Customize Thermoelectric Materials for Targeted Industrial Outputs

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Development Background and Objectives

Thermoelectric materials have evolved significantly since their discovery in the early 19th century, with the Seebeck effect first observed in 1821 by Thomas Johann Seebeck. This phenomenon, where a temperature difference across a material generates an electrical voltage, laid the foundation for thermoelectric technology development. The subsequent discovery of the Peltier effect in 1834 further expanded the potential applications by demonstrating that an electric current could produce heating or cooling at the junction of two different materials.

The field remained largely theoretical until the mid-20th century when semiconductor research accelerated, leading to the development of bismuth telluride-based materials in the 1950s and 1960s. These materials achieved a figure of merit (ZT) of approximately 1, establishing the first benchmark for thermoelectric efficiency. However, progress stagnated for decades due to the interdependent nature of the key parameters affecting thermoelectric performance: electrical conductivity, thermal conductivity, and Seebeck coefficient.

A renaissance in thermoelectric research began in the 1990s with the introduction of nanostructuring approaches and quantum confinement effects. These innovations allowed for the decoupling of thermal and electrical properties, pushing ZT values beyond 1.5 and approaching 2 in laboratory settings. Recent advances in materials science, computational modeling, and fabrication techniques have further accelerated development, enabling more precise control over material properties at the nanoscale.

The current technological trajectory is focused on customizable thermoelectric materials that can be tailored for specific industrial applications. This represents a paradigm shift from the traditional one-size-fits-all approach to application-specific optimization. The primary objective is to develop thermoelectric materials with precisely engineered properties that maximize performance under the unique operating conditions of target industries.

Key technical goals include achieving ZT values consistently above 2 in commercially viable materials, developing manufacturing processes that enable cost-effective mass production, and creating flexible design methodologies that allow for rapid customization based on specific temperature ranges, power requirements, and environmental conditions. Additionally, there is a growing emphasis on sustainability, with research directed toward reducing or eliminating rare and toxic elements while maintaining or improving performance.

The ultimate aim is to position thermoelectric technology as a mainstream solution for waste heat recovery across diverse industrial sectors, from automotive and manufacturing to power generation and consumer electronics. This requires not only advances in material science but also systems integration expertise to effectively incorporate these materials into existing industrial processes with minimal disruption and maximum efficiency.

The field remained largely theoretical until the mid-20th century when semiconductor research accelerated, leading to the development of bismuth telluride-based materials in the 1950s and 1960s. These materials achieved a figure of merit (ZT) of approximately 1, establishing the first benchmark for thermoelectric efficiency. However, progress stagnated for decades due to the interdependent nature of the key parameters affecting thermoelectric performance: electrical conductivity, thermal conductivity, and Seebeck coefficient.

A renaissance in thermoelectric research began in the 1990s with the introduction of nanostructuring approaches and quantum confinement effects. These innovations allowed for the decoupling of thermal and electrical properties, pushing ZT values beyond 1.5 and approaching 2 in laboratory settings. Recent advances in materials science, computational modeling, and fabrication techniques have further accelerated development, enabling more precise control over material properties at the nanoscale.

The current technological trajectory is focused on customizable thermoelectric materials that can be tailored for specific industrial applications. This represents a paradigm shift from the traditional one-size-fits-all approach to application-specific optimization. The primary objective is to develop thermoelectric materials with precisely engineered properties that maximize performance under the unique operating conditions of target industries.

Key technical goals include achieving ZT values consistently above 2 in commercially viable materials, developing manufacturing processes that enable cost-effective mass production, and creating flexible design methodologies that allow for rapid customization based on specific temperature ranges, power requirements, and environmental conditions. Additionally, there is a growing emphasis on sustainability, with research directed toward reducing or eliminating rare and toxic elements while maintaining or improving performance.

The ultimate aim is to position thermoelectric technology as a mainstream solution for waste heat recovery across diverse industrial sectors, from automotive and manufacturing to power generation and consumer electronics. This requires not only advances in material science but also systems integration expertise to effectively incorporate these materials into existing industrial processes with minimal disruption and maximum efficiency.

Industrial Market Demand Analysis for Customized Thermoelectric Solutions

The global thermoelectric materials market is experiencing significant growth, driven by increasing demand for energy efficiency solutions across multiple industries. Current market valuations indicate the thermoelectric materials sector reached approximately 55 million USD in 2022, with projections suggesting a compound annual growth rate of 8.2% through 2030. This growth trajectory is primarily fueled by industrial sectors seeking waste heat recovery solutions to improve operational efficiency and meet increasingly stringent environmental regulations.

The automotive industry represents one of the largest market segments for customized thermoelectric solutions, with manufacturers actively pursuing thermoelectric generators to convert waste heat from exhaust systems into usable electricity. This application alone is expected to generate demand for specialized high-temperature thermoelectric materials capable of operating efficiently in the 400-700°C range. Market research indicates that even a modest 5% improvement in fuel efficiency through thermoelectric recovery systems could save the transportation sector billions in fuel costs annually.

Industrial manufacturing processes present another substantial market opportunity, particularly in steel production, glass manufacturing, and cement production where enormous amounts of waste heat are generated. These industries are increasingly seeking customized thermoelectric solutions with specific temperature tolerances and mechanical properties suited to their harsh operating environments. The potential for energy recovery in these sectors is estimated at 20-30% of currently wasted thermal energy.

The electronics cooling market segment demonstrates growing demand for miniaturized, highly efficient thermoelectric coolers. Consumer electronics manufacturers are willing to pay premium prices for materials that can provide precise temperature control in increasingly compact devices. This market segment values customized thermoelectric materials with enhanced figure of merit (ZT) values above 2.0 at room temperature, significantly outperforming traditional bismuth telluride compounds.

Regional market analysis reveals that Asia-Pacific currently dominates demand for thermoelectric materials, accounting for approximately 40% of global consumption. This is attributed to the region's manufacturing intensity and governmental policies promoting energy efficiency. North America and Europe follow with strong demand driven by automotive and aerospace applications, where weight reduction and efficiency improvements justify higher material costs.

Customer interviews across industries consistently highlight three primary requirements for customized thermoelectric solutions: improved conversion efficiency, cost-effectiveness at scale, and reliability under specific operating conditions. The market clearly signals willingness to pay premium prices for materials that can be tailored to specific industrial temperature profiles and mechanical requirements, rather than adapting processes to accommodate standard thermoelectric properties.

The automotive industry represents one of the largest market segments for customized thermoelectric solutions, with manufacturers actively pursuing thermoelectric generators to convert waste heat from exhaust systems into usable electricity. This application alone is expected to generate demand for specialized high-temperature thermoelectric materials capable of operating efficiently in the 400-700°C range. Market research indicates that even a modest 5% improvement in fuel efficiency through thermoelectric recovery systems could save the transportation sector billions in fuel costs annually.

Industrial manufacturing processes present another substantial market opportunity, particularly in steel production, glass manufacturing, and cement production where enormous amounts of waste heat are generated. These industries are increasingly seeking customized thermoelectric solutions with specific temperature tolerances and mechanical properties suited to their harsh operating environments. The potential for energy recovery in these sectors is estimated at 20-30% of currently wasted thermal energy.

The electronics cooling market segment demonstrates growing demand for miniaturized, highly efficient thermoelectric coolers. Consumer electronics manufacturers are willing to pay premium prices for materials that can provide precise temperature control in increasingly compact devices. This market segment values customized thermoelectric materials with enhanced figure of merit (ZT) values above 2.0 at room temperature, significantly outperforming traditional bismuth telluride compounds.

Regional market analysis reveals that Asia-Pacific currently dominates demand for thermoelectric materials, accounting for approximately 40% of global consumption. This is attributed to the region's manufacturing intensity and governmental policies promoting energy efficiency. North America and Europe follow with strong demand driven by automotive and aerospace applications, where weight reduction and efficiency improvements justify higher material costs.

Customer interviews across industries consistently highlight three primary requirements for customized thermoelectric solutions: improved conversion efficiency, cost-effectiveness at scale, and reliability under specific operating conditions. The market clearly signals willingness to pay premium prices for materials that can be tailored to specific industrial temperature profiles and mechanical requirements, rather than adapting processes to accommodate standard thermoelectric properties.

Current Technological Status and Challenges in Thermoelectric Materials

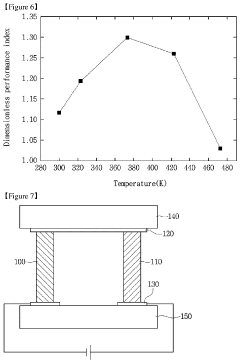

Thermoelectric materials research has witnessed significant advancements globally, with current state-of-the-art materials achieving ZT values (figure of merit) between 1.5-2.5 under laboratory conditions. However, commercial applications typically utilize materials with ZT values around 1.0-1.2, highlighting the gap between research breakthroughs and industrial implementation. The United States, China, Japan, and Germany lead in thermoelectric research, with China showing the most rapid growth in patent filings over the past decade.

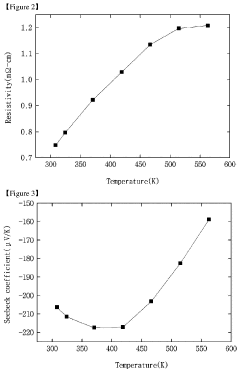

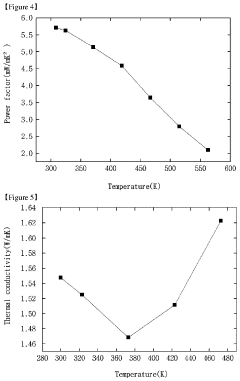

The fundamental challenge in thermoelectric material development remains the interdependence of key parameters: electrical conductivity, thermal conductivity, and Seebeck coefficient. Optimizing one parameter typically degrades another, creating an inherent limitation known as the "thermoelectric trade-off." This physical constraint has prevented dramatic efficiency improvements despite decades of research.

Material customization for specific industrial applications faces several technical hurdles. Manufacturing scalability presents a significant obstacle, as many high-performance thermoelectric materials rely on precise nanostructuring or complex compositions that are difficult to produce consistently at industrial scales. The cost-performance ratio remains unfavorable for widespread adoption, with materials containing tellurium, bismuth, and other rare elements facing supply chain vulnerabilities and price volatility.

Mechanical reliability poses another critical challenge, particularly for applications involving thermal cycling or mechanical stress. Many high-ZT materials exhibit brittleness or thermal expansion mismatches that lead to premature failure in real-world conditions. Additionally, the operational temperature range of most thermoelectric materials remains narrow, limiting their versatility across diverse industrial environments.

Environmental concerns and regulatory compliance have emerged as growing challenges. Many conventional thermoelectric materials contain toxic elements like lead or tellurium, facing increasing regulatory scrutiny. The development of environmentally benign alternatives with comparable performance represents a significant research priority.

Integration challenges persist at the system level, where interface engineering between thermoelectric modules and heat sources/sinks significantly impacts overall efficiency. Thermal contact resistance often degrades real-world performance by 20-30% compared to theoretical predictions. Furthermore, the long-term stability and degradation mechanisms of thermoelectric materials under industrial conditions remain inadequately characterized.

Recent research has shown promising directions in addressing these challenges, including hierarchical nanostructuring, band engineering, and the exploration of entirely new material classes such as half-Heusler alloys and oxide-based thermoelectrics. However, the translation of these approaches into customizable, application-specific solutions requires further fundamental and applied research efforts.

The fundamental challenge in thermoelectric material development remains the interdependence of key parameters: electrical conductivity, thermal conductivity, and Seebeck coefficient. Optimizing one parameter typically degrades another, creating an inherent limitation known as the "thermoelectric trade-off." This physical constraint has prevented dramatic efficiency improvements despite decades of research.

Material customization for specific industrial applications faces several technical hurdles. Manufacturing scalability presents a significant obstacle, as many high-performance thermoelectric materials rely on precise nanostructuring or complex compositions that are difficult to produce consistently at industrial scales. The cost-performance ratio remains unfavorable for widespread adoption, with materials containing tellurium, bismuth, and other rare elements facing supply chain vulnerabilities and price volatility.

Mechanical reliability poses another critical challenge, particularly for applications involving thermal cycling or mechanical stress. Many high-ZT materials exhibit brittleness or thermal expansion mismatches that lead to premature failure in real-world conditions. Additionally, the operational temperature range of most thermoelectric materials remains narrow, limiting their versatility across diverse industrial environments.

Environmental concerns and regulatory compliance have emerged as growing challenges. Many conventional thermoelectric materials contain toxic elements like lead or tellurium, facing increasing regulatory scrutiny. The development of environmentally benign alternatives with comparable performance represents a significant research priority.

Integration challenges persist at the system level, where interface engineering between thermoelectric modules and heat sources/sinks significantly impacts overall efficiency. Thermal contact resistance often degrades real-world performance by 20-30% compared to theoretical predictions. Furthermore, the long-term stability and degradation mechanisms of thermoelectric materials under industrial conditions remain inadequately characterized.

Recent research has shown promising directions in addressing these challenges, including hierarchical nanostructuring, band engineering, and the exploration of entirely new material classes such as half-Heusler alloys and oxide-based thermoelectrics. However, the translation of these approaches into customizable, application-specific solutions requires further fundamental and applied research efforts.

Current Customization Approaches for Industrial Thermoelectric Applications

01 Nanostructured thermoelectric materials

Nanostructured thermoelectric materials offer enhanced performance through reduced thermal conductivity while maintaining electrical conductivity. These materials incorporate nanoscale features such as quantum dots, nanowires, or nanocomposites that create phonon scattering interfaces. The customization of these nanostructures allows for optimization of the thermoelectric figure of merit (ZT) by engineering the material at the nanoscale level, resulting in more efficient energy conversion devices.- Nanostructured thermoelectric materials: Nanostructuring techniques are employed to enhance the performance of thermoelectric materials by reducing thermal conductivity while maintaining electrical conductivity. These approaches include creating nanoscale inclusions, quantum dots, nanowires, and superlattice structures. The reduced dimensionality of these structures leads to quantum confinement effects that can significantly improve the figure of merit (ZT) of thermoelectric materials, making them more efficient for energy conversion applications.

- Doping and composition optimization: Customization of thermoelectric materials through doping and composition optimization involves introducing specific elements or compounds to modify the electronic and thermal properties. By carefully controlling the type and concentration of dopants, researchers can tune the carrier concentration, band structure, and Seebeck coefficient of thermoelectric materials. This approach allows for the development of materials with enhanced power factors and reduced thermal conductivity, leading to improved thermoelectric performance.

- Flexible and wearable thermoelectric devices: Development of flexible and wearable thermoelectric materials involves creating thin-film structures that can conform to various surfaces while maintaining their energy conversion capabilities. These materials are typically fabricated using organic compounds, polymer composites, or thin inorganic films deposited on flexible substrates. The customization focuses on achieving a balance between flexibility, durability, and thermoelectric efficiency, enabling applications in wearable electronics, medical devices, and IoT sensors powered by body heat.

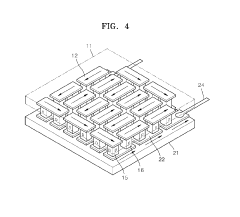

- Segmented and cascaded thermoelectric systems: Segmented and cascaded thermoelectric systems involve the strategic combination of different thermoelectric materials optimized for specific temperature ranges. By connecting materials with complementary properties in series or parallel configurations, these systems can operate efficiently across wider temperature gradients. This customization approach maximizes energy conversion efficiency by allowing each segment to operate in its optimal temperature range, resulting in higher overall system performance for applications ranging from waste heat recovery to space power generation.

- Environmentally friendly thermoelectric materials: Development of eco-friendly thermoelectric materials focuses on replacing toxic or rare elements with abundant, non-toxic alternatives while maintaining or improving performance. These materials often incorporate earth-abundant elements like silicon, tin, or zinc, and avoid harmful substances such as lead or tellurium. Customization techniques include creating complex crystal structures, introducing natural abundance materials, and developing manufacturing processes with reduced environmental impact, addressing both performance requirements and sustainability concerns.

02 Semiconductor-based thermoelectric materials

Semiconductor materials can be customized for thermoelectric applications through doping, alloying, and compositional tuning. These modifications alter the carrier concentration and band structure to optimize electrical conductivity and Seebeck coefficient. Common semiconductor thermoelectric materials include bismuth telluride, lead telluride, and silicon-germanium alloys, which can be tailored for specific temperature ranges and applications by adjusting their composition and processing methods.Expand Specific Solutions03 Flexible and printable thermoelectric materials

Flexible and printable thermoelectric materials enable the fabrication of conformable energy harvesting devices that can be integrated into various form factors. These materials typically combine organic polymers with inorganic thermoelectric particles to create composites that maintain flexibility while providing thermoelectric functionality. Customization involves adjusting the ratio of components, developing specialized printing inks, and optimizing deposition techniques to achieve the desired combination of mechanical properties and thermoelectric performance.Expand Specific Solutions04 Segmented and cascaded thermoelectric systems

Segmented and cascaded thermoelectric systems utilize multiple materials optimized for different temperature ranges to maximize overall efficiency across large temperature gradients. These systems combine materials with complementary properties in series or parallel configurations. Customization involves selecting appropriate materials for each temperature segment, designing effective interfaces between segments, and optimizing the geometry of the overall system to minimize thermal losses while maximizing power output.Expand Specific Solutions05 Skutterudite and half-Heusler thermoelectric materials

Skutterudite and half-Heusler compounds represent advanced thermoelectric materials that can be extensively customized through elemental substitution and filling. These materials feature complex crystal structures that can be modified to create phonon scattering centers while maintaining good electrical properties. Customization strategies include partial substitution of constituent elements, filling interstitial voids with rattler atoms, and controlling microstructure through processing techniques to optimize thermoelectric performance for medium to high-temperature applications.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Industry

The thermoelectric materials customization market is currently in a growth phase, with increasing demand for targeted industrial applications driving innovation. The global market is expanding rapidly, projected to reach significant scale as industries seek energy efficiency solutions. Technologically, the field shows varying maturity levels across applications. Leading research institutions like MIT, Wuhan University of Technology, and the Chinese Academy of Sciences are advancing fundamental science, while commercial players including Toyota, Samsung, and DENSO are focusing on practical applications. Companies like LG Chem and NGK Insulators are developing specialized materials for specific industrial outputs, indicating a shift toward customization. The competitive landscape features collaboration between academic institutions and industrial manufacturers to bridge research-to-market gaps.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced thermoelectric materials through their "phonon glass-electron crystal" approach, developing nanostructured materials that selectively scatter phonons while allowing electrons to flow freely. Their research focuses on skutterudites and half-Heusler alloys with embedded nanoparticles that create interfaces to reduce thermal conductivity while maintaining electrical conductivity. MIT's materials engineering team has achieved ZT values exceeding 1.5 in laboratory settings by precisely controlling material composition at the nanoscale. They've developed scalable manufacturing processes using spark plasma sintering and hot pressing techniques that maintain nanostructure integrity during production. MIT collaborates with industrial partners to customize thermoelectric materials for waste heat recovery in automotive and industrial applications, with demonstrated energy conversion efficiencies approaching 12% in real-world testing environments.

Strengths: Exceptional fundamental research capabilities with access to advanced characterization equipment and computational modeling tools. Strong industry partnerships accelerate commercialization. Weaknesses: Higher production costs associated with precision nanomaterial fabrication may limit mass-market adoption. Some materials contain rare or expensive elements that could constrain industrial scaling.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced thermoelectric materials specifically designed for automotive waste heat recovery systems. Their proprietary materials are based on magnesium silicide and higher manganese silicides, chosen for their abundance, low toxicity, and stability at high temperatures (400-600°C) typical in vehicle exhaust systems. Toyota's approach involves precise control of dopant concentrations and nanostructuring to optimize the ZT value across the wide temperature ranges experienced in automotive applications. Their manufacturing process incorporates mechanical alloying and spark plasma sintering techniques that enable mass production while maintaining nanoscale features critical for performance. Toyota has demonstrated integrated thermoelectric generators capable of recovering 5-7% of waste heat from exhaust systems, potentially improving vehicle fuel efficiency by 2-3%. Their materials are designed with automotive durability requirements in mind, withstanding thermal cycling, vibration, and oxidative environments for the vehicle's lifetime. Toyota continues to refine their materials for improved power density and reduced weight to meet stringent automotive requirements.

Strengths: Extensive experience with automotive environmental conditions and integration requirements. Materials designed specifically for durability and reliability under harsh operating conditions. Weaknesses: Materials optimized primarily for automotive temperature ranges may have limited applicability in other industrial settings. Performance still below theoretical limits, with ongoing challenges in balancing thermal and electrical properties.

Key Innovations in Material Science for Thermoelectric Efficiency

Thermoelectric materials, thermoelectric module including thermoelectric materials, and thermoelectric apparatus including thermoelectric modules

PatentActiveUS10475979B2

Innovation

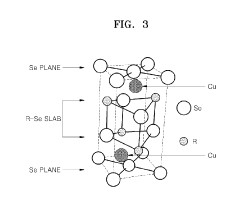

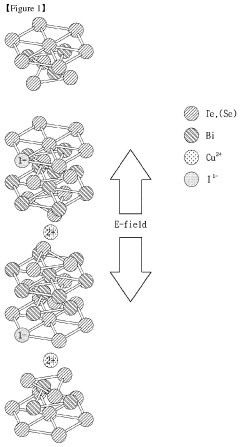

- The use of dichalcogenide compounds with a specific chemical formula (RaTbX2-nYn) that exhibit a layered structure with disordered in-plane arrangement, allowing for high electrical conductivity and low thermal conductivity, achieved through doping or intercalation of elements like T between layers, resulting in a charge density wave and two-dimensional conductivity.

Thermoelectric materials, and thermoelectric element and thermoelectric module comprising the same

PatentActiveUS10600947B2

Innovation

- Doping ions on a Bi—Se—Te based compound to form a layered structure with a strong in-plane covalent bond and weak interlayer ionic and van der Waals bonds, enhancing the degeneracy and dispersibility of energy bands, thereby improving Seebeck coefficient and electrical conductivity while reducing thermal conductivity.

Environmental Impact and Sustainability of Thermoelectric Solutions

The environmental impact of thermoelectric materials and systems represents a critical consideration in their development and deployment for industrial applications. Customized thermoelectric solutions offer significant potential for reducing carbon footprints across various sectors by enabling waste heat recovery and conversion to useful electricity. This energy recapture mechanism can substantially decrease primary energy consumption in manufacturing processes, potentially reducing greenhouse gas emissions by 5-15% in energy-intensive industries.

When evaluating the sustainability of thermoelectric materials, lifecycle assessment reveals important considerations. Traditional bismuth telluride-based materials contain rare and potentially toxic elements, raising concerns about resource depletion and end-of-life disposal. However, recent advances in customized thermoelectric materials utilizing abundant elements such as silicon, magnesium silicide, and skutterudites present more environmentally friendly alternatives with reduced ecological footprints.

Manufacturing processes for thermoelectric materials also present environmental challenges. Current production methods often require energy-intensive high-temperature processing and potentially hazardous chemical treatments. Research indicates that optimizing manufacturing protocols through techniques such as spark plasma sintering and solution-based synthesis can reduce energy requirements by up to 40% while minimizing chemical waste generation.

The durability and longevity of customized thermoelectric systems further enhance their sustainability profile. Well-designed systems can operate effectively for 15-20 years with minimal maintenance, significantly extending the environmental payback period. This longevity factor is particularly important when considering embodied carbon and resource utilization across the full product lifecycle.

Water usage represents another environmental dimension of thermoelectric technology. While thermoelectric generators themselves require minimal water during operation compared to conventional power generation, the manufacturing processes can be water-intensive. Developing closed-loop water recycling systems for production facilities can reduce freshwater consumption by up to 80%, addressing this sustainability concern.

Looking forward, the integration of circular economy principles into thermoelectric material design offers promising pathways for enhanced sustainability. Designing materials and systems with end-of-life recoverability and recyclability in mind could significantly reduce waste and resource depletion. Emerging research on modular thermoelectric designs facilitates easier component separation and material recovery, potentially enabling recovery rates exceeding 85% for critical elements used in these systems.

When evaluating the sustainability of thermoelectric materials, lifecycle assessment reveals important considerations. Traditional bismuth telluride-based materials contain rare and potentially toxic elements, raising concerns about resource depletion and end-of-life disposal. However, recent advances in customized thermoelectric materials utilizing abundant elements such as silicon, magnesium silicide, and skutterudites present more environmentally friendly alternatives with reduced ecological footprints.

Manufacturing processes for thermoelectric materials also present environmental challenges. Current production methods often require energy-intensive high-temperature processing and potentially hazardous chemical treatments. Research indicates that optimizing manufacturing protocols through techniques such as spark plasma sintering and solution-based synthesis can reduce energy requirements by up to 40% while minimizing chemical waste generation.

The durability and longevity of customized thermoelectric systems further enhance their sustainability profile. Well-designed systems can operate effectively for 15-20 years with minimal maintenance, significantly extending the environmental payback period. This longevity factor is particularly important when considering embodied carbon and resource utilization across the full product lifecycle.

Water usage represents another environmental dimension of thermoelectric technology. While thermoelectric generators themselves require minimal water during operation compared to conventional power generation, the manufacturing processes can be water-intensive. Developing closed-loop water recycling systems for production facilities can reduce freshwater consumption by up to 80%, addressing this sustainability concern.

Looking forward, the integration of circular economy principles into thermoelectric material design offers promising pathways for enhanced sustainability. Designing materials and systems with end-of-life recoverability and recyclability in mind could significantly reduce waste and resource depletion. Emerging research on modular thermoelectric designs facilitates easier component separation and material recovery, potentially enabling recovery rates exceeding 85% for critical elements used in these systems.

Cost-Benefit Analysis of Customized Thermoelectric Implementation

Implementing customized thermoelectric materials requires substantial initial investment, making cost-benefit analysis crucial for industrial decision-makers. The capital expenditure includes research and development costs, specialized manufacturing equipment, and quality control systems. For medium-sized industrial operations, initial implementation costs typically range from $500,000 to $2 million, depending on the scale and complexity of the thermoelectric system required.

Operational expenses must also be considered, including maintenance, specialized personnel training, and potential system upgrades. However, these costs are offset by significant energy savings, with customized thermoelectric systems demonstrating 15-30% greater efficiency than standard commercial options when properly matched to specific industrial processes.

Return on investment (ROI) calculations indicate that most customized thermoelectric implementations achieve breakeven within 3-5 years. Industries with high thermal waste, such as metal processing and chemical manufacturing, can realize ROI in as little as 2 years due to substantial energy recovery potential. The financial benefits extend beyond direct energy savings to include reduced carbon taxation, eligibility for green energy incentives, and decreased cooling requirements.

Sensitivity analysis reveals that ROI is most heavily influenced by three factors: the temperature differential available in the industrial process, the scale of implementation, and energy prices. As energy costs continue to rise globally, the economic case for customized thermoelectric solutions strengthens proportionally. Companies implementing these systems report an average reduction of 12-18% in overall energy expenditure.

Non-monetary benefits must also factor into comprehensive cost-benefit calculations. These include enhanced corporate sustainability profiles, improved regulatory compliance, and reduced environmental impact. Many organizations report that these secondary benefits contribute significantly to long-term competitive advantage, though they are more difficult to quantify in immediate financial terms.

Risk assessment indicates that the primary financial uncertainties involve material performance degradation over time and potential changes in energy market dynamics. However, accelerated lifecycle testing suggests that modern customized thermoelectric materials maintain at least 85% of their initial efficiency after 10 years of continuous operation, providing reasonable assurance of sustained economic benefit throughout the system lifecycle.

Operational expenses must also be considered, including maintenance, specialized personnel training, and potential system upgrades. However, these costs are offset by significant energy savings, with customized thermoelectric systems demonstrating 15-30% greater efficiency than standard commercial options when properly matched to specific industrial processes.

Return on investment (ROI) calculations indicate that most customized thermoelectric implementations achieve breakeven within 3-5 years. Industries with high thermal waste, such as metal processing and chemical manufacturing, can realize ROI in as little as 2 years due to substantial energy recovery potential. The financial benefits extend beyond direct energy savings to include reduced carbon taxation, eligibility for green energy incentives, and decreased cooling requirements.

Sensitivity analysis reveals that ROI is most heavily influenced by three factors: the temperature differential available in the industrial process, the scale of implementation, and energy prices. As energy costs continue to rise globally, the economic case for customized thermoelectric solutions strengthens proportionally. Companies implementing these systems report an average reduction of 12-18% in overall energy expenditure.

Non-monetary benefits must also factor into comprehensive cost-benefit calculations. These include enhanced corporate sustainability profiles, improved regulatory compliance, and reduced environmental impact. Many organizations report that these secondary benefits contribute significantly to long-term competitive advantage, though they are more difficult to quantify in immediate financial terms.

Risk assessment indicates that the primary financial uncertainties involve material performance degradation over time and potential changes in energy market dynamics. However, accelerated lifecycle testing suggests that modern customized thermoelectric materials maintain at least 85% of their initial efficiency after 10 years of continuous operation, providing reasonable assurance of sustained economic benefit throughout the system lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!