How to Evaluate Hydrofluoric Acid Safety Metrics in Operations

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HF Acid Safety Background and Objectives

Hydrofluoric acid (HF) represents one of the most hazardous chemicals utilized in industrial operations, with applications spanning semiconductor manufacturing, oil refining, glass etching, and numerous other industrial processes. The unique properties of HF that make it valuable for industrial applications also contribute to its exceptional hazard profile. Unlike other acids, HF penetrates tissues rapidly and causes deep, progressive damage that may not be immediately apparent, creating significant operational safety challenges.

The evolution of HF safety protocols has undergone significant transformation over the past several decades. Initially, safety measures were primarily reactive, developed in response to industrial accidents. However, as understanding of HF's unique hazard profile improved, safety approaches have become increasingly proactive and comprehensive. Modern safety frameworks now incorporate sophisticated risk assessment methodologies, advanced detection systems, specialized medical countermeasures, and rigorous training protocols.

Current technological trends in HF safety focus on real-time monitoring systems, improved personal protective equipment (PPE), automated handling systems to minimize direct human contact, and enhanced emergency response capabilities. The integration of digital technologies, including IoT sensors and artificial intelligence for predictive risk assessment, represents the cutting edge of safety innovation in this field.

The primary objective of evaluating hydrofluoric acid safety metrics in operations is to establish quantifiable parameters that accurately reflect the effectiveness of safety protocols while identifying areas for improvement. These metrics must capture both leading indicators (preventive measures) and lagging indicators (incident outcomes) to provide a comprehensive safety assessment framework.

Specific technical goals include developing standardized measurement methodologies for HF exposure that account for both acute and chronic exposure scenarios, establishing industry benchmarks for safety performance, creating validated risk assessment tools specific to HF operations, and designing integrated safety management systems that incorporate real-time monitoring with automated response protocols.

Additional objectives include quantifying the effectiveness of engineering controls versus administrative controls, evaluating the impact of training methodologies on safety outcomes, and assessing the correlation between near-miss reporting and serious incident prevention. The ultimate aim is to create a data-driven approach to HF safety that enables continuous improvement through systematic measurement and analysis of key safety parameters.

The technical evolution in this field is moving toward predictive safety systems that can anticipate potential failure points before incidents occur, representing a paradigm shift from reactive to preventive safety management in high-hazard chemical operations.

The evolution of HF safety protocols has undergone significant transformation over the past several decades. Initially, safety measures were primarily reactive, developed in response to industrial accidents. However, as understanding of HF's unique hazard profile improved, safety approaches have become increasingly proactive and comprehensive. Modern safety frameworks now incorporate sophisticated risk assessment methodologies, advanced detection systems, specialized medical countermeasures, and rigorous training protocols.

Current technological trends in HF safety focus on real-time monitoring systems, improved personal protective equipment (PPE), automated handling systems to minimize direct human contact, and enhanced emergency response capabilities. The integration of digital technologies, including IoT sensors and artificial intelligence for predictive risk assessment, represents the cutting edge of safety innovation in this field.

The primary objective of evaluating hydrofluoric acid safety metrics in operations is to establish quantifiable parameters that accurately reflect the effectiveness of safety protocols while identifying areas for improvement. These metrics must capture both leading indicators (preventive measures) and lagging indicators (incident outcomes) to provide a comprehensive safety assessment framework.

Specific technical goals include developing standardized measurement methodologies for HF exposure that account for both acute and chronic exposure scenarios, establishing industry benchmarks for safety performance, creating validated risk assessment tools specific to HF operations, and designing integrated safety management systems that incorporate real-time monitoring with automated response protocols.

Additional objectives include quantifying the effectiveness of engineering controls versus administrative controls, evaluating the impact of training methodologies on safety outcomes, and assessing the correlation between near-miss reporting and serious incident prevention. The ultimate aim is to create a data-driven approach to HF safety that enables continuous improvement through systematic measurement and analysis of key safety parameters.

The technical evolution in this field is moving toward predictive safety systems that can anticipate potential failure points before incidents occur, representing a paradigm shift from reactive to preventive safety management in high-hazard chemical operations.

Industrial Demand Analysis for HF Safety Solutions

The global market for hydrofluoric acid (HF) safety solutions has experienced significant growth in recent years, driven by increasing industrial applications and stricter regulatory frameworks. The semiconductor industry represents the largest demand segment, accounting for approximately 60% of the global HF safety solution market, as HF is extensively used in etching and cleaning processes during chip manufacturing. With the semiconductor industry projected to grow at 8-10% annually through 2030, the demand for advanced HF safety metrics and solutions is expected to follow a similar trajectory.

Petrochemical refineries constitute the second-largest market segment, where HF is used as a catalyst in alkylation units. This sector has shown particular interest in real-time monitoring systems and automated emergency response solutions following several high-profile incidents in the past decade. The glass etching and metal processing industries collectively represent about 15% of the market demand, with particular emphasis on personal protective equipment and containment systems.

Geographically, Asia-Pacific dominates the market with approximately 45% share, primarily due to the concentration of semiconductor manufacturing facilities in countries like Taiwan, South Korea, and increasingly China. North America follows with 30% market share, where the focus is predominantly on advanced monitoring technologies and regulatory compliance solutions for the petrochemical sector.

The demand for HF safety solutions is increasingly shifting from reactive to predictive systems. End-users are seeking integrated safety platforms that combine real-time exposure monitoring, automated emergency response, and comprehensive data analytics for risk assessment. This trend is reflected in the 35% year-over-year growth in IoT-enabled HF detection systems observed since 2020.

Industry surveys indicate that 78% of HF-handling facilities consider improving safety metrics and evaluation methodologies as a "high" or "critical" priority in their operational planning. The primary drivers cited include regulatory compliance (42%), risk management and insurance considerations (31%), and corporate social responsibility commitments (18%).

The economic impact of HF incidents has further catalyzed demand for robust safety metrics. The average cost of a significant HF release incident, including direct damages, regulatory penalties, and production downtime, is estimated at $3-7 million per occurrence. This has prompted industries to increase their safety technology budgets by an average of 12% annually over the past five years, with particular emphasis on quantifiable safety metrics that can demonstrate return on investment through incident prevention.

Petrochemical refineries constitute the second-largest market segment, where HF is used as a catalyst in alkylation units. This sector has shown particular interest in real-time monitoring systems and automated emergency response solutions following several high-profile incidents in the past decade. The glass etching and metal processing industries collectively represent about 15% of the market demand, with particular emphasis on personal protective equipment and containment systems.

Geographically, Asia-Pacific dominates the market with approximately 45% share, primarily due to the concentration of semiconductor manufacturing facilities in countries like Taiwan, South Korea, and increasingly China. North America follows with 30% market share, where the focus is predominantly on advanced monitoring technologies and regulatory compliance solutions for the petrochemical sector.

The demand for HF safety solutions is increasingly shifting from reactive to predictive systems. End-users are seeking integrated safety platforms that combine real-time exposure monitoring, automated emergency response, and comprehensive data analytics for risk assessment. This trend is reflected in the 35% year-over-year growth in IoT-enabled HF detection systems observed since 2020.

Industry surveys indicate that 78% of HF-handling facilities consider improving safety metrics and evaluation methodologies as a "high" or "critical" priority in their operational planning. The primary drivers cited include regulatory compliance (42%), risk management and insurance considerations (31%), and corporate social responsibility commitments (18%).

The economic impact of HF incidents has further catalyzed demand for robust safety metrics. The average cost of a significant HF release incident, including direct damages, regulatory penalties, and production downtime, is estimated at $3-7 million per occurrence. This has prompted industries to increase their safety technology budgets by an average of 12% annually over the past five years, with particular emphasis on quantifiable safety metrics that can demonstrate return on investment through incident prevention.

Current Safety Protocols and Technical Challenges

The current safety protocols for hydrofluoric acid (HF) operations are governed by stringent regulatory frameworks established by organizations such as OSHA, EPA, and industry-specific bodies. These protocols typically include comprehensive risk assessment methodologies, detailed emergency response procedures, and specific personal protective equipment (PPE) requirements. Standard operating procedures mandate regular monitoring of exposure levels using specialized detection equipment, with strict adherence to permissible exposure limits (PELs) of 3 ppm as an 8-hour time-weighted average.

Despite these established protocols, significant technical challenges persist in HF safety management. Real-time monitoring technologies often struggle with accuracy at lower concentration levels, creating potential blind spots in safety systems. The highly corrosive nature of HF presents ongoing materials compatibility issues, as containment systems and safety equipment deteriorate over time, sometimes in ways not easily detected through standard inspection procedures.

Another critical challenge lies in the rapid absorption properties of HF, which can penetrate skin and tissue before detection symptoms appear. This delayed response complicates both prevention strategies and emergency treatment protocols. Current medical countermeasures, including calcium gluconate treatments, require specialized training and immediate application to be effective, creating logistical challenges in emergency response scenarios.

The integration of safety metrics across different operational contexts presents additional complexity. Variations in temperature, pressure, and concentration significantly alter risk profiles, yet standardized metrics often fail to adequately account for these dynamic factors. This creates inconsistencies in how safety performance is measured and evaluated across different facilities or even within different units of the same operation.

Engineering control systems face particular challenges with HF due to its unique chemical properties. Ventilation systems must be specifically designed to handle HF vapors, with materials selected to withstand corrosion. However, the effectiveness of these systems can degrade over time in ways that routine maintenance checks might not detect, creating latent safety risks.

Data collection and analysis represent another significant hurdle. While incident reporting systems exist, near-miss events and subtle exposure incidents often go unreported or undetected. This creates gaps in the safety data used to develop and refine metrics, potentially masking emerging risk patterns until more serious incidents occur.

The psychological aspects of working with highly hazardous materials also impact safety protocol effectiveness. Research indicates that familiarity with hazards can lead to normalization of risk and decreased vigilance over time, a phenomenon particularly dangerous with HF given its severe health impacts even at low exposure levels.

Despite these established protocols, significant technical challenges persist in HF safety management. Real-time monitoring technologies often struggle with accuracy at lower concentration levels, creating potential blind spots in safety systems. The highly corrosive nature of HF presents ongoing materials compatibility issues, as containment systems and safety equipment deteriorate over time, sometimes in ways not easily detected through standard inspection procedures.

Another critical challenge lies in the rapid absorption properties of HF, which can penetrate skin and tissue before detection symptoms appear. This delayed response complicates both prevention strategies and emergency treatment protocols. Current medical countermeasures, including calcium gluconate treatments, require specialized training and immediate application to be effective, creating logistical challenges in emergency response scenarios.

The integration of safety metrics across different operational contexts presents additional complexity. Variations in temperature, pressure, and concentration significantly alter risk profiles, yet standardized metrics often fail to adequately account for these dynamic factors. This creates inconsistencies in how safety performance is measured and evaluated across different facilities or even within different units of the same operation.

Engineering control systems face particular challenges with HF due to its unique chemical properties. Ventilation systems must be specifically designed to handle HF vapors, with materials selected to withstand corrosion. However, the effectiveness of these systems can degrade over time in ways that routine maintenance checks might not detect, creating latent safety risks.

Data collection and analysis represent another significant hurdle. While incident reporting systems exist, near-miss events and subtle exposure incidents often go unreported or undetected. This creates gaps in the safety data used to develop and refine metrics, potentially masking emerging risk patterns until more serious incidents occur.

The psychological aspects of working with highly hazardous materials also impact safety protocol effectiveness. Research indicates that familiarity with hazards can lead to normalization of risk and decreased vigilance over time, a phenomenon particularly dangerous with HF given its severe health impacts even at low exposure levels.

Existing HF Safety Evaluation Methodologies

01 Safety monitoring and detection systems for hydrofluoric acid

Various monitoring and detection systems have been developed to ensure safety when handling hydrofluoric acid. These include sensors that can detect leaks or dangerous concentration levels of hydrofluoric acid in the air, automated alarm systems that trigger when safety thresholds are exceeded, and continuous monitoring equipment that provides real-time data on acid levels and environmental conditions. These systems help prevent accidents by providing early warnings and enabling prompt response to potential hazards.- Personal protective equipment and handling protocols: Proper personal protective equipment (PPE) and handling protocols are essential for hydrofluoric acid safety. This includes specialized acid-resistant gloves, face shields, chemical splash goggles, and full-body protection. Strict protocols for handling, storage, and transfer of hydrofluoric acid must be implemented to prevent exposure. Emergency response procedures should be established and regularly practiced to ensure quick action in case of accidental exposure.

- Detection and monitoring systems: Advanced detection and monitoring systems are crucial for maintaining safety in environments where hydrofluoric acid is used. These systems include real-time concentration monitors, leak detection equipment, and automated alarm systems that alert personnel to dangerous levels of exposure. Continuous monitoring helps prevent accidents by identifying potential hazards before they become critical, allowing for immediate corrective action.

- Neutralization and treatment methods: Effective neutralization and treatment methods are vital components of hydrofluoric acid safety protocols. These include calcium-based neutralizing agents such as calcium gluconate for skin exposure and specialized absorbents for spills. Treatment facilities should be equipped with emergency showers, eyewash stations, and first-aid supplies specifically designed for hydrofluoric acid exposure. Proper waste disposal methods are also essential to prevent environmental contamination.

- Facility design and engineering controls: Specialized facility design and engineering controls are necessary for safe handling of hydrofluoric acid. This includes corrosion-resistant materials for storage containers and transfer systems, proper ventilation systems with scrubbers to remove acid vapors, secondary containment structures to prevent spills from spreading, and segregated storage areas away from incompatible chemicals. Automated dispensing systems can minimize direct handling and reduce exposure risks.

- Training and certification requirements: Comprehensive training and certification requirements are essential for personnel working with hydrofluoric acid. This includes education on chemical properties, hazards, proper handling techniques, emergency response procedures, and first aid for exposure. Regular refresher courses and competency assessments ensure that knowledge remains current. Documentation of training and certification should be maintained, and only properly trained personnel should be authorized to handle hydrofluoric acid.

02 Personal protective equipment and emergency response protocols

Specialized personal protective equipment (PPE) is essential when working with hydrofluoric acid, including acid-resistant gloves, face shields, and full-body protection. Emergency response protocols involve specific first aid procedures for hydrofluoric acid exposure, such as calcium gluconate application for neutralizing the acid's effects on tissue. Training programs ensure workers can quickly implement these protocols, and emergency shower and eyewash stations must be readily accessible in areas where hydrofluoric acid is used.Expand Specific Solutions03 Storage and handling safety measures for hydrofluoric acid

Proper storage and handling of hydrofluoric acid requires specialized containers made of compatible materials that resist corrosion, such as certain plastics or specially treated metals. Safety measures include secondary containment systems to prevent spills from spreading, proper labeling and segregation from incompatible chemicals, ventilation systems to remove acid vapors, and temperature-controlled storage to prevent degradation. Standard operating procedures for transfer operations minimize exposure risks and establish clear guidelines for safe handling.Expand Specific Solutions04 Neutralization and waste treatment methods

Safe disposal of hydrofluoric acid requires specific neutralization techniques using appropriate bases like calcium hydroxide or sodium carbonate. Waste treatment methods include precipitation of fluoride ions as insoluble salts, ion exchange processes to remove fluoride from wastewater, and specialized treatment facilities designed to handle hydrofluoric acid waste. Monitoring of effluent pH and fluoride concentration ensures compliance with environmental regulations and prevents ecological damage from improper disposal.Expand Specific Solutions05 Risk assessment and safety management systems

Comprehensive risk assessment methodologies have been developed specifically for hydrofluoric acid handling, including hazard identification techniques, exposure modeling, and consequence analysis. Safety management systems incorporate regular audits, incident investigation protocols, and continuous improvement processes. Quantitative risk metrics track near-misses, exposure incidents, and process deviations to identify trends and implement preventive measures. These systems often include digital tracking tools that document compliance with safety standards and regulations.Expand Specific Solutions

Leading Organizations in HF Safety Management

The hydrofluoric acid safety metrics evaluation landscape is currently in a mature development phase, with established protocols across various industries. The global market for HF safety solutions is estimated at $2.5 billion, growing at 5-7% annually as regulatory requirements tighten worldwide. Leading players include Do-Fluoride New Materials Co., which specializes in inorganic fluorides production with advanced safety protocols, and Siemens AG, offering comprehensive industrial safety automation systems. MKS Inc. provides specialized monitoring equipment, while China Petroleum & Chemical Corp. has developed proprietary safety evaluation frameworks for large-scale operations. Academic institutions like Changzhou University and Beijing Institute of Technology contribute significant research on safety innovations, collaborating with industry leaders to establish standardized metrics that balance operational efficiency with stringent safety requirements.

Do-Fluoride New Materials Co., Ltd.

Technical Solution: Do-Fluoride New Materials has developed a comprehensive Hydrofluoric Acid Safety Management System (HASMS) that integrates real-time monitoring with predictive analytics. Their approach employs a multi-layered safety protocol featuring automated detection systems with specialized HF-resistant sensors placed strategically throughout production facilities. These sensors can detect HF concentrations as low as 0.5 ppm, well below dangerous thresholds. The company implements a proprietary "Safety Envelope" methodology that establishes operational parameters with built-in safety margins, continuously monitored by AI algorithms that can predict potential safety incidents before they occur. Their system includes automated emergency response protocols that activate neutralization systems and personal protective measures when anomalies are detected. Do-Fluoride also employs specialized training programs using virtual reality simulations to prepare workers for emergency scenarios, with performance metrics tracked to ensure competency.

Strengths: Industry-leading early detection capabilities with specialized sensors designed specifically for HF environments; integrated AI-driven predictive analytics that can forecast potential incidents before they occur. Weaknesses: System requires significant initial investment and specialized maintenance personnel; heavy reliance on technology creates vulnerability to system failures or power outages.

Siemens AG

Technical Solution: Siemens AG has developed the SafetyGuard HF monitoring and management platform, an integrated solution for hydrofluoric acid safety in industrial settings. Their system employs a distributed architecture with edge computing capabilities that process sensor data locally before transmission to central systems, reducing response latency to under 200 milliseconds. The platform incorporates multi-modal sensing technology including electrochemical sensors, optical detection systems, and thermal imaging to provide redundant monitoring capabilities. Siemens' approach emphasizes predictive maintenance of safety systems, using machine learning algorithms to identify potential sensor drift or system degradation before failures occur. Their Digital Twin technology creates virtual models of HF-handling facilities, enabling scenario testing and safety procedure optimization without operational disruption. The platform includes a Safety Performance Indicator (SPI) dashboard that aggregates multiple metrics including near-miss incidents, exposure events, and system response times to provide a comprehensive view of safety performance trends. Siemens also offers integration with their broader industrial automation systems, enabling safety protocols to be directly linked to process controls.

Strengths: Exceptional system integration capabilities with existing industrial control systems; advanced predictive maintenance features reduce system failures; sophisticated Digital Twin technology enables scenario planning and training. Weaknesses: Significant reliance on digital infrastructure creates cybersecurity concerns; system complexity requires specialized technical support; higher initial implementation costs compared to simpler monitoring solutions.

Critical Safety Metrics and Monitoring Technologies

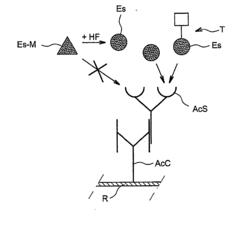

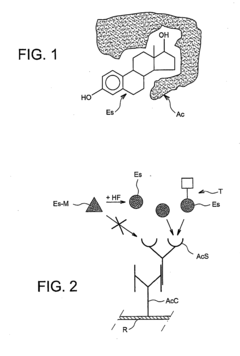

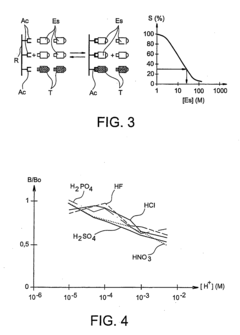

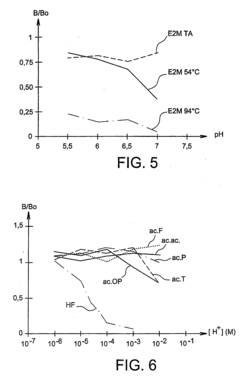

Method for the detection of fluoride or hydrogen fluoride and detection kit

PatentInactiveUS20050227368A1

Innovation

- A method involving a silylated organic compound that undergoes desilylation in the presence of HF, allowing for separate detection of the silylated and desilylated forms, using reagents like BTSFA and MTBSTFA, and employing immunological tests for enhanced sensitivity and specificity.

Method for risk evaluation to ensure safety of a product available to the human body

PatentWO2003107247A1

Innovation

- A risk assessment method that identifies specific risk classes, risk factors, and indicators, standardizes taxonomic information, and prescribes measures to ensure product safety by classifying hazards, determining preventive and subsequent measures, and addressing interdependencies between indicators to eliminate or mitigate risks.

Regulatory Compliance Framework for HF Operations

The regulatory landscape for hydrofluoric acid (HF) operations is complex and multifaceted, requiring organizations to navigate a web of international, national, and local regulations. At the international level, frameworks such as the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provide standardized approaches to chemical hazard communication. Organizations like the International Labour Organization (ILO) have established conventions that address occupational safety standards applicable to HF handling.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards under 29 CFR 1910.1200 (Hazard Communication) and 29 CFR 1910.119 (Process Safety Management) that directly impact HF operations. The Environmental Protection Agency (EPA) regulates HF under the Risk Management Program (40 CFR Part 68) and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), with reportable quantities established for accidental releases.

European regulations are governed by REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and the Seveso III Directive, which impose strict requirements for hazard assessment, documentation, and emergency planning for facilities handling dangerous substances like HF. These frameworks emphasize prevention of major accidents and limitation of their consequences.

Industry-specific standards complement regulatory requirements, with organizations such as the American Petroleum Institute (API) and the American Chemistry Council providing detailed guidelines for HF handling in refineries and chemical manufacturing facilities. These standards often exceed minimum regulatory requirements and represent industry best practices.

Compliance verification mechanisms typically include regular audits, inspections, and documentation reviews. Regulatory agencies may conduct unannounced inspections, while third-party certification bodies offer independent verification of compliance. Many organizations implement internal audit programs to proactively identify and address compliance gaps.

Penalties for non-compliance can be severe, ranging from substantial fines to facility shutdowns and criminal prosecution in cases of willful violations or incidents resulting in serious injury or death. The financial implications extend beyond direct penalties to include potential civil liability, increased insurance premiums, and reputational damage.

Effective compliance management requires integrated systems that track regulatory changes, manage documentation, schedule compliance activities, and provide real-time monitoring of safety metrics. Leading organizations are increasingly adopting digital solutions that automate compliance processes and provide analytics capabilities to identify trends and potential issues before they result in regulatory violations.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards under 29 CFR 1910.1200 (Hazard Communication) and 29 CFR 1910.119 (Process Safety Management) that directly impact HF operations. The Environmental Protection Agency (EPA) regulates HF under the Risk Management Program (40 CFR Part 68) and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), with reportable quantities established for accidental releases.

European regulations are governed by REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and the Seveso III Directive, which impose strict requirements for hazard assessment, documentation, and emergency planning for facilities handling dangerous substances like HF. These frameworks emphasize prevention of major accidents and limitation of their consequences.

Industry-specific standards complement regulatory requirements, with organizations such as the American Petroleum Institute (API) and the American Chemistry Council providing detailed guidelines for HF handling in refineries and chemical manufacturing facilities. These standards often exceed minimum regulatory requirements and represent industry best practices.

Compliance verification mechanisms typically include regular audits, inspections, and documentation reviews. Regulatory agencies may conduct unannounced inspections, while third-party certification bodies offer independent verification of compliance. Many organizations implement internal audit programs to proactively identify and address compliance gaps.

Penalties for non-compliance can be severe, ranging from substantial fines to facility shutdowns and criminal prosecution in cases of willful violations or incidents resulting in serious injury or death. The financial implications extend beyond direct penalties to include potential civil liability, increased insurance premiums, and reputational damage.

Effective compliance management requires integrated systems that track regulatory changes, manage documentation, schedule compliance activities, and provide real-time monitoring of safety metrics. Leading organizations are increasingly adopting digital solutions that automate compliance processes and provide analytics capabilities to identify trends and potential issues before they result in regulatory violations.

Emergency Response and Mitigation Strategies

Effective emergency response and mitigation strategies are critical components of any comprehensive hydrofluoric acid (HF) safety management system. Organizations handling HF must develop detailed emergency response plans that address the unique hazards associated with this highly corrosive and toxic substance. These plans should include clear protocols for immediate actions following an HF release, including evacuation procedures, decontamination methods, and medical treatment guidelines specific to HF exposure.

First responders must be equipped with specialized personal protective equipment (PPE) designed specifically for HF incidents, including chemical-resistant suits, respiratory protection, and appropriate gloves. Regular training exercises and simulations are essential to ensure that emergency response teams can execute protocols efficiently under pressure. These drills should incorporate realistic scenarios based on facility-specific risk assessments and potential failure modes.

Mitigation strategies should focus on both prevention and consequence reduction. Engineering controls such as secondary containment systems, automated leak detection, and emergency shutdown systems represent the first line of defense. These technical measures should be complemented by administrative controls including strict operating procedures, permit-to-work systems, and regular safety audits focused specifically on HF-related processes.

Calcium gluconate, the primary antidote for HF exposure, must be readily available in sufficient quantities at strategic locations throughout facilities where HF is present. Medical response protocols should be developed in consultation with specialists experienced in treating HF injuries, and coordination with local emergency medical services and hospitals should be established before incidents occur.

Communication systems play a vital role in emergency response effectiveness. Reliable alarm systems, clear communication channels, and predetermined notification procedures ensure that all personnel receive timely information during an incident. External communication protocols with regulatory authorities, community emergency services, and neighboring facilities should also be established to facilitate coordinated responses to major incidents.

Post-incident analysis represents a critical component of continuous improvement in emergency response capabilities. Each incident or near-miss involving HF should undergo thorough investigation to identify root causes and opportunities for enhancing response procedures. Lessons learned should be incorporated into revised emergency plans and shared across the organization to prevent similar occurrences.

Industry collaboration through sharing of best practices and lessons learned from incidents can significantly enhance overall safety performance. Participation in industry forums, technical working groups, and regulatory consultations provides valuable opportunities to remain current with evolving emergency response techniques and technologies specific to HF handling.

First responders must be equipped with specialized personal protective equipment (PPE) designed specifically for HF incidents, including chemical-resistant suits, respiratory protection, and appropriate gloves. Regular training exercises and simulations are essential to ensure that emergency response teams can execute protocols efficiently under pressure. These drills should incorporate realistic scenarios based on facility-specific risk assessments and potential failure modes.

Mitigation strategies should focus on both prevention and consequence reduction. Engineering controls such as secondary containment systems, automated leak detection, and emergency shutdown systems represent the first line of defense. These technical measures should be complemented by administrative controls including strict operating procedures, permit-to-work systems, and regular safety audits focused specifically on HF-related processes.

Calcium gluconate, the primary antidote for HF exposure, must be readily available in sufficient quantities at strategic locations throughout facilities where HF is present. Medical response protocols should be developed in consultation with specialists experienced in treating HF injuries, and coordination with local emergency medical services and hospitals should be established before incidents occur.

Communication systems play a vital role in emergency response effectiveness. Reliable alarm systems, clear communication channels, and predetermined notification procedures ensure that all personnel receive timely information during an incident. External communication protocols with regulatory authorities, community emergency services, and neighboring facilities should also be established to facilitate coordinated responses to major incidents.

Post-incident analysis represents a critical component of continuous improvement in emergency response capabilities. Each incident or near-miss involving HF should undergo thorough investigation to identify root causes and opportunities for enhancing response procedures. Lessons learned should be incorporated into revised emergency plans and shared across the organization to prevent similar occurrences.

Industry collaboration through sharing of best practices and lessons learned from incidents can significantly enhance overall safety performance. Participation in industry forums, technical working groups, and regulatory consultations provides valuable opportunities to remain current with evolving emergency response techniques and technologies specific to HF handling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!