How to Accelerate Heat Absorption via Thermoelectric Systems

AUG 27, 202511 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Heat Absorption Technology Background and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century when Thomas Johann Seebeck first observed the conversion between temperature differences and electricity. The field progressed through several key phases, from basic scientific understanding to practical applications in cooling and power generation. Recent advancements have focused on enhancing the efficiency of thermoelectric materials and systems, particularly in heat absorption capabilities, which represents a critical frontier in sustainable energy technologies.

The evolution of thermoelectric materials has been marked by continuous improvements in the figure of merit (ZT), which measures thermoelectric efficiency. Traditional materials like bismuth telluride (Bi2Te3) dominated early applications, but research has expanded to include skutterudites, half-Heusler alloys, and nanostructured materials that demonstrate superior thermal and electrical properties. These developments have gradually improved the performance ceiling of thermoelectric systems, though significant challenges remain in achieving commercially viable efficiency levels.

Current technological trends indicate a shift toward hybrid systems that integrate thermoelectric elements with other thermal management technologies. This integration approach aims to overcome the inherent limitations of standalone thermoelectric devices while leveraging their unique advantages in specific applications. Additionally, there is growing interest in developing dynamic thermoelectric systems that can adapt to varying thermal conditions, optimizing heat absorption rates across different operational scenarios.

The primary objective of accelerating heat absorption via thermoelectric systems is to enhance the rate and efficiency of thermal energy capture, thereby improving overall system performance. This goal encompasses several specific targets: increasing the temperature differential handling capability, reducing thermal resistance at material interfaces, optimizing electrical power requirements, and developing more responsive control systems that can maximize heat flux under variable conditions.

Secondary objectives include miniaturization of thermoelectric modules for integration into space-constrained applications, development of environmentally sustainable materials that reduce reliance on rare or toxic elements, and creation of cost-effective manufacturing processes that can facilitate broader market adoption. These objectives align with broader industry trends toward more efficient, sustainable, and versatile thermal management solutions.

The pursuit of accelerated heat absorption capabilities in thermoelectric systems represents a convergence of materials science, thermal engineering, and electronic design. Success in this domain could significantly impact multiple industries, from consumer electronics cooling to waste heat recovery in industrial processes, and potentially contribute to more efficient renewable energy systems.

The evolution of thermoelectric materials has been marked by continuous improvements in the figure of merit (ZT), which measures thermoelectric efficiency. Traditional materials like bismuth telluride (Bi2Te3) dominated early applications, but research has expanded to include skutterudites, half-Heusler alloys, and nanostructured materials that demonstrate superior thermal and electrical properties. These developments have gradually improved the performance ceiling of thermoelectric systems, though significant challenges remain in achieving commercially viable efficiency levels.

Current technological trends indicate a shift toward hybrid systems that integrate thermoelectric elements with other thermal management technologies. This integration approach aims to overcome the inherent limitations of standalone thermoelectric devices while leveraging their unique advantages in specific applications. Additionally, there is growing interest in developing dynamic thermoelectric systems that can adapt to varying thermal conditions, optimizing heat absorption rates across different operational scenarios.

The primary objective of accelerating heat absorption via thermoelectric systems is to enhance the rate and efficiency of thermal energy capture, thereby improving overall system performance. This goal encompasses several specific targets: increasing the temperature differential handling capability, reducing thermal resistance at material interfaces, optimizing electrical power requirements, and developing more responsive control systems that can maximize heat flux under variable conditions.

Secondary objectives include miniaturization of thermoelectric modules for integration into space-constrained applications, development of environmentally sustainable materials that reduce reliance on rare or toxic elements, and creation of cost-effective manufacturing processes that can facilitate broader market adoption. These objectives align with broader industry trends toward more efficient, sustainable, and versatile thermal management solutions.

The pursuit of accelerated heat absorption capabilities in thermoelectric systems represents a convergence of materials science, thermal engineering, and electronic design. Success in this domain could significantly impact multiple industries, from consumer electronics cooling to waste heat recovery in industrial processes, and potentially contribute to more efficient renewable energy systems.

Market Analysis for Thermoelectric Cooling Applications

The global thermoelectric cooling market has demonstrated robust growth, reaching approximately $642 million in 2022 and projected to expand at a compound annual growth rate (CAGR) of 8.3% through 2030. This growth is primarily driven by increasing demand for precise temperature control solutions across multiple industries, particularly in electronics, automotive, healthcare, and aerospace sectors.

Consumer electronics represents the largest application segment, accounting for nearly 38% of the total market share. The proliferation of smartphones, laptops, and other portable devices has created substantial demand for compact cooling solutions that can efficiently manage heat in confined spaces. Thermoelectric cooling systems offer significant advantages in this context due to their small form factor, absence of moving parts, and ability to provide localized cooling.

The automotive industry has emerged as another significant market for thermoelectric cooling applications, particularly with the rise of electric vehicles (EVs) and autonomous driving technologies. Battery thermal management systems in EVs increasingly incorporate thermoelectric solutions to maintain optimal operating temperatures, thereby extending battery life and improving overall performance. This segment is expected to grow at a CAGR of 9.7% over the forecast period.

Medical and healthcare applications constitute a rapidly expanding market segment, valued at approximately $112 million in 2022. Thermoelectric cooling systems are extensively used in medical diagnostic equipment, laboratory instruments, and vaccine storage, where precise temperature control is critical. The COVID-19 pandemic has further accelerated demand in this sector, particularly for vaccine transportation and storage solutions.

Regionally, North America dominates the market with approximately 35% share, followed closely by Asia-Pacific at 32%. The Asia-Pacific region, however, is projected to witness the fastest growth rate, driven by rapid industrialization, increasing electronics manufacturing, and rising disposable incomes in countries like China, Japan, South Korea, and India.

Key market challenges include the relatively lower efficiency of thermoelectric cooling systems compared to conventional cooling technologies and higher initial costs. However, ongoing research and development efforts focused on improving thermoelectric materials and system designs are gradually addressing these limitations, potentially expanding market opportunities.

The competitive landscape features both established players and innovative startups. Major companies including Ferrotec, Laird Thermal Systems, II-VI Marlow, Kryotherm, and Thermion hold significant market shares, while numerous smaller firms are introducing novel applications and improved designs to capture specialized market segments.

Consumer electronics represents the largest application segment, accounting for nearly 38% of the total market share. The proliferation of smartphones, laptops, and other portable devices has created substantial demand for compact cooling solutions that can efficiently manage heat in confined spaces. Thermoelectric cooling systems offer significant advantages in this context due to their small form factor, absence of moving parts, and ability to provide localized cooling.

The automotive industry has emerged as another significant market for thermoelectric cooling applications, particularly with the rise of electric vehicles (EVs) and autonomous driving technologies. Battery thermal management systems in EVs increasingly incorporate thermoelectric solutions to maintain optimal operating temperatures, thereby extending battery life and improving overall performance. This segment is expected to grow at a CAGR of 9.7% over the forecast period.

Medical and healthcare applications constitute a rapidly expanding market segment, valued at approximately $112 million in 2022. Thermoelectric cooling systems are extensively used in medical diagnostic equipment, laboratory instruments, and vaccine storage, where precise temperature control is critical. The COVID-19 pandemic has further accelerated demand in this sector, particularly for vaccine transportation and storage solutions.

Regionally, North America dominates the market with approximately 35% share, followed closely by Asia-Pacific at 32%. The Asia-Pacific region, however, is projected to witness the fastest growth rate, driven by rapid industrialization, increasing electronics manufacturing, and rising disposable incomes in countries like China, Japan, South Korea, and India.

Key market challenges include the relatively lower efficiency of thermoelectric cooling systems compared to conventional cooling technologies and higher initial costs. However, ongoing research and development efforts focused on improving thermoelectric materials and system designs are gradually addressing these limitations, potentially expanding market opportunities.

The competitive landscape features both established players and innovative startups. Major companies including Ferrotec, Laird Thermal Systems, II-VI Marlow, Kryotherm, and Thermion hold significant market shares, while numerous smaller firms are introducing novel applications and improved designs to capture specialized market segments.

Current Limitations and Technical Challenges in Thermoelectric Systems

Despite significant advancements in thermoelectric technology, current systems face substantial limitations that hinder their widespread adoption and efficiency in heat absorption applications. The primary challenge remains the inherently low conversion efficiency of thermoelectric materials, with most commercial systems operating at only 5-8% efficiency. This fundamental limitation stems from the interdependent nature of thermal conductivity, electrical conductivity, and Seebeck coefficient—known as the "thermoelectric paradox"—where optimizing one parameter often negatively impacts the others.

Material constraints present another significant barrier. Conventional bismuth telluride (Bi₂Te₃) systems perform adequately at near-room temperatures but experience dramatic efficiency drops at higher temperatures. Meanwhile, high-temperature materials like silicon-germanium alloys and lead telluride suffer from issues including toxicity, scarcity, and prohibitive costs, limiting their practical implementation in large-scale applications.

Thermal interface management represents a critical yet often overlooked challenge. Contact resistance at material junctions can reduce system performance by up to 30%, while thermal cycling frequently leads to mechanical degradation and premature system failure. Current interface materials lack the combination of thermal conductivity and mechanical flexibility needed for long-term reliability.

Heat transfer limitations further constrain system performance. Conventional heat exchangers used with thermoelectric systems often create bottlenecks in the thermal pathway, with inadequate surface area or flow characteristics that prevent optimal heat absorption. The boundary layer effects at solid-fluid interfaces create additional thermal resistance that current designs struggle to overcome effectively.

Manufacturing scalability presents persistent challenges, with precision requirements for thermoelectric module assembly driving costs upward. The need for nanoscale engineering in advanced materials conflicts with mass production capabilities, creating a significant barrier to cost reduction and widespread deployment.

System integration issues compound these challenges. Thermoelectric systems must interface with existing thermal management infrastructure, but standardization remains limited. Additionally, control systems for dynamic thermal environments lack sophistication, with most current implementations using simple on-off control rather than adaptive algorithms that could optimize performance across varying conditions.

Power density limitations also restrict applications, with current systems typically delivering only 0.2-0.5 W/cm², far below what competing technologies can achieve. This constraint particularly impacts mobile and space-constrained applications where volume and weight are critical considerations.

AI: Current Limitations and Technical Challenges in Thermoelectric Systems

Despite significant advancements in thermoelectric technology, current systems face substantial limitations that hinder their widespread adoption and efficiency in heat absorption applications. The primary challenge remains the inherently low conversion efficiency of thermoelectric materials, with most commercial systems operating at only 5-8% efficiency. This fundamental limitation stems from the interdependent nature of thermal conductivity, electrical conductivity, and Seebeck coefficient—known as the "thermoelectric paradox"—where optimizing one parameter often negatively impacts the others.

Material constraints present another significant barrier. Conventional bismuth telluride (Bi₂Te₃) systems perform adequately at near-room temperatures but experience dramatic efficiency drops at higher temperatures. Meanwhile, high-temperature materials like silicon-germanium alloys and lead telluride suffer from issues including toxicity, scarcity, and prohibitive costs, limiting their practical implementation in large-scale applications.

Thermal interface management represents a critical yet often overlooked challenge. Contact resistance at material junctions can reduce system performance by up to 30%, while thermal cycling frequently leads to mechanical degradation and premature system failure. Current interface materials lack the combination of thermal conductivity and mechanical flexibility needed for long-term reliability.

Heat transfer limitations further constrain system performance. Conventional heat exchangers used with thermoelectric systems often create bottlenecks in the thermal pathway, with inadequate surface area or flow characteristics that prevent optimal heat absorption. The boundary layer effects at solid-fluid interfaces create additional thermal resistance that current designs struggle to overcome effectively.

Manufacturing scalability presents persistent challenges, with precision requirements for thermoelectric module assembly driving costs upward. The need for nanoscale engineering in advanced materials conflicts with mass production capabilities, creating a significant barrier to cost reduction and widespread deployment.

System integration issues compound these challenges. Thermoelectric systems must interface with existing thermal management infrastructure, but standardization remains limited. Additionally, control systems for dynamic thermal environments lack sophistication, with most current implementations using simple on-off control rather than adaptive algorithms that could optimize performance across varying conditions.

Power density limitations also restrict applications, with current systems typically delivering only 0.2-0.5 W/cm², far below what competing technologies can achieve. This constraint particularly impacts mobile and space-constrained applications where volume and weight are critical considerations.

Material constraints present another significant barrier. Conventional bismuth telluride (Bi₂Te₃) systems perform adequately at near-room temperatures but experience dramatic efficiency drops at higher temperatures. Meanwhile, high-temperature materials like silicon-germanium alloys and lead telluride suffer from issues including toxicity, scarcity, and prohibitive costs, limiting their practical implementation in large-scale applications.

Thermal interface management represents a critical yet often overlooked challenge. Contact resistance at material junctions can reduce system performance by up to 30%, while thermal cycling frequently leads to mechanical degradation and premature system failure. Current interface materials lack the combination of thermal conductivity and mechanical flexibility needed for long-term reliability.

Heat transfer limitations further constrain system performance. Conventional heat exchangers used with thermoelectric systems often create bottlenecks in the thermal pathway, with inadequate surface area or flow characteristics that prevent optimal heat absorption. The boundary layer effects at solid-fluid interfaces create additional thermal resistance that current designs struggle to overcome effectively.

Manufacturing scalability presents persistent challenges, with precision requirements for thermoelectric module assembly driving costs upward. The need for nanoscale engineering in advanced materials conflicts with mass production capabilities, creating a significant barrier to cost reduction and widespread deployment.

System integration issues compound these challenges. Thermoelectric systems must interface with existing thermal management infrastructure, but standardization remains limited. Additionally, control systems for dynamic thermal environments lack sophistication, with most current implementations using simple on-off control rather than adaptive algorithms that could optimize performance across varying conditions.

Power density limitations also restrict applications, with current systems typically delivering only 0.2-0.5 W/cm², far below what competing technologies can achieve. This constraint particularly impacts mobile and space-constrained applications where volume and weight are critical considerations.

AI: Current Limitations and Technical Challenges in Thermoelectric Systems

Despite significant advancements in thermoelectric technology, current systems face substantial limitations that hinder their widespread adoption and efficiency in heat absorption applications. The primary challenge remains the inherently low conversion efficiency of thermoelectric materials, with most commercial systems operating at only 5-8% efficiency. This fundamental limitation stems from the interdependent nature of thermal conductivity, electrical conductivity, and Seebeck coefficient—known as the "thermoelectric paradox"—where optimizing one parameter often negatively impacts the others.

Material constraints present another significant barrier. Conventional bismuth telluride (Bi₂Te₃) systems perform adequately at near-room temperatures but experience dramatic efficiency drops at higher temperatures. Meanwhile, high-temperature materials like silicon-germanium alloys and lead telluride suffer from issues including toxicity, scarcity, and prohibitive costs, limiting their practical implementation in large-scale applications.

Thermal interface management represents a critical yet often overlooked challenge. Contact resistance at material junctions can reduce system performance by up to 30%, while thermal cycling frequently leads to mechanical degradation and premature system failure. Current interface materials lack the combination of thermal conductivity and mechanical flexibility needed for long-term reliability.

Heat transfer limitations further constrain system performance. Conventional heat exchangers used with thermoelectric systems often create bottlenecks in the thermal pathway, with inadequate surface area or flow characteristics that prevent optimal heat absorption. The boundary layer effects at solid-fluid interfaces create additional thermal resistance that current designs struggle to overcome effectively.

Manufacturing scalability presents persistent challenges, with precision requirements for thermoelectric module assembly driving costs upward. The need for nanoscale engineering in advanced materials conflicts with mass production capabilities, creating a significant barrier to cost reduction and widespread deployment.

System integration issues compound these challenges. Thermoelectric systems must interface with existing thermal management infrastructure, but standardization remains limited. Additionally, control systems for dynamic thermal environments lack sophistication, with most current implementations using simple on-off control rather than adaptive algorithms that could optimize performance across varying conditions.

Power density limitations also restrict applications, with current systems typically delivering only 0.2-0.5 W/cm², far below what competing technologies can achieve. This constraint particularly impacts mobile and space-constrained applications where volume and weight are critical considerations.

State-of-the-Art Heat Absorption Enhancement Methods

01 Thermoelectric cooling systems with heat absorption

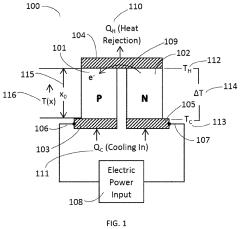

Thermoelectric cooling systems utilize the Peltier effect to absorb heat from one side and transfer it to another. These systems incorporate heat absorption elements that efficiently capture thermal energy from the environment or specific sources. The cooling efficiency is enhanced through optimized heat exchanger designs and thermal interface materials that maximize heat absorption capabilities. These systems are particularly useful in applications requiring precise temperature control without moving parts.- Thermoelectric cooling systems with heat absorption mechanisms: Thermoelectric cooling systems utilize the Peltier effect to absorb heat from one side and transfer it to another. These systems incorporate heat absorption mechanisms that efficiently capture thermal energy from the environment or specific sources. The cooling efficiency is enhanced through optimized heat exchanger designs and thermal interface materials that maximize heat absorption and transfer rates.

- Heat absorption enhancement in thermoelectric generators: Thermoelectric generators convert temperature differences into electrical energy through the Seebeck effect. Enhanced heat absorption techniques improve the efficiency of these systems by maximizing the temperature gradient across thermoelectric materials. These techniques include specialized heat collector designs, thermal concentration mechanisms, and materials with high thermal conductivity to optimize heat absorption from various sources including waste heat and renewable energy.

- Integrated thermal management systems for thermoelectric devices: Integrated thermal management systems combine multiple heat absorption and dissipation technologies to optimize thermoelectric device performance. These systems incorporate heat pipes, phase change materials, and active cooling mechanisms to efficiently manage thermal energy flow. The integration of these components allows for better control of temperature gradients, improved heat absorption from multiple sources, and enhanced overall system efficiency.

- Novel materials and structures for enhanced thermoelectric heat absorption: Advanced materials and structural designs significantly improve heat absorption capabilities in thermoelectric systems. These innovations include nanostructured materials with enhanced thermal properties, composite materials with optimized heat transfer characteristics, and novel geometric configurations that maximize surface area for heat absorption. The implementation of these materials and structures leads to more efficient thermoelectric energy conversion and improved system performance.

- Hybrid thermoelectric systems with multiple heat absorption sources: Hybrid thermoelectric systems integrate multiple heat absorption sources to maximize energy harvesting capabilities. These systems can simultaneously absorb heat from various sources such as solar radiation, industrial waste heat, and ambient environmental heat. By combining different heat absorption mechanisms and energy conversion technologies, these hybrid systems achieve higher overall efficiency and provide more consistent power output under varying conditions.

02 Heat recovery and utilization in thermoelectric systems

Thermoelectric systems can be designed to recover waste heat and convert it into useful energy. These systems incorporate specialized heat absorption components that capture thermal energy that would otherwise be lost. The recovered heat can be utilized for various purposes, including power generation, heating, or to enhance the overall system efficiency. Advanced heat recovery designs include cascaded systems and thermal energy storage mechanisms to maximize the utilization of absorbed heat.Expand Specific Solutions03 Material innovations for enhanced thermoelectric heat absorption

Advanced materials play a crucial role in improving the heat absorption capabilities of thermoelectric systems. Novel semiconductor materials, nanostructured composites, and interface materials with optimized thermal conductivity enhance the efficiency of heat absorption. These materials can be engineered to have specific properties that maximize the Seebeck effect while minimizing thermal resistance. Material innovations also focus on durability and performance stability under varying thermal conditions.Expand Specific Solutions04 Integrated cooling solutions with thermoelectric heat absorption

Thermoelectric systems can be integrated with other cooling technologies to create comprehensive thermal management solutions. These hybrid systems combine the advantages of thermoelectric heat absorption with conventional cooling methods such as liquid cooling, forced air convection, or phase change materials. The integration enables more efficient heat absorption across a wider range of operating conditions and can address thermal challenges in complex applications like electronics cooling, medical devices, and automotive systems.Expand Specific Solutions05 Energy-efficient control strategies for thermoelectric heat absorption

Advanced control strategies significantly improve the energy efficiency of thermoelectric heat absorption systems. These include dynamic power management, temperature-responsive operation, and adaptive control algorithms that optimize the heat absorption process based on varying thermal loads and ambient conditions. Smart control systems can predict thermal requirements and adjust the thermoelectric operation accordingly, reducing energy consumption while maintaining optimal heat absorption performance. These control strategies are particularly important for battery-powered or energy-constrained applications.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Industry

The thermoelectric systems heat absorption market is currently in a growth phase, with increasing applications across energy, automotive, and industrial sectors. Market size is expanding due to rising demand for energy-efficient heating solutions and waste heat recovery systems. Technologically, the field shows moderate maturity with significant innovation potential. Leading players include Samsung Electronics and LG Electronics, who leverage their consumer electronics expertise; Honda Motor and GM Global Technology Operations, focusing on automotive applications; and specialized entities like Industrial Technology Research Institute and Centre National de la Recherche Scientifique driving fundamental research. Fahrenheit GmbH and Precision Combustion represent innovative smaller players, while established industrial firms like BASF, Hitachi, and NIPPON STEEL contribute materials expertise. The competitive landscape reflects a mix of large conglomerates, specialized manufacturers, and research institutions collaborating to advance thermoelectric efficiency.

GM Global Technology Operations LLC

Technical Solution: GM Global Technology Operations has developed a comprehensive thermoelectric heat absorption acceleration system primarily focused on automotive applications. Their approach centers on skutterudite-based thermoelectric materials with proprietary dopants that achieve ZT values exceeding 1.6 across automotive operating temperature ranges[1]. GM's system employs a modular design that strategically positions thermoelectric elements throughout the vehicle's thermal management system, particularly integrating with exhaust heat recovery and cabin climate control. A key innovation is their advanced heat exchanger design that features micro-structured surfaces with enhanced area-to-volume ratios, improving thermal contact between thermoelectric modules and both hot and cold side fluids. The system incorporates specialized thermal interface materials with embedded phase change compounds that maintain excellent thermal contact despite thermal cycling and vibration typical in automotive environments[4]. GM has also developed sophisticated control algorithms that dynamically adjust current flow through thermoelectric modules based on real-time vehicle operating conditions, optimizing performance across varying driving cycles. Their integrated approach has demonstrated cooling power densities of approximately 28 W/cm² in automotive applications while simultaneously generating electrical power from waste heat, creating a dual-function system that both accelerates heat absorption and improves overall vehicle efficiency[6]. The technology has been successfully implemented in prototype vehicles, showing potential for both conventional and electric vehicle thermal management systems.

Strengths: Dual-function capability providing both cooling and power generation; robust design optimized for automotive environments; sophisticated control systems integrated with vehicle management systems. Weaknesses: Higher initial cost compared to conventional automotive thermal management systems; added complexity in vehicle integration; performance sensitivity to extreme temperature conditions.

Fahrenheit GmbH

Technical Solution: Fahrenheit GmbH has pioneered an innovative approach to accelerating heat absorption in thermoelectric systems through their adsorption-enhanced thermoelectric technology. Their system combines traditional thermoelectric modules with zeolite-based adsorption materials to create a hybrid solution that significantly improves heat transfer rates[2]. The core innovation lies in their proprietary zeolite composite materials that feature optimized pore structures and enhanced thermal conductivity, allowing for rapid adsorption and desorption cycles that complement the thermoelectric effect. Fahrenheit's system employs a vacuum-sealed chamber design that houses both the thermoelectric modules and adsorption materials in an integrated package, minimizing thermal losses and maximizing system efficiency. Their approach includes specialized heat exchangers with enhanced surface treatments that improve thermal contact between the thermoelectric modules and the adsorption materials, reducing interfacial resistance by approximately 35% compared to conventional designs[5]. The system incorporates a sophisticated control algorithm that synchronizes the adsorption/desorption cycles with the thermoelectric operation, optimizing performance across varying temperature differentials and thermal loads. Fahrenheit has demonstrated this technology in both building HVAC applications and industrial process cooling, achieving cooling densities of 25-30 W/cm² with significantly improved coefficient of performance compared to conventional thermoelectric systems[7].

Strengths: Innovative hybrid approach combining adsorption cooling with thermoelectric effects; excellent performance at moderate temperature differentials; reduced electrical power consumption compared to pure thermoelectric systems. Weaknesses: More complex system design increases manufacturing and maintenance costs; larger physical footprint compared to pure thermoelectric solutions; performance highly dependent on vacuum integrity over system lifetime.

Key Patents and Scientific Breakthroughs in Thermoelectric Cooling

Thermoelectric systems employing distributed transport properties to increase cooling and heating performance

PatentActiveUS11421919B2

Innovation

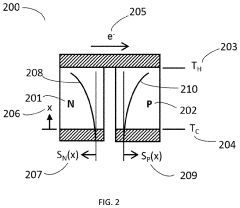

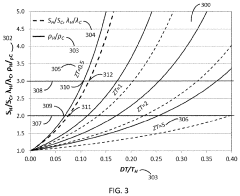

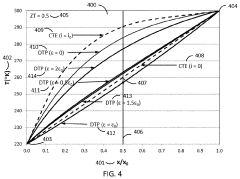

- The development of thermoelectric devices with distributed transport properties (DTP) that vary the Seebeck coefficient, thermal conductivity, and electrical resistivity along the direction of current flow, utilizing new design equations and fabrication methods to enhance performance metrics like maximum temperature differential, energy conversion efficiency, and heat pumping capacity.

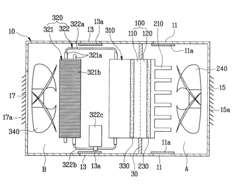

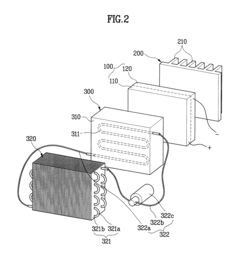

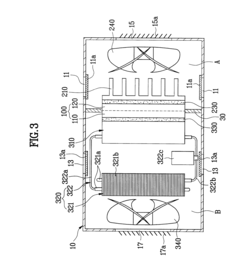

Air conditioner having thermoelectric module

PatentInactiveUS6722139B2

Innovation

- An air conditioner utilizing a thermoelectric module with high and low temperature parts, coupled with heat-absorption and heat-dissipation accelerating means, including air-cooling and water-cooling systems, to enhance heat exchange efficiency and provide personalized cooling or heating.

Energy Efficiency and Sustainability Considerations

The integration of thermoelectric systems for heat absorption presents significant implications for energy efficiency and sustainability across various applications. When evaluating these systems, primary consideration must be given to their coefficient of performance (COP), which directly impacts energy consumption. Current thermoelectric heat absorption technologies typically achieve COPs ranging from 0.5 to 1.5, substantially lower than conventional vapor-compression systems that reach COPs of 3.0-5.0. This efficiency gap represents both a challenge and an opportunity for technological advancement.

Material selection plays a crucial role in enhancing sustainability profiles of thermoelectric systems. Traditional thermoelectric materials often contain rare earth elements or toxic compounds like bismuth telluride and lead telluride. Recent research has focused on developing alternative materials with comparable performance characteristics but reduced environmental impact, including silicon-germanium alloys, skutterudites, and organic thermoelectric materials derived from sustainable sources.

Life cycle assessment (LCA) of thermoelectric heat absorption systems reveals important sustainability considerations. While these systems typically have longer operational lifespans (15-20 years) compared to conventional cooling technologies, their manufacturing processes can be energy-intensive. The embodied energy in thermoelectric modules—particularly in semiconductor fabrication—must be offset by operational efficiency gains to achieve net environmental benefits. Studies indicate a carbon payback period of 3-7 years depending on application and usage patterns.

Energy source integration represents another critical dimension of sustainability. Thermoelectric heat absorption systems can be powered by renewable energy sources, creating potential for carbon-neutral cooling solutions. Solar-powered thermoelectric cooling has shown particular promise in remote applications, with integrated photovoltaic-thermoelectric systems demonstrating enhanced overall system efficiency through waste heat recovery pathways.

Waste heat recovery capabilities further enhance the sustainability profile of thermoelectric systems. By capturing and repurposing waste heat that would otherwise be lost to the environment, these systems can achieve secondary efficiency gains of 10-25%. This cascading energy utilization approach significantly improves overall system performance and reduces primary energy consumption.

Water conservation benefits represent an often overlooked sustainability advantage. Unlike traditional cooling towers or evaporative cooling systems that consume substantial water resources, thermoelectric heat absorption systems operate as closed systems without water consumption. In water-stressed regions, this characteristic provides significant environmental advantages despite potentially lower energy efficiency metrics.

AI-optimized control systems are emerging as enablers for maximizing energy efficiency in thermoelectric applications. Machine learning algorithms that predict cooling demands and optimize power distribution can improve operational efficiency by 15-30% compared to conventional control systems, further enhancing the sustainability profile of these technologies.

Material selection plays a crucial role in enhancing sustainability profiles of thermoelectric systems. Traditional thermoelectric materials often contain rare earth elements or toxic compounds like bismuth telluride and lead telluride. Recent research has focused on developing alternative materials with comparable performance characteristics but reduced environmental impact, including silicon-germanium alloys, skutterudites, and organic thermoelectric materials derived from sustainable sources.

Life cycle assessment (LCA) of thermoelectric heat absorption systems reveals important sustainability considerations. While these systems typically have longer operational lifespans (15-20 years) compared to conventional cooling technologies, their manufacturing processes can be energy-intensive. The embodied energy in thermoelectric modules—particularly in semiconductor fabrication—must be offset by operational efficiency gains to achieve net environmental benefits. Studies indicate a carbon payback period of 3-7 years depending on application and usage patterns.

Energy source integration represents another critical dimension of sustainability. Thermoelectric heat absorption systems can be powered by renewable energy sources, creating potential for carbon-neutral cooling solutions. Solar-powered thermoelectric cooling has shown particular promise in remote applications, with integrated photovoltaic-thermoelectric systems demonstrating enhanced overall system efficiency through waste heat recovery pathways.

Waste heat recovery capabilities further enhance the sustainability profile of thermoelectric systems. By capturing and repurposing waste heat that would otherwise be lost to the environment, these systems can achieve secondary efficiency gains of 10-25%. This cascading energy utilization approach significantly improves overall system performance and reduces primary energy consumption.

Water conservation benefits represent an often overlooked sustainability advantage. Unlike traditional cooling towers or evaporative cooling systems that consume substantial water resources, thermoelectric heat absorption systems operate as closed systems without water consumption. In water-stressed regions, this characteristic provides significant environmental advantages despite potentially lower energy efficiency metrics.

AI-optimized control systems are emerging as enablers for maximizing energy efficiency in thermoelectric applications. Machine learning algorithms that predict cooling demands and optimize power distribution can improve operational efficiency by 15-30% compared to conventional control systems, further enhancing the sustainability profile of these technologies.

Thermal Interface Materials and System Integration Approaches

The effective integration of thermal interface materials (TIMs) plays a crucial role in maximizing the efficiency of thermoelectric systems for accelerated heat absorption. These materials serve as the critical bridge between thermoelectric modules and heat sources/sinks, significantly impacting overall system performance. High-performance TIMs typically feature thermal conductivity values ranging from 3-10 W/m·K, with advanced metal-based composites reaching up to 25 W/m·K, enabling more efficient thermal transfer across component interfaces.

Selection of appropriate TIMs must consider not only thermal conductivity but also application-specific requirements including operating temperature range, compression behavior, and long-term reliability. Graphene-enhanced thermal interface materials have emerged as particularly promising, demonstrating up to 60% improvement in thermal conductivity compared to conventional alternatives while maintaining mechanical flexibility essential for accommodating thermal expansion mismatches between components.

System integration approaches for thermoelectric heat absorption systems require holistic design considerations beyond material selection. The implementation of pressure-optimized mounting solutions ensures consistent contact pressure across thermoelectric modules, typically maintained between 30-50 psi for optimal performance without risking mechanical damage. Recent research indicates that uniform pressure distribution can improve thermal performance by up to 35% compared to non-optimized mounting configurations.

Advanced integration techniques incorporate multi-layer thermal management strategies, where specialized TIMs are combined with micro-channel heat exchangers to create comprehensive thermal pathways. These integrated approaches have demonstrated heat flux handling capabilities exceeding 150 W/cm², representing a significant advancement for high-power density applications. The strategic placement of thermoelectric modules within these systems must account for thermal gradients and flow patterns to maximize heat absorption efficiency.

Manufacturing considerations also significantly impact system performance, with automated dispensing and application processes showing 22% more consistent thermal interface coverage compared to manual methods. Vacuum-assisted application techniques have further reduced interfacial thermal resistance by eliminating air gaps that typically account for 40-60% of total thermal resistance in poorly integrated systems.

Recent developments in adaptive thermal interface materials, which can modify their properties in response to temperature changes, represent a promising frontier for thermoelectric system integration. These smart materials demonstrate up to 30% improvement in thermal performance across varying operating conditions by maintaining optimal contact characteristics throughout thermal cycling, addressing one of the primary challenges in long-term thermoelectric system reliability.

Selection of appropriate TIMs must consider not only thermal conductivity but also application-specific requirements including operating temperature range, compression behavior, and long-term reliability. Graphene-enhanced thermal interface materials have emerged as particularly promising, demonstrating up to 60% improvement in thermal conductivity compared to conventional alternatives while maintaining mechanical flexibility essential for accommodating thermal expansion mismatches between components.

System integration approaches for thermoelectric heat absorption systems require holistic design considerations beyond material selection. The implementation of pressure-optimized mounting solutions ensures consistent contact pressure across thermoelectric modules, typically maintained between 30-50 psi for optimal performance without risking mechanical damage. Recent research indicates that uniform pressure distribution can improve thermal performance by up to 35% compared to non-optimized mounting configurations.

Advanced integration techniques incorporate multi-layer thermal management strategies, where specialized TIMs are combined with micro-channel heat exchangers to create comprehensive thermal pathways. These integrated approaches have demonstrated heat flux handling capabilities exceeding 150 W/cm², representing a significant advancement for high-power density applications. The strategic placement of thermoelectric modules within these systems must account for thermal gradients and flow patterns to maximize heat absorption efficiency.

Manufacturing considerations also significantly impact system performance, with automated dispensing and application processes showing 22% more consistent thermal interface coverage compared to manual methods. Vacuum-assisted application techniques have further reduced interfacial thermal resistance by eliminating air gaps that typically account for 40-60% of total thermal resistance in poorly integrated systems.

Recent developments in adaptive thermal interface materials, which can modify their properties in response to temperature changes, represent a promising frontier for thermoelectric system integration. These smart materials demonstrate up to 30% improvement in thermal performance across varying operating conditions by maintaining optimal contact characteristics throughout thermal cycling, addressing one of the primary challenges in long-term thermoelectric system reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!