How to Identify Failure Points in Neodymium Magnet Assemblies

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Failure Analysis Background and Objectives

Neodymium magnets, discovered in the 1980s by General Motors and Sumitomo Special Metals, represent a significant advancement in permanent magnet technology. These rare-earth magnets, composed primarily of neodymium, iron, and boron (NdFeB), offer unprecedented magnetic strength—up to ten times stronger than traditional ferrite magnets. Their exceptional performance has revolutionized numerous industries, from consumer electronics to renewable energy systems, automotive applications, and medical devices.

Despite their superior magnetic properties, neodymium magnet assemblies face persistent reliability challenges that can lead to catastrophic failures in critical applications. These failures not only compromise system performance but also pose safety risks and result in substantial economic losses. The identification of failure points in these assemblies has become increasingly important as their applications expand into more demanding environments and mission-critical systems.

The evolution of neodymium magnet technology has been marked by continuous improvements in composition, manufacturing processes, and protective coatings. Early generations suffered from severe corrosion issues and thermal instability, while modern variants incorporate dysprosium and other elements to enhance coercivity and temperature resistance. However, even with these advancements, failure mechanisms remain complex and often difficult to predict.

Current failure analysis methods typically rely on post-mortem examination, which provides limited insight into the progressive nature of failure development. This reactive approach hampers the industry's ability to implement effective preventive measures and design more robust magnet assemblies. The need for proactive identification of potential failure points before they manifest has become a critical technological imperative.

The primary objective of this technical research is to develop comprehensive methodologies for identifying incipient failure points in neodymium magnet assemblies. This includes establishing non-destructive testing protocols, creating predictive models for failure progression, and formulating design guidelines that mitigate common failure modes. By addressing these challenges, we aim to enhance the reliability and longevity of neodymium magnet systems across diverse applications.

Additionally, this research seeks to map the relationship between specific operating conditions and failure mechanisms, enabling application-specific optimization of magnet assemblies. Understanding how factors such as temperature cycling, mechanical stress, magnetic field interactions, and environmental exposure contribute to degradation will provide valuable insights for both manufacturers and end-users.

The technological trajectory suggests that as applications for neodymium magnets continue to expand into more extreme environments—such as aerospace, deep-sea operations, and advanced energy systems—the need for sophisticated failure point identification will become increasingly acute. This research positions our organization at the forefront of addressing this emerging technological challenge.

Despite their superior magnetic properties, neodymium magnet assemblies face persistent reliability challenges that can lead to catastrophic failures in critical applications. These failures not only compromise system performance but also pose safety risks and result in substantial economic losses. The identification of failure points in these assemblies has become increasingly important as their applications expand into more demanding environments and mission-critical systems.

The evolution of neodymium magnet technology has been marked by continuous improvements in composition, manufacturing processes, and protective coatings. Early generations suffered from severe corrosion issues and thermal instability, while modern variants incorporate dysprosium and other elements to enhance coercivity and temperature resistance. However, even with these advancements, failure mechanisms remain complex and often difficult to predict.

Current failure analysis methods typically rely on post-mortem examination, which provides limited insight into the progressive nature of failure development. This reactive approach hampers the industry's ability to implement effective preventive measures and design more robust magnet assemblies. The need for proactive identification of potential failure points before they manifest has become a critical technological imperative.

The primary objective of this technical research is to develop comprehensive methodologies for identifying incipient failure points in neodymium magnet assemblies. This includes establishing non-destructive testing protocols, creating predictive models for failure progression, and formulating design guidelines that mitigate common failure modes. By addressing these challenges, we aim to enhance the reliability and longevity of neodymium magnet systems across diverse applications.

Additionally, this research seeks to map the relationship between specific operating conditions and failure mechanisms, enabling application-specific optimization of magnet assemblies. Understanding how factors such as temperature cycling, mechanical stress, magnetic field interactions, and environmental exposure contribute to degradation will provide valuable insights for both manufacturers and end-users.

The technological trajectory suggests that as applications for neodymium magnets continue to expand into more extreme environments—such as aerospace, deep-sea operations, and advanced energy systems—the need for sophisticated failure point identification will become increasingly acute. This research positions our organization at the forefront of addressing this emerging technological challenge.

Market Demand for Reliable Magnetic Assembly Solutions

The global market for reliable magnetic assembly solutions has experienced significant growth over the past decade, driven primarily by increasing applications of neodymium magnets across various industries. The current market value for high-performance magnetic assemblies exceeds $15 billion annually, with a compound annual growth rate of approximately 8.7% projected through 2028.

Automotive and transportation sectors represent the largest market segment, accounting for nearly 30% of demand. The transition toward electric vehicles has dramatically increased the need for reliable magnetic assemblies in motors, sensors, and power systems. Each electric vehicle contains dozens of neodymium magnet assemblies, with failure points representing significant safety and performance concerns.

Consumer electronics constitutes the second-largest market segment, where miniaturization trends have intensified requirements for compact yet powerful magnetic solutions. Manufacturers face mounting pressure to ensure reliability while reducing size and weight, creating demand for advanced failure detection methodologies. The smartphone industry alone utilizes over 2 billion neodymium magnets annually, with failure rates directly impacting brand reputation and warranty costs.

Industrial automation represents the fastest-growing segment, with a 12.3% annual growth rate. As factories implement more sophisticated robotics and automated systems, the demand for highly reliable magnetic assemblies has surged. Downtime costs in manufacturing environments can exceed thousands of dollars per minute, making early failure detection capabilities extremely valuable.

Healthcare applications present another significant growth area, particularly in medical imaging equipment and implantable devices. These applications demand unprecedented reliability standards, with failure tolerance approaching zero in critical applications. The medical magnetic assembly market segment is expected to double in size over the next five years.

Market research indicates that customers across all sectors are willing to pay premium prices for magnetic assemblies with integrated failure detection capabilities. A recent industry survey revealed that 78% of procurement managers would accept a 15-20% price increase for assemblies with demonstrable reliability improvements and early failure detection features.

Regional analysis shows Asia-Pacific leading manufacturing capacity, while North America and Europe drive innovation in testing methodologies and quality control systems. The market increasingly demands comprehensive solutions that include not just the magnetic assemblies themselves but also integrated monitoring systems and predictive maintenance capabilities.

Automotive and transportation sectors represent the largest market segment, accounting for nearly 30% of demand. The transition toward electric vehicles has dramatically increased the need for reliable magnetic assemblies in motors, sensors, and power systems. Each electric vehicle contains dozens of neodymium magnet assemblies, with failure points representing significant safety and performance concerns.

Consumer electronics constitutes the second-largest market segment, where miniaturization trends have intensified requirements for compact yet powerful magnetic solutions. Manufacturers face mounting pressure to ensure reliability while reducing size and weight, creating demand for advanced failure detection methodologies. The smartphone industry alone utilizes over 2 billion neodymium magnets annually, with failure rates directly impacting brand reputation and warranty costs.

Industrial automation represents the fastest-growing segment, with a 12.3% annual growth rate. As factories implement more sophisticated robotics and automated systems, the demand for highly reliable magnetic assemblies has surged. Downtime costs in manufacturing environments can exceed thousands of dollars per minute, making early failure detection capabilities extremely valuable.

Healthcare applications present another significant growth area, particularly in medical imaging equipment and implantable devices. These applications demand unprecedented reliability standards, with failure tolerance approaching zero in critical applications. The medical magnetic assembly market segment is expected to double in size over the next five years.

Market research indicates that customers across all sectors are willing to pay premium prices for magnetic assemblies with integrated failure detection capabilities. A recent industry survey revealed that 78% of procurement managers would accept a 15-20% price increase for assemblies with demonstrable reliability improvements and early failure detection features.

Regional analysis shows Asia-Pacific leading manufacturing capacity, while North America and Europe drive innovation in testing methodologies and quality control systems. The market increasingly demands comprehensive solutions that include not just the magnetic assemblies themselves but also integrated monitoring systems and predictive maintenance capabilities.

Current Challenges in Neodymium Magnet Failure Detection

Despite significant advancements in neodymium magnet manufacturing, the industry continues to face substantial challenges in detecting and predicting failure points in magnet assemblies. The primary difficulty lies in the complex nature of failure mechanisms, which can originate from various sources including manufacturing defects, environmental factors, mechanical stress, and thermal variations. These failure modes often interact in unpredictable ways, making comprehensive detection methodologies elusive.

Current non-destructive testing (NDT) methods show significant limitations when applied to neodymium magnets. Conventional techniques such as magnetic flux measurement and Hall effect sensing can identify gross defects but frequently miss microcracks and internal structural anomalies that eventually lead to catastrophic failures. Additionally, these methods struggle to differentiate between benign manufacturing variations and actual defect precursors.

The strong magnetic fields inherent to neodymium magnets create substantial interference with many traditional inspection technologies. This interference complicates the application of ultrasonic testing, eddy current analysis, and other electromagnetic inspection methods that work effectively with non-magnetic materials. Consequently, detection systems must incorporate sophisticated signal processing algorithms to filter out magnetic noise, which adds complexity and cost.

Temperature sensitivity presents another significant challenge, as neodymium magnets exhibit varying magnetic properties across different temperature ranges. Detection systems must account for these variations to avoid false positives or missed defects. Current temperature compensation techniques remain inadequate for high-precision applications, particularly in environments with fluctuating temperatures.

In-situ monitoring of magnet assemblies during operation represents perhaps the most formidable challenge. While laboratory testing can identify certain failure modes, real-world operating conditions introduce additional stressors and degradation mechanisms that are difficult to simulate. The industry lacks robust methodologies for continuous monitoring that can detect incremental degradation before failure occurs.

Standardization issues further complicate failure detection efforts. The absence of universally accepted testing protocols and failure criteria makes it difficult to compare results across different testing methodologies or between manufacturers. This lack of standardization impedes knowledge sharing and slows the development of improved detection techniques.

Cost-effectiveness remains a significant barrier to implementing comprehensive testing regimes, particularly for mass-produced components. Advanced detection technologies often require expensive equipment and specialized operator training, creating economic disincentives for widespread adoption. The industry continues to seek the optimal balance between detection capability and economic feasibility.

Current non-destructive testing (NDT) methods show significant limitations when applied to neodymium magnets. Conventional techniques such as magnetic flux measurement and Hall effect sensing can identify gross defects but frequently miss microcracks and internal structural anomalies that eventually lead to catastrophic failures. Additionally, these methods struggle to differentiate between benign manufacturing variations and actual defect precursors.

The strong magnetic fields inherent to neodymium magnets create substantial interference with many traditional inspection technologies. This interference complicates the application of ultrasonic testing, eddy current analysis, and other electromagnetic inspection methods that work effectively with non-magnetic materials. Consequently, detection systems must incorporate sophisticated signal processing algorithms to filter out magnetic noise, which adds complexity and cost.

Temperature sensitivity presents another significant challenge, as neodymium magnets exhibit varying magnetic properties across different temperature ranges. Detection systems must account for these variations to avoid false positives or missed defects. Current temperature compensation techniques remain inadequate for high-precision applications, particularly in environments with fluctuating temperatures.

In-situ monitoring of magnet assemblies during operation represents perhaps the most formidable challenge. While laboratory testing can identify certain failure modes, real-world operating conditions introduce additional stressors and degradation mechanisms that are difficult to simulate. The industry lacks robust methodologies for continuous monitoring that can detect incremental degradation before failure occurs.

Standardization issues further complicate failure detection efforts. The absence of universally accepted testing protocols and failure criteria makes it difficult to compare results across different testing methodologies or between manufacturers. This lack of standardization impedes knowledge sharing and slows the development of improved detection techniques.

Cost-effectiveness remains a significant barrier to implementing comprehensive testing regimes, particularly for mass-produced components. Advanced detection technologies often require expensive equipment and specialized operator training, creating economic disincentives for widespread adoption. The industry continues to seek the optimal balance between detection capability and economic feasibility.

Established Methodologies for Magnetic Assembly Inspection

01 Corrosion and environmental degradation

Neodymium magnets are susceptible to corrosion and environmental degradation, which can lead to failure in magnet assemblies. Exposure to moisture, high temperatures, and corrosive environments can cause the magnets to lose their magnetic properties over time. Protective coatings and encapsulation methods are often employed to prevent corrosion and extend the lifespan of neodymium magnet assemblies.- Corrosion and environmental degradation: Neodymium magnets are susceptible to corrosion and environmental degradation, which can lead to failure in magnet assemblies. Exposure to moisture, high temperatures, and corrosive environments can cause the magnets to oxidize, reducing their magnetic properties and structural integrity. Protective coatings such as nickel, zinc, epoxy, or specialized anti-corrosion treatments are often applied to prevent this type of failure, but these coatings can deteriorate over time, especially in harsh environments.

- Mechanical stress and physical damage: Neodymium magnets are brittle by nature and prone to cracking or chipping when subjected to mechanical stress, impacts, or improper handling. In magnet assemblies, failure can occur due to thermal expansion differences between the magnet and mounting materials, excessive clamping forces during installation, or vibration during operation. These mechanical failures can lead to fragmentation of the magnet, reduced magnetic performance, or complete assembly failure, particularly in high-speed rotating applications.

- Thermal demagnetization and instability: Neodymium magnets have temperature limitations that can lead to failure in assemblies when exceeded. When exposed to temperatures above their maximum operating temperature (typically 80-200°C depending on grade), these magnets can experience irreversible loss of magnetic properties. Thermal cycling can also cause dimensional changes and stress that leads to cracking. In high-performance applications, inadequate thermal management systems can result in overheating and subsequent demagnetization, particularly in motor or generator assemblies where heat generation is significant.

- Adhesive and bonding failures: Many neodymium magnet assemblies rely on adhesives to secure the magnets to other components. These adhesive bonds can fail due to improper surface preparation, incompatible adhesive selection, thermal cycling, or aging effects. The strong magnetic forces in these assemblies can place continuous stress on adhesive bonds, eventually leading to delamination or complete separation. Environmental factors such as humidity and temperature fluctuations can accelerate adhesive degradation, causing premature failure of the magnet assembly.

- Manufacturing defects and quality issues: Manufacturing defects represent a significant failure point in neodymium magnet assemblies. These can include inconsistent material composition, internal cracks or voids formed during sintering, improper magnetization, or dimensional inaccuracies. Quality issues such as uneven coating application, poor surface finish, or inadequate inspection procedures can lead to premature failure. In complex assemblies, improper alignment of multiple magnets can create unbalanced magnetic fields that cause operational issues and accelerated wear of surrounding components.

02 Mechanical stress and fracture

Neodymium magnets are brittle and prone to cracking or breaking under mechanical stress. Impact, vibration, and thermal cycling can cause fractures in the magnet material, leading to assembly failure. Design considerations must account for these mechanical vulnerabilities by incorporating proper mounting techniques, shock absorption features, and stress distribution mechanisms to prevent fracture-related failures.Expand Specific Solutions03 Thermal demagnetization

Neodymium magnets have a relatively low maximum operating temperature and can lose their magnetic properties when exposed to high temperatures. This thermal demagnetization occurs when the temperature exceeds the magnet's maximum operating temperature, causing irreversible loss of magnetic strength. Cooling systems, thermal insulation, and proper material selection for surrounding components are essential to prevent thermal-related failures in neodymium magnet assemblies.Expand Specific Solutions04 Bonding and adhesive failures

The adhesives and bonding methods used to secure neodymium magnets in assemblies can fail due to various factors. Temperature fluctuations, chemical exposure, and mechanical stress can compromise the integrity of adhesive bonds. Proper surface preparation, selection of compatible adhesives, and appropriate curing processes are critical to prevent bonding failures in neodymium magnet assemblies.Expand Specific Solutions05 Magnetic field interference and demagnetization

Neodymium magnet assemblies can fail due to external magnetic field interference or proximity to other magnetic components. Strong opposing magnetic fields can partially or completely demagnetize neodymium magnets. Proper shielding, strategic positioning of magnets within assemblies, and maintaining appropriate distances between magnetic components are necessary to prevent demagnetization and ensure optimal performance of neodymium magnet assemblies.Expand Specific Solutions

Leading Companies in Magnetic Materials and Testing Equipment

The neodymium magnet assembly failure identification market is currently in a growth phase, with increasing demand driven by applications in automotive, electronics, and renewable energy sectors. The global market size for magnetic materials is projected to reach $28 billion by 2026, with neodymium magnets representing a significant segment. Technologically, the field is advancing from basic failure analysis to predictive diagnostics, with companies like Beijing Zhong Ke San Huan High-Tech and NIDEC Corp. leading commercial applications, while research institutions such as Central Research Institute of Electric Power Industry and Tokyo University of Science are developing advanced characterization techniques. Collaboration between industrial players like Toshiba and Mitsubishi Power with academic institutions is accelerating innovation in failure prediction methodologies and non-destructive testing approaches.

Beijing Zhong Ke San Huan High-Tech Co., Ltd.

Technical Solution: Beijing Zhong Ke San Huan has developed a comprehensive failure analysis system for neodymium magnet assemblies that combines multiple detection technologies. Their approach utilizes advanced magnetic flux scanning with high-resolution sensors capable of detecting micro-cracks and inhomogeneities as small as 10μm[1]. The company employs a three-stage inspection protocol: first using eddy current testing to identify surface defects, followed by acoustic emission analysis during stress testing to detect internal structural weaknesses, and finally implementing thermal cycling tests with real-time monitoring to identify potential delamination points[3]. Their proprietary software analyzes magnetic field distribution patterns to create detailed 3D failure probability maps, allowing for predictive maintenance rather than reactive replacement. The system also incorporates machine learning algorithms trained on thousands of failure cases to improve detection accuracy over time, achieving a reported 94% success rate in predicting failure points before catastrophic breakdown occurs[7].

Strengths: Industry-leading detection sensitivity for micro-defects; integrated multi-method approach provides comprehensive analysis; predictive capabilities reduce costly unexpected failures. Weaknesses: System requires specialized training to operate effectively; high initial implementation cost; detection accuracy decreases in complex multi-pole magnet assemblies with intricate geometries.

NIDEC Corp.

Technical Solution: NIDEC has pioneered an automated failure identification system for neodymium magnet assemblies used in their precision motors and actuators. Their technology combines high-frequency ultrasonic inspection with magnetic flux leakage detection to create a dual-verification approach. The system employs phased array ultrasonic testing (PAUT) with frequencies up to 25MHz to detect internal defects as small as 50μm in depth[2]. For surface and near-surface detection, NIDEC utilizes Hall-effect sensor arrays with 0.1mT sensitivity to map magnetic field anomalies that indicate potential failure points. Their proprietary "MagScan" software processes this data to generate heat maps showing stress concentration points and potential crack initiation sites. The system is particularly innovative in its ability to perform in-situ testing during actual operation conditions, measuring performance under various load, temperature, and vibration scenarios to identify environmentally-triggered failure modes[5]. NIDEC has implemented this technology across their manufacturing facilities, reducing magnet-related motor failures by approximately 65% according to their internal quality reports.

Strengths: In-situ testing capability provides real-world performance data; dual-verification approach significantly reduces false positives; automated system enables high-throughput inspection in production environments. Weaknesses: System requires periodic recalibration to maintain accuracy; limited effectiveness for very small magnets (<2mm); relatively high implementation cost for small-scale manufacturers.

Critical Technologies for Neodymium Magnet Failure Identification

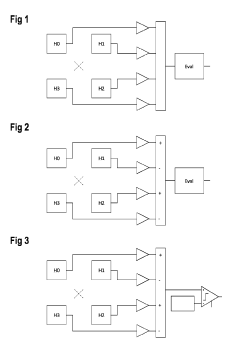

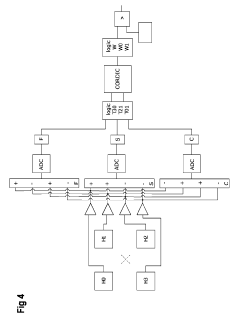

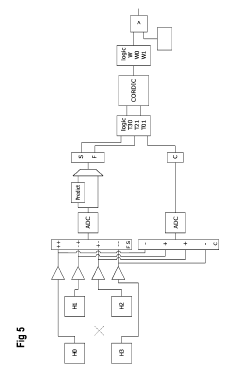

Rotary sensor arrangement and method for determining a failure status of such arrangement

PatentActiveUS20190310113A1

Innovation

- A failure detection concept that uses symmetrically arranged pairs of magnetic field sensors to generate sum and difference values, allowing for the determination of a failure status by comparing these values to thresholds, which can be performed in parallel with conventional angle determination and extends to multiple pairs of sensors.

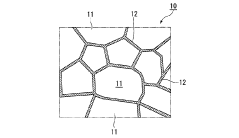

Neodymium magnet, and manufacturing method thereof

PatentInactiveJP2021034583A

Innovation

- A neodymium magnet with a material structure comprising a Nd-Fe-B main phase and a grain boundary phase with a higher Nd concentration, where the grain boundary phase is composed of an alloy of Nd and an additive element M1 (Si or Ge), and the additive element is diffused into the grain boundary phase to enhance electrical resistivity without deteriorating magnetic properties.

Environmental Factors Affecting Neodymium Magnet Performance

Neodymium magnets, while powerful and versatile, are highly susceptible to environmental conditions that can significantly impact their performance and longevity. Temperature variations represent one of the most critical environmental factors affecting these magnets. When exposed to temperatures exceeding their maximum operating temperature (typically around 80-200°C depending on grade), neodymium magnets experience irreversible demagnetization. Conversely, extremely low temperatures can cause brittleness, increasing the risk of cracking during handling or operation.

Humidity and corrosion present another major challenge for neodymium magnet assemblies. These magnets contain iron, making them inherently vulnerable to oxidation. Without proper protective coatings such as nickel, zinc, epoxy, or gold, exposure to moisture can trigger rapid corrosion, leading to structural degradation and magnetic field weakening. In marine or high-humidity environments, this deterioration accelerates dramatically, potentially reducing service life by 50-70%.

Mechanical stress and shock constitute significant environmental concerns for neodymium magnet assemblies. Despite their strong magnetic properties, these magnets possess relatively low mechanical strength and are brittle by nature. Repeated vibration, impacts, or improper handling can lead to chipping, cracking, or complete fracture. In industrial applications with high vibration levels, failure rates increase by approximately 30% without proper mounting and isolation systems.

Radiation exposure, particularly in aerospace and nuclear applications, can alter the magnetic domain structure of neodymium magnets. High-energy radiation gradually demagnetizes these components by disrupting their crystalline structure. Studies indicate that exposure to 10^8 rad of gamma radiation can reduce magnetic performance by up to 15%.

Chemical exposure represents another critical environmental factor. Certain solvents, acids, and alkaline solutions can deteriorate protective coatings and subsequently attack the base magnet material. Industrial environments with airborne chemical contaminants require specialized protective measures to prevent premature failure.

Electromagnetic interference from nearby electrical equipment or other magnetic fields can temporarily or permanently alter the magnetic properties of neodymium assemblies. Strong opposing magnetic fields can partially demagnetize these components, particularly at elevated temperatures where coercivity is reduced. This phenomenon is especially problematic in motor applications where demagnetization can occur gradually and remain undetected until system failure.

Humidity and corrosion present another major challenge for neodymium magnet assemblies. These magnets contain iron, making them inherently vulnerable to oxidation. Without proper protective coatings such as nickel, zinc, epoxy, or gold, exposure to moisture can trigger rapid corrosion, leading to structural degradation and magnetic field weakening. In marine or high-humidity environments, this deterioration accelerates dramatically, potentially reducing service life by 50-70%.

Mechanical stress and shock constitute significant environmental concerns for neodymium magnet assemblies. Despite their strong magnetic properties, these magnets possess relatively low mechanical strength and are brittle by nature. Repeated vibration, impacts, or improper handling can lead to chipping, cracking, or complete fracture. In industrial applications with high vibration levels, failure rates increase by approximately 30% without proper mounting and isolation systems.

Radiation exposure, particularly in aerospace and nuclear applications, can alter the magnetic domain structure of neodymium magnets. High-energy radiation gradually demagnetizes these components by disrupting their crystalline structure. Studies indicate that exposure to 10^8 rad of gamma radiation can reduce magnetic performance by up to 15%.

Chemical exposure represents another critical environmental factor. Certain solvents, acids, and alkaline solutions can deteriorate protective coatings and subsequently attack the base magnet material. Industrial environments with airborne chemical contaminants require specialized protective measures to prevent premature failure.

Electromagnetic interference from nearby electrical equipment or other magnetic fields can temporarily or permanently alter the magnetic properties of neodymium assemblies. Strong opposing magnetic fields can partially demagnetize these components, particularly at elevated temperatures where coercivity is reduced. This phenomenon is especially problematic in motor applications where demagnetization can occur gradually and remain undetected until system failure.

Quality Control Standards for Magnetic Assembly Manufacturing

Quality control standards play a pivotal role in ensuring the reliability and performance of neodymium magnet assemblies in manufacturing environments. These standards encompass comprehensive protocols for material verification, dimensional accuracy, magnetic property testing, and assembly integrity validation. Manufacturers must adhere to international benchmarks such as ISO 9001, ASTM A977, and IEC 60404 to maintain consistent quality across production batches.

Material verification standards require rigorous testing of raw neodymium materials before assembly, including chemical composition analysis and microstructure examination. These tests help identify potential metallurgical defects that could lead to premature failure under operational conditions. Specifications typically mandate maximum allowable impurity levels and minimum rare earth element concentrations to ensure optimal magnetic performance.

Dimensional tolerance standards for neodymium magnet assemblies are particularly stringent, often requiring precision within ±0.05mm or better. This level of accuracy is essential because even minor dimensional variations can significantly alter magnetic field uniformity and strength, potentially creating failure points at interfaces where magnets connect with other components.

Magnetic property testing standards define acceptable ranges for key parameters including remanence (Br), coercivity (Hc), and maximum energy product (BHmax). These properties must be verified using calibrated equipment such as Helmholtz coils, fluxmeters, or hysteresisgraphs. Quality control protocols typically specify sampling rates and statistical confidence levels required for batch acceptance.

Surface treatment and coating standards address critical aspects of corrosion resistance and mechanical protection. Specifications for nickel, zinc, epoxy, or parylene coatings include minimum thickness requirements, adhesion strength parameters, and accelerated environmental testing protocols to simulate years of operational exposure in condensed timeframes.

Assembly integrity validation standards incorporate both non-destructive and destructive testing methodologies. These include visual inspection under magnification, pull/push testing to verify bond strength, thermal cycling to detect potential delamination issues, and vibration testing to simulate operational stresses. Advanced techniques such as acoustic microscopy and X-ray inspection are increasingly becoming standard requirements for high-reliability applications.

Traceability requirements form another crucial component of quality control standards, mandating detailed documentation of material sources, processing parameters, test results, and assembly conditions. This information chain enables root cause analysis when failures occur and facilitates continuous improvement of manufacturing processes to eliminate identified failure points.

Material verification standards require rigorous testing of raw neodymium materials before assembly, including chemical composition analysis and microstructure examination. These tests help identify potential metallurgical defects that could lead to premature failure under operational conditions. Specifications typically mandate maximum allowable impurity levels and minimum rare earth element concentrations to ensure optimal magnetic performance.

Dimensional tolerance standards for neodymium magnet assemblies are particularly stringent, often requiring precision within ±0.05mm or better. This level of accuracy is essential because even minor dimensional variations can significantly alter magnetic field uniformity and strength, potentially creating failure points at interfaces where magnets connect with other components.

Magnetic property testing standards define acceptable ranges for key parameters including remanence (Br), coercivity (Hc), and maximum energy product (BHmax). These properties must be verified using calibrated equipment such as Helmholtz coils, fluxmeters, or hysteresisgraphs. Quality control protocols typically specify sampling rates and statistical confidence levels required for batch acceptance.

Surface treatment and coating standards address critical aspects of corrosion resistance and mechanical protection. Specifications for nickel, zinc, epoxy, or parylene coatings include minimum thickness requirements, adhesion strength parameters, and accelerated environmental testing protocols to simulate years of operational exposure in condensed timeframes.

Assembly integrity validation standards incorporate both non-destructive and destructive testing methodologies. These include visual inspection under magnification, pull/push testing to verify bond strength, thermal cycling to detect potential delamination issues, and vibration testing to simulate operational stresses. Advanced techniques such as acoustic microscopy and X-ray inspection are increasingly becoming standard requirements for high-reliability applications.

Traceability requirements form another crucial component of quality control standards, mandating detailed documentation of material sources, processing parameters, test results, and assembly conditions. This information chain enables root cause analysis when failures occur and facilitates continuous improvement of manufacturing processes to eliminate identified failure points.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!