, with research indicating potential COP increases of up to 40% through comprehensive system optimization.

Current Efficiency Enhancement Solutions for LiBr Chillers

01 Heat exchanger design improvements

Various designs of heat exchangers can significantly improve the efficiency of lithium bromide absorption chillers. Enhanced heat transfer surfaces, optimized tube arrangements, and improved flow distribution mechanisms help maximize thermal exchange between the refrigerant and the absorbent solution. These design improvements reduce thermal resistance, minimize pressure drops, and enhance overall system performance, resulting in higher coefficient of performance (COP) values for the chiller system.- Heat exchanger design improvements: Optimizing heat exchanger designs in lithium bromide absorption chillers can significantly improve efficiency. This includes enhancing heat transfer surfaces, implementing multi-stage heat exchange systems, and utilizing advanced materials that provide better thermal conductivity. These improvements allow for more effective heat transfer between the refrigerant and absorbent solution, reducing energy consumption and increasing the coefficient of performance (COP) of the chiller system.

- Solution concentration control mechanisms: Advanced control mechanisms for maintaining optimal lithium bromide solution concentration can enhance absorption chiller efficiency. These systems monitor and adjust the concentration of the lithium bromide solution in real-time, preventing crystallization issues while maximizing absorption capacity. Precise concentration control ensures efficient operation across varying load conditions and ambient temperatures, leading to improved overall system performance and reliability.

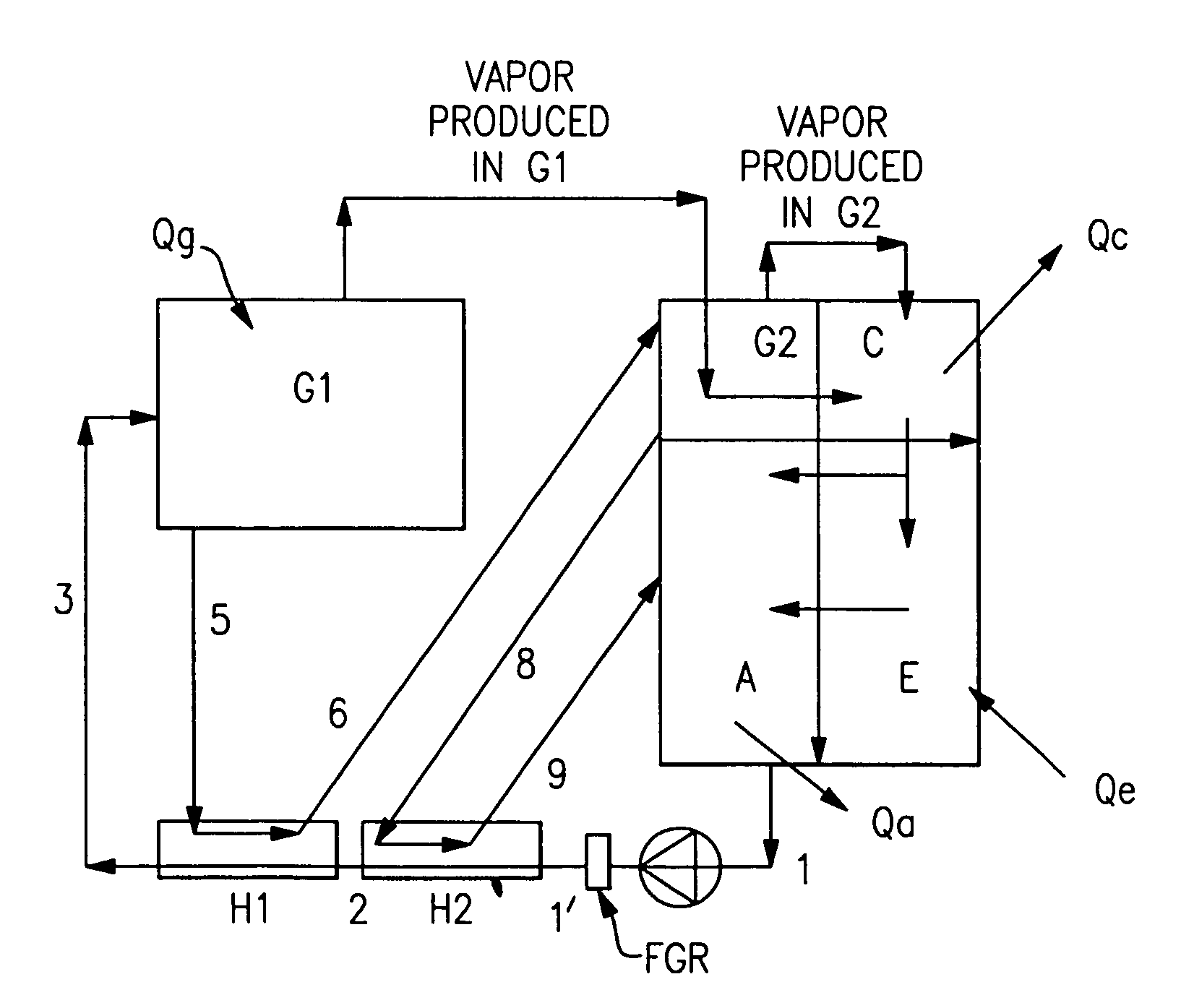

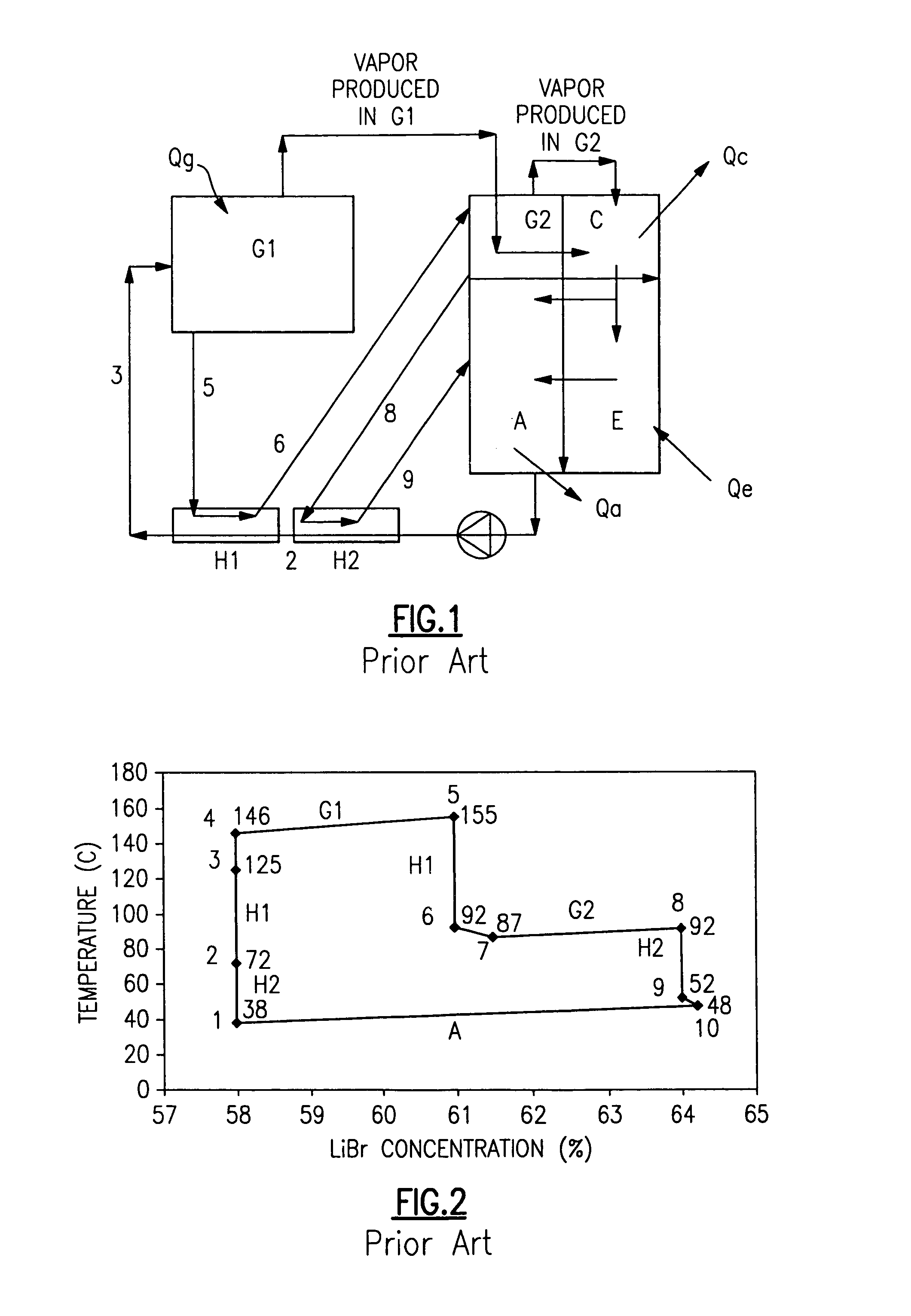

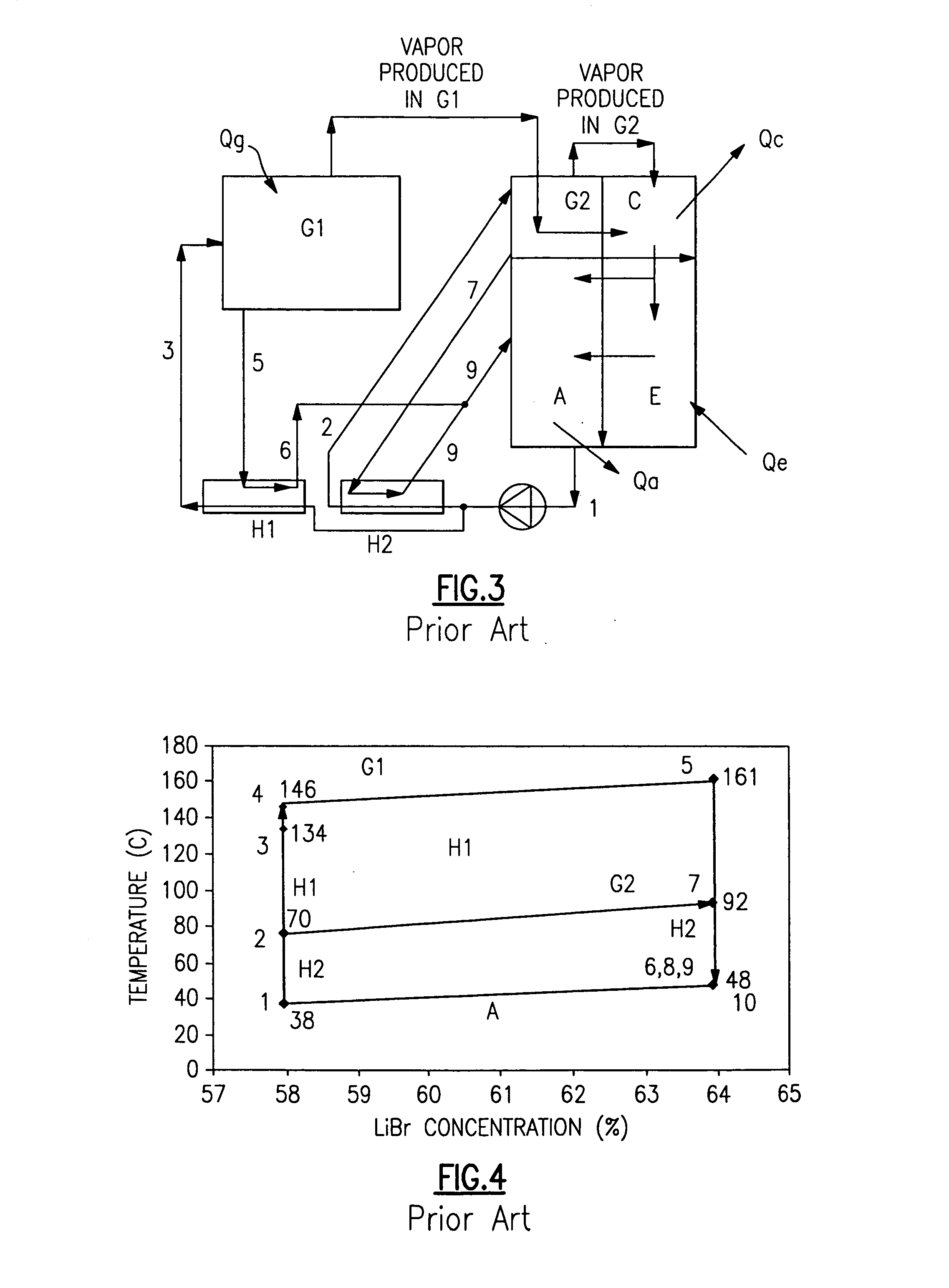

- Multi-stage absorption systems: Multi-stage absorption systems utilize cascading absorption cycles to improve efficiency in lithium bromide chillers. By implementing double or triple-effect configurations, these systems can reuse waste heat from one stage to power subsequent stages, significantly increasing the coefficient of performance. This approach maximizes energy utilization and reduces primary energy consumption, making the chiller more economical and environmentally friendly to operate.

- Vacuum maintenance and crystallization prevention: Maintaining proper vacuum conditions and preventing lithium bromide crystallization are crucial for absorption chiller efficiency. Advanced vacuum systems remove non-condensable gases that can impede heat transfer and absorption processes. Additionally, specialized anti-crystallization technologies, including solution circulation methods and temperature control systems, prevent the formation of lithium bromide crystals that can block flow passages and reduce efficiency.

- Integration with renewable energy sources: Integrating lithium bromide absorption chillers with renewable energy sources can significantly improve overall system efficiency. These systems can utilize solar thermal energy, waste heat from industrial processes, or geothermal energy to drive the absorption cycle, reducing or eliminating the need for conventional energy sources. This integration often includes specialized heat storage systems and control algorithms that optimize performance based on the availability of renewable energy inputs.

02 Solution concentration control systems

Advanced control systems for managing lithium bromide solution concentration can optimize absorption chiller efficiency. These systems monitor and adjust the concentration of lithium bromide in real-time based on operating conditions, preventing crystallization issues while maintaining optimal absorption rates. By precisely controlling solution strength through automated valves, sensors, and control algorithms, these systems ensure the chiller operates at peak efficiency across varying load conditions and ambient temperatures.Expand Specific Solutions03 Multi-stage and cascade system configurations

Multi-stage and cascade configurations enhance lithium bromide absorption chiller efficiency by utilizing heat recovery between stages. These designs allow for better utilization of input energy, with the waste heat from one stage powering another stage of the cooling process. Double-effect, triple-effect, and cascade systems progressively increase efficiency by reusing thermal energy that would otherwise be wasted, resulting in significantly higher COP values compared to single-effect systems.Expand Specific Solutions04 Working fluid additives and inhibitors

Chemical additives and corrosion inhibitors improve the performance and longevity of lithium bromide absorption chillers. These additives enhance heat and mass transfer properties of the working fluid, reduce surface tension, prevent crystallization, and protect system components from corrosion. By maintaining optimal solution properties and preventing degradation of system components, these chemical enhancements ensure sustained efficiency over the operational life of the chiller.Expand Specific Solutions05 Vacuum maintenance and purge systems

Effective vacuum maintenance and purge systems are critical for lithium bromide absorption chiller efficiency. These systems continuously remove non-condensable gases that accumulate within the chiller and impede heat transfer. Advanced purge systems utilize automated detection and removal mechanisms to maintain optimal vacuum conditions, preventing performance degradation over time. By ensuring proper vacuum levels, these systems maintain design efficiency and prevent capacity losses that would otherwise occur due to air infiltration.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The lithium bromide absorption chiller market is in a growth phase, driven by increasing demand for energy-efficient cooling solutions. The global market size is expanding steadily, projected to reach significant value due to rising industrial waste heat recovery applications and sustainable cooling needs. Technologically, the field shows varying maturity levels across players. Industry leaders like Carrier Corp. and Shuangliang Eco-Energy Systems demonstrate advanced capabilities in commercial systems, while chemical companies such as DuPont and Evonik contribute innovations in working fluids. Academic institutions including Tsinghua University and Chongqing University are advancing fundamental research, collaborating with industrial partners like Yazaki Corp. and Shanghai Disen Energy Technology to bridge efficiency gaps through heat transfer enhancements and system optimization.

Carrier Corp.

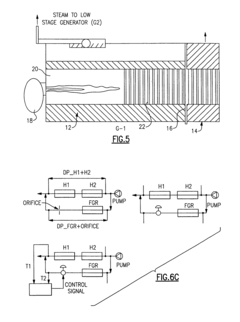

Technical Solution: Carrier has developed advanced absorption chiller systems that utilize a two-stage lithium bromide cycle to enhance efficiency. Their technology incorporates microprocessor-based controls that optimize solution flow rates and heat transfer based on real-time operating conditions. The system features patented spray distribution technology that ensures uniform wetting of heat exchanger tubes, minimizing crystallization risks while maximizing absorption efficiency. Carrier's solution also includes advanced heat recovery systems that capture waste heat from the absorption process and redirect it to preheat the dilute solution, reducing overall energy consumption. Their chillers incorporate vacuum maintenance systems that automatically purge non-condensable gases, which can significantly impair heat transfer efficiency when allowed to accumulate.

Strengths: Superior microprocessor control systems provide precise operation across varying loads; proprietary spray distribution technology ensures optimal solution coverage and heat transfer. Weaknesses: Higher initial capital costs compared to conventional systems; requires more sophisticated maintenance protocols and trained technicians for optimal performance.

Shuangliang Eco-Energy Systems Co., Ltd.

Technical Solution: Shuangliang has pioneered a multi-effect lithium bromide absorption chiller technology that achieves coefficient of performance (COP) values up to 1.8, significantly higher than conventional single-effect systems. Their approach incorporates specialized heat exchanger designs with enhanced surface treatments that improve wettability and heat transfer coefficients by approximately 30%. The company has developed proprietary solution additives that inhibit crystallization while extending the operational range of their systems. Shuangliang's technology also features an innovative vacuum system with automatic air purging capabilities that maintains optimal internal pressure conditions. Their solution distribution system employs precision nozzles and distribution plates that ensure uniform solution flow across heat exchanger surfaces, minimizing thermal resistance and improving overall system efficiency.

Strengths: Industry-leading COP values through multi-effect design; specialized surface treatments significantly enhance heat transfer; proprietary additives extend operational range. Weaknesses: Higher complexity in system design increases maintenance requirements; greater sensitivity to cooling water temperature fluctuations compared to simpler systems.

Critical Patents and Technical Literature on Absorption Cooling

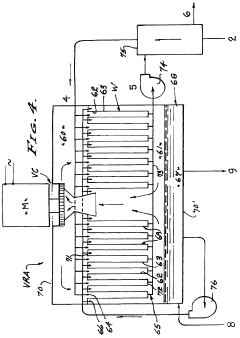

Heat exchanger for high stage generator of absorption chiller

PatentInactiveUS6877338B2

Innovation

- A partition plate is introduced in the high stage generator to create a flue gas recuperator, allowing for the recovery of energy from exhaust gases by preheating the solution at lower pressure, enhancing energy utilization and reducing energy waste, thereby improving the system's efficiency.

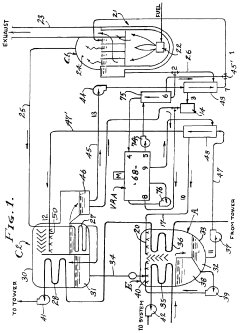

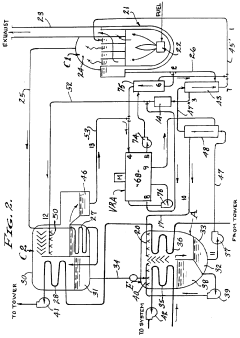

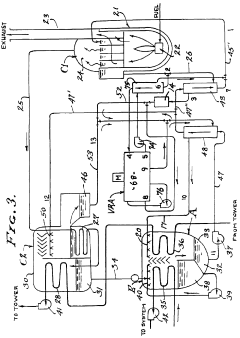

Enhanced lithium bromide absorption cycle water vapor recompression absorber

PatentInactiveUS5816070A

Innovation

- The introduction of a Vapor Recompression Absorber (VRA) unit that enhances the concentration of the Lithium-Bromide solution and increases the volume of water refrigerant, allowing for improved heat absorption and refrigeration efficiency by applying heat energy to a closed circuit within the system, reducing the need for additional energy sources and system complexity.

Energy Efficiency Standards and Environmental Regulations

The regulatory landscape surrounding energy efficiency has become increasingly stringent, directly impacting the development and deployment of lithium bromide absorption chillers. In the United States, the Department of Energy (DOE) has established minimum efficiency standards for cooling equipment, including absorption chillers, through the Energy Policy and Conservation Act. These standards mandate specific Coefficient of Performance (COP) values that manufacturers must meet, driving continuous innovation in absorption chiller technology.

The European Union's Ecodesign Directive similarly imposes strict efficiency requirements, with the Energy-related Products (ErP) regulations specifically targeting HVAC systems. These regulations establish tiered efficiency targets with increasingly stringent requirements scheduled for implementation through 2030, compelling manufacturers to prioritize efficiency enhancements in their product development roadmaps.

In Asia, countries like Japan and China have implemented their own efficiency standards. Japan's Top Runner Program identifies the most efficient products in each category and sets them as benchmarks for future standards, while China's Green Building Evaluation Standard offers incentives for buildings utilizing high-efficiency cooling systems, including advanced absorption chillers.

Environmental regulations concerning refrigerants have created additional momentum for absorption chiller adoption. The Montreal Protocol and subsequent Kigali Amendment have accelerated the phase-out of hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs), positioning lithium bromide absorption chillers—which use water as a refrigerant—as environmentally advantageous alternatives to conventional vapor compression systems.

Carbon pricing mechanisms and emissions trading schemes in various regions have further enhanced the economic case for high-efficiency absorption chillers, particularly when powered by waste heat or renewable thermal energy. Buildings and industrial facilities can reduce their carbon footprint and potentially generate carbon credits through the implementation of these systems.

Green building certification programs like LEED, BREEAM, and WELL have incorporated criteria that reward the use of energy-efficient cooling technologies. These programs typically award points for systems that exceed minimum efficiency standards, creating market incentives for building developers to specify high-performance absorption chillers in their projects.

The regulatory trend is clearly moving toward more stringent efficiency requirements and stricter environmental controls. Manufacturers focusing on enhancing lithium bromide absorption chiller efficiency are not merely pursuing technical improvements but responding to a regulatory imperative that will increasingly define market access and competitive positioning in the coming decades.

The European Union's Ecodesign Directive similarly imposes strict efficiency requirements, with the Energy-related Products (ErP) regulations specifically targeting HVAC systems. These regulations establish tiered efficiency targets with increasingly stringent requirements scheduled for implementation through 2030, compelling manufacturers to prioritize efficiency enhancements in their product development roadmaps.

In Asia, countries like Japan and China have implemented their own efficiency standards. Japan's Top Runner Program identifies the most efficient products in each category and sets them as benchmarks for future standards, while China's Green Building Evaluation Standard offers incentives for buildings utilizing high-efficiency cooling systems, including advanced absorption chillers.

Environmental regulations concerning refrigerants have created additional momentum for absorption chiller adoption. The Montreal Protocol and subsequent Kigali Amendment have accelerated the phase-out of hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs), positioning lithium bromide absorption chillers—which use water as a refrigerant—as environmentally advantageous alternatives to conventional vapor compression systems.

Carbon pricing mechanisms and emissions trading schemes in various regions have further enhanced the economic case for high-efficiency absorption chillers, particularly when powered by waste heat or renewable thermal energy. Buildings and industrial facilities can reduce their carbon footprint and potentially generate carbon credits through the implementation of these systems.

Green building certification programs like LEED, BREEAM, and WELL have incorporated criteria that reward the use of energy-efficient cooling technologies. These programs typically award points for systems that exceed minimum efficiency standards, creating market incentives for building developers to specify high-performance absorption chillers in their projects.

The regulatory trend is clearly moving toward more stringent efficiency requirements and stricter environmental controls. Manufacturers focusing on enhancing lithium bromide absorption chiller efficiency are not merely pursuing technical improvements but responding to a regulatory imperative that will increasingly define market access and competitive positioning in the coming decades.

Heat Transfer Enhancement and Working Fluid Modifications

Heat transfer enhancement in lithium bromide absorption chillers represents a critical pathway to improving overall system efficiency. Current research focuses on advanced heat exchanger designs that maximize surface area while minimizing fluid resistance. Micro-channel heat exchangers have demonstrated up to 30% improvement in heat transfer coefficients compared to conventional tube designs, while maintaining compact dimensions. These innovations leverage enhanced geometries such as corrugated surfaces, finned tubes, and specialized flow patterns that create turbulence at the boundary layer, significantly improving thermal exchange rates.

Surface modification techniques have emerged as another promising approach, with hydrophilic coatings showing particular effectiveness in absorption processes. These coatings can increase wetting characteristics by up to 40%, ensuring more uniform solution distribution and reducing thermal resistance at the liquid-solid interface. Nanoscale surface treatments that create controlled roughness patterns have demonstrated heat transfer improvements of 15-25% in laboratory settings.

Working fluid modifications constitute another significant avenue for efficiency enhancement. The traditional lithium bromide-water solution presents limitations in terms of crystallization risk and corrosion potential. Research indicates that carefully selected additives can substantially improve performance characteristics. For instance, the addition of 1-2% surfactants such as 2-ethyl-1-hexanol reduces surface tension and enhances absorption rates by 10-15% through the Marangoni effect, which improves solution mixing and mass transfer.

Ionic liquids as partial replacements or additives to conventional LiBr solutions have shown promising results, with some formulations extending the operating temperature range by 5-10°C while reducing crystallization risks. These advanced working fluids demonstrate improved thermal stability and reduced corrosive properties, potentially extending equipment lifespan by 20-30% according to accelerated testing protocols.

Nanofluid technology represents the cutting edge of working fluid enhancement. The suspension of nanoparticles (20-100nm) such as TiO2, Al2O3, or carbon nanotubes at concentrations of 0.01-0.1% by volume has demonstrated thermal conductivity improvements of 5-15%. These nanofluids enhance both heat and mass transfer processes, though challenges remain in maintaining stable suspensions over extended operational periods.

Combined approaches that integrate advanced heat exchanger designs with optimized working fluids show the greatest potential, with laboratory prototypes demonstrating efficiency improvements of 25-35% compared to conventional systems. These integrated solutions represent the most promising direction for next-generation lithium bromide absorption chillers in commercial and industrial applications.

Surface modification techniques have emerged as another promising approach, with hydrophilic coatings showing particular effectiveness in absorption processes. These coatings can increase wetting characteristics by up to 40%, ensuring more uniform solution distribution and reducing thermal resistance at the liquid-solid interface. Nanoscale surface treatments that create controlled roughness patterns have demonstrated heat transfer improvements of 15-25% in laboratory settings.

Working fluid modifications constitute another significant avenue for efficiency enhancement. The traditional lithium bromide-water solution presents limitations in terms of crystallization risk and corrosion potential. Research indicates that carefully selected additives can substantially improve performance characteristics. For instance, the addition of 1-2% surfactants such as 2-ethyl-1-hexanol reduces surface tension and enhances absorption rates by 10-15% through the Marangoni effect, which improves solution mixing and mass transfer.

Ionic liquids as partial replacements or additives to conventional LiBr solutions have shown promising results, with some formulations extending the operating temperature range by 5-10°C while reducing crystallization risks. These advanced working fluids demonstrate improved thermal stability and reduced corrosive properties, potentially extending equipment lifespan by 20-30% according to accelerated testing protocols.

Nanofluid technology represents the cutting edge of working fluid enhancement. The suspension of nanoparticles (20-100nm) such as TiO2, Al2O3, or carbon nanotubes at concentrations of 0.01-0.1% by volume has demonstrated thermal conductivity improvements of 5-15%. These nanofluids enhance both heat and mass transfer processes, though challenges remain in maintaining stable suspensions over extended operational periods.

Combined approaches that integrate advanced heat exchanger designs with optimized working fluids show the greatest potential, with laboratory prototypes demonstrating efficiency improvements of 25-35% compared to conventional systems. These integrated solutions represent the most promising direction for next-generation lithium bromide absorption chillers in commercial and industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!