Assess Power Production with Thermoelectric Hybrid Systems

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Hybrid Systems Background and Objectives

Thermoelectric hybrid systems represent a significant advancement in the field of energy conversion technologies, combining traditional power generation methods with thermoelectric generators (TEGs) to enhance overall system efficiency. The evolution of these systems can be traced back to the mid-20th century with the discovery of the Seebeck effect, which forms the fundamental principle behind thermoelectric generation. Over subsequent decades, research has progressively focused on improving material properties, system integration, and application versatility.

The technological trajectory of thermoelectric hybrid systems has been characterized by continuous improvements in conversion efficiency, from less than 1% in early implementations to modern systems achieving 5-10% efficiency. Recent breakthroughs in nanomaterials and advanced semiconductors have pushed theoretical limits further, suggesting potential for efficiencies exceeding 15% in next-generation systems. This progression represents a significant trend toward making thermoelectric technology increasingly viable for commercial applications.

The primary objective of thermoelectric hybrid system development is to harness waste heat from existing processes, effectively creating power generation opportunities where traditional methods alone would be insufficient. By capturing thermal energy that would otherwise be lost to the environment, these systems aim to improve overall energy utilization across industrial, automotive, residential, and remote power applications.

Current research goals focus on several key areas: enhancing the figure of merit (ZT) of thermoelectric materials to improve conversion efficiency; developing more cost-effective manufacturing processes to reduce implementation barriers; optimizing system integration with existing power generation infrastructure; and expanding the temperature range at which these systems can operate effectively.

The integration of thermoelectric generators with conventional power systems presents unique engineering challenges, including thermal management, electrical integration, and durability under varying operational conditions. Addressing these challenges requires interdisciplinary approaches combining materials science, electrical engineering, thermal physics, and system design.

Looking forward, the technological roadmap for thermoelectric hybrid systems includes the development of flexible and conformable generators, integration with renewable energy sources such as solar and geothermal, and implementation in smart grid applications. The ultimate goal is to position these systems as a standard component in energy efficiency strategies, contributing to global efforts in reducing carbon emissions while maximizing energy resource utilization.

As global energy demands continue to rise and environmental concerns intensify, thermoelectric hybrid systems represent a promising approach to addressing both challenges simultaneously, offering a pathway to more sustainable power generation through improved efficiency rather than increased consumption of primary resources.

The technological trajectory of thermoelectric hybrid systems has been characterized by continuous improvements in conversion efficiency, from less than 1% in early implementations to modern systems achieving 5-10% efficiency. Recent breakthroughs in nanomaterials and advanced semiconductors have pushed theoretical limits further, suggesting potential for efficiencies exceeding 15% in next-generation systems. This progression represents a significant trend toward making thermoelectric technology increasingly viable for commercial applications.

The primary objective of thermoelectric hybrid system development is to harness waste heat from existing processes, effectively creating power generation opportunities where traditional methods alone would be insufficient. By capturing thermal energy that would otherwise be lost to the environment, these systems aim to improve overall energy utilization across industrial, automotive, residential, and remote power applications.

Current research goals focus on several key areas: enhancing the figure of merit (ZT) of thermoelectric materials to improve conversion efficiency; developing more cost-effective manufacturing processes to reduce implementation barriers; optimizing system integration with existing power generation infrastructure; and expanding the temperature range at which these systems can operate effectively.

The integration of thermoelectric generators with conventional power systems presents unique engineering challenges, including thermal management, electrical integration, and durability under varying operational conditions. Addressing these challenges requires interdisciplinary approaches combining materials science, electrical engineering, thermal physics, and system design.

Looking forward, the technological roadmap for thermoelectric hybrid systems includes the development of flexible and conformable generators, integration with renewable energy sources such as solar and geothermal, and implementation in smart grid applications. The ultimate goal is to position these systems as a standard component in energy efficiency strategies, contributing to global efforts in reducing carbon emissions while maximizing energy resource utilization.

As global energy demands continue to rise and environmental concerns intensify, thermoelectric hybrid systems represent a promising approach to addressing both challenges simultaneously, offering a pathway to more sustainable power generation through improved efficiency rather than increased consumption of primary resources.

Market Analysis for Thermoelectric Power Generation

The global thermoelectric power generation market is experiencing significant growth, driven by increasing demand for waste heat recovery systems and renewable energy solutions. Current market valuations place the thermoelectric generator market at approximately 460 million USD in 2022, with projections indicating a compound annual growth rate (CAGR) of 8.3% through 2030. This growth trajectory reflects the expanding applications of thermoelectric technology across multiple industries.

Industrial sectors represent the largest market segment, where thermoelectric generators are increasingly deployed to capture and convert waste heat from manufacturing processes, power plants, and industrial equipment. The automotive sector follows closely, with thermoelectric systems being integrated into vehicle exhaust systems to improve fuel efficiency and reduce emissions. This application has gained particular traction amid stringent environmental regulations in major automotive markets.

Consumer electronics constitutes another rapidly growing segment, with thermoelectric cooling and power generation solutions being incorporated into portable devices, wearables, and smart home systems. The aerospace and defense sectors also demonstrate substantial demand, utilizing thermoelectric technology for power generation in remote and challenging environments.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization in China and India, coupled with increasing government initiatives promoting clean energy technologies.

Key market drivers include the growing emphasis on energy efficiency across industries, rising electricity costs, and the push toward carbon neutrality. The ability of thermoelectric systems to operate without moving parts, offering silent operation and minimal maintenance requirements, presents a compelling value proposition for many applications.

Market challenges primarily revolve around the relatively low conversion efficiency of current thermoelectric materials, which typically ranges from 5-8%. This efficiency limitation impacts the economic viability of large-scale implementations. Additionally, high initial costs compared to conventional power generation methods remain a significant barrier to widespread adoption.

Emerging market opportunities include integration with solar photovoltaic systems to create hybrid energy harvesting solutions, application in remote IoT sensors for self-powered operation, and deployment in microgrids for distributed energy generation. The development of flexible and wearable thermoelectric generators also opens new market segments in healthcare monitoring and consumer electronics.

Industrial sectors represent the largest market segment, where thermoelectric generators are increasingly deployed to capture and convert waste heat from manufacturing processes, power plants, and industrial equipment. The automotive sector follows closely, with thermoelectric systems being integrated into vehicle exhaust systems to improve fuel efficiency and reduce emissions. This application has gained particular traction amid stringent environmental regulations in major automotive markets.

Consumer electronics constitutes another rapidly growing segment, with thermoelectric cooling and power generation solutions being incorporated into portable devices, wearables, and smart home systems. The aerospace and defense sectors also demonstrate substantial demand, utilizing thermoelectric technology for power generation in remote and challenging environments.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization in China and India, coupled with increasing government initiatives promoting clean energy technologies.

Key market drivers include the growing emphasis on energy efficiency across industries, rising electricity costs, and the push toward carbon neutrality. The ability of thermoelectric systems to operate without moving parts, offering silent operation and minimal maintenance requirements, presents a compelling value proposition for many applications.

Market challenges primarily revolve around the relatively low conversion efficiency of current thermoelectric materials, which typically ranges from 5-8%. This efficiency limitation impacts the economic viability of large-scale implementations. Additionally, high initial costs compared to conventional power generation methods remain a significant barrier to widespread adoption.

Emerging market opportunities include integration with solar photovoltaic systems to create hybrid energy harvesting solutions, application in remote IoT sensors for self-powered operation, and deployment in microgrids for distributed energy generation. The development of flexible and wearable thermoelectric generators also opens new market segments in healthcare monitoring and consumer electronics.

Technical Challenges and Global Development Status

Thermoelectric hybrid systems face significant technical challenges despite their promising potential for sustainable power generation. The primary obstacle remains the relatively low conversion efficiency of thermoelectric materials, typically ranging between 5-8% in commercial applications. This efficiency limitation stems from the inherent physical constraints of the Seebeck effect and the interdependence of thermal and electrical conductivity properties, creating a fundamental trade-off that researchers have struggled to overcome for decades.

Material science limitations present another major hurdle. Current state-of-the-art thermoelectric materials often contain rare, expensive, or toxic elements such as tellurium, bismuth, and lead. The development of high-performance, environmentally friendly alternatives using earth-abundant materials remains an active but challenging research area, with recent advances in skutterudites and half-Heusler alloys showing promise but still falling short of commercial viability.

System integration challenges further complicate implementation. Thermoelectric generators require effective thermal management systems to maintain temperature differentials, adding complexity and cost. The mechanical durability of these systems under thermal cycling conditions presents reliability concerns, particularly in applications with frequent temperature fluctuations or extreme operating environments.

Globally, thermoelectric technology development shows significant regional variations. North America and Europe lead in fundamental research and advanced material development, with substantial government funding supporting university and national laboratory initiatives. Japan maintains a strong position in automotive thermoelectric applications, with Toyota and Honda actively developing waste heat recovery systems for vehicles.

China has rapidly expanded its thermoelectric research capacity over the past decade, now producing the largest volume of academic publications in the field and establishing manufacturing capabilities for commercial thermoelectric modules. However, the quality and innovation level of these outputs varies considerably.

Industrial adoption remains fragmented across different sectors. Space exploration represents the most mature application, with radioisotope thermoelectric generators powering deep space missions for decades. Automotive waste heat recovery has seen increased interest but limited commercial deployment due to cost-benefit considerations. Consumer applications remain niche, though wearable thermoelectric generators and self-powered IoT devices show growing potential.

The technology readiness level (TRL) varies significantly by application, ranging from TRL 9 for specialized space applications to TRL 4-6 for most terrestrial hybrid systems. This disparity highlights the context-specific nature of thermoelectric technology development and the need for application-tailored solutions rather than universal approaches.

Material science limitations present another major hurdle. Current state-of-the-art thermoelectric materials often contain rare, expensive, or toxic elements such as tellurium, bismuth, and lead. The development of high-performance, environmentally friendly alternatives using earth-abundant materials remains an active but challenging research area, with recent advances in skutterudites and half-Heusler alloys showing promise but still falling short of commercial viability.

System integration challenges further complicate implementation. Thermoelectric generators require effective thermal management systems to maintain temperature differentials, adding complexity and cost. The mechanical durability of these systems under thermal cycling conditions presents reliability concerns, particularly in applications with frequent temperature fluctuations or extreme operating environments.

Globally, thermoelectric technology development shows significant regional variations. North America and Europe lead in fundamental research and advanced material development, with substantial government funding supporting university and national laboratory initiatives. Japan maintains a strong position in automotive thermoelectric applications, with Toyota and Honda actively developing waste heat recovery systems for vehicles.

China has rapidly expanded its thermoelectric research capacity over the past decade, now producing the largest volume of academic publications in the field and establishing manufacturing capabilities for commercial thermoelectric modules. However, the quality and innovation level of these outputs varies considerably.

Industrial adoption remains fragmented across different sectors. Space exploration represents the most mature application, with radioisotope thermoelectric generators powering deep space missions for decades. Automotive waste heat recovery has seen increased interest but limited commercial deployment due to cost-benefit considerations. Consumer applications remain niche, though wearable thermoelectric generators and self-powered IoT devices show growing potential.

The technology readiness level (TRL) varies significantly by application, ranging from TRL 9 for specialized space applications to TRL 4-6 for most terrestrial hybrid systems. This disparity highlights the context-specific nature of thermoelectric technology development and the need for application-tailored solutions rather than universal approaches.

Current Thermoelectric Hybrid System Solutions

01 Thermoelectric-Solar Hybrid Systems

Integration of thermoelectric generators with solar energy systems to enhance overall power production efficiency. These hybrid systems utilize solar thermal energy to create temperature differentials for thermoelectric conversion while also generating electricity directly from photovoltaic cells. The combination allows for better utilization of solar energy across the spectrum and provides more consistent power output throughout varying environmental conditions.- Thermoelectric-Solar Hybrid Systems: Integration of thermoelectric generators with solar technologies to create hybrid power systems. These systems utilize both thermal energy and solar radiation to generate electricity, improving overall efficiency. The solar component can be photovoltaic panels or solar thermal collectors that work in conjunction with thermoelectric elements to maximize energy harvesting from multiple sources.

- Waste Heat Recovery Systems: Systems designed to capture and convert waste heat from industrial processes, engines, or other heat-generating operations into electrical power using thermoelectric generators. These hybrid systems improve energy efficiency by utilizing heat that would otherwise be lost to the environment, thereby increasing the overall power production and reducing energy waste in various applications.

- Thermoelectric-Mechanical Hybrid Power Generation: Combination of thermoelectric generators with conventional mechanical power generation systems such as turbines or engines. These hybrid systems leverage temperature differentials to produce electricity via thermoelectric effects while simultaneously utilizing mechanical energy conversion methods, creating a more robust and versatile power production approach that can operate under various conditions.

- Advanced Thermoelectric Materials and Configurations: Development of novel thermoelectric materials, structures, and configurations to enhance power generation efficiency in hybrid systems. These innovations include nanostructured materials, segmented thermoelectric elements, and advanced junction designs that improve the conversion of thermal energy to electrical energy, resulting in higher power output and better performance in hybrid applications.

- Renewable Energy Integration with Thermoelectric Systems: Integration of thermoelectric generators with various renewable energy sources beyond solar, such as biomass, geothermal, or wind power. These hybrid systems create synergistic effects by combining multiple renewable technologies with thermoelectric generation, enabling more consistent power production regardless of environmental conditions and increasing the overall sustainability of the energy system.

02 Waste Heat Recovery Systems

Systems designed to capture and convert waste heat from industrial processes, engines, or other thermal sources into electrical energy using thermoelectric generators. These hybrid systems improve overall energy efficiency by recovering thermal energy that would otherwise be lost to the environment. The integration of waste heat recovery with conventional power systems creates a more sustainable energy solution with reduced environmental impact.Expand Specific Solutions03 Advanced Thermoelectric Materials and Configurations

Development of novel thermoelectric materials and innovative device configurations to enhance conversion efficiency in hybrid power systems. These advancements include nanostructured materials, segmented thermoelectric legs, and optimized thermal interfaces that improve the Seebeck coefficient and reduce thermal conductivity. The improved materials enable higher temperature differentials to be maintained and increase the overall power output of thermoelectric hybrid systems.Expand Specific Solutions04 Integrated Cooling and Power Generation

Hybrid systems that simultaneously provide cooling effects while generating electrical power through thermoelectric conversion. These systems utilize the Peltier effect in reverse to create temperature differentials that can be used for both refrigeration and electricity generation. The dual functionality makes these systems particularly valuable in applications where both cooling and autonomous power are required.Expand Specific Solutions05 Grid-Independent Hybrid Power Solutions

Self-contained thermoelectric hybrid systems designed for off-grid applications or remote locations where conventional power infrastructure is unavailable. These systems often combine thermoelectric generators with other renewable energy sources and energy storage solutions to provide reliable, continuous power. The hybrid approach ensures power availability under varying environmental conditions and reduces dependence on single energy sources.Expand Specific Solutions

Leading Companies and Competitive Landscape

Thermoelectric hybrid systems for power production are currently in an early growth phase, with the market expected to expand significantly due to increasing demand for efficient energy solutions. The global market size is projected to reach substantial growth as integration with renewable energy sources accelerates. From a technological maturity perspective, established players like State Grid Corp. of China, Siemens AG, and LG Electronics are leading commercial deployment, while research institutions such as China Electric Power Research Institute and North China Electric Power University are advancing fundamental technologies. Emerging companies like Vast Solar are developing innovative hybrid approaches combining concentrated solar thermal with thermoelectric generation. The competitive landscape features traditional power utilities collaborating with technology providers to overcome efficiency and cost barriers in this promising energy production method.

Dalian University of Technology

Technical Solution: Dalian University of Technology has developed innovative thermoelectric hybrid systems focusing on nano-engineered materials and novel system architectures. Their research team has created advanced skutterudite-based thermoelectric materials with enhanced ZT values exceeding 1.7 at mid-range temperatures (300-500°C), making them particularly suitable for industrial waste heat recovery. The university's hybrid system design incorporates these materials into a cascaded configuration that optimizes performance across different temperature ranges. Their approach includes a three-stage thermoelectric generator system where each stage utilizes materials optimized for specific temperature zones, maximizing overall conversion efficiency. Additionally, they've pioneered integration methods combining thermoelectric generation with phase-change thermal storage, allowing for continuous electricity production despite intermittent heat sources. Their latest prototype demonstrated sustained power generation with thermal-to-electrical conversion efficiencies reaching 9.8% in laboratory conditions.

Strengths: Cutting-edge materials research with some of the highest reported ZT values; innovative system architecture optimized for variable temperature profiles; strong theoretical foundation and modeling capabilities. Weaknesses: Limited industrial-scale implementation experience; reliance on some rare earth materials that may face supply constraints; gap between laboratory performance and real-world operating conditions.

Vast Solar Pty Ltd.

Technical Solution: Vast Solar has developed an innovative concentrated solar power (CSP) system that integrates thermoelectric generation to create a highly efficient hybrid power production solution. Their technology utilizes a modular tower design with sodium-based heat transfer fluid that achieves operating temperatures exceeding 565°C, significantly higher than conventional CSP systems. This high-temperature capability creates ideal conditions for thermoelectric power generation as a secondary conversion pathway. Vast Solar's hybrid approach incorporates specialized high-temperature thermoelectric modules at strategic points in the thermal circuit, particularly where temperature differentials would otherwise represent energy losses. Their system architecture includes thermal energy storage using molten salt technology, which enables continuous operation of both the primary steam turbine generation and the supplementary thermoelectric generation during non-sunlight hours. Field demonstrations have shown that the addition of thermoelectric elements increases overall plant efficiency by 2-3% while providing valuable power for plant parasitic loads even during startup and shutdown phases.

Strengths: Exceptionally high operating temperatures creating favorable conditions for thermoelectric conversion; integrated thermal storage enabling 24/7 operation; modular design allowing for optimized scaling. Weaknesses: Geographic limitations requiring high direct normal irradiance locations; higher capital costs compared to conventional renewable technologies; complex maintenance requirements for the combined thermal-electric systems.

Key Patents and Technical Innovations Analysis

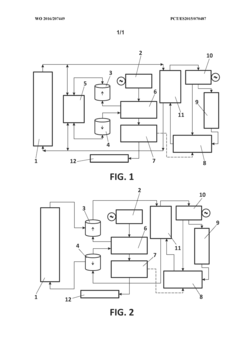

Hybrid solar installation

PatentWO2016207449A1

Innovation

- A hybrid solar installation combining thermoelectric solar technology with thermal storage and an auxiliary combustion machine, like a gas turbine, allows for flexible and predictable electricity production by scaling power sources and utilizing energy from both solar and auxiliary fuels, enhancing storage capacity and efficiency.

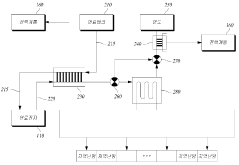

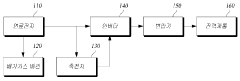

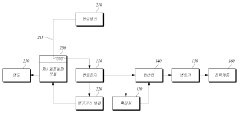

Hybrid power plant system using fuel cell generation and thermoelectric generation

PatentActiveKR1020100002360A

Innovation

- A combined power generation facility integrating fuel cell and thermoelectric power generation systems, utilizing waste heat for thermoelectric power generation, with a configuration that includes a fuel cell generating current and high-temperature waste heat, a low-temperature fuel supply pipe, a high-temperature exhaust gas pipe, and thermoelectric power generation modules using these as heat sources to enhance thermal efficiency and achieve eco-friendly power generation.

Energy Efficiency and Performance Metrics

The evaluation of energy efficiency in thermoelectric hybrid systems requires comprehensive metrics that accurately reflect system performance across various operating conditions. Conversion efficiency stands as the primary metric, typically measured as the ratio of electrical energy output to thermal energy input. For thermoelectric generators (TEGs), this efficiency generally ranges from 5-8% in commercial applications, though laboratory prototypes have demonstrated efficiencies approaching 15% under optimal conditions.

Power density represents another critical performance indicator, measuring the electrical output per unit area or volume of the thermoelectric material. Current commercial TEGs achieve 0.2-0.5 W/cm², while advanced materials incorporating nanoscale engineering techniques have shown potential to reach 1.0-1.2 W/cm² in controlled environments.

The figure of merit ZT quantifies the intrinsic efficiency of thermoelectric materials, combining electrical conductivity, thermal conductivity, and Seebeck coefficient properties. Contemporary bismuth telluride compounds typically achieve ZT values of 1.0-1.5, while cutting-edge materials incorporating quantum confinement effects have demonstrated ZT values exceeding 2.0 in laboratory settings.

System-level metrics must also account for thermal management efficiency, as heat transfer characteristics significantly impact overall performance. The thermal resistance network analysis provides insights into heat flow pathways, with effective heat exchangers reducing thermal resistance by 30-40% compared to basic designs.

When evaluating hybrid systems that combine thermoelectric generation with other technologies (such as photovoltaic or fuel cell systems), integrated efficiency metrics become essential. The Combined Energy Efficiency Ratio (CEER) measures total useful energy output against total energy input across all system components. Well-designed hybrid systems can achieve CEER values 15-25% higher than individual technologies operating independently.

Lifecycle performance assessment incorporates degradation factors, with thermoelectric efficiency typically declining 0.5-1.5% annually depending on operating conditions and material composition. Advanced systems implementing active thermal cycling management have demonstrated reduced degradation rates of 0.3-0.7% annually.

Cost-performance metrics, particularly the levelized cost of energy (LCOE), provide economic context for efficiency evaluations. Current thermoelectric hybrid systems achieve LCOE values of $0.12-0.18 per kWh, with projections indicating potential reductions to $0.08-0.10 per kWh as manufacturing scales and material advances continue to develop.

Power density represents another critical performance indicator, measuring the electrical output per unit area or volume of the thermoelectric material. Current commercial TEGs achieve 0.2-0.5 W/cm², while advanced materials incorporating nanoscale engineering techniques have shown potential to reach 1.0-1.2 W/cm² in controlled environments.

The figure of merit ZT quantifies the intrinsic efficiency of thermoelectric materials, combining electrical conductivity, thermal conductivity, and Seebeck coefficient properties. Contemporary bismuth telluride compounds typically achieve ZT values of 1.0-1.5, while cutting-edge materials incorporating quantum confinement effects have demonstrated ZT values exceeding 2.0 in laboratory settings.

System-level metrics must also account for thermal management efficiency, as heat transfer characteristics significantly impact overall performance. The thermal resistance network analysis provides insights into heat flow pathways, with effective heat exchangers reducing thermal resistance by 30-40% compared to basic designs.

When evaluating hybrid systems that combine thermoelectric generation with other technologies (such as photovoltaic or fuel cell systems), integrated efficiency metrics become essential. The Combined Energy Efficiency Ratio (CEER) measures total useful energy output against total energy input across all system components. Well-designed hybrid systems can achieve CEER values 15-25% higher than individual technologies operating independently.

Lifecycle performance assessment incorporates degradation factors, with thermoelectric efficiency typically declining 0.5-1.5% annually depending on operating conditions and material composition. Advanced systems implementing active thermal cycling management have demonstrated reduced degradation rates of 0.3-0.7% annually.

Cost-performance metrics, particularly the levelized cost of energy (LCOE), provide economic context for efficiency evaluations. Current thermoelectric hybrid systems achieve LCOE values of $0.12-0.18 per kWh, with projections indicating potential reductions to $0.08-0.10 per kWh as manufacturing scales and material advances continue to develop.

Integration with Renewable Energy Systems

Thermoelectric hybrid systems represent a significant opportunity for integration with various renewable energy technologies, creating synergistic relationships that enhance overall system efficiency and reliability. Solar photovoltaic-thermoelectric (PV-TE) combinations have emerged as particularly promising, utilizing waste heat from solar panels to generate additional electricity through thermoelectric generators. This integration addresses one of the fundamental limitations of photovoltaic technology - decreasing efficiency at higher temperatures - by converting that thermal energy into useful power output.

Wind energy systems can also benefit from thermoelectric integration, particularly in the nacelle where significant heat is generated by mechanical components. By capturing this waste heat through strategically placed thermoelectric modules, these hybrid systems can produce supplementary power while simultaneously providing cooling effects that extend equipment lifespan and reliability.

Biomass and geothermal energy sources present natural integration points for thermoelectric technology due to their inherent thermal gradients. In biomass applications, thermoelectric generators can harvest energy from combustion processes that would otherwise be lost, improving the overall conversion efficiency. Similarly, in geothermal installations, thermoelectric devices can be deployed at various points in the heat exchange system to capture additional energy from temperature differentials.

Ocean thermal energy conversion (OTEC) systems represent another frontier for thermoelectric integration, leveraging natural temperature differences between surface and deep ocean waters. While traditional OTEC relies on working fluids and turbines, thermoelectric generators offer a solid-state alternative with fewer moving parts, potentially reducing maintenance requirements in harsh marine environments.

The integration of thermoelectric technology with existing renewable energy infrastructure provides several system-level benefits beyond simple efficiency improvements. These include enhanced grid stability through diversified generation methods, reduced reliance on energy storage in some applications, and improved system resilience. The solid-state nature of thermoelectric devices contributes to these advantages through high reliability and minimal maintenance requirements.

Challenges to widespread integration include current cost-effectiveness limitations, material constraints, and optimization complexities across different renewable energy platforms. However, ongoing research in advanced thermoelectric materials and system design continues to improve performance metrics and economic viability, suggesting a growing role for these hybrid systems in the renewable energy landscape.

Wind energy systems can also benefit from thermoelectric integration, particularly in the nacelle where significant heat is generated by mechanical components. By capturing this waste heat through strategically placed thermoelectric modules, these hybrid systems can produce supplementary power while simultaneously providing cooling effects that extend equipment lifespan and reliability.

Biomass and geothermal energy sources present natural integration points for thermoelectric technology due to their inherent thermal gradients. In biomass applications, thermoelectric generators can harvest energy from combustion processes that would otherwise be lost, improving the overall conversion efficiency. Similarly, in geothermal installations, thermoelectric devices can be deployed at various points in the heat exchange system to capture additional energy from temperature differentials.

Ocean thermal energy conversion (OTEC) systems represent another frontier for thermoelectric integration, leveraging natural temperature differences between surface and deep ocean waters. While traditional OTEC relies on working fluids and turbines, thermoelectric generators offer a solid-state alternative with fewer moving parts, potentially reducing maintenance requirements in harsh marine environments.

The integration of thermoelectric technology with existing renewable energy infrastructure provides several system-level benefits beyond simple efficiency improvements. These include enhanced grid stability through diversified generation methods, reduced reliance on energy storage in some applications, and improved system resilience. The solid-state nature of thermoelectric devices contributes to these advantages through high reliability and minimal maintenance requirements.

Challenges to widespread integration include current cost-effectiveness limitations, material constraints, and optimization complexities across different renewable energy platforms. However, ongoing research in advanced thermoelectric materials and system design continues to improve performance metrics and economic viability, suggesting a growing role for these hybrid systems in the renewable energy landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!