How to Ensure Compliance with Industry Standards Using Topology Optimization

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization Standards Background and Objectives

Topology optimization has emerged as a transformative approach in engineering design, evolving from theoretical concepts in the 1980s to becoming an essential tool in modern manufacturing. This mathematical method determines the optimal material distribution within a design space, subject to specified constraints and performance criteria. The evolution of topology optimization has been closely tied to advancements in computational capabilities, allowing for increasingly complex optimization problems to be solved efficiently.

The field has progressed through several key developmental phases, beginning with homogenization methods, followed by the introduction of the Solid Isotropic Material with Penalization (SIMP) approach in the 1990s, and more recently incorporating level-set methods and phase field approaches. Each advancement has expanded the applicability and effectiveness of topology optimization across various engineering disciplines.

Industry standards for topology optimization have developed in response to the growing adoption of this technology in critical sectors such as aerospace, automotive, and medical device manufacturing. These standards aim to ensure that optimized designs meet functional requirements while maintaining safety, reliability, and manufacturability. The establishment of standardized practices has become increasingly important as topology optimization transitions from academic research to widespread industrial implementation.

The primary objective of ensuring compliance with industry standards using topology optimization is to bridge the gap between innovative design possibilities and practical manufacturing constraints. This involves developing methodologies that can systematically incorporate regulatory requirements and industry-specific standards directly into the optimization process, rather than applying them as post-optimization modifications.

Current technical goals in this domain include the development of multi-physics optimization frameworks that can simultaneously address structural, thermal, and fluid dynamics considerations while maintaining compliance with relevant standards. Additionally, there is a push toward creating more accessible tools that democratize topology optimization capabilities while ensuring that resulting designs inherently satisfy industry requirements.

The trajectory of topology optimization technology indicates a move toward more integrated design-to-manufacturing workflows, where compliance with standards is verified throughout the entire process. This integration aims to reduce development cycles and minimize the need for iterative redesigns due to compliance issues discovered late in the product development process.

As additive manufacturing continues to mature, topology optimization standards must evolve to address the unique capabilities and constraints of these production methods, including considerations for material properties, build orientation, and post-processing requirements. The convergence of these technologies presents both challenges and opportunities for establishing comprehensive standards that enable innovation while ensuring product integrity.

The field has progressed through several key developmental phases, beginning with homogenization methods, followed by the introduction of the Solid Isotropic Material with Penalization (SIMP) approach in the 1990s, and more recently incorporating level-set methods and phase field approaches. Each advancement has expanded the applicability and effectiveness of topology optimization across various engineering disciplines.

Industry standards for topology optimization have developed in response to the growing adoption of this technology in critical sectors such as aerospace, automotive, and medical device manufacturing. These standards aim to ensure that optimized designs meet functional requirements while maintaining safety, reliability, and manufacturability. The establishment of standardized practices has become increasingly important as topology optimization transitions from academic research to widespread industrial implementation.

The primary objective of ensuring compliance with industry standards using topology optimization is to bridge the gap between innovative design possibilities and practical manufacturing constraints. This involves developing methodologies that can systematically incorporate regulatory requirements and industry-specific standards directly into the optimization process, rather than applying them as post-optimization modifications.

Current technical goals in this domain include the development of multi-physics optimization frameworks that can simultaneously address structural, thermal, and fluid dynamics considerations while maintaining compliance with relevant standards. Additionally, there is a push toward creating more accessible tools that democratize topology optimization capabilities while ensuring that resulting designs inherently satisfy industry requirements.

The trajectory of topology optimization technology indicates a move toward more integrated design-to-manufacturing workflows, where compliance with standards is verified throughout the entire process. This integration aims to reduce development cycles and minimize the need for iterative redesigns due to compliance issues discovered late in the product development process.

As additive manufacturing continues to mature, topology optimization standards must evolve to address the unique capabilities and constraints of these production methods, including considerations for material properties, build orientation, and post-processing requirements. The convergence of these technologies presents both challenges and opportunities for establishing comprehensive standards that enable innovation while ensuring product integrity.

Market Demand for Standards-Compliant Topology Optimization

The market for topology optimization solutions that ensure compliance with industry standards has experienced significant growth in recent years, driven by increasing regulatory requirements across manufacturing sectors. According to recent market analyses, the global topology optimization software market reached approximately $1.2 billion in 2022, with a compound annual growth rate of 15.3% projected through 2028.

Industries such as aerospace, automotive, and medical device manufacturing demonstrate the strongest demand for standards-compliant topology optimization solutions. These sectors face stringent regulatory frameworks that necessitate adherence to specific performance, safety, and quality standards while simultaneously pursuing weight reduction and material efficiency goals.

Aerospace manufacturers particularly value topology optimization tools that can ensure compliance with FAA, EASA, and military standards while optimizing structural components. The need to balance weight reduction with strict safety requirements creates a premium market segment willing to invest in advanced solutions that provide certification-ready designs.

The automotive industry represents another significant market driver, with OEMs increasingly adopting topology optimization to meet fuel efficiency and emissions standards while maintaining crash safety requirements. The transition toward electric vehicles has further accelerated this demand, as manufacturers seek to optimize battery enclosures and structural components within regulatory constraints.

Medical device manufacturers constitute a rapidly growing market segment, requiring topology optimization solutions that can navigate FDA and international regulatory frameworks. The ability to create patient-specific implants that meet biocompatibility and mechanical performance standards represents a high-value application area.

Market research indicates that customers increasingly demand integrated solutions that combine topology optimization algorithms with built-in compliance checking and verification tools. The ability to automatically validate designs against relevant standards during the optimization process, rather than as a separate verification step, represents a key competitive differentiator.

Regional analysis shows North America leading the market with approximately 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 18.7% annually, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies in China, Japan, and South Korea.

Customer surveys reveal that 73% of engineering firms consider standards compliance capabilities as "very important" or "critical" when selecting topology optimization software, highlighting the market's prioritization of regulatory alignment alongside performance optimization.

Industries such as aerospace, automotive, and medical device manufacturing demonstrate the strongest demand for standards-compliant topology optimization solutions. These sectors face stringent regulatory frameworks that necessitate adherence to specific performance, safety, and quality standards while simultaneously pursuing weight reduction and material efficiency goals.

Aerospace manufacturers particularly value topology optimization tools that can ensure compliance with FAA, EASA, and military standards while optimizing structural components. The need to balance weight reduction with strict safety requirements creates a premium market segment willing to invest in advanced solutions that provide certification-ready designs.

The automotive industry represents another significant market driver, with OEMs increasingly adopting topology optimization to meet fuel efficiency and emissions standards while maintaining crash safety requirements. The transition toward electric vehicles has further accelerated this demand, as manufacturers seek to optimize battery enclosures and structural components within regulatory constraints.

Medical device manufacturers constitute a rapidly growing market segment, requiring topology optimization solutions that can navigate FDA and international regulatory frameworks. The ability to create patient-specific implants that meet biocompatibility and mechanical performance standards represents a high-value application area.

Market research indicates that customers increasingly demand integrated solutions that combine topology optimization algorithms with built-in compliance checking and verification tools. The ability to automatically validate designs against relevant standards during the optimization process, rather than as a separate verification step, represents a key competitive differentiator.

Regional analysis shows North America leading the market with approximately 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 18.7% annually, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies in China, Japan, and South Korea.

Customer surveys reveal that 73% of engineering firms consider standards compliance capabilities as "very important" or "critical" when selecting topology optimization software, highlighting the market's prioritization of regulatory alignment alongside performance optimization.

Current Challenges in Standards-Compliant Topology Optimization

Despite the significant advancements in topology optimization techniques, implementing these methods while ensuring compliance with industry standards presents several substantial challenges. The complexity arises from the inherent tension between the free-form nature of topology optimization and the rigid requirements of standardization across various industries.

One primary challenge is the interpretation and translation of qualitative industry standards into quantitative constraints that can be incorporated into topology optimization algorithms. Many standards were developed before topology optimization became widespread, resulting in specifications that may not be directly compatible with algorithmic implementation. For instance, standards often specify minimum feature sizes or specific geometric requirements that must be maintained throughout the optimization process.

Manufacturing constraints pose another significant hurdle. While topology optimization may generate theoretically optimal designs, these solutions frequently contain complex geometries that are difficult or impossible to manufacture using conventional methods. Ensuring that optimized designs remain manufacturable while still meeting industry standards requires sophisticated constraint handling within the optimization framework.

Verification and validation processes present additional complications. Traditional testing methodologies may not be directly applicable to topology-optimized structures due to their unconventional geometries. This necessitates the development of new testing protocols or simulation methodologies that can adequately verify compliance without requiring excessive physical prototyping.

The multi-disciplinary nature of modern engineering projects further complicates standards compliance. A single component may need to satisfy mechanical, thermal, electromagnetic, and safety standards simultaneously. Integrating these diverse requirements into a cohesive optimization framework remains technically challenging and computationally expensive.

Regulatory approval processes often lag behind technological innovation. Many certification bodies lack established procedures for evaluating topology-optimized components, creating uncertainty in the approval pathway. This regulatory ambiguity can significantly extend product development timelines and increase costs.

Documentation and traceability requirements present yet another obstacle. The iterative nature of topology optimization makes it difficult to document the design rationale and decision-making process in the traditional manner expected by regulatory bodies. Establishing clear traceability between optimization parameters, constraints, and final designs is essential for compliance but remains challenging to implement systematically.

Finally, the rapid evolution of both topology optimization techniques and industry standards creates a moving target for compliance efforts. Organizations must continuously update their optimization frameworks to accommodate new or revised standards, requiring significant ongoing investment in research and development.

One primary challenge is the interpretation and translation of qualitative industry standards into quantitative constraints that can be incorporated into topology optimization algorithms. Many standards were developed before topology optimization became widespread, resulting in specifications that may not be directly compatible with algorithmic implementation. For instance, standards often specify minimum feature sizes or specific geometric requirements that must be maintained throughout the optimization process.

Manufacturing constraints pose another significant hurdle. While topology optimization may generate theoretically optimal designs, these solutions frequently contain complex geometries that are difficult or impossible to manufacture using conventional methods. Ensuring that optimized designs remain manufacturable while still meeting industry standards requires sophisticated constraint handling within the optimization framework.

Verification and validation processes present additional complications. Traditional testing methodologies may not be directly applicable to topology-optimized structures due to their unconventional geometries. This necessitates the development of new testing protocols or simulation methodologies that can adequately verify compliance without requiring excessive physical prototyping.

The multi-disciplinary nature of modern engineering projects further complicates standards compliance. A single component may need to satisfy mechanical, thermal, electromagnetic, and safety standards simultaneously. Integrating these diverse requirements into a cohesive optimization framework remains technically challenging and computationally expensive.

Regulatory approval processes often lag behind technological innovation. Many certification bodies lack established procedures for evaluating topology-optimized components, creating uncertainty in the approval pathway. This regulatory ambiguity can significantly extend product development timelines and increase costs.

Documentation and traceability requirements present yet another obstacle. The iterative nature of topology optimization makes it difficult to document the design rationale and decision-making process in the traditional manner expected by regulatory bodies. Establishing clear traceability between optimization parameters, constraints, and final designs is essential for compliance but remains challenging to implement systematically.

Finally, the rapid evolution of both topology optimization techniques and industry standards creates a moving target for compliance efforts. Organizations must continuously update their optimization frameworks to accommodate new or revised standards, requiring significant ongoing investment in research and development.

Current Approaches to Standards-Compliant Topology Optimization

01 Structural optimization methods for compliance minimization

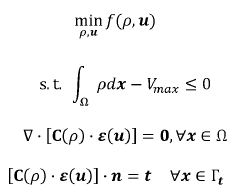

Topology optimization techniques are used to minimize structural compliance, which is a measure of the structure's stiffness. These methods involve iterative processes to distribute material efficiently within a design space while satisfying constraints. The optimization algorithms typically aim to maximize stiffness (minimize compliance) for a given amount of material, resulting in lightweight yet strong structures. These approaches often incorporate finite element analysis to evaluate structural performance during the optimization process.- Structural optimization methods for compliance minimization: Topology optimization techniques are used to minimize compliance in structural designs, ensuring optimal material distribution while meeting specified constraints. These methods involve iterative algorithms that analyze stress distributions and adjust material layouts to achieve maximum stiffness with minimum material usage. The optimization process typically considers boundary conditions, load cases, and manufacturing constraints to produce designs with improved mechanical performance.

- Multi-objective topology optimization frameworks: Advanced frameworks for topology optimization incorporate multiple objectives beyond just compliance, such as weight reduction, thermal management, and manufacturability. These frameworks utilize mathematical models to balance competing design goals while maintaining structural integrity. They often employ machine learning techniques to accelerate convergence and improve solution quality, enabling designers to explore trade-offs between different performance metrics in complex engineering applications.

- Additive manufacturing-oriented topology optimization: Specialized topology optimization approaches have been developed specifically for additive manufacturing processes, addressing unique constraints and opportunities of these fabrication methods. These approaches consider build orientation, support structures, and material anisotropy while optimizing for compliance. The resulting designs often feature complex organic geometries that would be impossible to produce with traditional manufacturing methods, enabling significant performance improvements in aerospace, automotive, and medical applications.

- Network architecture optimization for compliance monitoring: Topology optimization principles are applied to communication networks and monitoring systems to ensure compliance with performance requirements and regulatory standards. These approaches optimize network layouts, sensor placements, and data flow paths to maximize coverage while minimizing resource usage. The optimization algorithms balance factors such as latency, bandwidth, reliability, and energy consumption to create resilient network architectures that maintain compliance under varying operational conditions.

- Computational methods for large-scale compliance optimization: Advanced computational techniques enable topology optimization of large-scale structures with millions of design variables while maintaining compliance with mechanical requirements. These methods employ parallel computing, model reduction techniques, and specialized solvers to handle the computational complexity of large optimization problems. They often incorporate multi-scale approaches that can simultaneously address macro-level structural performance and micro-level material behavior, resulting in hierarchically optimized designs with superior mechanical properties.

02 Multi-objective topology optimization considering compliance

Advanced topology optimization frameworks that consider multiple objectives simultaneously, with structural compliance being one of the key factors. These approaches balance compliance minimization with other design goals such as weight reduction, thermal performance, or manufacturing constraints. The multi-objective optimization techniques employ various algorithms including genetic algorithms, particle swarm optimization, and gradient-based methods to find Pareto-optimal solutions that represent the best trade-offs between competing objectives.Expand Specific Solutions03 Lattice and cellular structure optimization for compliance control

Specialized topology optimization methods focused on generating lattice and cellular structures with tailored compliance properties. These approaches create periodic or non-periodic internal architectures that can be tuned to achieve specific mechanical responses. The optimization of these cellular structures allows for precise control of local and global compliance characteristics, enabling the design of materials with programmable mechanical properties, including stiffness gradients and anisotropic behavior.Expand Specific Solutions04 Compliance-based topology optimization for additive manufacturing

Topology optimization methods specifically adapted for additive manufacturing processes, where compliance minimization is integrated with manufacturing constraints. These approaches account for the unique capabilities and limitations of 3D printing technologies, such as support structure requirements, build orientation effects, and material anisotropy. The optimization algorithms incorporate these manufacturing considerations while still achieving optimal compliance properties, resulting in designs that are both structurally efficient and manufacturable.Expand Specific Solutions05 Machine learning approaches for compliance-based topology optimization

Novel methods that leverage machine learning and artificial intelligence to enhance compliance-based topology optimization. These approaches use neural networks, deep learning, and other AI techniques to accelerate optimization processes, predict structural performance, or generate initial design concepts. Machine learning models can be trained on existing optimization results to quickly propose new designs with optimal compliance characteristics, significantly reducing computational time compared to traditional iterative methods.Expand Specific Solutions

Leading Organizations and Companies in Topology Optimization Standards

Topology optimization compliance is evolving rapidly in a market transitioning from early adoption to mainstream implementation, with projected growth reaching $2-3 billion by 2025. The technology maturity varies across industry leaders: Siemens AG, ANSYS, and Dassault Systèmes offer comprehensive commercial solutions with advanced compliance verification tools; Autodesk and Altair Engineering provide robust platforms with growing compliance capabilities; while academic institutions like Georgia Tech and Zhejiang University contribute fundamental research. Automotive and aerospace manufacturers (Toyota, Honda) are increasingly implementing topology optimization with built-in compliance checks, while engineering service providers (Engineering Technology Associates) are developing specialized compliance verification methodologies tailored to specific industry standards.

Siemens AG

Technical Solution: Siemens AG has developed a comprehensive topology optimization framework that integrates compliance verification throughout the design process. Their solution combines simulation-driven design with automated compliance checking against industry standards such as ISO, ASME, and IEC. The platform utilizes multi-physics simulation capabilities to predict structural performance while simultaneously evaluating regulatory requirements. Siemens' approach incorporates parametric design exploration that automatically flags non-compliant design iterations, enabling engineers to focus only on solutions that meet industry standards. Their system includes a digital twin methodology where virtual prototypes undergo simulated testing against regulatory requirements before physical production begins[1]. The platform features a compliance management database that is continuously updated with the latest industry standards, ensuring designs remain current with evolving regulations. Siemens has implemented this technology across various industries including aerospace, automotive, and medical device manufacturing, where compliance with standards like ISO 13485 and FAA regulations is critical to product certification and market access[3].

Strengths: Comprehensive integration of compliance verification within the design workflow reduces iteration cycles and time-to-market. The continuously updated standards database ensures designs meet current regulations. Weaknesses: The system requires significant computational resources for complex simulations, and implementation costs can be prohibitive for smaller organizations. The learning curve for utilizing the full capabilities of the platform can be steep for new users.

Dassault Systèmes SE

Technical Solution: Dassault Systèmes has implemented a holistic approach to ensuring compliance with industry standards through their 3DEXPERIENCE platform, which integrates topology optimization with regulatory verification. Their solution employs a knowledge-based engineering framework that captures industry standards as parametric rules and constraints that actively guide the optimization process. The platform features a Standards Management System that maintains a digital repository of industry regulations from organizations like ISO, ASTM, and industry-specific bodies, which are automatically applied as boundary conditions during topology optimization[5]. Dassault's approach incorporates simulation governance protocols that ensure all optimization runs are traceable and auditable, with complete documentation of compliance verification steps. Their system includes specialized validation workflows for different industries, with particular strength in aerospace, automotive, and medical device sectors where regulatory compliance is critical. The platform employs a collaborative compliance verification process where subject matter experts can review optimization results against standards in real-time, providing feedback that informs subsequent design iterations. Dassault has implemented semantic analysis capabilities that can interpret textual standards and convert them into computational constraints that can be directly applied to topology optimization algorithms[6].

Strengths: The integrated knowledge management system ensures consistent application of standards across all design projects. The collaborative platform enables regulatory experts to participate directly in the optimization process. Weaknesses: The system requires significant initial setup to properly encode industry standards as computational rules. The platform's enterprise focus makes it less accessible to smaller organizations with limited resources.

Key Technical Innovations in Compliance Verification Methods

Performing topology optimization fully with deep learning networks

PatentWO2023027700A1

Innovation

- A novel framework using deep learning neural networks (DNNs) to output density and displacement fields, trained with a loss function that includes design constraints, allowing for simultaneous analysis and design without the need for a finite element mesh, leveraging the capabilities of PINNs to eliminate the requirement for discrete element meshes.

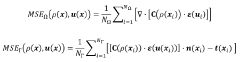

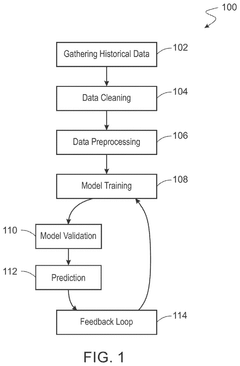

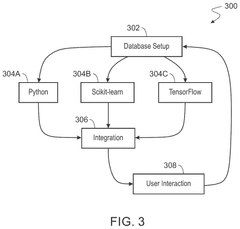

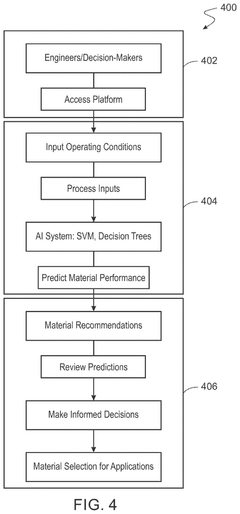

Integrated Artificial Intelligence Based Material Selection for Industrial Assets

PatentPendingUS20250244752A1

Innovation

- An AI-driven method that integrates historical data with industry standards to train machine learning models, predicting material performance and ensuring compliance with safety and durability criteria, using supervised learning techniques like Support Vector Machines and Decision Trees, and incorporating feedback loops for continuous improvement.

Certification Processes for Topology-Optimized Designs

Certification processes for topology-optimized designs represent a critical intersection between innovative engineering methodologies and regulatory compliance frameworks. These processes ensure that components designed using topology optimization algorithms meet the stringent requirements established by industry standards bodies and regulatory authorities. The certification pathway typically begins with a comprehensive documentation of the optimization parameters, constraints, and objectives that guided the design process.

Industry standards such as ISO 10303 (STEP) for product data exchange and ASTM F3301 for additive manufacturing provide foundational frameworks for certification. However, topology-optimized parts present unique challenges due to their complex geometries and non-traditional load paths that may not align with conventional certification approaches developed for traditionally manufactured components.

Verification and validation protocols for topology-optimized designs generally follow a multi-tiered approach. Initial computational validation through finite element analysis (FEA) verifies that the optimized structure meets performance requirements under specified loading conditions. This is followed by physical testing of prototypes manufactured using the same processes intended for production components, ensuring that the as-built parts perform as predicted by simulation.

Material certification represents another critical dimension of the certification process. The mechanical properties of materials can vary significantly based on manufacturing processes, particularly in additive manufacturing where build orientation, thermal history, and post-processing treatments substantially influence material behavior. Certification protocols must account for these variations through standardized material testing procedures specific to the manufacturing method employed.

Non-destructive testing (NDT) methodologies play an essential role in the certification workflow. Techniques such as computed tomography (CT) scanning enable detailed inspection of internal features that might be inaccessible through conventional inspection methods. These advanced NDT approaches are particularly valuable for topology-optimized components where internal lattice structures or complex void patterns may be present.

Documentation requirements for certification typically include design rationale, optimization parameters, simulation results, manufacturing process specifications, and test data. This comprehensive documentation package provides traceability throughout the design-to-manufacture process and serves as evidence of compliance with relevant standards during regulatory reviews.

Industry-specific certification requirements add another layer of complexity. Aerospace applications, for instance, must adhere to standards such as FAA AC 33.70-1 for engine components, while medical devices must satisfy FDA requirements outlined in documents like 21 CFR Part 820. These sector-specific requirements necessitate tailored certification approaches for topology-optimized designs in different application domains.

Industry standards such as ISO 10303 (STEP) for product data exchange and ASTM F3301 for additive manufacturing provide foundational frameworks for certification. However, topology-optimized parts present unique challenges due to their complex geometries and non-traditional load paths that may not align with conventional certification approaches developed for traditionally manufactured components.

Verification and validation protocols for topology-optimized designs generally follow a multi-tiered approach. Initial computational validation through finite element analysis (FEA) verifies that the optimized structure meets performance requirements under specified loading conditions. This is followed by physical testing of prototypes manufactured using the same processes intended for production components, ensuring that the as-built parts perform as predicted by simulation.

Material certification represents another critical dimension of the certification process. The mechanical properties of materials can vary significantly based on manufacturing processes, particularly in additive manufacturing where build orientation, thermal history, and post-processing treatments substantially influence material behavior. Certification protocols must account for these variations through standardized material testing procedures specific to the manufacturing method employed.

Non-destructive testing (NDT) methodologies play an essential role in the certification workflow. Techniques such as computed tomography (CT) scanning enable detailed inspection of internal features that might be inaccessible through conventional inspection methods. These advanced NDT approaches are particularly valuable for topology-optimized components where internal lattice structures or complex void patterns may be present.

Documentation requirements for certification typically include design rationale, optimization parameters, simulation results, manufacturing process specifications, and test data. This comprehensive documentation package provides traceability throughout the design-to-manufacture process and serves as evidence of compliance with relevant standards during regulatory reviews.

Industry-specific certification requirements add another layer of complexity. Aerospace applications, for instance, must adhere to standards such as FAA AC 33.70-1 for engine components, while medical devices must satisfy FDA requirements outlined in documents like 21 CFR Part 820. These sector-specific requirements necessitate tailored certification approaches for topology-optimized designs in different application domains.

Cross-Industry Implementation Case Studies

The aerospace industry has pioneered topology optimization implementation to meet stringent safety and performance standards. Boeing's 787 Dreamliner project utilized topology optimization to redesign structural components, resulting in 20% weight reduction while maintaining compliance with FAA regulations. The optimization algorithms were specifically calibrated to incorporate fatigue life requirements and damage tolerance criteria, demonstrating how compliance can be embedded within the design process itself.

In automotive manufacturing, BMW's implementation of topology optimization for chassis components showcases integration with ISO 26262 functional safety standards. Their approach incorporated safety verification checkpoints throughout the optimization workflow, ensuring that lightweighting objectives never compromised safety requirements. The process included automated verification against material property databases and standardized load cases, creating a compliance-assured design pipeline.

Medical device manufacturers have developed specialized topology optimization frameworks that automatically incorporate FDA regulatory requirements. Stryker's approach to orthopedic implant design uses topology optimization with built-in constraints that ensure biocompatibility standards are met while optimizing mechanical performance. Their workflow includes automated documentation generation that tracks design decisions against regulatory requirements, creating an audit trail that significantly streamlines the approval process.

The construction industry demonstrates how topology optimization can address complex regional building code variations. Arup's implementation for structural components incorporates geographically-specific seismic requirements and building codes directly into the optimization constraints. Their system automatically adjusts optimization parameters based on the project location, ensuring that generated designs inherently comply with local regulations while maximizing material efficiency.

Energy sector applications reveal how topology optimization supports compliance with evolving environmental standards. General Electric's implementation for turbine component design incorporates emissions requirements and efficiency standards as optimization constraints. Their approach demonstrates how topology optimization can be used to proactively address anticipated regulatory changes by exploring design spaces that meet both current and projected future standards.

These cross-industry examples highlight a common pattern: successful compliance-focused topology optimization requires integration of standards directly into the optimization algorithm's constraint definitions, coupled with automated verification systems that validate results against regulatory requirements. The most effective implementations treat compliance not as a post-design verification step but as an inherent aspect of the design space exploration process.

In automotive manufacturing, BMW's implementation of topology optimization for chassis components showcases integration with ISO 26262 functional safety standards. Their approach incorporated safety verification checkpoints throughout the optimization workflow, ensuring that lightweighting objectives never compromised safety requirements. The process included automated verification against material property databases and standardized load cases, creating a compliance-assured design pipeline.

Medical device manufacturers have developed specialized topology optimization frameworks that automatically incorporate FDA regulatory requirements. Stryker's approach to orthopedic implant design uses topology optimization with built-in constraints that ensure biocompatibility standards are met while optimizing mechanical performance. Their workflow includes automated documentation generation that tracks design decisions against regulatory requirements, creating an audit trail that significantly streamlines the approval process.

The construction industry demonstrates how topology optimization can address complex regional building code variations. Arup's implementation for structural components incorporates geographically-specific seismic requirements and building codes directly into the optimization constraints. Their system automatically adjusts optimization parameters based on the project location, ensuring that generated designs inherently comply with local regulations while maximizing material efficiency.

Energy sector applications reveal how topology optimization supports compliance with evolving environmental standards. General Electric's implementation for turbine component design incorporates emissions requirements and efficiency standards as optimization constraints. Their approach demonstrates how topology optimization can be used to proactively address anticipated regulatory changes by exploring design spaces that meet both current and projected future standards.

These cross-industry examples highlight a common pattern: successful compliance-focused topology optimization requires integration of standards directly into the optimization algorithm's constraint definitions, coupled with automated verification systems that validate results against regulatory requirements. The most effective implementations treat compliance not as a post-design verification step but as an inherent aspect of the design space exploration process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!