Superior Bonding Techniques for Complex Thermoelectric Assemblies

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Bonding Evolution and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century, with the Seebeck effect identified in 1821 and the Peltier effect in 1834. These discoveries laid the foundation for modern thermoelectric devices that convert temperature differentials into electrical energy and vice versa. The evolution of bonding techniques for thermoelectric assemblies has been particularly critical, as these interfaces directly impact device efficiency, reliability, and lifespan.

In the 1950s and 1960s, thermoelectric applications were primarily limited to niche areas like space exploration, where reliability outweighed efficiency concerns. Bonding techniques during this era relied heavily on soldering with lead-based alloys, which offered adequate but suboptimal thermal and electrical conductivity at interfaces. The 1970s through 1990s saw incremental improvements with the introduction of silver-filled epoxies and early diffusion bonding approaches.

The 2000s marked a significant turning point with the emergence of nanotechnology and advanced materials science. This period introduced novel bonding methods including transient liquid phase bonding, which creates joints with melting points higher than the original bonding temperature, and nanoparticle-enhanced solders that dramatically improved thermal conductivity at interfaces.

Current technological trends focus on addressing the unique challenges posed by complex thermoelectric assemblies, particularly those with multiple material interfaces and operating under extreme temperature gradients. Modern bonding techniques must accommodate the coefficient of thermal expansion (CTE) mismatch between dissimilar materials while maintaining excellent thermal and electrical conductivity across a wide temperature range.

The primary objectives of advanced thermoelectric bonding research include developing techniques that minimize interfacial thermal resistance, which can account for up to 30% of efficiency losses in thermoelectric systems. Additionally, researchers aim to create bonds that maintain integrity under thermal cycling conditions, with target lifespans exceeding 100,000 cycles for automotive and industrial applications.

Another critical goal is the development of environmentally sustainable bonding methods that eliminate toxic materials like lead while maintaining or improving performance characteristics. This aligns with global regulatory trends toward lead-free electronics and sustainable manufacturing processes.

Looking forward, the field is moving toward integrated design approaches where bonding techniques are considered from the earliest stages of thermoelectric module development rather than as an afterthought. This holistic approach promises to yield assemblies with unprecedented efficiency and reliability, potentially enabling thermoelectric technology to expand beyond current niche applications into mainstream energy harvesting and cooling solutions.

In the 1950s and 1960s, thermoelectric applications were primarily limited to niche areas like space exploration, where reliability outweighed efficiency concerns. Bonding techniques during this era relied heavily on soldering with lead-based alloys, which offered adequate but suboptimal thermal and electrical conductivity at interfaces. The 1970s through 1990s saw incremental improvements with the introduction of silver-filled epoxies and early diffusion bonding approaches.

The 2000s marked a significant turning point with the emergence of nanotechnology and advanced materials science. This period introduced novel bonding methods including transient liquid phase bonding, which creates joints with melting points higher than the original bonding temperature, and nanoparticle-enhanced solders that dramatically improved thermal conductivity at interfaces.

Current technological trends focus on addressing the unique challenges posed by complex thermoelectric assemblies, particularly those with multiple material interfaces and operating under extreme temperature gradients. Modern bonding techniques must accommodate the coefficient of thermal expansion (CTE) mismatch between dissimilar materials while maintaining excellent thermal and electrical conductivity across a wide temperature range.

The primary objectives of advanced thermoelectric bonding research include developing techniques that minimize interfacial thermal resistance, which can account for up to 30% of efficiency losses in thermoelectric systems. Additionally, researchers aim to create bonds that maintain integrity under thermal cycling conditions, with target lifespans exceeding 100,000 cycles for automotive and industrial applications.

Another critical goal is the development of environmentally sustainable bonding methods that eliminate toxic materials like lead while maintaining or improving performance characteristics. This aligns with global regulatory trends toward lead-free electronics and sustainable manufacturing processes.

Looking forward, the field is moving toward integrated design approaches where bonding techniques are considered from the earliest stages of thermoelectric module development rather than as an afterthought. This holistic approach promises to yield assemblies with unprecedented efficiency and reliability, potentially enabling thermoelectric technology to expand beyond current niche applications into mainstream energy harvesting and cooling solutions.

Market Analysis for Advanced Thermoelectric Systems

The global thermoelectric systems market is experiencing robust growth, driven by increasing demand for energy-efficient solutions across multiple industries. Current market valuations place the advanced thermoelectric systems sector at approximately 600 million USD in 2023, with projections indicating a compound annual growth rate of 8.2% through 2030. This growth trajectory is particularly significant in regions with stringent energy efficiency regulations, including Europe, North America, and parts of Asia.

The automotive sector represents the largest market segment for advanced thermoelectric systems, accounting for nearly 35% of total market share. This dominance stems from the automotive industry's push toward electrification and the need for efficient thermal management systems in both conventional and electric vehicles. Waste heat recovery applications in internal combustion engines and temperature regulation in electric vehicle battery systems are primary drivers in this segment.

Industrial applications constitute the second-largest market segment at 28%, where thermoelectric systems are increasingly deployed for precision temperature control in manufacturing processes and waste heat recovery in energy-intensive industries. The aerospace and defense sectors, though smaller in overall market share at 15%, demonstrate the highest willingness to invest in premium bonding solutions for thermoelectric assemblies due to their extreme reliability requirements and performance demands.

Consumer electronics and medical devices represent emerging high-growth segments, with annual growth rates exceeding 10%. These applications demand miniaturized thermoelectric solutions with superior bonding techniques to ensure reliability in compact form factors. The medical device segment in particular values the precise temperature control capabilities that advanced thermoelectric systems offer for diagnostic equipment and patient care devices.

Geographically, North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate over the next five years due to rapid industrialization, increasing automotive production, and growing consumer electronics manufacturing. China and South Korea are particularly notable markets within this region, with domestic manufacturers rapidly developing capabilities in advanced thermoelectric technologies.

Market analysis indicates that superior bonding techniques represent a critical differentiator in the competitive landscape. End-users across all segments demonstrate willingness to pay premium prices for thermoelectric assemblies with proven reliability, thermal cycling resistance, and extended operational lifespans. This trend is creating significant opportunities for materials science innovations and advanced manufacturing processes that can deliver enhanced bonding solutions for complex thermoelectric assemblies.

The automotive sector represents the largest market segment for advanced thermoelectric systems, accounting for nearly 35% of total market share. This dominance stems from the automotive industry's push toward electrification and the need for efficient thermal management systems in both conventional and electric vehicles. Waste heat recovery applications in internal combustion engines and temperature regulation in electric vehicle battery systems are primary drivers in this segment.

Industrial applications constitute the second-largest market segment at 28%, where thermoelectric systems are increasingly deployed for precision temperature control in manufacturing processes and waste heat recovery in energy-intensive industries. The aerospace and defense sectors, though smaller in overall market share at 15%, demonstrate the highest willingness to invest in premium bonding solutions for thermoelectric assemblies due to their extreme reliability requirements and performance demands.

Consumer electronics and medical devices represent emerging high-growth segments, with annual growth rates exceeding 10%. These applications demand miniaturized thermoelectric solutions with superior bonding techniques to ensure reliability in compact form factors. The medical device segment in particular values the precise temperature control capabilities that advanced thermoelectric systems offer for diagnostic equipment and patient care devices.

Geographically, North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate over the next five years due to rapid industrialization, increasing automotive production, and growing consumer electronics manufacturing. China and South Korea are particularly notable markets within this region, with domestic manufacturers rapidly developing capabilities in advanced thermoelectric technologies.

Market analysis indicates that superior bonding techniques represent a critical differentiator in the competitive landscape. End-users across all segments demonstrate willingness to pay premium prices for thermoelectric assemblies with proven reliability, thermal cycling resistance, and extended operational lifespans. This trend is creating significant opportunities for materials science innovations and advanced manufacturing processes that can deliver enhanced bonding solutions for complex thermoelectric assemblies.

Current Bonding Technologies and Challenges

The current landscape of bonding technologies for thermoelectric assemblies presents a complex array of established methods, each with distinct advantages and limitations. Traditional soldering techniques using lead-based alloys have been the industry standard for decades due to their reliability and cost-effectiveness. However, environmental regulations such as RoHS (Restriction of Hazardous Substances) have accelerated the transition toward lead-free alternatives, which typically require higher processing temperatures and often exhibit inferior wetting properties.

Mechanical bonding methods, including compression and spring-loaded mechanisms, offer simplicity but frequently struggle with thermal cycling stability in complex thermoelectric assemblies. These approaches can lead to increased thermal resistance at interfaces and potential mechanical failure under repeated thermal expansion and contraction cycles, particularly problematic for thermoelectric generators operating across substantial temperature gradients.

Brazing techniques utilizing silver-based and gold-based fillers provide excellent electrical conductivity and thermal performance but introduce significant cost implications for large-scale manufacturing. The high processing temperatures required for brazing (typically 450-850°C) can also induce thermal stress and potential degradation in sensitive thermoelectric materials, limiting their applicability for certain semiconductor-based thermoelectric elements.

Conductive adhesives represent an emerging alternative, with silver-filled epoxies gaining traction in specialized applications. While these materials offer processing advantages through lower curing temperatures, they generally exhibit 2-5 times higher electrical resistivity compared to metallic bonds, creating efficiency challenges for thermoelectric systems where minimizing parasitic resistance is critical.

The fundamental challenge across all bonding technologies remains achieving simultaneously optimal thermal conductivity, electrical conductivity, and mechanical reliability. Current solutions typically excel in one or two properties while compromising others. For instance, indium-based solders offer excellent thermal conductivity but poor mechanical strength, while conductive polymers provide mechanical flexibility but inferior thermal performance.

Interface stability presents another significant hurdle, with diffusion and intermetallic compound formation at bonding interfaces potentially degrading performance over time. This is particularly problematic in thermoelectric applications where operating temperatures can accelerate diffusion processes and chemical reactions between bonding materials and thermoelectric elements.

Manufacturing scalability constitutes a final major challenge, as many laboratory-demonstrated bonding techniques prove difficult to implement in high-volume production environments. Techniques requiring precise temperature control, specialized atmospheres, or extended processing times face significant barriers to industrial adoption despite promising technical performance.

Mechanical bonding methods, including compression and spring-loaded mechanisms, offer simplicity but frequently struggle with thermal cycling stability in complex thermoelectric assemblies. These approaches can lead to increased thermal resistance at interfaces and potential mechanical failure under repeated thermal expansion and contraction cycles, particularly problematic for thermoelectric generators operating across substantial temperature gradients.

Brazing techniques utilizing silver-based and gold-based fillers provide excellent electrical conductivity and thermal performance but introduce significant cost implications for large-scale manufacturing. The high processing temperatures required for brazing (typically 450-850°C) can also induce thermal stress and potential degradation in sensitive thermoelectric materials, limiting their applicability for certain semiconductor-based thermoelectric elements.

Conductive adhesives represent an emerging alternative, with silver-filled epoxies gaining traction in specialized applications. While these materials offer processing advantages through lower curing temperatures, they generally exhibit 2-5 times higher electrical resistivity compared to metallic bonds, creating efficiency challenges for thermoelectric systems where minimizing parasitic resistance is critical.

The fundamental challenge across all bonding technologies remains achieving simultaneously optimal thermal conductivity, electrical conductivity, and mechanical reliability. Current solutions typically excel in one or two properties while compromising others. For instance, indium-based solders offer excellent thermal conductivity but poor mechanical strength, while conductive polymers provide mechanical flexibility but inferior thermal performance.

Interface stability presents another significant hurdle, with diffusion and intermetallic compound formation at bonding interfaces potentially degrading performance over time. This is particularly problematic in thermoelectric applications where operating temperatures can accelerate diffusion processes and chemical reactions between bonding materials and thermoelectric elements.

Manufacturing scalability constitutes a final major challenge, as many laboratory-demonstrated bonding techniques prove difficult to implement in high-volume production environments. Techniques requiring precise temperature control, specialized atmospheres, or extended processing times face significant barriers to industrial adoption despite promising technical performance.

State-of-the-Art Bonding Solutions

01 Ultrasonic bonding techniques and quality assessment

Ultrasonic bonding is a technique that uses high-frequency vibrations to create bonds between materials. The quality of these bonds can be assessed through various methods including real-time monitoring systems that analyze the ultrasonic parameters during the bonding process. These systems can detect variations in bond strength, consistency, and potential defects, allowing for immediate adjustments to improve bonding quality.- Bonding quality assessment techniques: Various techniques are employed to assess the quality of bonds in materials and components. These include non-destructive testing methods, optical inspection systems, and automated quality control processes that can detect defects, voids, or weaknesses in bonded interfaces. Advanced imaging and sensing technologies allow for real-time monitoring of bond integrity, ensuring consistent quality in manufacturing processes.

- Wire bonding techniques for semiconductor devices: Wire bonding is a critical technique for creating electrical connections in semiconductor devices. The process involves forming bonds between fine metal wires and connection pads on semiconductor chips. Various methods such as thermosonic, ultrasonic, and thermocompression bonding are used to create reliable electrical connections. The quality of these bonds directly impacts device performance and reliability, with factors such as bond strength, loop height, and wire placement being crucial parameters.

- Adhesive bonding methods and quality control: Adhesive bonding involves joining materials using chemical substances that adhere to surfaces and harden to create strong bonds. The quality of adhesive bonds depends on surface preparation, adhesive selection, curing conditions, and application techniques. Quality control methods include destructive testing, environmental stress testing, and analytical techniques to evaluate bond strength and durability. Proper process control ensures consistent adhesive distribution and optimal bond performance across various industrial applications.

- Thermal bonding processes and quality factors: Thermal bonding techniques utilize heat to join materials through melting, diffusion, or chemical reactions. These processes include soldering, brazing, diffusion bonding, and thermoplastic welding. The quality of thermal bonds is influenced by temperature control, heating rate, cooling conditions, and material compatibility. Proper thermal profiles prevent defects such as voids, cracks, or weak interfaces. Advanced monitoring systems can track thermal parameters in real-time to ensure optimal bond formation and structural integrity.

- Advanced bonding quality verification systems: Modern bonding quality verification systems incorporate automated inspection technologies, machine learning algorithms, and integrated sensors to provide comprehensive bond quality assessment. These systems can detect subtle defects that might be missed by conventional methods, analyze bond characteristics across multiple parameters, and provide statistical process control data. Real-time monitoring capabilities allow for immediate process adjustments, reducing defects and ensuring consistent bond quality in high-volume manufacturing environments.

02 Wire bonding methods for semiconductor devices

Wire bonding is a critical process in semiconductor packaging that connects integrated circuits to their packaging. Various techniques such as ball bonding, wedge bonding, and thermosonic bonding are employed to create reliable electrical connections. The quality of these bonds is essential for device performance and reliability, with factors such as bond strength, loop height, and wire deformation being key quality indicators that can be measured and controlled through specialized equipment and processes.Expand Specific Solutions03 Non-destructive testing methods for bond quality

Non-destructive testing methods allow for the evaluation of bond quality without damaging the bonded components. These techniques include acoustic microscopy, X-ray inspection, thermal imaging, and electrical testing. By analyzing parameters such as bond interface characteristics, void formation, and stress distribution, these methods provide valuable insights into bond integrity and reliability without compromising the structure of the bonded materials.Expand Specific Solutions04 Adhesive bonding technologies and quality control

Adhesive bonding involves joining materials using chemical adhesives, with quality dependent on proper surface preparation, adhesive selection, and curing conditions. Quality control methods include monitoring cure parameters, testing bond strength through mechanical tests, and evaluating environmental resistance. Advanced techniques such as spectroscopic analysis and thermal profiling help ensure consistent adhesive distribution and optimal curing, resulting in high-quality bonds that meet performance requirements across various industries.Expand Specific Solutions05 Automated bonding systems with integrated quality monitoring

Automated bonding systems incorporate advanced robotics and control systems to perform precise bonding operations with minimal human intervention. These systems often include integrated quality monitoring features such as machine vision inspection, force feedback control, and real-time process parameter analysis. By continuously monitoring bonding parameters and making automatic adjustments, these systems can maintain consistent bond quality while increasing production efficiency and reducing defect rates.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermoelectric assembly bonding techniques market is currently in a growth phase, with increasing demand driven by automotive, electronics, and energy sectors. The market size is expanding at approximately 8-10% annually, reaching an estimated $2.5 billion globally. Technologically, the field shows varying maturity levels across applications. Industry leaders like Toyota Motor Corp. and Infineon Technologies AG have established advanced manufacturing capabilities, while specialized players such as TEGma AS and Resonac Corp. focus on high-performance bonding solutions. Research institutions including Fraunhofer-Gesellschaft and Industrial Technology Research Institute are advancing next-generation techniques. Companies like Dexerials Corp. and LINTEC Corp. are developing proprietary adhesive technologies specifically for complex thermoelectric assemblies, indicating a competitive landscape balancing established manufacturers and innovative specialists.

TEGma AS

Technical Solution: TEGma AS has developed proprietary bonding techniques specifically for thermoelectric generators (TEGs) that address the critical challenge of thermal cycling in complex assemblies. Their solution incorporates a multi-layer bonding approach using specialized metal alloys with matched coefficient of thermal expansion (CTE) to minimize stress at interfaces. The company's patented "ThermoFuse" technology creates metallurgical bonds between thermoelectric materials and heat exchangers that can withstand temperatures up to 600°C while maintaining electrical connectivity. TEGma's process utilizes pressure-assisted sintering combined with reactive bonding layers that form intermetallic compounds during the joining process, creating both mechanical strength and optimal electrical/thermal conductivity. Their manufacturing process has demonstrated bond strength retention above 95% after 10,000 thermal cycles, significantly outperforming conventional soldering techniques used in thermoelectric assemblies.

Strengths: Exceptional thermal cycling durability, high-temperature capability (up to 600°C), and minimal contact resistance at bonded interfaces. Their process is particularly effective for waste heat recovery applications in harsh environments. Weaknesses: The specialized materials and multi-step bonding process increase manufacturing costs and complexity compared to conventional methods, potentially limiting scalability for mass production.

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has pioneered advanced bonding solutions for thermoelectric assemblies through their "Thermal-Mechanical Adaptive Joining" (TMAJ) technology. This approach utilizes a gradient-structured bonding layer that accommodates thermal expansion mismatches between dissimilar materials in thermoelectric modules. ITRI's process incorporates nano-enhanced composite solders with dispersed ceramic nanoparticles that strengthen the bond while maintaining thermal and electrical conductivity. Their research has demonstrated that these specialized interfaces can reduce thermal contact resistance by up to 40% compared to conventional bonding methods. ITRI has also developed low-temperature sintering techniques using silver nanoparticles that form strong bonds at temperatures below 300°C, preventing damage to temperature-sensitive thermoelectric materials. The institute's comprehensive approach addresses both electrical and thermal interfaces, with specialized coatings that prevent oxidation and degradation at high operating temperatures.

Strengths: Exceptional thermal interface performance with significantly reduced contact resistance, compatibility with a wide range of thermoelectric materials, and proven reliability in thermal cycling tests. Weaknesses: The complex multi-material approach requires precise process control and specialized equipment, potentially limiting adoption by manufacturers without advanced materials processing capabilities.

Critical Patents in Thermoelectric Interface Materials

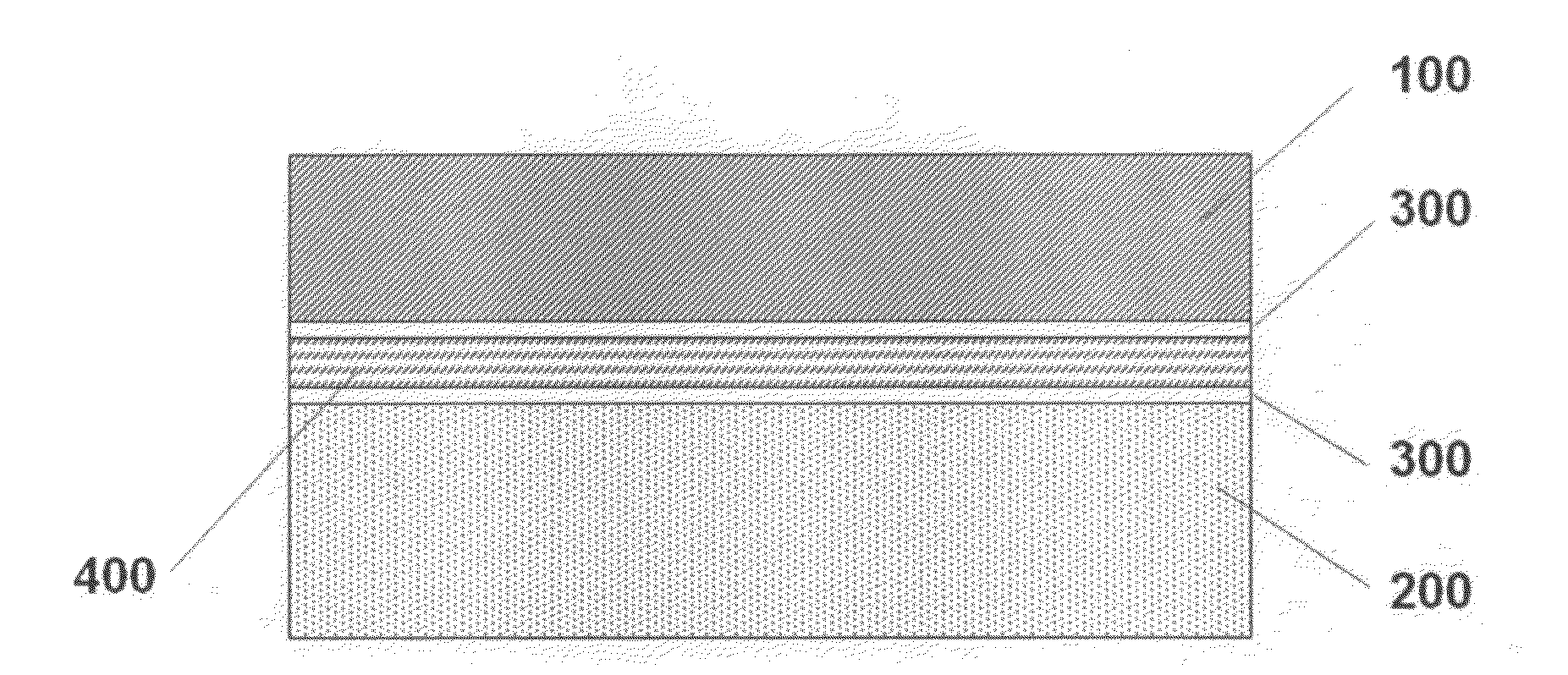

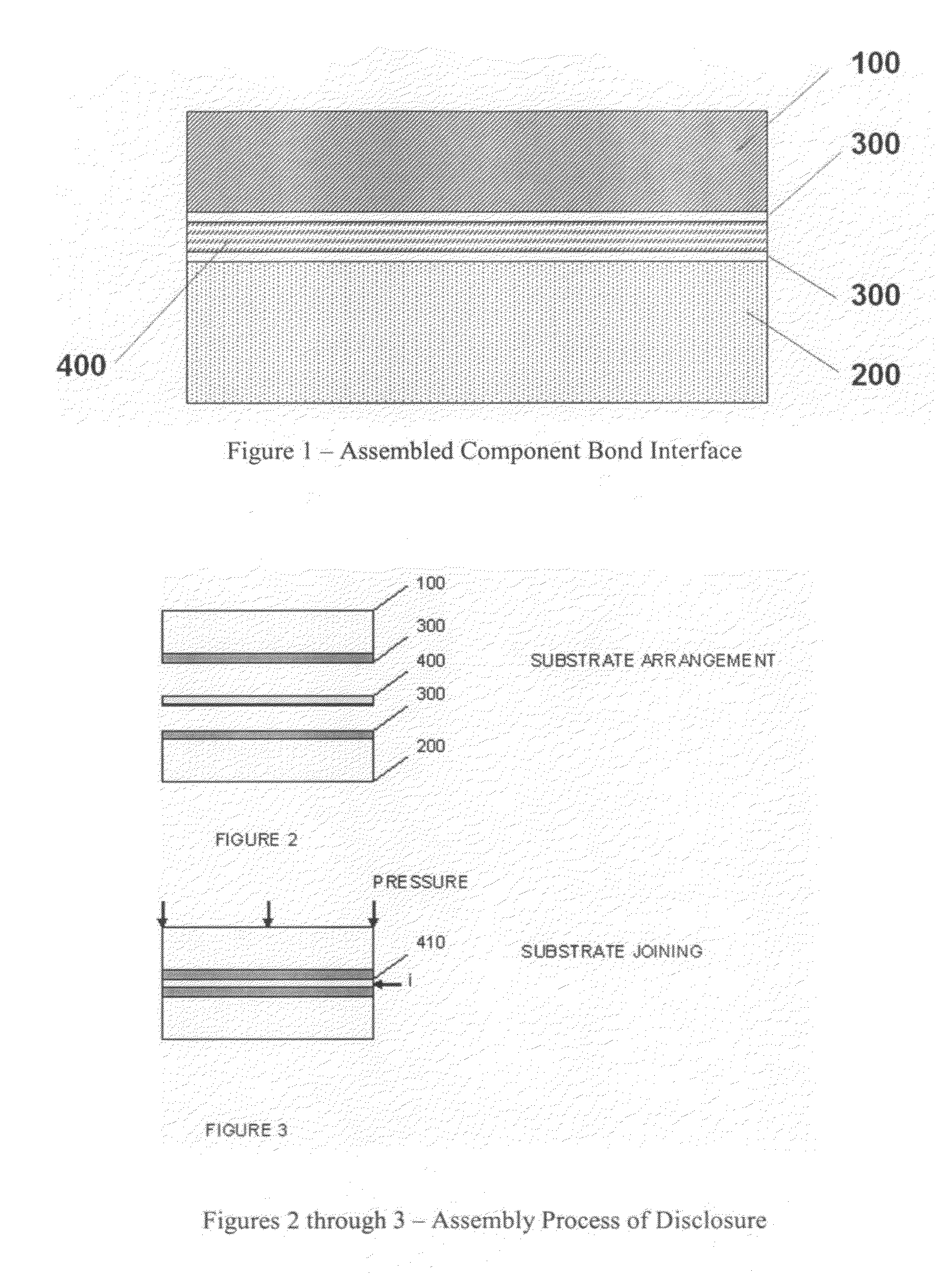

Method for creating thermal bonds while minimizing heating of parts

PatentInactiveUS20110114705A1

Innovation

- A continuous/semi-continuous ambient temperature solder bond using multi-layer nano-engineered reactive metal foils, such as Ni—Al or Ti—Al, which facilitate a controlled exothermic reaction to form a conductive bond without raising substrate temperatures significantly, utilizing a solder alloy and allowing for stress/strain compensation across dissimilar materials.

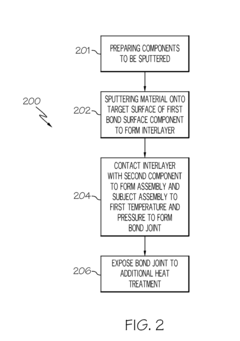

Methods of joining a first component and a second component to form a bond joint

PatentActiveEP2327501A1

Innovation

- A method involving sputtering a material with a nanocrystalline or amorphous microstructure onto the bond surfaces of components, forming an interlayer, and subjecting the assembly to heat and pressure to create a bond joint with a microstructure substantially identical to the components, reducing porosity and distortion while maintaining mechanical properties.

Thermal Reliability and Performance Testing Methodologies

Thermal reliability and performance testing methodologies are critical components in evaluating superior bonding techniques for complex thermoelectric assemblies. These methodologies provide quantitative measures to assess the durability and efficiency of bonding interfaces under various thermal conditions, ensuring long-term operational stability of thermoelectric devices.

The thermal cycling test represents a fundamental methodology, subjecting bonded assemblies to repeated temperature fluctuations between extreme points, typically ranging from -40°C to 150°C. This test simulates real-world operational conditions and reveals potential weaknesses in bond integrity over time. Advanced testing protocols implement programmable temperature profiles with controlled ramp rates to accurately replicate specific application environments.

Thermal shock testing provides complementary data by exposing assemblies to sudden temperature changes, often transferring specimens between hot and cold chambers with transition times under 10 seconds. This methodology specifically evaluates bond resilience against thermal expansion coefficient mismatches that can lead to catastrophic failure in thermoelectric systems.

High-temperature storage tests maintain bonded assemblies at elevated temperatures (typically 125-200°C) for extended periods, often 1000+ hours, to accelerate aging processes and identify potential degradation mechanisms. These tests are particularly valuable for applications in automotive and industrial environments where sustained high-temperature operation is expected.

Performance characterization methodologies include thermal impedance measurements using transient thermal testing equipment, which quantifies the thermal resistance across bonding interfaces with microsecond-level resolution. Laser flash analysis provides complementary data on thermal diffusivity through bonded layers, while infrared thermography enables non-destructive visualization of heat distribution patterns across bonding interfaces.

Mechanical testing methodologies complement thermal evaluations through shear strength tests, which apply lateral force to bonded interfaces until failure occurs. Die shear testing specifically measures the force required to separate bonded components, providing critical data on bond strength. Pull tests evaluate tensile strength by applying perpendicular force to the bonding plane.

Advanced reliability assessment incorporates accelerated life testing with Weibull statistical analysis to predict long-term performance and establish mean time to failure metrics. Combined environmental stress testing introduces additional factors such as humidity, vibration, and electrical loading to simulate complex real-world conditions and identify potential interaction effects between different stressors.

The thermal cycling test represents a fundamental methodology, subjecting bonded assemblies to repeated temperature fluctuations between extreme points, typically ranging from -40°C to 150°C. This test simulates real-world operational conditions and reveals potential weaknesses in bond integrity over time. Advanced testing protocols implement programmable temperature profiles with controlled ramp rates to accurately replicate specific application environments.

Thermal shock testing provides complementary data by exposing assemblies to sudden temperature changes, often transferring specimens between hot and cold chambers with transition times under 10 seconds. This methodology specifically evaluates bond resilience against thermal expansion coefficient mismatches that can lead to catastrophic failure in thermoelectric systems.

High-temperature storage tests maintain bonded assemblies at elevated temperatures (typically 125-200°C) for extended periods, often 1000+ hours, to accelerate aging processes and identify potential degradation mechanisms. These tests are particularly valuable for applications in automotive and industrial environments where sustained high-temperature operation is expected.

Performance characterization methodologies include thermal impedance measurements using transient thermal testing equipment, which quantifies the thermal resistance across bonding interfaces with microsecond-level resolution. Laser flash analysis provides complementary data on thermal diffusivity through bonded layers, while infrared thermography enables non-destructive visualization of heat distribution patterns across bonding interfaces.

Mechanical testing methodologies complement thermal evaluations through shear strength tests, which apply lateral force to bonded interfaces until failure occurs. Die shear testing specifically measures the force required to separate bonded components, providing critical data on bond strength. Pull tests evaluate tensile strength by applying perpendicular force to the bonding plane.

Advanced reliability assessment incorporates accelerated life testing with Weibull statistical analysis to predict long-term performance and establish mean time to failure metrics. Combined environmental stress testing introduces additional factors such as humidity, vibration, and electrical loading to simulate complex real-world conditions and identify potential interaction effects between different stressors.

Environmental Impact of Bonding Materials and Processes

The environmental impact of bonding materials and processes in thermoelectric assemblies represents a critical consideration in the sustainable development of these technologies. Traditional bonding methods often employ lead-based solders and adhesives containing volatile organic compounds (VOCs), which pose significant environmental hazards throughout their lifecycle. These materials can leach into soil and water systems during disposal, contributing to environmental contamination and potential bioaccumulation in living organisms. Furthermore, the manufacturing processes associated with conventional bonding techniques frequently require high temperatures and energy-intensive procedures, resulting in substantial carbon footprints.

Recent advancements in eco-friendly bonding alternatives have emerged as promising solutions to mitigate these environmental concerns. Bismuth-based and indium-based solders offer lead-free alternatives with comparable thermal and electrical performance characteristics while significantly reducing toxicity. Similarly, water-based adhesives and UV-curable epoxies have demonstrated reduced VOC emissions during application and curing processes, enhancing workplace safety and diminishing atmospheric pollution.

Life cycle assessment (LCA) studies of thermoelectric assembly bonding materials reveal that environmental impacts extend beyond the immediate manufacturing phase. The extraction of raw materials for traditional bonding compounds often involves environmentally destructive mining practices and energy-intensive refinement processes. Additionally, the end-of-life management of thermoelectric devices presents challenges in material recovery and recycling, particularly when hazardous bonding materials complicate disassembly and material separation.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns through legislation such as the European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in North America and Asia. These frameworks have accelerated industry transition toward greener bonding technologies and more sustainable manufacturing practices, though implementation costs and technical challenges remain significant barriers to widespread adoption.

Energy efficiency improvements in bonding processes represent another avenue for environmental impact reduction. Low-temperature bonding techniques, such as transient liquid phase sintering and pressure-assisted sintering, can substantially reduce energy consumption during manufacturing while maintaining or even enhancing bond integrity. These approaches not only decrease carbon emissions but also extend equipment lifespan and reduce maintenance requirements.

Waste management strategies specific to thermoelectric assembly production have evolved to address bonding material residues and byproducts. Closed-loop solvent recovery systems, material reclamation processes, and improved filtration technologies help minimize environmental discharge and promote circular economy principles within manufacturing facilities. These innovations demonstrate the industry's growing commitment to environmental stewardship throughout the product lifecycle.

Recent advancements in eco-friendly bonding alternatives have emerged as promising solutions to mitigate these environmental concerns. Bismuth-based and indium-based solders offer lead-free alternatives with comparable thermal and electrical performance characteristics while significantly reducing toxicity. Similarly, water-based adhesives and UV-curable epoxies have demonstrated reduced VOC emissions during application and curing processes, enhancing workplace safety and diminishing atmospheric pollution.

Life cycle assessment (LCA) studies of thermoelectric assembly bonding materials reveal that environmental impacts extend beyond the immediate manufacturing phase. The extraction of raw materials for traditional bonding compounds often involves environmentally destructive mining practices and energy-intensive refinement processes. Additionally, the end-of-life management of thermoelectric devices presents challenges in material recovery and recycling, particularly when hazardous bonding materials complicate disassembly and material separation.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns through legislation such as the European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in North America and Asia. These frameworks have accelerated industry transition toward greener bonding technologies and more sustainable manufacturing practices, though implementation costs and technical challenges remain significant barriers to widespread adoption.

Energy efficiency improvements in bonding processes represent another avenue for environmental impact reduction. Low-temperature bonding techniques, such as transient liquid phase sintering and pressure-assisted sintering, can substantially reduce energy consumption during manufacturing while maintaining or even enhancing bond integrity. These approaches not only decrease carbon emissions but also extend equipment lifespan and reduce maintenance requirements.

Waste management strategies specific to thermoelectric assembly production have evolved to address bonding material residues and byproducts. Closed-loop solvent recovery systems, material reclamation processes, and improved filtration technologies help minimize environmental discharge and promote circular economy principles within manufacturing facilities. These innovations demonstrate the industry's growing commitment to environmental stewardship throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!