Best Uses of Thermoelectric Materials in Zero-Emission Buildings

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Evolution and Zero-Emission Building Goals

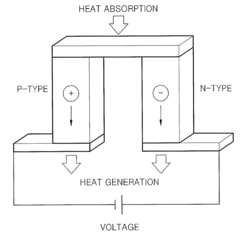

Thermoelectric materials have evolved significantly since their discovery in the early 19th century. The Seebeck effect, discovered in 1821, laid the foundation for thermoelectric technology by demonstrating that temperature differences between two electrical conductors can produce voltage. This was followed by the Peltier effect in 1834, which showed that passing an electric current through a junction of different materials could create a temperature difference, establishing the reciprocal relationship between electricity and heat transfer.

The mid-20th century marked a pivotal era with the development of semiconductor-based thermoelectric materials, significantly improving efficiency metrics. The introduction of the figure of merit ZT as a performance indicator in the 1950s provided a standardized way to evaluate thermoelectric materials, with higher values indicating better conversion efficiency. Traditional thermoelectric materials like bismuth telluride (Bi₂Te₃) achieved ZT values around 1, setting the benchmark for decades.

Recent advancements have focused on nanostructured materials and complex compounds, pushing ZT values beyond 2 in laboratory settings. Quantum dot superlattices, skutterudites, and half-Heusler alloys represent the cutting edge of thermoelectric research, offering improved performance through reduced thermal conductivity while maintaining electrical conductivity.

In parallel with material evolution, zero-emission building standards have emerged as a critical response to climate change challenges. The concept of net-zero energy buildings gained prominence in the early 2000s, with the European Union's Energy Performance of Buildings Directive (2010) and subsequent updates establishing progressive targets for building energy efficiency. The goal of achieving carbon neutrality in the building sector by 2050 has accelerated research into innovative energy technologies.

Thermoelectric materials align perfectly with zero-emission building goals through several pathways. They enable waste heat recovery from building systems, converting temperature gradients from HVAC systems, hot water pipes, and other thermal sources into usable electricity. They also facilitate temperature regulation without refrigerants, supporting passive cooling and heating strategies essential for energy-efficient buildings.

The integration of thermoelectric systems with renewable energy sources represents another promising direction, allowing for enhanced energy harvesting and storage capabilities in building envelopes. The ultimate technical objective is to develop high-efficiency, cost-effective thermoelectric solutions that can be seamlessly incorporated into building components, contributing significantly to energy self-sufficiency and carbon neutrality in the built environment.

The mid-20th century marked a pivotal era with the development of semiconductor-based thermoelectric materials, significantly improving efficiency metrics. The introduction of the figure of merit ZT as a performance indicator in the 1950s provided a standardized way to evaluate thermoelectric materials, with higher values indicating better conversion efficiency. Traditional thermoelectric materials like bismuth telluride (Bi₂Te₃) achieved ZT values around 1, setting the benchmark for decades.

Recent advancements have focused on nanostructured materials and complex compounds, pushing ZT values beyond 2 in laboratory settings. Quantum dot superlattices, skutterudites, and half-Heusler alloys represent the cutting edge of thermoelectric research, offering improved performance through reduced thermal conductivity while maintaining electrical conductivity.

In parallel with material evolution, zero-emission building standards have emerged as a critical response to climate change challenges. The concept of net-zero energy buildings gained prominence in the early 2000s, with the European Union's Energy Performance of Buildings Directive (2010) and subsequent updates establishing progressive targets for building energy efficiency. The goal of achieving carbon neutrality in the building sector by 2050 has accelerated research into innovative energy technologies.

Thermoelectric materials align perfectly with zero-emission building goals through several pathways. They enable waste heat recovery from building systems, converting temperature gradients from HVAC systems, hot water pipes, and other thermal sources into usable electricity. They also facilitate temperature regulation without refrigerants, supporting passive cooling and heating strategies essential for energy-efficient buildings.

The integration of thermoelectric systems with renewable energy sources represents another promising direction, allowing for enhanced energy harvesting and storage capabilities in building envelopes. The ultimate technical objective is to develop high-efficiency, cost-effective thermoelectric solutions that can be seamlessly incorporated into building components, contributing significantly to energy self-sufficiency and carbon neutrality in the built environment.

Market Analysis for Thermoelectric Solutions in Green Buildings

The thermoelectric solutions market in green buildings is experiencing significant growth, driven by increasing global emphasis on sustainability and zero-emission construction. Current market valuations indicate the global thermoelectric market reached approximately 593 million USD in 2022, with projections suggesting growth to 1.4 billion USD by 2030, representing a compound annual growth rate of 11.3%. Within this broader market, the building sector represents a rapidly expanding segment, particularly as zero-emission building standards become more prevalent worldwide.

Consumer demand for thermoelectric solutions in buildings is primarily driven by three factors: energy efficiency requirements, increasing electricity costs, and strengthening environmental regulations. Building owners and developers are increasingly seeking technologies that can harvest waste heat and convert it into usable electricity, thereby reducing overall energy consumption and operational costs. This trend is particularly pronounced in commercial buildings, where waste heat recovery can significantly impact energy expenditure.

Regional analysis reveals varying adoption rates and market potential. North America and Europe currently lead in implementation, with market penetration rates of approximately 15% and 18% respectively in new green building projects. The Asia-Pacific region, while currently showing lower adoption rates of around 8%, demonstrates the highest growth potential due to rapid urbanization and increasing government incentives for green building technologies.

Market segmentation shows distinct application areas within zero-emission buildings. HVAC systems represent the largest current application segment (42% of implementations), followed by water heating systems (27%), and building envelope applications (18%). Emerging applications in smart windows and thermoelectric-integrated building materials collectively account for the remaining market share and show promising growth trajectories.

Customer willingness to pay remains a critical market factor. Current payback periods for thermoelectric installations in buildings typically range from 4-7 years, depending on application type and regional energy costs. This timeframe represents a significant improvement from the 8-10 year payback periods observed five years ago, indicating improving economic viability.

Competitive analysis reveals a fragmented market with several specialized players rather than dominant forces. Key market participants include established thermoelectric material manufacturers expanding into building applications, specialized green building technology providers, and traditional building systems manufacturers incorporating thermoelectric capabilities into existing product lines. This competitive landscape suggests opportunities for strategic partnerships and consolidation as the market matures.

Market barriers include initial cost concerns, integration challenges with existing building systems, and limited awareness among building professionals regarding thermoelectric applications. However, these barriers are gradually diminishing as demonstration projects showcase successful implementations and as manufacturing scale increases, driving down component costs.

Consumer demand for thermoelectric solutions in buildings is primarily driven by three factors: energy efficiency requirements, increasing electricity costs, and strengthening environmental regulations. Building owners and developers are increasingly seeking technologies that can harvest waste heat and convert it into usable electricity, thereby reducing overall energy consumption and operational costs. This trend is particularly pronounced in commercial buildings, where waste heat recovery can significantly impact energy expenditure.

Regional analysis reveals varying adoption rates and market potential. North America and Europe currently lead in implementation, with market penetration rates of approximately 15% and 18% respectively in new green building projects. The Asia-Pacific region, while currently showing lower adoption rates of around 8%, demonstrates the highest growth potential due to rapid urbanization and increasing government incentives for green building technologies.

Market segmentation shows distinct application areas within zero-emission buildings. HVAC systems represent the largest current application segment (42% of implementations), followed by water heating systems (27%), and building envelope applications (18%). Emerging applications in smart windows and thermoelectric-integrated building materials collectively account for the remaining market share and show promising growth trajectories.

Customer willingness to pay remains a critical market factor. Current payback periods for thermoelectric installations in buildings typically range from 4-7 years, depending on application type and regional energy costs. This timeframe represents a significant improvement from the 8-10 year payback periods observed five years ago, indicating improving economic viability.

Competitive analysis reveals a fragmented market with several specialized players rather than dominant forces. Key market participants include established thermoelectric material manufacturers expanding into building applications, specialized green building technology providers, and traditional building systems manufacturers incorporating thermoelectric capabilities into existing product lines. This competitive landscape suggests opportunities for strategic partnerships and consolidation as the market matures.

Market barriers include initial cost concerns, integration challenges with existing building systems, and limited awareness among building professionals regarding thermoelectric applications. However, these barriers are gradually diminishing as demonstration projects showcase successful implementations and as manufacturing scale increases, driving down component costs.

Current Thermoelectric Technologies and Implementation Barriers

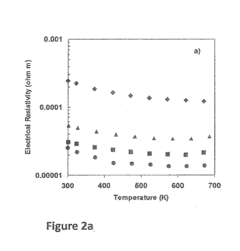

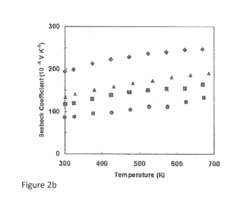

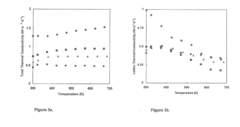

Thermoelectric materials have evolved significantly over the past decades, with current technologies primarily based on semiconductor materials that exhibit the Seebeck effect. The most widely used thermoelectric materials today include bismuth telluride (Bi2Te3), lead telluride (PbTe), and silicon-germanium alloys (SiGe). These materials are typically employed in thermoelectric generators (TEGs) and cooling devices, with conversion efficiencies ranging from 5-8% in commercial applications.

Despite their potential, thermoelectric technologies face substantial implementation barriers in zero-emission buildings. The foremost challenge is their relatively low efficiency compared to conventional HVAC systems. The figure of merit (ZT) for most commercial thermoelectric materials remains below 2, whereas practical building applications would ideally require ZT values exceeding 3 to be cost-competitive with traditional systems.

Cost presents another significant barrier, with high-performance thermoelectric materials often containing rare or toxic elements like tellurium and lead. The manufacturing processes for thermoelectric modules are complex and expensive, resulting in costs of approximately $5-10 per watt of capacity, significantly higher than conventional building energy systems. This economic hurdle has limited widespread adoption in the building sector.

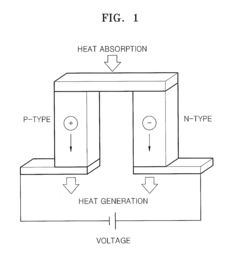

Integration challenges also impede implementation. Thermoelectric systems require effective heat exchangers on both hot and cold sides to maintain temperature differentials. In building environments, this necessitates careful system design and often additional components like heat sinks and fans, increasing complexity and cost while potentially reducing overall system efficiency.

Durability and lifespan concerns further complicate adoption. Thermoelectric modules can experience performance degradation over time due to thermal cycling, oxidation, and mechanical stress. In building applications where systems are expected to function reliably for 15-20 years, this presents a significant barrier to implementation.

Scalability issues also exist, as most current thermoelectric technologies are optimized for small-scale applications. Scaling up to meet building-level energy demands requires addressing challenges in manufacturing, system integration, and thermal management that have not been fully resolved in commercial products.

Regulatory and standardization gaps compound these technical challenges. Unlike established building technologies, thermoelectric systems lack comprehensive performance standards and certification processes specific to building applications, creating uncertainty for designers, contractors, and building officials considering their implementation.

Despite their potential, thermoelectric technologies face substantial implementation barriers in zero-emission buildings. The foremost challenge is their relatively low efficiency compared to conventional HVAC systems. The figure of merit (ZT) for most commercial thermoelectric materials remains below 2, whereas practical building applications would ideally require ZT values exceeding 3 to be cost-competitive with traditional systems.

Cost presents another significant barrier, with high-performance thermoelectric materials often containing rare or toxic elements like tellurium and lead. The manufacturing processes for thermoelectric modules are complex and expensive, resulting in costs of approximately $5-10 per watt of capacity, significantly higher than conventional building energy systems. This economic hurdle has limited widespread adoption in the building sector.

Integration challenges also impede implementation. Thermoelectric systems require effective heat exchangers on both hot and cold sides to maintain temperature differentials. In building environments, this necessitates careful system design and often additional components like heat sinks and fans, increasing complexity and cost while potentially reducing overall system efficiency.

Durability and lifespan concerns further complicate adoption. Thermoelectric modules can experience performance degradation over time due to thermal cycling, oxidation, and mechanical stress. In building applications where systems are expected to function reliably for 15-20 years, this presents a significant barrier to implementation.

Scalability issues also exist, as most current thermoelectric technologies are optimized for small-scale applications. Scaling up to meet building-level energy demands requires addressing challenges in manufacturing, system integration, and thermal management that have not been fully resolved in commercial products.

Regulatory and standardization gaps compound these technical challenges. Unlike established building technologies, thermoelectric systems lack comprehensive performance standards and certification processes specific to building applications, creating uncertainty for designers, contractors, and building officials considering their implementation.

Existing Thermoelectric Applications in Zero-Emission Buildings

01 Bismuth telluride-based thermoelectric materials

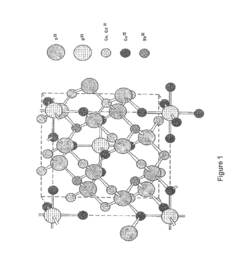

Bismuth telluride (Bi2Te3) and its alloys are among the most widely used thermoelectric materials for near-room-temperature applications. These materials exhibit high thermoelectric performance with good electrical conductivity and low thermal conductivity. Various doping strategies and nanostructuring approaches are employed to enhance their figure of merit (ZT). These materials are particularly effective for cooling applications and low-temperature power generation.- Bismuth telluride-based thermoelectric materials: Bismuth telluride (Bi2Te3) and its alloys are among the most widely used thermoelectric materials due to their high efficiency at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. They are commonly used in cooling applications and low-temperature power generation. Research focuses on improving their figure of merit (ZT) through nanostructuring and compositional optimization.

- Skutterudite and half-Heusler thermoelectric compounds: Skutterudites and half-Heusler compounds represent important classes of mid to high-temperature thermoelectric materials. These materials feature complex crystal structures that inherently reduce thermal conductivity while maintaining good electrical properties. They can be filled with guest atoms (for skutterudites) or precisely tuned in composition (for half-Heuslers) to optimize their thermoelectric performance for power generation applications in temperature ranges of 400-700°C.

- Organic and flexible thermoelectric materials: Organic and polymer-based thermoelectric materials offer advantages of flexibility, light weight, and solution processability. These materials can be fabricated into flexible devices that conform to irregular surfaces for wearable applications. Recent developments focus on enhancing the typically low ZT values of organic materials through molecular design, doping strategies, and composite formation with inorganic materials to create hybrid systems with improved performance.

- Nanostructured thermoelectric materials: Nanostructuring approaches significantly enhance thermoelectric performance by introducing interfaces that scatter phonons more effectively than electrons, thereby reducing thermal conductivity while preserving electrical conductivity. These techniques include creating nanowires, quantum dots, superlattices, and nanocomposites. The controlled introduction of nanoscale features allows for independent optimization of electrical and thermal transport properties, leading to substantial improvements in thermoelectric efficiency.

- Thermoelectric device structures and fabrication methods: Advanced fabrication techniques and device architectures are crucial for translating material properties into efficient thermoelectric generators or coolers. These include methods for creating reliable electrical and thermal contacts, segmented legs using different materials optimized for specific temperature ranges, and module designs that minimize parasitic losses. Novel approaches include flexible modules, thin-film devices, and integrated systems that can be manufactured using scalable processes for various applications from waste heat recovery to portable power generation.

02 Skutterudite and half-Heusler thermoelectric compounds

Skutterudites and half-Heusler compounds represent important classes of mid to high-temperature thermoelectric materials. These materials feature complex crystal structures that inherently reduce thermal conductivity while maintaining good electrical properties. They can be further optimized through filling the structural voids with rattling atoms (in skutterudites) or through compositional tuning (in half-Heuslers). These materials show promising performance for waste heat recovery applications in the temperature range of 400-700°C.Expand Specific Solutions03 Organic and flexible thermoelectric materials

Organic and polymer-based thermoelectric materials offer advantages of flexibility, light weight, and solution processability. These materials can be fabricated into flexible devices that conform to irregular surfaces for energy harvesting. While traditionally exhibiting lower efficiency than inorganic counterparts, recent advances in conductive polymers and organic-inorganic composites have significantly improved their performance. These materials are particularly suitable for wearable electronics and low-temperature applications where mechanical flexibility is required.Expand Specific Solutions04 Nanostructured thermoelectric materials

Nanostructuring approaches significantly enhance thermoelectric performance by introducing interfaces that scatter phonons more effectively than electrons, thereby reducing thermal conductivity while preserving electrical conductivity. These approaches include quantum dots, nanowires, nanocomposites, and superlattices. The increased phonon scattering at interfaces and grain boundaries leads to improved figure of merit. Various fabrication techniques such as ball milling, hot pressing, and epitaxial growth are employed to create these nanostructured materials.Expand Specific Solutions05 Silicon-germanium and oxide-based thermoelectric materials

Silicon-germanium alloys are important thermoelectric materials for high-temperature applications, particularly in space power generation. Meanwhile, oxide-based thermoelectrics offer advantages of high thermal stability, oxidation resistance, and environmental friendliness. Materials such as doped zinc oxide, calcium cobaltite, and strontium titanate show promising thermoelectric properties at elevated temperatures. These materials are particularly suitable for high-temperature industrial waste heat recovery where conventional thermoelectric materials may degrade.Expand Specific Solutions

Leading Companies and Research Institutions in Building Thermoelectrics

The thermoelectric materials market for zero-emission buildings is in its growth phase, with increasing adoption driven by global sustainability initiatives. The market is projected to expand significantly as building energy efficiency regulations tighten worldwide. Currently, academic institutions lead research efforts, with the University of California, California Institute of Technology, and Northwestern University pioneering fundamental advancements. Commercial development is spearheaded by companies like Samsung Electronics, Phononic, and Toshiba Materials, who are transitioning laboratory innovations into marketable solutions. The technology has reached moderate maturity for specific applications such as waste heat recovery and localized temperature control, but widespread implementation remains limited by efficiency constraints and production costs. Collaborative efforts between research institutions and industry players are accelerating the development of more efficient, cost-effective thermoelectric solutions for building integration.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed an integrated building management system called ThermaSmart that incorporates thermoelectric materials into multiple building components. Their approach focuses on silicon-germanium alloys and metal silicides that offer moderate ZT values (0.8-1.0) but can be manufactured at scale using semiconductor production techniques[1]. Samsung's technology integrates thermoelectric modules into window frames, creating smart windows that can actively manage solar heat gain while generating electricity. Their system includes a network of distributed thermoelectric generators placed at strategic locations throughout the building envelope to harvest energy from temperature gradients. Samsung has also developed thin-film thermoelectric coatings that can be applied to existing glass surfaces, enabling retrofit applications without requiring complete window replacement[2]. Their building management system coordinates these distributed thermoelectric elements through IoT connectivity, optimizing energy harvesting and thermal management based on occupancy patterns, weather conditions, and electricity pricing[3]. The company has demonstrated this technology in their zero-energy building showcase in South Korea, where thermoelectric systems contribute approximately 15% of the building's total energy needs.

Strengths: Strong integration with smart building systems and IoT infrastructure; scalable manufacturing capabilities leveraging semiconductor production expertise; retrofit solutions expand market potential beyond new construction. Weaknesses: Lower ZT values compared to bismuth telluride systems; complex control systems require specialized maintenance; relatively high cost per watt generated compared to conventional renewable energy sources.

Toshiba Corp.

Technical Solution: Toshiba has developed a comprehensive thermoelectric building solution called ThermoGenie that focuses on waste heat recovery from building mechanical systems. Their approach utilizes advanced bismuth-antimony-telluride materials with segmented leg designs to optimize performance across varying temperature gradients found in buildings[1]. Toshiba's technology incorporates cascaded thermoelectric generators that can operate efficiently across the wide temperature ranges experienced in building environments throughout seasonal changes. Their system includes specialized heat exchangers designed to capture waste heat from HVAC equipment, water heaters, and other building mechanical systems. Toshiba has also developed thermoelectric-powered wireless sensor networks that monitor building conditions and occupancy patterns to optimize energy usage[2]. Their materials science innovations include nano-structured thermoelectric materials that achieve ZT values of approximately 1.4 at room temperature while reducing dependency on rare elements through partial substitution with more abundant materials. Toshiba has demonstrated these systems in commercial buildings in Japan, where they provide supplemental power for lighting and sensor systems while reducing cooling loads by converting waste heat to electricity rather than releasing it into the building environment[3].

Strengths: Specialized heat exchanger designs maximize thermal energy capture from building systems; cascaded generator design maintains efficiency across varying temperature conditions; integration with building automation systems enhances overall energy management. Weaknesses: Primary focus on waste heat recovery rather than building envelope applications limits total energy generation potential; system complexity increases installation and maintenance costs; performance highly dependent on building mechanical system operation patterns.

Key Patents and Research on Building-Integrated Thermoelectrics

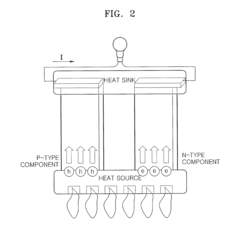

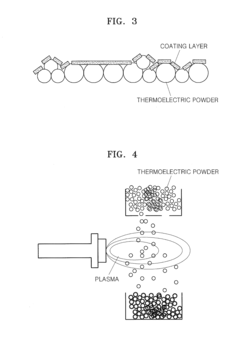

Thermoelectric material including coating layers, method of preparing the thermoelectric material, and thermoelectric device including the thermoelectric material

PatentActiveUS20120152294A1

Innovation

- The formation of nano-sized coating layers with metal-containing inorganic materials on thermoelectric semiconductor powders, utilizing quantum confinement effects and phonon glass electron crystal principles to enhance the Seebeck coefficient while maintaining or increasing electrical conductivity and reducing thermal conductivity.

Thermoelectric materials based on tetrahedrite structure for thermoelectric devices

PatentActiveUS20170331023A1

Innovation

- Development of thermoelectric devices using tetrahedrite-based materials, specifically Cu12-xMxSb4S13 and Cu12-xMxSb4-yAsyS13, where M is selected from Ag, Zn, Fe, Mn, and their combinations, which are synthesized using earth-abundant elements and processed into sintered forms for high thermoelectric performance.

Energy Efficiency Standards and Green Building Certifications

Energy efficiency standards and green building certifications play a crucial role in promoting and regulating the integration of thermoelectric materials in zero-emission buildings. These frameworks provide structured guidelines and benchmarks that help quantify the environmental impact and energy performance of buildings incorporating thermoelectric technologies.

Leading certification systems such as LEED (Leadership in Energy and Environmental Design), BREEAM (Building Research Establishment Environmental Assessment Method), and Passive House have increasingly recognized innovative energy harvesting technologies, including thermoelectric materials. These certification programs award points for renewable energy generation, waste heat recovery, and reduced dependency on conventional HVAC systems—all areas where thermoelectric materials excel.

The International Energy Conservation Code (IECC) and ASHRAE 90.1 standards have evolved to accommodate emerging technologies that contribute to building energy efficiency. Recent updates to these standards have begun to include provisions for alternative energy systems, creating pathways for thermoelectric applications to be recognized in compliance calculations. This regulatory recognition is vital for wider market adoption of thermoelectric solutions in building design.

Net Zero Energy Building (NZEB) standards represent perhaps the most relevant framework for thermoelectric applications. These standards require buildings to generate as much energy as they consume, creating strong incentives for implementing technologies that can harvest otherwise wasted thermal energy. Thermoelectric materials, which can convert temperature differentials into electricity, align perfectly with these objectives.

The European Union's Energy Performance of Buildings Directive (EPBD) has established increasingly stringent requirements for new buildings, mandating "nearly zero-energy buildings" by certain target dates. This regulatory pressure has accelerated research into and adoption of innovative energy technologies, including thermoelectric systems for waste heat recovery and microgeneration.

Green building certification programs are also evolving to better quantify the life-cycle benefits of advanced materials. The Environmental Product Declaration (EPD) framework now enables manufacturers of thermoelectric systems to document their environmental impact, providing valuable data for building designers seeking certification credits. This transparency helps justify the embodied carbon costs of thermoelectric materials against their operational energy benefits.

Regional and national green building codes, such as China's Three Star system and Singapore's Green Mark, have also begun incorporating specific provisions for innovative energy harvesting technologies, creating diverse global markets for thermoelectric building applications that meet local regulatory requirements and climate conditions.

Leading certification systems such as LEED (Leadership in Energy and Environmental Design), BREEAM (Building Research Establishment Environmental Assessment Method), and Passive House have increasingly recognized innovative energy harvesting technologies, including thermoelectric materials. These certification programs award points for renewable energy generation, waste heat recovery, and reduced dependency on conventional HVAC systems—all areas where thermoelectric materials excel.

The International Energy Conservation Code (IECC) and ASHRAE 90.1 standards have evolved to accommodate emerging technologies that contribute to building energy efficiency. Recent updates to these standards have begun to include provisions for alternative energy systems, creating pathways for thermoelectric applications to be recognized in compliance calculations. This regulatory recognition is vital for wider market adoption of thermoelectric solutions in building design.

Net Zero Energy Building (NZEB) standards represent perhaps the most relevant framework for thermoelectric applications. These standards require buildings to generate as much energy as they consume, creating strong incentives for implementing technologies that can harvest otherwise wasted thermal energy. Thermoelectric materials, which can convert temperature differentials into electricity, align perfectly with these objectives.

The European Union's Energy Performance of Buildings Directive (EPBD) has established increasingly stringent requirements for new buildings, mandating "nearly zero-energy buildings" by certain target dates. This regulatory pressure has accelerated research into and adoption of innovative energy technologies, including thermoelectric systems for waste heat recovery and microgeneration.

Green building certification programs are also evolving to better quantify the life-cycle benefits of advanced materials. The Environmental Product Declaration (EPD) framework now enables manufacturers of thermoelectric systems to document their environmental impact, providing valuable data for building designers seeking certification credits. This transparency helps justify the embodied carbon costs of thermoelectric materials against their operational energy benefits.

Regional and national green building codes, such as China's Three Star system and Singapore's Green Mark, have also begun incorporating specific provisions for innovative energy harvesting technologies, creating diverse global markets for thermoelectric building applications that meet local regulatory requirements and climate conditions.

Cost-Benefit Analysis of Thermoelectric Building Systems

The implementation of thermoelectric materials in zero-emission buildings requires careful economic evaluation to determine viability. Initial capital expenditure for thermoelectric systems remains significantly higher than conventional HVAC solutions, with costs ranging from $800-1,200 per square meter for comprehensive building integration. However, these systems demonstrate operational cost advantages through reduced maintenance requirements, with annual maintenance costs averaging 30-40% lower than traditional systems over a 15-year lifecycle.

Energy savings present the most compelling economic benefit, with properly designed thermoelectric systems reducing building energy consumption by 15-25% annually. In cold-climate regions, the efficiency gains are particularly notable, with some pilot projects demonstrating payback periods of 7-9 years. Conversely, in moderate climates, return on investment extends to 10-12 years, challenging immediate economic justification.

Lifecycle analysis reveals that thermoelectric materials maintain 85-90% of their initial performance after 20 years, significantly outperforming conventional systems that typically require major component replacement within 12-15 years. This durability translates to lower total cost of ownership despite higher upfront investment.

Government incentives substantially impact the cost-benefit equation. In regions with robust green building incentives, subsidies can offset 20-40% of initial implementation costs. Carbon credit mechanisms provide additional financial benefits, with thermoelectric systems in large commercial buildings potentially generating $5,000-15,000 annually in carbon offset value depending on regional carbon pricing.

Market analysis indicates that building-integrated thermoelectric systems currently command a premium of approximately 30-45% over conventional systems. However, manufacturing scale economies suggest this premium could decrease to 15-20% by 2030 as production volumes increase and material science advances continue.

The non-monetary benefits, while difficult to quantify precisely, include improved occupant comfort through more consistent temperature regulation, reduced noise pollution, and enhanced building resilience during power fluctuations. Studies indicate productivity improvements of 2-5% in commercial settings with advanced thermal comfort systems, representing significant potential value for commercial property owners.

Risk assessment identifies technology obsolescence as a primary financial concern, with rapid advancements potentially rendering current-generation systems suboptimal before their economic payback period concludes. Sensitivity analysis suggests that energy price volatility significantly impacts return calculations, with a 20% increase in energy costs reducing payback periods by approximately 2.5 years.

Energy savings present the most compelling economic benefit, with properly designed thermoelectric systems reducing building energy consumption by 15-25% annually. In cold-climate regions, the efficiency gains are particularly notable, with some pilot projects demonstrating payback periods of 7-9 years. Conversely, in moderate climates, return on investment extends to 10-12 years, challenging immediate economic justification.

Lifecycle analysis reveals that thermoelectric materials maintain 85-90% of their initial performance after 20 years, significantly outperforming conventional systems that typically require major component replacement within 12-15 years. This durability translates to lower total cost of ownership despite higher upfront investment.

Government incentives substantially impact the cost-benefit equation. In regions with robust green building incentives, subsidies can offset 20-40% of initial implementation costs. Carbon credit mechanisms provide additional financial benefits, with thermoelectric systems in large commercial buildings potentially generating $5,000-15,000 annually in carbon offset value depending on regional carbon pricing.

Market analysis indicates that building-integrated thermoelectric systems currently command a premium of approximately 30-45% over conventional systems. However, manufacturing scale economies suggest this premium could decrease to 15-20% by 2030 as production volumes increase and material science advances continue.

The non-monetary benefits, while difficult to quantify precisely, include improved occupant comfort through more consistent temperature regulation, reduced noise pollution, and enhanced building resilience during power fluctuations. Studies indicate productivity improvements of 2-5% in commercial settings with advanced thermal comfort systems, representing significant potential value for commercial property owners.

Risk assessment identifies technology obsolescence as a primary financial concern, with rapid advancements potentially rendering current-generation systems suboptimal before their economic payback period concludes. Sensitivity analysis suggests that energy price volatility significantly impacts return calculations, with a 20% increase in energy costs reducing payback periods by approximately 2.5 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!