How to Enhance Textile Performance with Sodium Acetate?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate in Textiles: Background and Objectives

Sodium acetate has emerged as a promising compound in the textile industry, offering potential enhancements to fabric performance. The journey of sodium acetate in textiles traces back to the early 2000s when researchers began exploring its properties for various applications. As a salt formed by the combination of acetic acid and sodium hydroxide, sodium acetate exhibits unique characteristics that make it suitable for textile treatments.

The evolution of sodium acetate in textile applications has been driven by the increasing demand for high-performance fabrics in various sectors, including sportswear, outdoor gear, and protective clothing. Initially, sodium acetate was primarily used as a pH buffer in textile processing. However, recent advancements have unveiled its potential in enhancing fabric properties such as moisture management, thermal regulation, and antimicrobial resistance.

The primary objective of incorporating sodium acetate into textiles is to improve the overall performance and functionality of fabrics. Researchers and industry professionals aim to leverage the compound's phase-change properties to develop temperature-regulating textiles. When sodium acetate transitions from its solid to liquid state, it absorbs heat, and when it crystallizes, it releases heat. This characteristic opens up possibilities for creating fabrics that can adapt to changing environmental conditions and maintain optimal comfort for the wearer.

Another key goal is to exploit sodium acetate's hygroscopic nature to enhance moisture management in textiles. By incorporating sodium acetate into fabric fibers or finishes, manufacturers seek to improve the material's ability to absorb and release moisture, thereby enhancing breathability and comfort. This property is particularly valuable in athletic wear and outdoor apparel, where moisture control is crucial for performance and user comfort.

Furthermore, the textile industry is exploring sodium acetate's potential as a sustainable alternative to traditional chemical treatments. As environmental concerns grow, there is an increasing focus on developing eco-friendly textile enhancement methods. Sodium acetate, being a relatively benign compound, aligns with this sustainability trend and offers a promising avenue for green textile technologies.

The technical landscape surrounding sodium acetate in textiles is rapidly evolving, with ongoing research aimed at optimizing its integration into fabric structures and finishes. Scientists are investigating various methods of incorporating sodium acetate, including microencapsulation, coating technologies, and fiber impregnation. These efforts are geared towards maximizing the compound's effectiveness while ensuring durability and washability of the treated textiles.

As the textile industry continues to innovate, the role of sodium acetate in enhancing fabric performance is expected to expand. The compound's versatility and potential for multi-functional improvements position it as a significant player in the future of smart and high-performance textiles.

The evolution of sodium acetate in textile applications has been driven by the increasing demand for high-performance fabrics in various sectors, including sportswear, outdoor gear, and protective clothing. Initially, sodium acetate was primarily used as a pH buffer in textile processing. However, recent advancements have unveiled its potential in enhancing fabric properties such as moisture management, thermal regulation, and antimicrobial resistance.

The primary objective of incorporating sodium acetate into textiles is to improve the overall performance and functionality of fabrics. Researchers and industry professionals aim to leverage the compound's phase-change properties to develop temperature-regulating textiles. When sodium acetate transitions from its solid to liquid state, it absorbs heat, and when it crystallizes, it releases heat. This characteristic opens up possibilities for creating fabrics that can adapt to changing environmental conditions and maintain optimal comfort for the wearer.

Another key goal is to exploit sodium acetate's hygroscopic nature to enhance moisture management in textiles. By incorporating sodium acetate into fabric fibers or finishes, manufacturers seek to improve the material's ability to absorb and release moisture, thereby enhancing breathability and comfort. This property is particularly valuable in athletic wear and outdoor apparel, where moisture control is crucial for performance and user comfort.

Furthermore, the textile industry is exploring sodium acetate's potential as a sustainable alternative to traditional chemical treatments. As environmental concerns grow, there is an increasing focus on developing eco-friendly textile enhancement methods. Sodium acetate, being a relatively benign compound, aligns with this sustainability trend and offers a promising avenue for green textile technologies.

The technical landscape surrounding sodium acetate in textiles is rapidly evolving, with ongoing research aimed at optimizing its integration into fabric structures and finishes. Scientists are investigating various methods of incorporating sodium acetate, including microencapsulation, coating technologies, and fiber impregnation. These efforts are geared towards maximizing the compound's effectiveness while ensuring durability and washability of the treated textiles.

As the textile industry continues to innovate, the role of sodium acetate in enhancing fabric performance is expected to expand. The compound's versatility and potential for multi-functional improvements position it as a significant player in the future of smart and high-performance textiles.

Market Analysis for Enhanced Textile Performance

The global textile industry is experiencing a significant shift towards enhanced performance fabrics, driven by increasing consumer demand for clothing and textiles with superior functionality. The market for enhanced textile performance is projected to grow substantially in the coming years, with a particular focus on moisture management, durability, and comfort. Sodium acetate, a versatile chemical compound, has emerged as a promising agent for improving textile performance across various applications.

In the sportswear and activewear segments, there is a growing demand for fabrics that can effectively manage moisture and regulate temperature. Sodium acetate's hygroscopic properties make it an attractive option for manufacturers looking to develop moisture-wicking and quick-drying textiles. This aligns with the increasing health consciousness among consumers and the popularity of athleisure wear, which has created a lucrative market for performance-enhanced fabrics.

The outdoor apparel sector is another key market driver for enhanced textile performance. Consumers engaged in outdoor activities seek clothing that offers protection against the elements while maintaining comfort. Sodium acetate's potential to improve the water-repellent properties of fabrics without compromising breathability addresses this market need, potentially capturing a significant share of the outdoor gear market.

In the workwear and protective clothing industry, there is a constant demand for fabrics that can withstand harsh conditions while providing comfort to the wearer. Sodium acetate's ability to enhance the durability and resistance of textiles to various environmental factors positions it as a valuable additive in this sector. The growing emphasis on workplace safety and regulations mandating high-performance protective gear further drives the market potential for sodium acetate-enhanced textiles.

The home textiles market, including bedding, upholstery, and curtains, is also showing interest in performance-enhanced fabrics. Consumers are increasingly looking for easy-to-maintain, durable, and functional home textiles. Sodium acetate's potential to improve stain resistance, reduce wrinkles, and enhance overall fabric performance aligns well with these consumer preferences, opening up new opportunities in the residential and commercial interior textile markets.

Geographically, the market for enhanced textile performance is seeing strong growth in regions with a developed textile industry and high consumer spending power, such as North America, Europe, and parts of Asia. However, emerging economies with growing middle-class populations and increasing disposable incomes are also showing significant potential for market expansion. The versatility of sodium acetate in enhancing various textile properties makes it adaptable to different regional market needs and preferences.

As sustainability becomes an increasingly important factor in consumer purchasing decisions, the market is also seeing a trend towards eco-friendly performance enhancements. Sodium acetate's potential as a more sustainable alternative to some synthetic performance enhancers could position it favorably in this growing market segment, appealing to environmentally conscious consumers and brands committed to reducing their ecological footprint.

In the sportswear and activewear segments, there is a growing demand for fabrics that can effectively manage moisture and regulate temperature. Sodium acetate's hygroscopic properties make it an attractive option for manufacturers looking to develop moisture-wicking and quick-drying textiles. This aligns with the increasing health consciousness among consumers and the popularity of athleisure wear, which has created a lucrative market for performance-enhanced fabrics.

The outdoor apparel sector is another key market driver for enhanced textile performance. Consumers engaged in outdoor activities seek clothing that offers protection against the elements while maintaining comfort. Sodium acetate's potential to improve the water-repellent properties of fabrics without compromising breathability addresses this market need, potentially capturing a significant share of the outdoor gear market.

In the workwear and protective clothing industry, there is a constant demand for fabrics that can withstand harsh conditions while providing comfort to the wearer. Sodium acetate's ability to enhance the durability and resistance of textiles to various environmental factors positions it as a valuable additive in this sector. The growing emphasis on workplace safety and regulations mandating high-performance protective gear further drives the market potential for sodium acetate-enhanced textiles.

The home textiles market, including bedding, upholstery, and curtains, is also showing interest in performance-enhanced fabrics. Consumers are increasingly looking for easy-to-maintain, durable, and functional home textiles. Sodium acetate's potential to improve stain resistance, reduce wrinkles, and enhance overall fabric performance aligns well with these consumer preferences, opening up new opportunities in the residential and commercial interior textile markets.

Geographically, the market for enhanced textile performance is seeing strong growth in regions with a developed textile industry and high consumer spending power, such as North America, Europe, and parts of Asia. However, emerging economies with growing middle-class populations and increasing disposable incomes are also showing significant potential for market expansion. The versatility of sodium acetate in enhancing various textile properties makes it adaptable to different regional market needs and preferences.

As sustainability becomes an increasingly important factor in consumer purchasing decisions, the market is also seeing a trend towards eco-friendly performance enhancements. Sodium acetate's potential as a more sustainable alternative to some synthetic performance enhancers could position it favorably in this growing market segment, appealing to environmentally conscious consumers and brands committed to reducing their ecological footprint.

Current Challenges in Sodium Acetate Textile Applications

The integration of sodium acetate into textile applications presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary obstacles is achieving uniform distribution of sodium acetate within the fabric structure. The uneven distribution can lead to inconsistent performance across the textile, compromising its overall effectiveness in moisture management and thermal regulation.

Another challenge lies in maintaining the stability of sodium acetate within the textile matrix over extended periods. Environmental factors such as humidity, temperature fluctuations, and repeated washing cycles can potentially degrade the sodium acetate's performance or cause it to leach out of the fabric. This instability not only reduces the longevity of the enhanced textile properties but also raises concerns about the environmental impact of sodium acetate-treated textiles.

The scalability of sodium acetate application processes in textile manufacturing presents a significant hurdle. While laboratory-scale treatments have shown promising results, translating these methods to industrial-scale production while maintaining cost-effectiveness and quality consistency remains a complex task. The integration of sodium acetate treatment into existing textile production lines without disrupting established workflows or requiring substantial equipment modifications is a key consideration for widespread adoption.

Furthermore, the potential impact of sodium acetate on the inherent properties of textiles, such as breathability, flexibility, and tactile comfort, is an area of ongoing investigation. Striking the right balance between enhancing performance characteristics and preserving the desirable qualities of the base fabric is crucial for consumer acceptance and market success.

The regulatory landscape surrounding the use of sodium acetate in textiles, particularly in applications involving prolonged skin contact or potential ingestion (e.g., in children's clothing), is another challenge. Ensuring compliance with safety standards and obtaining necessary certifications across different global markets adds complexity to the development and commercialization process.

Lastly, the optimization of sodium acetate formulations for specific textile applications remains an active area of research. Different fabric types, end-use requirements, and performance goals necessitate tailored approaches to sodium acetate integration. Developing a versatile yet customizable solution that can be adapted to various textile scenarios without compromising efficacy or cost-effectiveness is a significant challenge facing researchers and product developers in this field.

Another challenge lies in maintaining the stability of sodium acetate within the textile matrix over extended periods. Environmental factors such as humidity, temperature fluctuations, and repeated washing cycles can potentially degrade the sodium acetate's performance or cause it to leach out of the fabric. This instability not only reduces the longevity of the enhanced textile properties but also raises concerns about the environmental impact of sodium acetate-treated textiles.

The scalability of sodium acetate application processes in textile manufacturing presents a significant hurdle. While laboratory-scale treatments have shown promising results, translating these methods to industrial-scale production while maintaining cost-effectiveness and quality consistency remains a complex task. The integration of sodium acetate treatment into existing textile production lines without disrupting established workflows or requiring substantial equipment modifications is a key consideration for widespread adoption.

Furthermore, the potential impact of sodium acetate on the inherent properties of textiles, such as breathability, flexibility, and tactile comfort, is an area of ongoing investigation. Striking the right balance between enhancing performance characteristics and preserving the desirable qualities of the base fabric is crucial for consumer acceptance and market success.

The regulatory landscape surrounding the use of sodium acetate in textiles, particularly in applications involving prolonged skin contact or potential ingestion (e.g., in children's clothing), is another challenge. Ensuring compliance with safety standards and obtaining necessary certifications across different global markets adds complexity to the development and commercialization process.

Lastly, the optimization of sodium acetate formulations for specific textile applications remains an active area of research. Different fabric types, end-use requirements, and performance goals necessitate tailored approaches to sodium acetate integration. Developing a versatile yet customizable solution that can be adapted to various textile scenarios without compromising efficacy or cost-effectiveness is a significant challenge facing researchers and product developers in this field.

Existing Sodium Acetate Textile Enhancement Methods

01 Textile treatment with sodium acetate

Sodium acetate is used in various textile treatments to improve fabric performance. It can be applied as a finishing agent to enhance properties such as wrinkle resistance, dimensional stability, and moisture management. The compound may be used in combination with other chemicals to achieve specific textile performance characteristics.- Textile treatment with sodium acetate: Sodium acetate is used in various textile treatments to improve fabric performance. It can be applied as a finishing agent to enhance properties such as wrinkle resistance, dimensional stability, and moisture management. The compound may be used in combination with other chemicals to achieve specific textile characteristics.

- Flame retardant properties: Sodium acetate can be incorporated into textile treatments to impart flame retardant properties. When applied to fabrics, it can help reduce flammability and improve fire resistance. This is particularly useful for protective clothing and furnishings where fire safety is a concern.

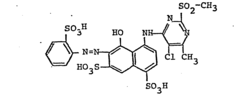

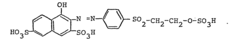

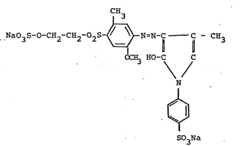

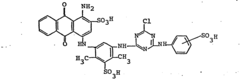

- Dyeing and color fastness improvement: In textile dyeing processes, sodium acetate can be used as a pH buffer or auxiliary agent. It helps to improve color fastness, dye uptake, and overall dyeing efficiency. The compound may also contribute to the evenness of dye distribution on the fabric surface.

- Anti-static and softening effects: Sodium acetate can be used in textile finishing to impart anti-static properties to fabrics. It helps to reduce static electricity buildup, making garments more comfortable to wear. Additionally, it may contribute to a softer hand feel of the treated textiles.

- Moisture management and hygroscopic properties: When applied to textiles, sodium acetate can enhance moisture management capabilities. It may improve the fabric's ability to absorb and release moisture, contributing to better comfort and performance in various environmental conditions. This property is particularly beneficial for sportswear and technical textiles.

02 Flame retardant properties

Sodium acetate can be incorporated into textile treatments to impart flame retardant properties. When applied to fabrics, it can help reduce flammability and improve fire resistance. This application is particularly useful for protective clothing and furnishings where fire safety is a concern.Expand Specific Solutions03 Dyeing and color fastness improvement

In textile dyeing processes, sodium acetate can be used as an auxiliary agent to improve color fastness and dye uptake. It may help in achieving more uniform dyeing results and enhancing the overall quality of dyed fabrics. The compound can also assist in pH regulation during the dyeing process.Expand Specific Solutions04 Antimicrobial and odor control

Sodium acetate can be utilized in textile treatments to provide antimicrobial properties and odor control. When applied to fabrics, it can help inhibit the growth of bacteria and fungi, reducing unpleasant odors and improving the hygiene of textiles. This is particularly beneficial for sportswear and medical textiles.Expand Specific Solutions05 Moisture management and comfort enhancement

Sodium acetate can be incorporated into textile finishes to improve moisture management properties. It can help regulate moisture absorption and release, enhancing the comfort of the wearer. This application is particularly useful in performance fabrics and sportswear where moisture control is crucial for comfort and performance.Expand Specific Solutions

Key Players in Sodium Acetate Textile Industry

The textile performance enhancement market using sodium acetate is in a growth phase, with increasing demand for innovative solutions in the textile industry. The market size is expanding as more companies recognize the potential of sodium acetate in improving fabric properties. Technologically, the field is advancing rapidly, with several key players driving innovation. Companies like Henkel AG & Co. KGaA, BASF Corp., and Kao Corp. are at the forefront, leveraging their expertise in chemical engineering to develop advanced sodium acetate-based solutions. Academic institutions such as Wuhan Textile University and The Hong Kong Polytechnic University are contributing significantly to research and development, bridging the gap between theoretical knowledge and practical applications in this emerging field.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed an innovative approach to enhance textile performance using sodium acetate. Their method involves incorporating sodium acetate into fabric finishes and treatments. This process creates a phase-change material (PCM) effect, allowing textiles to absorb and release heat as needed[1]. The sodium acetate crystals melt when exposed to body heat, storing energy, and then solidify as they cool, releasing the stored heat. This technology has been applied to various textile products, including sportswear, bedding, and outdoor gear. Henkel's solution also includes a proprietary binding system that ensures the sodium acetate remains effective even after multiple wash cycles[3]. The company has further enhanced this technology by combining it with other performance-boosting additives, creating a multi-functional textile treatment that offers both thermal regulation and moisture management properties[5].

Strengths: Excellent thermal regulation, long-lasting effectiveness, and versatility across various textile applications. Weaknesses: Potential cost increase in textile production and possible limitations in extreme temperature conditions.

BASF Corp.

Technical Solution: BASF has developed a cutting-edge approach to enhancing textile performance using sodium acetate as a key component. Their technology, known as "AceTex," involves a microencapsulation process where tiny capsules containing sodium acetate are integrated into the fabric structure[2]. These microcapsules are designed to rupture under specific conditions, releasing the sodium acetate solution. Upon exposure to moisture or temperature changes, the sodium acetate undergoes a phase transition, absorbing or releasing heat as needed. This creates a dynamic thermoregulation system within the textile. BASF has also incorporated antimicrobial properties into this system, utilizing the mild acidity of sodium acetate to inhibit bacterial growth[4]. The company has successfully applied this technology to a wide range of textiles, from high-performance sportswear to industrial protective clothing[6].

Strengths: Advanced thermoregulation, added antimicrobial properties, and broad applicability across textile industries. Weaknesses: Potential durability issues with microcapsules over time and increased production complexity.

Innovative Sodium Acetate Textile Technologies

Process for the continuous dyeing and printing of wool fibres

PatentInactiveEP0058433A1

Innovation

- A process involving an aqueous solution with 60 to 100 g/l of sodium acetate in the dye liquor, followed by brief drying and rapid steaming at 102° to 115°C, allows for fast dye fixation without additional auxiliaries, reducing steaming time and wastewater generation, while achieving high color strength and fastness properties.

Solid fragrance-containing composition

PatentWO2020015878A1

Innovation

- A method using sodium acetate trihydrate as a carrier material, melted with a specific weight ratio of water to sodium acetate above 0.63, forming melt bodies that are then shaped and cooled, which improves solubility and process stability, allowing for robust and low-maintenance production.

Environmental Impact of Sodium Acetate in Textiles

The environmental impact of sodium acetate in textiles is a crucial consideration as the industry seeks to enhance textile performance. Sodium acetate, while offering benefits in terms of moisture management and thermal regulation, also presents potential environmental challenges that must be carefully evaluated.

One of the primary environmental concerns associated with sodium acetate in textiles is its potential for water pollution. When textiles treated with sodium acetate are washed, there is a risk of the compound being released into wastewater systems. This can lead to increased salinity in water bodies, potentially affecting aquatic ecosystems and biodiversity. The impact on water treatment facilities must also be considered, as high levels of sodium acetate may require additional processing steps to ensure safe water discharge.

The production process of sodium acetate itself has environmental implications. The synthesis of sodium acetate typically involves the reaction of acetic acid with sodium hydroxide or sodium carbonate. These processes can be energy-intensive and may contribute to greenhouse gas emissions if not managed efficiently. Additionally, the sourcing of raw materials for sodium acetate production may have associated environmental impacts, such as land use changes or resource depletion.

On the positive side, the use of sodium acetate in textiles can potentially reduce the need for certain chemical treatments or finishes that may have more severe environmental impacts. For instance, its moisture-wicking properties could decrease the reliance on synthetic moisture management treatments that might be less biodegradable or more toxic to aquatic life.

The end-of-life considerations for textiles treated with sodium acetate are also important. While sodium acetate is generally considered biodegradable, the rate and completeness of biodegradation in various environmental conditions need to be thoroughly assessed. The potential for sodium acetate to interfere with textile recycling processes or to impact the quality of recycled fibers is another area that requires investigation.

From a lifecycle perspective, the environmental footprint of sodium acetate-treated textiles must be evaluated holistically. This includes considering the energy and water consumption during the treatment process, the potential for extended garment life due to improved performance (which could reduce overall textile waste), and the implications for textile disposal or recycling.

To mitigate potential negative environmental impacts, research into more sustainable production methods for sodium acetate and its application in textiles is essential. This may include exploring bio-based sources for sodium acetate, developing closed-loop systems for its application in textile manufacturing, and investigating methods to recover and reuse sodium acetate from wastewater streams.

One of the primary environmental concerns associated with sodium acetate in textiles is its potential for water pollution. When textiles treated with sodium acetate are washed, there is a risk of the compound being released into wastewater systems. This can lead to increased salinity in water bodies, potentially affecting aquatic ecosystems and biodiversity. The impact on water treatment facilities must also be considered, as high levels of sodium acetate may require additional processing steps to ensure safe water discharge.

The production process of sodium acetate itself has environmental implications. The synthesis of sodium acetate typically involves the reaction of acetic acid with sodium hydroxide or sodium carbonate. These processes can be energy-intensive and may contribute to greenhouse gas emissions if not managed efficiently. Additionally, the sourcing of raw materials for sodium acetate production may have associated environmental impacts, such as land use changes or resource depletion.

On the positive side, the use of sodium acetate in textiles can potentially reduce the need for certain chemical treatments or finishes that may have more severe environmental impacts. For instance, its moisture-wicking properties could decrease the reliance on synthetic moisture management treatments that might be less biodegradable or more toxic to aquatic life.

The end-of-life considerations for textiles treated with sodium acetate are also important. While sodium acetate is generally considered biodegradable, the rate and completeness of biodegradation in various environmental conditions need to be thoroughly assessed. The potential for sodium acetate to interfere with textile recycling processes or to impact the quality of recycled fibers is another area that requires investigation.

From a lifecycle perspective, the environmental footprint of sodium acetate-treated textiles must be evaluated holistically. This includes considering the energy and water consumption during the treatment process, the potential for extended garment life due to improved performance (which could reduce overall textile waste), and the implications for textile disposal or recycling.

To mitigate potential negative environmental impacts, research into more sustainable production methods for sodium acetate and its application in textiles is essential. This may include exploring bio-based sources for sodium acetate, developing closed-loop systems for its application in textile manufacturing, and investigating methods to recover and reuse sodium acetate from wastewater streams.

Regulatory Framework for Chemical Textile Treatments

The regulatory framework for chemical textile treatments plays a crucial role in ensuring the safe and responsible use of substances like sodium acetate in enhancing textile performance. In the context of using sodium acetate for textile enhancement, manufacturers and researchers must navigate a complex landscape of regulations and standards set by various national and international bodies.

At the forefront of these regulations is the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation. REACH requires companies to register chemical substances and provide safety data, including potential risks and appropriate risk management measures. For sodium acetate used in textiles, this means thorough documentation of its properties, potential environmental impacts, and safe handling procedures.

In the United States, the Environmental Protection Agency (EPA) oversees chemical regulations through the Toxic Substances Control Act (TSCA). Under TSCA, new chemical substances must be reviewed before they can be manufactured or imported. For existing chemicals like sodium acetate, the EPA may require additional testing or impose restrictions if new safety concerns arise.

The textile industry also faces regulations specific to consumer safety. In the EU, the General Product Safety Directive ensures that products placed on the market are safe for consumers. This directive would apply to textiles treated with sodium acetate, requiring manufacturers to assess and mitigate any potential risks associated with the treatment.

International standards organizations, such as the International Organization for Standardization (ISO), provide guidelines for testing and quality control in textile production. These standards often include protocols for assessing the performance and safety of chemical treatments, which would be applicable to sodium acetate-enhanced textiles.

Environmental regulations are increasingly important in the textile industry. Many countries have implemented strict controls on wastewater discharge from textile manufacturing processes. The use of sodium acetate in textile treatments would need to comply with these regulations, potentially requiring wastewater treatment systems to remove or neutralize the chemical before discharge.

Labeling and certification requirements also form part of the regulatory framework. In some jurisdictions, textiles treated with chemicals may need to carry specific labels or meet certain certification standards. For example, the OEKO-TEX Standard 100 is a widely recognized certification for textiles, which sets limits on the use of certain chemicals and could impact the use of sodium acetate in textile treatments.

As sustainability becomes a greater focus in the textile industry, regulations are evolving to address the entire lifecycle of textile products. This includes considerations for the recyclability and biodegradability of treated textiles, which could influence the choice and application of chemicals like sodium acetate in textile enhancement processes.

At the forefront of these regulations is the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation. REACH requires companies to register chemical substances and provide safety data, including potential risks and appropriate risk management measures. For sodium acetate used in textiles, this means thorough documentation of its properties, potential environmental impacts, and safe handling procedures.

In the United States, the Environmental Protection Agency (EPA) oversees chemical regulations through the Toxic Substances Control Act (TSCA). Under TSCA, new chemical substances must be reviewed before they can be manufactured or imported. For existing chemicals like sodium acetate, the EPA may require additional testing or impose restrictions if new safety concerns arise.

The textile industry also faces regulations specific to consumer safety. In the EU, the General Product Safety Directive ensures that products placed on the market are safe for consumers. This directive would apply to textiles treated with sodium acetate, requiring manufacturers to assess and mitigate any potential risks associated with the treatment.

International standards organizations, such as the International Organization for Standardization (ISO), provide guidelines for testing and quality control in textile production. These standards often include protocols for assessing the performance and safety of chemical treatments, which would be applicable to sodium acetate-enhanced textiles.

Environmental regulations are increasingly important in the textile industry. Many countries have implemented strict controls on wastewater discharge from textile manufacturing processes. The use of sodium acetate in textile treatments would need to comply with these regulations, potentially requiring wastewater treatment systems to remove or neutralize the chemical before discharge.

Labeling and certification requirements also form part of the regulatory framework. In some jurisdictions, textiles treated with chemicals may need to carry specific labels or meet certain certification standards. For example, the OEKO-TEX Standard 100 is a widely recognized certification for textiles, which sets limits on the use of certain chemicals and could impact the use of sodium acetate in textile treatments.

As sustainability becomes a greater focus in the textile industry, regulations are evolving to address the entire lifecycle of textile products. This includes considerations for the recyclability and biodegradability of treated textiles, which could influence the choice and application of chemicals like sodium acetate in textile enhancement processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!