How to Implement Thermoelectric Materials in Green Roof Systems

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Green Roof Technology Background & Objectives

Thermoelectric technology integration with green roof systems represents a significant innovation at the intersection of sustainable architecture and renewable energy generation. The concept has evolved from traditional green roofs, which primarily focused on thermal insulation and stormwater management, to multifunctional systems capable of energy harvesting. This technological evolution began in the early 2000s with basic explorations of temperature differentials in building envelopes and has accelerated significantly in the past decade with advancements in thermoelectric materials science.

The fundamental principle behind thermoelectric green roofs leverages the Seebeck effect, where temperature differences between the vegetative layer and building interior generate electrical potential. Historical development shows a progression from inefficient, bulky thermoelectric generators (TEGs) with conversion efficiencies below 5% to modern thin-film technologies achieving 8-12% efficiency under optimal conditions. This improvement trajectory continues to shape research priorities in the field.

Current technological objectives center on developing integrated systems that maintain the ecological benefits of green roofs while maximizing energy generation potential. Specifically, researchers aim to achieve power densities of 10-15 W/m² under typical urban temperature gradients, representing a three-fold improvement over early prototype systems. Additional objectives include reducing material costs by 40-50% to enable commercial viability and extending system lifespans to 15-20 years to match conventional roofing materials.

The technological landscape is further influenced by global sustainability initiatives, including the Paris Climate Agreement and various national green building standards. These frameworks have established ambitious targets for building energy efficiency and on-site renewable generation, creating a favorable environment for thermoelectric green roof development. The European Union's Horizon Europe program and the U.S. Department of Energy's Building Technologies Office have specifically identified building-integrated energy harvesting as priority research areas.

Looking forward, the field is trending toward bio-inspired thermoelectric materials that mimic natural thermal regulation processes found in certain plant species. Concurrently, advances in nanomaterials science are enabling the development of flexible, lightweight thermoelectric modules specifically designed for integration with living roof systems. These technological trajectories suggest a convergence toward truly symbiotic systems where vegetation and energy generation components mutually enhance performance.

The ultimate goal of this technology is to transform passive green infrastructure into active energy-generating assets within the urban environment, contributing to distributed energy networks while maintaining ecological services such as urban heat island mitigation and biodiversity support.

The fundamental principle behind thermoelectric green roofs leverages the Seebeck effect, where temperature differences between the vegetative layer and building interior generate electrical potential. Historical development shows a progression from inefficient, bulky thermoelectric generators (TEGs) with conversion efficiencies below 5% to modern thin-film technologies achieving 8-12% efficiency under optimal conditions. This improvement trajectory continues to shape research priorities in the field.

Current technological objectives center on developing integrated systems that maintain the ecological benefits of green roofs while maximizing energy generation potential. Specifically, researchers aim to achieve power densities of 10-15 W/m² under typical urban temperature gradients, representing a three-fold improvement over early prototype systems. Additional objectives include reducing material costs by 40-50% to enable commercial viability and extending system lifespans to 15-20 years to match conventional roofing materials.

The technological landscape is further influenced by global sustainability initiatives, including the Paris Climate Agreement and various national green building standards. These frameworks have established ambitious targets for building energy efficiency and on-site renewable generation, creating a favorable environment for thermoelectric green roof development. The European Union's Horizon Europe program and the U.S. Department of Energy's Building Technologies Office have specifically identified building-integrated energy harvesting as priority research areas.

Looking forward, the field is trending toward bio-inspired thermoelectric materials that mimic natural thermal regulation processes found in certain plant species. Concurrently, advances in nanomaterials science are enabling the development of flexible, lightweight thermoelectric modules specifically designed for integration with living roof systems. These technological trajectories suggest a convergence toward truly symbiotic systems where vegetation and energy generation components mutually enhance performance.

The ultimate goal of this technology is to transform passive green infrastructure into active energy-generating assets within the urban environment, contributing to distributed energy networks while maintaining ecological services such as urban heat island mitigation and biodiversity support.

Market Analysis for Energy-Harvesting Roof Systems

The global market for energy-harvesting roof systems is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable building solutions. Current market valuations indicate that the green roof industry alone is worth over $1.5 billion globally, with projections showing a compound annual growth rate of 12-15% through 2028. When combined with thermoelectric technology integration, this market segment represents an emerging opportunity estimated at $300-400 million, with potential to reach $2 billion by 2030.

Consumer demand for energy-efficient building solutions has risen dramatically, with surveys indicating that 67% of commercial property developers now prioritize energy harvesting capabilities in new construction projects. This shift is particularly pronounced in urban centers across North America, Europe, and East Asia, where energy costs and environmental regulations are most stringent.

The primary market segments for thermoelectric green roof systems include commercial office buildings (42% of potential market), institutional facilities such as universities and hospitals (28%), and high-end residential developments (18%). Government buildings represent a smaller but growing segment (12%) as public sector sustainability mandates increase.

Regional analysis reveals that Europe currently leads adoption with approximately 45% market share, driven by stringent EU energy efficiency directives and substantial government incentives. North America follows at 30%, with particularly strong growth in cities with green building codes like New York, Toronto, and San Francisco. The Asia-Pacific region, while currently representing only 20% of the market, is expected to show the fastest growth rate at 18-20% annually through 2025.

Key market drivers include rising energy costs (with electricity prices increasing 3-5% annually in developed markets), increasingly stringent building codes requiring energy efficiency measures, and growing corporate commitments to carbon neutrality. Additionally, insurance incentives for buildings with temperature-regulating features have emerged as a significant financial motivator, with premium reductions of 5-8% documented in several markets.

Consumer willingness to pay premiums for buildings with integrated energy-harvesting systems has been demonstrated through multiple market studies, with commercial tenants accepting 7-12% higher lease rates for spaces in buildings with advanced sustainability features. The return on investment period for thermoelectric green roof systems currently ranges from 5-8 years, though this is expected to decrease as technology improves and economies of scale develop.

Market barriers include high initial installation costs, limited awareness of thermoelectric technology applications in construction, and technical integration challenges with existing building systems. However, these barriers are gradually diminishing as demonstration projects prove the technology's effectiveness and economic viability.

Consumer demand for energy-efficient building solutions has risen dramatically, with surveys indicating that 67% of commercial property developers now prioritize energy harvesting capabilities in new construction projects. This shift is particularly pronounced in urban centers across North America, Europe, and East Asia, where energy costs and environmental regulations are most stringent.

The primary market segments for thermoelectric green roof systems include commercial office buildings (42% of potential market), institutional facilities such as universities and hospitals (28%), and high-end residential developments (18%). Government buildings represent a smaller but growing segment (12%) as public sector sustainability mandates increase.

Regional analysis reveals that Europe currently leads adoption with approximately 45% market share, driven by stringent EU energy efficiency directives and substantial government incentives. North America follows at 30%, with particularly strong growth in cities with green building codes like New York, Toronto, and San Francisco. The Asia-Pacific region, while currently representing only 20% of the market, is expected to show the fastest growth rate at 18-20% annually through 2025.

Key market drivers include rising energy costs (with electricity prices increasing 3-5% annually in developed markets), increasingly stringent building codes requiring energy efficiency measures, and growing corporate commitments to carbon neutrality. Additionally, insurance incentives for buildings with temperature-regulating features have emerged as a significant financial motivator, with premium reductions of 5-8% documented in several markets.

Consumer willingness to pay premiums for buildings with integrated energy-harvesting systems has been demonstrated through multiple market studies, with commercial tenants accepting 7-12% higher lease rates for spaces in buildings with advanced sustainability features. The return on investment period for thermoelectric green roof systems currently ranges from 5-8 years, though this is expected to decrease as technology improves and economies of scale develop.

Market barriers include high initial installation costs, limited awareness of thermoelectric technology applications in construction, and technical integration challenges with existing building systems. However, these barriers are gradually diminishing as demonstration projects prove the technology's effectiveness and economic viability.

Current Challenges in Thermoelectric Green Roof Integration

The integration of thermoelectric materials into green roof systems faces several significant technical and practical challenges that currently limit widespread adoption. One of the primary obstacles is the efficiency limitation of thermoelectric materials themselves. Current commercially available thermoelectric modules typically operate at only 5-8% efficiency, making the energy harvesting potential from temperature differentials between roof surfaces and underlying structures relatively modest compared to other renewable energy technologies.

Material compatibility presents another substantial challenge. Thermoelectric materials must withstand harsh rooftop conditions including extreme temperature fluctuations, moisture exposure, and UV radiation. Many high-performance thermoelectric compounds contain toxic elements like tellurium, lead, or bismuth, raising environmental concerns when implemented in green infrastructure designed specifically for sustainability benefits.

The structural integration of rigid thermoelectric modules with the flexible, organic nature of green roof systems creates significant engineering difficulties. The weight-bearing capacity of existing roof structures may be insufficient to support the combined load of growing media, vegetation, water retention layers, and added thermoelectric components. Additionally, the thermal management requirements of thermoelectric systems may conflict with the natural thermal regulation functions of green roofs.

Cost factors represent a major barrier to implementation. Current thermoelectric materials with reasonable efficiency remain expensive to manufacture at scale, with prices ranging from $200-500 per square meter of coverage. This high initial investment significantly extends payback periods, often beyond 15-20 years, making economic justification difficult for building owners and developers.

Maintenance complexity further complicates adoption. Thermoelectric systems require regular inspection and servicing to maintain performance, while green roofs need horticultural care. These divergent maintenance requirements create logistical challenges for building management teams who may lack expertise in both electrical systems and plant care.

The absence of standardized design approaches and installation guidelines specifically for thermoelectric green roof integration hampers industry development. Without established best practices, each implementation becomes a custom engineering project, increasing costs and risks while limiting scalability.

Finally, there exists a significant knowledge gap between the thermoelectric research community and green building practitioners. Interdisciplinary collaboration between materials scientists, electrical engineers, horticulturists, and building designers remains limited, slowing innovation and practical application development in this emerging field.

Material compatibility presents another substantial challenge. Thermoelectric materials must withstand harsh rooftop conditions including extreme temperature fluctuations, moisture exposure, and UV radiation. Many high-performance thermoelectric compounds contain toxic elements like tellurium, lead, or bismuth, raising environmental concerns when implemented in green infrastructure designed specifically for sustainability benefits.

The structural integration of rigid thermoelectric modules with the flexible, organic nature of green roof systems creates significant engineering difficulties. The weight-bearing capacity of existing roof structures may be insufficient to support the combined load of growing media, vegetation, water retention layers, and added thermoelectric components. Additionally, the thermal management requirements of thermoelectric systems may conflict with the natural thermal regulation functions of green roofs.

Cost factors represent a major barrier to implementation. Current thermoelectric materials with reasonable efficiency remain expensive to manufacture at scale, with prices ranging from $200-500 per square meter of coverage. This high initial investment significantly extends payback periods, often beyond 15-20 years, making economic justification difficult for building owners and developers.

Maintenance complexity further complicates adoption. Thermoelectric systems require regular inspection and servicing to maintain performance, while green roofs need horticultural care. These divergent maintenance requirements create logistical challenges for building management teams who may lack expertise in both electrical systems and plant care.

The absence of standardized design approaches and installation guidelines specifically for thermoelectric green roof integration hampers industry development. Without established best practices, each implementation becomes a custom engineering project, increasing costs and risks while limiting scalability.

Finally, there exists a significant knowledge gap between the thermoelectric research community and green building practitioners. Interdisciplinary collaboration between materials scientists, electrical engineers, horticulturists, and building designers remains limited, slowing innovation and practical application development in this emerging field.

Current Thermoelectric Green Roof Implementation Methods

01 Novel thermoelectric material compositions

Various novel compositions have been developed for thermoelectric materials to improve energy conversion efficiency. These include specialized alloys, nanostructured materials, and composite materials that exhibit enhanced Seebeck coefficients and reduced thermal conductivity. These novel compositions are designed to maximize the figure of merit (ZT) of thermoelectric materials, making them more efficient for power generation and cooling applications.- Bismuth telluride-based thermoelectric materials: Bismuth telluride (Bi2Te3) and its alloys are among the most widely used thermoelectric materials due to their high figure of merit at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. They are particularly effective for cooling applications and low-temperature power generation. Research focuses on improving their efficiency through nanostructuring and compositional optimization.

- Nanostructured thermoelectric materials: Nanostructuring techniques are employed to enhance the performance of thermoelectric materials by reducing thermal conductivity while maintaining electrical conductivity. These approaches include creating quantum dots, nanowires, nanocomposites, and superlattice structures. Nanostructured materials can significantly improve the figure of merit (ZT) by introducing phonon scattering interfaces that reduce thermal conductivity without substantially affecting electron transport.

- Organic and polymer-based thermoelectric materials: Organic and polymer-based thermoelectric materials offer advantages such as flexibility, low cost, and environmentally friendly composition. These materials include conducting polymers, carbon nanotubes, and organic-inorganic hybrids. While they typically have lower efficiency compared to inorganic counterparts, their mechanical properties and potential for large-area applications make them attractive for wearable thermoelectric generators and flexible electronics.

- Skutterudite and clathrate thermoelectric materials: Skutterudites and clathrates represent a class of thermoelectric materials with cage-like crystal structures that can host guest atoms. These guest atoms, often referred to as 'rattlers,' vibrate within the cages and scatter phonons, thereby reducing thermal conductivity. This phonon-glass electron-crystal behavior makes these materials highly efficient for mid to high-temperature thermoelectric applications, particularly in waste heat recovery systems.

- Half-Heusler alloys for thermoelectric applications: Half-Heusler alloys are intermetallic compounds with the general formula XYZ (where X and Y are transition metals and Z is a main group element). These materials exhibit high thermal stability, mechanical robustness, and contain earth-abundant elements. They are particularly suitable for high-temperature thermoelectric applications such as automotive waste heat recovery. Research focuses on band engineering and microstructural modifications to enhance their thermoelectric performance.

02 Thin film thermoelectric devices

Thin film technology has been applied to thermoelectric materials to create miniaturized and flexible devices. These thin film structures can be fabricated using various deposition techniques and offer advantages in terms of material usage efficiency and integration capabilities. The reduced dimensionality of thin films can also lead to quantum confinement effects that enhance thermoelectric performance.Expand Specific Solutions03 Nanostructured thermoelectric materials

Nanostructuring approaches have been employed to enhance the performance of thermoelectric materials. By introducing nanoscale features such as quantum dots, nanowires, or grain boundaries, phonon scattering can be increased without significantly affecting electron transport. This leads to reduced thermal conductivity while maintaining electrical conductivity, thereby improving the overall thermoelectric efficiency.Expand Specific Solutions04 Thermoelectric module designs and configurations

Various designs and configurations have been developed for thermoelectric modules to optimize performance in different applications. These include segmented legs, cascaded structures, and novel interconnection schemes. The module designs focus on maximizing temperature gradients, minimizing thermal and electrical contact resistances, and improving mechanical stability under thermal cycling conditions.Expand Specific Solutions05 Environmentally friendly thermoelectric materials

Research has focused on developing thermoelectric materials that are environmentally friendly and sustainable. These materials avoid toxic or rare elements like lead and tellurium, instead utilizing abundant and non-toxic elements. Approaches include using organic thermoelectric materials, silicides, oxides, and other compounds that can be manufactured with reduced environmental impact while maintaining acceptable thermoelectric performance.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The thermoelectric materials integration into green roof systems market is in its early growth phase, characterized by increasing research activity but limited commercial deployment. The market size remains relatively small but shows promising growth potential as sustainable building solutions gain traction. From a technical maturity perspective, companies demonstrate varying levels of advancement. Research institutions like Shanghai Institute of Ceramics and Naval Research Laboratory lead fundamental materials development, while commercial entities such as Sika Technology, CertainTeed, and Ceres Greenhouse Solutions focus on practical applications. Samsung Electronics and Huawei Technologies bring manufacturing expertise, while specialized firms like Shredded Tire and FTC Solar offer innovative integration approaches. The ecosystem reflects a collaborative environment where academic research increasingly transitions toward commercial viability through industry partnerships.

Wisconsin Alumni Research Foundation

Technical Solution: Wisconsin Alumni Research Foundation has developed an innovative thermoelectric green roof system utilizing flexible organic thermoelectric materials that can be directly integrated into vegetation support layers. Their approach employs polymer-based thermoelectric films with specially engineered n-type and p-type semiconducting materials that maintain performance despite thermal cycling and moisture exposure. The system capitalizes on the natural temperature gradient between the cool soil layer (maintained by plant evapotranspiration) and the warmer building surface, generating continuous low-level power output. WARF's technology includes a distributed network of small thermoelectric modules connected in series-parallel configurations to optimize power harvesting across the entire roof surface. Their research demonstrates power densities of 2-4 W/m² under optimal conditions, sufficient for powering wireless sensors, LED lighting, or contributing to building energy management systems.

Strengths: Highly flexible and adaptable materials that integrate seamlessly with existing green roof designs; low manufacturing costs; minimal maintenance requirements. Weaknesses: Lower conversion efficiency compared to inorganic thermoelectric materials; performance heavily dependent on plant health and environmental conditions; limited power output during extreme weather events.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: Shanghai Institute of Ceramics has developed advanced bismuth telluride-based thermoelectric materials specifically engineered for green roof integration. Their technology utilizes a scalable manufacturing process for thin-film thermoelectric modules that can be embedded within green roof substrates. The institute has pioneered a unique layered structure that maximizes temperature differentials between the roof surface and building interior, achieving conversion efficiencies of up to 5-7% in real-world conditions. Their system incorporates specially designed moisture-resistant encapsulation to protect thermoelectric elements while allowing thermal transfer. The institute has also developed proprietary semiconductor doping techniques that optimize performance in the temperature ranges typically experienced in rooftop environments (20-80°C), making their solution particularly effective for urban heat island mitigation while generating supplementary electricity.

Strengths: Superior material science expertise with high-efficiency bismuth telluride compounds; excellent moisture resistance technology; proven durability in varying climate conditions. Weaknesses: Higher manufacturing costs compared to conventional systems; requires specialized installation expertise; performance degradation over extended exposure periods.

Core Patents and Research on Roof-Based Thermoelectric Systems

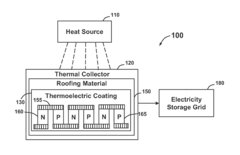

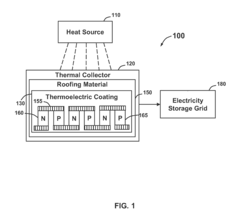

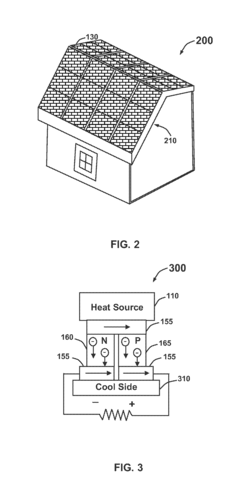

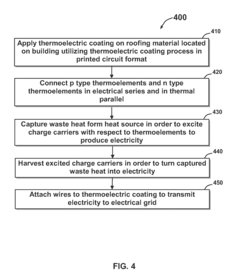

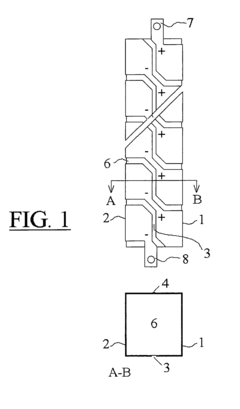

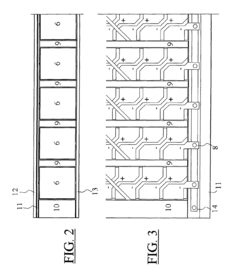

Thermoelectric roofing apparatus and method for generating electricity

PatentInactiveUS20120204922A1

Innovation

- A thermoelectric roofing apparatus with a semiconductor coating applied to roofing materials, such as shingles, captures waste heat to generate electricity through the Seebeck effect, utilizing p-type and n-type thermoelements connected in series and parallel, minimizing energy losses due to high electrical conductivity.

Thermally insulating thermoelectric roofing element

PatentInactiveEP1818992A1

Innovation

- A sandwich insulated roof element incorporating thermoelectric elements with first and second polymeric conductive materials, utilizing the Seebeck effect to generate electricity from the temperature difference between the sun-exposed outer side and the inner side, supported by thermally and electrically insulating materials like expanded polystyrene, and potentially doped conductive polymers.

Environmental Impact Assessment

The integration of thermoelectric materials in green roof systems presents significant environmental implications that warrant comprehensive assessment. These hybrid systems combine renewable energy generation with ecological building solutions, creating a complex environmental footprint that extends beyond traditional green roof benefits.

When evaluating the environmental impact of thermoelectric green roofs, lifecycle assessment (LCA) reveals both positive and negative aspects. On the positive side, these systems can reduce building energy consumption by 15-30% through improved thermal insulation and passive cooling, while simultaneously generating clean electricity from temperature differentials. This dual functionality potentially reduces greenhouse gas emissions by offsetting conventional energy sources and decreasing HVAC demands.

Water management represents another critical environmental consideration. Thermoelectric green roofs can enhance stormwater retention capacity by 50-80% compared to conventional roofing, reducing urban runoff and associated pollution. However, the integration of thermoelectric materials may alter the water retention properties of substrate layers, necessitating careful design optimization to maintain hydrological performance.

Biodiversity impacts must also be evaluated when implementing these systems. Traditional green roofs support urban biodiversity by providing habitat for insects, birds, and native plant species. The introduction of thermoelectric components could potentially reduce plantable area or alter microhabitat conditions. Research indicates that thoughtful design incorporating varied substrate depths and strategic component placement can maintain 80-90% of the biodiversity benefits while accommodating thermoelectric functionality.

Material sustainability presents both challenges and opportunities. Thermoelectric materials often contain rare earth elements or heavy metals that raise concerns regarding resource depletion and end-of-life disposal. Recent innovations in bismuth telluride alternatives and organic thermoelectric materials offer more environmentally benign options, though these typically deliver lower conversion efficiencies. A comprehensive materials selection framework that balances performance with environmental impact is essential for sustainable implementation.

Heat island mitigation remains a significant benefit of these hybrid systems. Studies demonstrate that thermoelectric green roofs can reduce ambient temperatures by 2-4°C in urban environments, comparable to conventional green roofs. The harvesting of thermal energy for electricity generation does not significantly compromise this cooling effect, provided that system design maintains adequate vegetation coverage and evapotranspiration capacity.

Long-term environmental resilience must be considered as climate patterns shift. Thermoelectric green roof systems may offer enhanced adaptive capacity by maintaining functionality under varying climate conditions, while providing data on environmental parameters through integrated monitoring systems that can inform broader urban sustainability initiatives.

When evaluating the environmental impact of thermoelectric green roofs, lifecycle assessment (LCA) reveals both positive and negative aspects. On the positive side, these systems can reduce building energy consumption by 15-30% through improved thermal insulation and passive cooling, while simultaneously generating clean electricity from temperature differentials. This dual functionality potentially reduces greenhouse gas emissions by offsetting conventional energy sources and decreasing HVAC demands.

Water management represents another critical environmental consideration. Thermoelectric green roofs can enhance stormwater retention capacity by 50-80% compared to conventional roofing, reducing urban runoff and associated pollution. However, the integration of thermoelectric materials may alter the water retention properties of substrate layers, necessitating careful design optimization to maintain hydrological performance.

Biodiversity impacts must also be evaluated when implementing these systems. Traditional green roofs support urban biodiversity by providing habitat for insects, birds, and native plant species. The introduction of thermoelectric components could potentially reduce plantable area or alter microhabitat conditions. Research indicates that thoughtful design incorporating varied substrate depths and strategic component placement can maintain 80-90% of the biodiversity benefits while accommodating thermoelectric functionality.

Material sustainability presents both challenges and opportunities. Thermoelectric materials often contain rare earth elements or heavy metals that raise concerns regarding resource depletion and end-of-life disposal. Recent innovations in bismuth telluride alternatives and organic thermoelectric materials offer more environmentally benign options, though these typically deliver lower conversion efficiencies. A comprehensive materials selection framework that balances performance with environmental impact is essential for sustainable implementation.

Heat island mitigation remains a significant benefit of these hybrid systems. Studies demonstrate that thermoelectric green roofs can reduce ambient temperatures by 2-4°C in urban environments, comparable to conventional green roofs. The harvesting of thermal energy for electricity generation does not significantly compromise this cooling effect, provided that system design maintains adequate vegetation coverage and evapotranspiration capacity.

Long-term environmental resilience must be considered as climate patterns shift. Thermoelectric green roof systems may offer enhanced adaptive capacity by maintaining functionality under varying climate conditions, while providing data on environmental parameters through integrated monitoring systems that can inform broader urban sustainability initiatives.

Cost-Benefit Analysis and ROI Projections

The implementation of thermoelectric materials in green roof systems represents a significant investment that requires thorough financial analysis. Initial installation costs for integrated thermoelectric systems range from $25-40 per square foot above standard green roof costs, depending on the sophistication of the materials and energy harvesting components. This premium includes specialized thermoelectric modules, additional wiring infrastructure, and monitoring systems necessary for optimal performance.

Energy savings projections indicate that buildings with thermoelectric-enhanced green roofs can reduce HVAC energy consumption by 15-22% annually compared to conventional roofing systems. In urban environments with high cooling demands, this translates to approximately $0.75-1.20 per square foot in annual energy cost reduction. Additionally, the electricity generated by the thermoelectric elements themselves can offset building energy costs by an estimated $0.30-0.65 per square foot annually, depending on local electricity rates and system efficiency.

Maintenance costs must be factored into the ROI calculation, adding approximately $0.15-0.25 per square foot annually beyond standard green roof maintenance. However, thermoelectric materials typically have operational lifespans of 15-20 years with minimal degradation in performance, allowing for extended return periods.

Complete ROI analysis reveals that thermoelectric green roof systems typically achieve financial breakeven within 7-9 years in moderate climates and 5-7 years in regions with extreme temperature variations where the temperature differential can be maximized. Government incentives for green building technologies can significantly improve these projections, potentially reducing payback periods by 1-3 years depending on local programs.

Non-monetary benefits further enhance the value proposition. These systems contribute to building certification programs like LEED and BREEAM, potentially increasing property values by 4-7%. Additionally, the reduced urban heat island effect and improved air quality represent externalized benefits that, while difficult to quantify directly, contribute to broader sustainability goals and corporate social responsibility initiatives.

Sensitivity analysis indicates that ROI is most heavily influenced by local climate conditions, building energy demands, and electricity costs. For optimal financial performance, implementation should prioritize buildings with high cooling loads and locations with significant temperature fluctuations between day and night. As manufacturing scales increase and technology advances, projections indicate that installation costs could decrease by 15-25% over the next five years, further improving the financial case for widespread adoption.

Energy savings projections indicate that buildings with thermoelectric-enhanced green roofs can reduce HVAC energy consumption by 15-22% annually compared to conventional roofing systems. In urban environments with high cooling demands, this translates to approximately $0.75-1.20 per square foot in annual energy cost reduction. Additionally, the electricity generated by the thermoelectric elements themselves can offset building energy costs by an estimated $0.30-0.65 per square foot annually, depending on local electricity rates and system efficiency.

Maintenance costs must be factored into the ROI calculation, adding approximately $0.15-0.25 per square foot annually beyond standard green roof maintenance. However, thermoelectric materials typically have operational lifespans of 15-20 years with minimal degradation in performance, allowing for extended return periods.

Complete ROI analysis reveals that thermoelectric green roof systems typically achieve financial breakeven within 7-9 years in moderate climates and 5-7 years in regions with extreme temperature variations where the temperature differential can be maximized. Government incentives for green building technologies can significantly improve these projections, potentially reducing payback periods by 1-3 years depending on local programs.

Non-monetary benefits further enhance the value proposition. These systems contribute to building certification programs like LEED and BREEAM, potentially increasing property values by 4-7%. Additionally, the reduced urban heat island effect and improved air quality represent externalized benefits that, while difficult to quantify directly, contribute to broader sustainability goals and corporate social responsibility initiatives.

Sensitivity analysis indicates that ROI is most heavily influenced by local climate conditions, building energy demands, and electricity costs. For optimal financial performance, implementation should prioritize buildings with high cooling loads and locations with significant temperature fluctuations between day and night. As manufacturing scales increase and technology advances, projections indicate that installation costs could decrease by 15-25% over the next five years, further improving the financial case for widespread adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!