How to Implement Hydrofluoric Acid in Glass Manufacturing

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HF Acid in Glass Manufacturing: Background and Objectives

Hydrofluoric acid (HF) has been an integral component in glass manufacturing processes since the early 19th century when it was first discovered that this compound could effectively etch glass surfaces. The evolution of HF application in glass production has transformed from rudimentary etching techniques to sophisticated manufacturing processes that enable the creation of specialized glass products with unique properties and finishes.

The glass manufacturing industry has witnessed significant technological advancements over the past decades, with HF acid playing a pivotal role in various stages of production. Initially utilized primarily for decorative etching, the application scope has expanded to include critical processes such as surface preparation, quality control, and the development of specialty glass products. This technological progression has been driven by increasing market demands for higher quality glass with specific performance characteristics.

Current trends in HF implementation focus on enhancing efficiency while simultaneously addressing safety and environmental concerns. The highly corrosive and toxic nature of hydrofluoric acid presents substantial challenges that have spurred innovation in handling methodologies, protective equipment, and alternative formulations with reduced hazard profiles. Industry leaders are increasingly investing in closed-loop systems that minimize worker exposure and environmental release.

The primary technical objectives for implementing hydrofluoric acid in glass manufacturing encompass several dimensions. First, process optimization aims to achieve consistent etching results while minimizing acid consumption. Second, safety enhancement focuses on developing robust protocols and engineering controls that protect workers from potential exposure. Third, environmental sustainability goals drive efforts to reduce waste generation and implement effective treatment systems for HF-containing effluents.

Regulatory compliance represents another critical objective, as international standards for HF handling continue to evolve toward more stringent requirements. Manufacturers must navigate complex regulatory landscapes that vary by region, necessitating adaptable implementation strategies that can satisfy diverse compliance obligations while maintaining operational efficiency.

Looking forward, the industry is exploring next-generation approaches that may fundamentally alter how HF is utilized in glass manufacturing. These include the development of nano-scale etching techniques that require significantly lower acid concentrations, computer-controlled application systems that optimize acid usage through precise targeting, and hybrid processes that combine HF with other compounds to achieve novel surface effects while reducing overall acid requirements.

The ultimate goal for advanced HF implementation is to establish manufacturing processes that balance technical performance, worker safety, environmental responsibility, and economic viability. This multifaceted objective drives ongoing research and development efforts across the glass manufacturing sector, positioning hydrofluoric acid as a continuing focus of technological innovation despite its long history in the industry.

The glass manufacturing industry has witnessed significant technological advancements over the past decades, with HF acid playing a pivotal role in various stages of production. Initially utilized primarily for decorative etching, the application scope has expanded to include critical processes such as surface preparation, quality control, and the development of specialty glass products. This technological progression has been driven by increasing market demands for higher quality glass with specific performance characteristics.

Current trends in HF implementation focus on enhancing efficiency while simultaneously addressing safety and environmental concerns. The highly corrosive and toxic nature of hydrofluoric acid presents substantial challenges that have spurred innovation in handling methodologies, protective equipment, and alternative formulations with reduced hazard profiles. Industry leaders are increasingly investing in closed-loop systems that minimize worker exposure and environmental release.

The primary technical objectives for implementing hydrofluoric acid in glass manufacturing encompass several dimensions. First, process optimization aims to achieve consistent etching results while minimizing acid consumption. Second, safety enhancement focuses on developing robust protocols and engineering controls that protect workers from potential exposure. Third, environmental sustainability goals drive efforts to reduce waste generation and implement effective treatment systems for HF-containing effluents.

Regulatory compliance represents another critical objective, as international standards for HF handling continue to evolve toward more stringent requirements. Manufacturers must navigate complex regulatory landscapes that vary by region, necessitating adaptable implementation strategies that can satisfy diverse compliance obligations while maintaining operational efficiency.

Looking forward, the industry is exploring next-generation approaches that may fundamentally alter how HF is utilized in glass manufacturing. These include the development of nano-scale etching techniques that require significantly lower acid concentrations, computer-controlled application systems that optimize acid usage through precise targeting, and hybrid processes that combine HF with other compounds to achieve novel surface effects while reducing overall acid requirements.

The ultimate goal for advanced HF implementation is to establish manufacturing processes that balance technical performance, worker safety, environmental responsibility, and economic viability. This multifaceted objective drives ongoing research and development efforts across the glass manufacturing sector, positioning hydrofluoric acid as a continuing focus of technological innovation despite its long history in the industry.

Market Analysis of HF-Processed Glass Products

The global market for HF-processed glass products has experienced significant growth over the past decade, driven primarily by increasing demand in electronics, automotive, and architectural applications. The market size for these specialized glass products reached approximately $12.5 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028.

The electronics sector represents the largest market segment, accounting for nearly 42% of total demand. This is largely attributed to the expanding use of etched glass in display panels, touchscreens, and semiconductor manufacturing. The unique properties achieved through hydrofluoric acid processing—including enhanced clarity, reduced reflectivity, and precise micro-texturing—have made these products essential components in high-end consumer electronics.

Architectural applications constitute the second-largest market segment at 28%, where HF-processed glass is increasingly specified for its aesthetic qualities and functional benefits. The ability to create frosted, textured, or patterned surfaces without compromising structural integrity has positioned these products as premium offerings in commercial and residential construction projects.

The automotive industry represents a rapidly growing segment (18% market share), where HF-etched glass is utilized in advanced windshields, side windows, and mirrors. The technology enables improved visibility, reduced glare, and integration of display capabilities directly into glass surfaces, aligning with the industry's shift toward more sophisticated vehicle interfaces.

Regional analysis reveals Asia-Pacific as the dominant market (39% share), driven by the concentration of electronics manufacturing and rapid urbanization. North America and Europe follow at 27% and 24% respectively, with both regions showing increased adoption in premium architectural applications and automotive innovations.

Consumer preferences are shifting toward more environmentally sustainable manufacturing processes, creating market pressure for reduced HF consumption and closed-loop processing systems. This trend has accelerated development of alternative etching technologies, though none have yet matched the precision and cost-effectiveness of traditional HF processing at scale.

Price sensitivity varies significantly by application segment, with electronics manufacturers demonstrating willingness to pay premium prices for high-precision etching, while architectural applications remain more cost-conscious. This market dynamic has encouraged manufacturers to develop tiered product offerings with varying levels of processing complexity and corresponding price points.

The electronics sector represents the largest market segment, accounting for nearly 42% of total demand. This is largely attributed to the expanding use of etched glass in display panels, touchscreens, and semiconductor manufacturing. The unique properties achieved through hydrofluoric acid processing—including enhanced clarity, reduced reflectivity, and precise micro-texturing—have made these products essential components in high-end consumer electronics.

Architectural applications constitute the second-largest market segment at 28%, where HF-processed glass is increasingly specified for its aesthetic qualities and functional benefits. The ability to create frosted, textured, or patterned surfaces without compromising structural integrity has positioned these products as premium offerings in commercial and residential construction projects.

The automotive industry represents a rapidly growing segment (18% market share), where HF-etched glass is utilized in advanced windshields, side windows, and mirrors. The technology enables improved visibility, reduced glare, and integration of display capabilities directly into glass surfaces, aligning with the industry's shift toward more sophisticated vehicle interfaces.

Regional analysis reveals Asia-Pacific as the dominant market (39% share), driven by the concentration of electronics manufacturing and rapid urbanization. North America and Europe follow at 27% and 24% respectively, with both regions showing increased adoption in premium architectural applications and automotive innovations.

Consumer preferences are shifting toward more environmentally sustainable manufacturing processes, creating market pressure for reduced HF consumption and closed-loop processing systems. This trend has accelerated development of alternative etching technologies, though none have yet matched the precision and cost-effectiveness of traditional HF processing at scale.

Price sensitivity varies significantly by application segment, with electronics manufacturers demonstrating willingness to pay premium prices for high-precision etching, while architectural applications remain more cost-conscious. This market dynamic has encouraged manufacturers to develop tiered product offerings with varying levels of processing complexity and corresponding price points.

Technical Challenges and Safety Constraints in HF Implementation

The implementation of hydrofluoric acid (HF) in glass manufacturing presents significant technical challenges and safety constraints that must be carefully addressed. HF is primarily used in glass etching processes, where its unique ability to dissolve silica makes it invaluable for creating frosted glass, decorative patterns, and precision optical components. However, its implementation requires overcoming substantial hurdles.

The foremost technical challenge lies in material compatibility. HF rapidly attacks silicates, making conventional glass storage containers unsuitable. Manufacturing facilities must utilize specialized containers made from fluoropolymers like PTFE (Teflon), PVDF, or certain grades of polyethylene. Even stainless steel equipment requires careful selection, as only specific alloys offer adequate resistance to HF corrosion.

Process control presents another significant challenge. The etching rate of HF on glass surfaces is highly sensitive to concentration, temperature, and exposure time. Achieving consistent results requires sophisticated monitoring systems and precise process parameters. Variations in glass composition further complicate matters, as different formulations react at varying rates with HF, necessitating customized protocols for each glass type.

Waste management constitutes a critical technical constraint. HF-containing waste streams cannot be disposed of through conventional methods due to environmental regulations and the acid's persistent hazardous properties. Neutralization processes using calcium compounds must be carefully controlled to prevent dangerous heat generation and ensure complete reaction.

From a safety perspective, HF presents exceptional hazards compared to other industrial acids. Unlike most acids that cause immediate pain upon contact, HF can penetrate skin without immediate symptoms, potentially causing deep tissue damage and systemic toxicity through calcium sequestration. This delayed effect makes exposure particularly dangerous, as workers may not seek immediate treatment.

Engineering controls must be exceptionally robust, including fully enclosed processing systems, redundant containment measures, and specialized ventilation systems with scrubbers to capture any vapor emissions. Personal protective equipment requirements exceed those for other acids, necessitating impermeable suits, face shields, and specialized gloves rated specifically for HF resistance.

Emergency response capabilities present additional implementation challenges. Facilities must maintain calcium gluconate gel and other specialized first aid supplies, and staff must receive extensive training on HF-specific emergency procedures. Detection systems for HF vapor must be installed throughout processing areas, with regular calibration and maintenance protocols.

Regulatory compliance adds another layer of complexity, with stringent requirements from agencies including OSHA, EPA, and local authorities. Documentation, employee training programs, and regular audits must meet exacting standards, creating significant administrative overhead for manufacturing operations.

The foremost technical challenge lies in material compatibility. HF rapidly attacks silicates, making conventional glass storage containers unsuitable. Manufacturing facilities must utilize specialized containers made from fluoropolymers like PTFE (Teflon), PVDF, or certain grades of polyethylene. Even stainless steel equipment requires careful selection, as only specific alloys offer adequate resistance to HF corrosion.

Process control presents another significant challenge. The etching rate of HF on glass surfaces is highly sensitive to concentration, temperature, and exposure time. Achieving consistent results requires sophisticated monitoring systems and precise process parameters. Variations in glass composition further complicate matters, as different formulations react at varying rates with HF, necessitating customized protocols for each glass type.

Waste management constitutes a critical technical constraint. HF-containing waste streams cannot be disposed of through conventional methods due to environmental regulations and the acid's persistent hazardous properties. Neutralization processes using calcium compounds must be carefully controlled to prevent dangerous heat generation and ensure complete reaction.

From a safety perspective, HF presents exceptional hazards compared to other industrial acids. Unlike most acids that cause immediate pain upon contact, HF can penetrate skin without immediate symptoms, potentially causing deep tissue damage and systemic toxicity through calcium sequestration. This delayed effect makes exposure particularly dangerous, as workers may not seek immediate treatment.

Engineering controls must be exceptionally robust, including fully enclosed processing systems, redundant containment measures, and specialized ventilation systems with scrubbers to capture any vapor emissions. Personal protective equipment requirements exceed those for other acids, necessitating impermeable suits, face shields, and specialized gloves rated specifically for HF resistance.

Emergency response capabilities present additional implementation challenges. Facilities must maintain calcium gluconate gel and other specialized first aid supplies, and staff must receive extensive training on HF-specific emergency procedures. Detection systems for HF vapor must be installed throughout processing areas, with regular calibration and maintenance protocols.

Regulatory compliance adds another layer of complexity, with stringent requirements from agencies including OSHA, EPA, and local authorities. Documentation, employee training programs, and regular audits must meet exacting standards, creating significant administrative overhead for manufacturing operations.

Current HF Acid Etching and Processing Methodologies

01 Etching and cleaning applications in semiconductor manufacturing

Hydrofluoric acid is widely used in semiconductor manufacturing processes for etching silicon dioxide and cleaning silicon wafers. It effectively removes oxide layers, contaminants, and residues from semiconductor surfaces. Various formulations and concentrations of hydrofluoric acid are employed depending on the specific requirements of the etching or cleaning process, often in combination with other chemicals to enhance performance and control the etching rate.- Etching applications of hydrofluoric acid: Hydrofluoric acid is widely used as an etching agent in semiconductor manufacturing and glass processing. It effectively removes silicon dioxide layers and can be formulated with various additives to control the etching rate and surface quality. These formulations are crucial for microelectronics fabrication processes where precise etching is required for circuit patterns and surface preparation.

- Purification and recovery methods for hydrofluoric acid: Various techniques have been developed to purify and recover hydrofluoric acid from industrial waste streams. These methods include distillation, adsorption, membrane filtration, and chemical precipitation processes. Purification is essential to remove contaminants such as metal ions and particulates, allowing for the recycling of hydrofluoric acid in manufacturing processes and reducing environmental impact.

- Safety measures and neutralization techniques: Due to its highly corrosive and toxic nature, specialized safety protocols and neutralization methods have been developed for handling hydrofluoric acid. These include the use of specific neutralizing agents like calcium compounds, specialized containment systems, and emergency treatment procedures. Innovations in this area focus on rapid neutralization techniques and protective equipment to minimize risks in industrial settings.

- Production methods of hydrofluoric acid: Various processes have been developed for the industrial production of hydrofluoric acid, primarily involving the reaction of calcium fluoride (fluorspar) with sulfuric acid. Innovations in this field include continuous production systems, catalytic methods, and techniques to improve yield and purity. These methods aim to enhance production efficiency while reducing environmental impact and energy consumption.

- Specialized formulations for specific applications: Hydrofluoric acid is formulated with various additives for specialized applications across different industries. These formulations may include buffering agents, surfactants, inhibitors, and other chemicals to enhance performance for specific uses such as metal surface treatment, cleaning solutions, and chemical synthesis. The compositions are designed to optimize effectiveness while minimizing damage to substrates and equipment.

02 Production and purification methods of hydrofluoric acid

Various methods are employed for the production and purification of hydrofluoric acid. These include processes involving the reaction of calcium fluoride with sulfuric acid, as well as techniques for removing impurities from crude hydrofluoric acid. Advanced purification methods involve distillation, adsorption, and filtration to achieve high-purity hydrofluoric acid suitable for specialized applications in electronics and other industries.Expand Specific Solutions03 Safety measures and handling of hydrofluoric acid

Due to its highly corrosive and toxic nature, specialized safety measures are essential when handling hydrofluoric acid. These include the use of specific neutralizing agents, personal protective equipment, and emergency response protocols. Various containment systems, monitoring devices, and treatment methods have been developed to minimize risks associated with hydrofluoric acid exposure, storage, and transportation.Expand Specific Solutions04 Waste treatment and recovery systems

Environmental concerns have led to the development of various waste treatment and recovery systems for hydrofluoric acid. These include neutralization processes, precipitation methods, and recycling techniques to minimize environmental impact. Advanced systems can recover and purify used hydrofluoric acid for reuse, reducing waste and operational costs while meeting stringent environmental regulations.Expand Specific Solutions05 Specialized formulations for specific industrial applications

Specialized hydrofluoric acid formulations have been developed for various industrial applications beyond semiconductor manufacturing. These include glass etching, metal surface treatment, oil well stimulation, and chemical synthesis. The formulations often contain additives, stabilizers, or are part of complex mixtures designed to achieve specific performance characteristics while minimizing hazards associated with pure hydrofluoric acid.Expand Specific Solutions

Leading Manufacturers and Suppliers in HF Glass Processing

The hydrofluoric acid implementation in glass manufacturing market is currently in a growth phase, with increasing demand driven by advanced glass applications in electronics, automotive, and construction sectors. The global market size is estimated to exceed $7 billion, expanding at approximately 5% CAGR. Technologically, companies demonstrate varying maturity levels across the value chain. Industry leaders like Corning, AGC Inc., and Nippon Sheet Glass have established advanced HF etching processes for specialty glass production, while chemical suppliers such as Do-Fluoride New Materials and Foosung provide high-purity HF reagents. Emerging players like Jiangyin Runma Electronic Material and Jianghua Micro-electronics Materials are developing specialized formulations for semiconductor and display applications, indicating a competitive landscape with significant innovation potential in process efficiency and safety protocols.

AGC Glass Europe SA

Technical Solution: AGC Glass Europe has developed a proprietary hydrofluoric acid etching process for glass manufacturing that enables precise surface modification and texture control. Their technology utilizes controlled HF concentrations (typically 1-5%) in combination with buffering agents to create uniform matte finishes on architectural and specialty glass products. The process incorporates advanced safety systems including automated handling equipment, closed-loop acid recycling, and neutralization systems that reduce environmental impact. AGC's implementation includes specialized polymer-lined etching tanks with temperature control systems (maintaining optimal 20-25°C range) and computerized monitoring of acid concentration to ensure consistent quality across large glass sheets[1]. Their approach also features innovative acid vapor suppression technology and waste treatment processes that recover fluoride compounds for reuse, significantly reducing disposal requirements[3].

Strengths: Superior control over etching uniformity across large glass surfaces; integrated safety systems that exceed regulatory requirements; reduced environmental footprint through acid recycling. Weaknesses: Higher implementation costs compared to traditional methods; requires specialized training for operators; process speed limitations for deep etching applications.

AGC, Inc. (Japan)

Technical Solution: AGC Inc. has pioneered an advanced hydrofluoric acid implementation system for glass manufacturing that focuses on precision microetching for high-tech applications. Their technology employs dilute HF solutions (0.5-3%) combined with proprietary surfactants to achieve nanoscale surface modifications critical for optical and electronic glass components. The system features fully automated robotic handling that eliminates human exposure to HF, along with real-time monitoring using spectroscopic analysis to maintain precise acid concentrations within ±0.05%[2]. AGC's implementation includes patented vapor containment technology that reduces HF emissions to near-zero levels and specialized filtration systems that extend acid bath life by removing glass particles continuously. Their process also incorporates a closed-loop water recycling system that reduces water consumption by approximately 60% compared to conventional etching operations[4]. This technology is particularly valuable for manufacturing high-performance display glass, photovoltaic substrates, and precision optical components.

Strengths: Exceptional precision for nanoscale surface modifications; industry-leading safety automation; significantly reduced water consumption and waste generation. Weaknesses: High capital investment requirements; limited throughput for mass production applications; requires specialized maintenance expertise.

Key Patents and Innovations in HF Glass Treatment

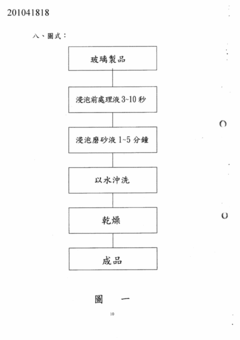

Surface grinding processing and producing method of glass product

PatentInactiveTW201041818A

Innovation

- A method involving a pre-treatment with a solution of water, hydrofluoric acid, nitric acid, and nitric acid, followed by a scrubbing process with a mixture of nitric acid, ammonium hydrofluoride, hydrofluoric acid, water, and hydrochloric acid, to create a scaly pattern on the glass surface, ensuring a smooth and sparkling finish.

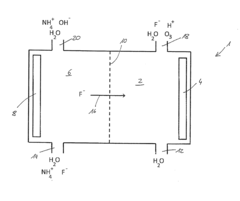

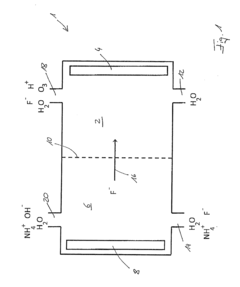

Method for producing diluted hydrofluoric acid

PatentActiveUS20180148332A1

Innovation

- A method using an electrode arrangement with an anode and cathode chambers separated by an anion exchange membrane, where pure water and an electrolyte solution containing fluoride ions are electrolyzed to produce dilute hydrofluoric acid with precise concentration control, and ozone can be simultaneously produced, with the ability to adjust concentrations independently using electrical current and electrolyte concentration.

Environmental Impact and Waste Management Protocols

The implementation of hydrofluoric acid (HF) in glass manufacturing presents significant environmental challenges that require comprehensive management protocols. HF emissions from glass manufacturing facilities can contaminate air, water, and soil, potentially causing severe ecological damage and health risks to surrounding communities. Atmospheric releases of fluoride compounds contribute to acid rain formation and can travel considerable distances, affecting ecosystems far from the source.

Water contamination represents another critical concern, as HF waste streams can alter aquatic pH levels and introduce toxic fluoride compounds into water bodies. Even at low concentrations, these compounds can bioaccumulate in aquatic organisms and disrupt ecosystem balance. Soil contamination from improper disposal or accidental spills can persist for extended periods, rendering affected areas unsuitable for agriculture or other productive uses.

Modern waste management protocols for HF in glass manufacturing employ a multi-tiered approach. Primary treatment systems typically include neutralization processes using calcium or sodium compounds to convert HF into less hazardous fluoride salts. These systems achieve removal efficiencies of 95-99% when properly maintained and operated. Secondary treatment often involves precipitation methods and advanced filtration technologies to capture remaining fluoride compounds before final discharge.

Closed-loop recycling systems represent the gold standard in HF management, allowing facilities to recover and reuse acid components while minimizing waste generation. Such systems can reduce fresh HF requirements by up to 60% while simultaneously decreasing environmental discharge volumes. Continuous monitoring technologies, including real-time fluoride sensors and automated sampling systems, provide essential data for regulatory compliance and process optimization.

Regulatory frameworks governing HF waste management vary globally but generally trend toward increasing stringency. The European Union's Industrial Emissions Directive and the United States EPA's National Emission Standards for Hazardous Air Pollutants establish specific limits for fluoride emissions and waste disposal. Compliance with these regulations requires detailed documentation of waste streams, treatment methodologies, and disposal practices.

Industry best practices now emphasize preventive approaches, including process modifications that reduce initial HF requirements and substitute less hazardous alternatives where technically feasible. Emergency response protocols for accidental releases have also evolved to include specialized neutralization agents, containment strategies, and community notification systems that can significantly mitigate environmental impacts during incidents.

Water contamination represents another critical concern, as HF waste streams can alter aquatic pH levels and introduce toxic fluoride compounds into water bodies. Even at low concentrations, these compounds can bioaccumulate in aquatic organisms and disrupt ecosystem balance. Soil contamination from improper disposal or accidental spills can persist for extended periods, rendering affected areas unsuitable for agriculture or other productive uses.

Modern waste management protocols for HF in glass manufacturing employ a multi-tiered approach. Primary treatment systems typically include neutralization processes using calcium or sodium compounds to convert HF into less hazardous fluoride salts. These systems achieve removal efficiencies of 95-99% when properly maintained and operated. Secondary treatment often involves precipitation methods and advanced filtration technologies to capture remaining fluoride compounds before final discharge.

Closed-loop recycling systems represent the gold standard in HF management, allowing facilities to recover and reuse acid components while minimizing waste generation. Such systems can reduce fresh HF requirements by up to 60% while simultaneously decreasing environmental discharge volumes. Continuous monitoring technologies, including real-time fluoride sensors and automated sampling systems, provide essential data for regulatory compliance and process optimization.

Regulatory frameworks governing HF waste management vary globally but generally trend toward increasing stringency. The European Union's Industrial Emissions Directive and the United States EPA's National Emission Standards for Hazardous Air Pollutants establish specific limits for fluoride emissions and waste disposal. Compliance with these regulations requires detailed documentation of waste streams, treatment methodologies, and disposal practices.

Industry best practices now emphasize preventive approaches, including process modifications that reduce initial HF requirements and substitute less hazardous alternatives where technically feasible. Emergency response protocols for accidental releases have also evolved to include specialized neutralization agents, containment strategies, and community notification systems that can significantly mitigate environmental impacts during incidents.

Regulatory Compliance and Worker Safety Standards

The implementation of hydrofluoric acid (HF) in glass manufacturing necessitates strict adherence to comprehensive regulatory frameworks established by various governmental agencies. In the United States, the Occupational Safety and Health Administration (OSHA) mandates specific exposure limits, with the permissible exposure limit (PEL) set at 3 parts per million (ppm) as an 8-hour time-weighted average. Similarly, the National Institute for Occupational Safety and Health (NIOSH) recommends an even lower ceiling limit of 2 ppm for up to a 15-minute period. European regulations, particularly under REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), impose additional restrictions on HF usage and require detailed documentation of safety protocols.

Manufacturing facilities must implement rigorous engineering controls as the primary defense against HF exposure. These include closed-system processing equipment, automated handling systems, and sophisticated local exhaust ventilation with scrubber technology capable of neutralizing HF vapors. Regular maintenance schedules for these systems must be documented and strictly followed to ensure continuous protection. Additionally, continuous air monitoring systems with real-time alerts are essential for detecting even minor leaks before they pose significant health risks.

Personal protective equipment (PPE) requirements for workers handling HF are exceptionally stringent. Full-body protection includes chemical-resistant suits made of materials specifically tested against HF penetration, such as Viton or specialized multi-layer fabrics. Respiratory protection must include supplied air systems rather than standard cartridge respirators when concentrations may exceed established limits. Face and eye protection must include full-face shields over chemical splash goggles, while hand protection requires specific HF-resistant gloves, often in double-layer configurations.

Emergency response protocols represent a critical component of worker safety standards. Facilities must maintain calcium gluconate gel stations throughout work areas for immediate treatment of skin exposure. Specialized emergency showers and eyewash stations with specific flow rates and water temperatures must be installed within 10 seconds' travel distance from all HF handling areas. Medical response teams require specialized training in HF exposure treatment, and transportation arrangements to medical facilities with experience in treating HF injuries must be established in advance.

Training programs must exceed standard hazardous material handling instruction, with HF-specific modules covering unique properties, delayed injury mechanisms, and specialized first aid techniques. Certification requirements typically include hands-on demonstrations of emergency procedures and regular refresher courses at intervals not exceeding six months. Documentation of all training activities must be maintained for regulatory inspection and include competency verification through written and practical examinations.

Manufacturing facilities must implement rigorous engineering controls as the primary defense against HF exposure. These include closed-system processing equipment, automated handling systems, and sophisticated local exhaust ventilation with scrubber technology capable of neutralizing HF vapors. Regular maintenance schedules for these systems must be documented and strictly followed to ensure continuous protection. Additionally, continuous air monitoring systems with real-time alerts are essential for detecting even minor leaks before they pose significant health risks.

Personal protective equipment (PPE) requirements for workers handling HF are exceptionally stringent. Full-body protection includes chemical-resistant suits made of materials specifically tested against HF penetration, such as Viton or specialized multi-layer fabrics. Respiratory protection must include supplied air systems rather than standard cartridge respirators when concentrations may exceed established limits. Face and eye protection must include full-face shields over chemical splash goggles, while hand protection requires specific HF-resistant gloves, often in double-layer configurations.

Emergency response protocols represent a critical component of worker safety standards. Facilities must maintain calcium gluconate gel stations throughout work areas for immediate treatment of skin exposure. Specialized emergency showers and eyewash stations with specific flow rates and water temperatures must be installed within 10 seconds' travel distance from all HF handling areas. Medical response teams require specialized training in HF exposure treatment, and transportation arrangements to medical facilities with experience in treating HF injuries must be established in advance.

Training programs must exceed standard hazardous material handling instruction, with HF-specific modules covering unique properties, delayed injury mechanisms, and specialized first aid techniques. Certification requirements typically include hands-on demonstrations of emergency procedures and regular refresher courses at intervals not exceeding six months. Documentation of all training activities must be maintained for regulatory inspection and include competency verification through written and practical examinations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!