How to Construct High-Efficiency Thermoelectric Modules

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Background and Objectives

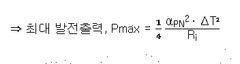

Thermoelectric technology has evolved significantly since its discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion between temperature differences and electric voltage. This discovery laid the foundation for thermoelectric materials and devices that can convert waste heat into useful electricity or provide cooling through electrical input. The field remained relatively dormant until the mid-20th century when semiconductor theory advanced, enabling more efficient thermoelectric materials.

In recent decades, thermoelectric technology has gained renewed attention due to increasing global energy concerns and the push for sustainable energy solutions. The ability to harvest waste heat, which accounts for approximately 60% of all energy produced globally, represents an enormous opportunity for improving energy efficiency across various sectors including automotive, industrial manufacturing, and consumer electronics.

The fundamental performance of thermoelectric materials is characterized by the dimensionless figure of merit ZT, which depends on the Seebeck coefficient, electrical conductivity, and thermal conductivity. Historically, commercial thermoelectric modules have operated at relatively low efficiency with ZT values typically below 1, limiting their widespread adoption despite their reliability and lack of moving parts.

Current research objectives in thermoelectric technology focus on developing materials and module designs that can achieve ZT values exceeding 2, which would make thermoelectric generators competitive with traditional power generation methods in specific applications. This involves addressing the inherent coupling between electrical and thermal properties that has traditionally limited efficiency improvements.

The construction of high-efficiency thermoelectric modules presents multifaceted challenges spanning material science, thermal engineering, and manufacturing processes. Researchers are exploring various approaches including nanostructuring, band engineering, and the development of novel material systems such as skutterudites, half-Heusler alloys, and organic thermoelectrics.

Beyond material development, module design and system integration represent critical areas for advancement. This includes optimizing thermal and electrical contacts, reducing parasitic losses, and developing more effective heat exchangers to maximize temperature differentials across the thermoelectric elements.

The overarching goal of current thermoelectric research is to develop commercially viable modules that can operate efficiently across diverse temperature ranges and environmental conditions. Success in this field could revolutionize waste heat recovery in industrial processes, enable self-powered sensors and IoT devices, and contribute significantly to reducing global carbon emissions through improved energy utilization efficiency.

In recent decades, thermoelectric technology has gained renewed attention due to increasing global energy concerns and the push for sustainable energy solutions. The ability to harvest waste heat, which accounts for approximately 60% of all energy produced globally, represents an enormous opportunity for improving energy efficiency across various sectors including automotive, industrial manufacturing, and consumer electronics.

The fundamental performance of thermoelectric materials is characterized by the dimensionless figure of merit ZT, which depends on the Seebeck coefficient, electrical conductivity, and thermal conductivity. Historically, commercial thermoelectric modules have operated at relatively low efficiency with ZT values typically below 1, limiting their widespread adoption despite their reliability and lack of moving parts.

Current research objectives in thermoelectric technology focus on developing materials and module designs that can achieve ZT values exceeding 2, which would make thermoelectric generators competitive with traditional power generation methods in specific applications. This involves addressing the inherent coupling between electrical and thermal properties that has traditionally limited efficiency improvements.

The construction of high-efficiency thermoelectric modules presents multifaceted challenges spanning material science, thermal engineering, and manufacturing processes. Researchers are exploring various approaches including nanostructuring, band engineering, and the development of novel material systems such as skutterudites, half-Heusler alloys, and organic thermoelectrics.

Beyond material development, module design and system integration represent critical areas for advancement. This includes optimizing thermal and electrical contacts, reducing parasitic losses, and developing more effective heat exchangers to maximize temperature differentials across the thermoelectric elements.

The overarching goal of current thermoelectric research is to develop commercially viable modules that can operate efficiently across diverse temperature ranges and environmental conditions. Success in this field could revolutionize waste heat recovery in industrial processes, enable self-powered sensors and IoT devices, and contribute significantly to reducing global carbon emissions through improved energy utilization efficiency.

Market Analysis for High-Efficiency Thermoelectric Applications

The global thermoelectric module market is experiencing significant growth, driven by increasing demand for energy-efficient solutions across multiple industries. Current market valuations place the sector at approximately 600 million USD in 2023, with projections indicating growth to reach 950 million USD by 2028, representing a compound annual growth rate of 9.6%. This expansion is primarily fueled by applications in automotive, aerospace, industrial manufacturing, and consumer electronics sectors.

The automotive industry represents the largest market segment for high-efficiency thermoelectric modules, with applications focusing on waste heat recovery systems and climate control solutions. Major automotive manufacturers are increasingly incorporating thermoelectric generators to convert exhaust heat into usable electricity, improving overall vehicle efficiency by 3-5% in conventional vehicles and extending range in electric vehicles.

Consumer electronics constitutes another rapidly growing segment, with thermoelectric cooling solutions being integrated into high-performance computing systems, smartphones, and wearable devices. The miniaturization trend in electronics has created demand for compact, efficient cooling solutions where traditional methods prove inadequate.

Medical and healthcare applications represent an emerging high-value market, with thermoelectric modules being utilized in precise temperature control for diagnostic equipment, patient cooling systems, and portable medical devices. This segment is expected to grow at 12.8% annually through 2028, outpacing the overall market average.

Geographically, North America and Asia-Pacific dominate the market landscape. North America leads in research and development initiatives, while Asia-Pacific, particularly China, Japan, and South Korea, represents the largest manufacturing base and fastest-growing consumer market. Europe shows strong growth potential driven by stringent energy efficiency regulations and sustainability initiatives.

Market challenges include high initial production costs, with high-performance thermoelectric materials remaining expensive to synthesize at scale. The average cost-to-performance ratio remains a significant barrier to wider adoption in price-sensitive applications. Additionally, competition from alternative technologies such as phase-change materials and advanced heat pipes creates market pressure in certain application segments.

Customer demand increasingly focuses on modules with higher ZT values (figure of merit), with current commercial products typically offering ZT values between 0.8 and 1.2. Research breakthroughs demonstrating laboratory ZT values exceeding 2.0 indicate significant market disruption potential if successfully commercialized. Industry analysts project that achieving cost-effective production of modules with ZT values above 1.5 would expand the addressable market by 40% through enabling new applications previously considered impractical.

The automotive industry represents the largest market segment for high-efficiency thermoelectric modules, with applications focusing on waste heat recovery systems and climate control solutions. Major automotive manufacturers are increasingly incorporating thermoelectric generators to convert exhaust heat into usable electricity, improving overall vehicle efficiency by 3-5% in conventional vehicles and extending range in electric vehicles.

Consumer electronics constitutes another rapidly growing segment, with thermoelectric cooling solutions being integrated into high-performance computing systems, smartphones, and wearable devices. The miniaturization trend in electronics has created demand for compact, efficient cooling solutions where traditional methods prove inadequate.

Medical and healthcare applications represent an emerging high-value market, with thermoelectric modules being utilized in precise temperature control for diagnostic equipment, patient cooling systems, and portable medical devices. This segment is expected to grow at 12.8% annually through 2028, outpacing the overall market average.

Geographically, North America and Asia-Pacific dominate the market landscape. North America leads in research and development initiatives, while Asia-Pacific, particularly China, Japan, and South Korea, represents the largest manufacturing base and fastest-growing consumer market. Europe shows strong growth potential driven by stringent energy efficiency regulations and sustainability initiatives.

Market challenges include high initial production costs, with high-performance thermoelectric materials remaining expensive to synthesize at scale. The average cost-to-performance ratio remains a significant barrier to wider adoption in price-sensitive applications. Additionally, competition from alternative technologies such as phase-change materials and advanced heat pipes creates market pressure in certain application segments.

Customer demand increasingly focuses on modules with higher ZT values (figure of merit), with current commercial products typically offering ZT values between 0.8 and 1.2. Research breakthroughs demonstrating laboratory ZT values exceeding 2.0 indicate significant market disruption potential if successfully commercialized. Industry analysts project that achieving cost-effective production of modules with ZT values above 1.5 would expand the addressable market by 40% through enabling new applications previously considered impractical.

Current Challenges in Thermoelectric Module Development

Despite significant advancements in thermoelectric technology over recent decades, the development of high-efficiency thermoelectric modules continues to face substantial challenges. The fundamental limitation remains the interdependent nature of thermoelectric properties, specifically the conflicting relationship between electrical conductivity, thermal conductivity, and Seebeck coefficient. Optimizing one parameter typically degrades another, creating an inherent barrier to achieving high ZT values (figure of merit) necessary for commercial viability.

Material selection presents another significant hurdle. Current high-performance thermoelectric materials often contain rare, expensive, or toxic elements such as tellurium, lead, or bismuth. This dependency on critical materials restricts large-scale production and raises sustainability concerns. Additionally, many promising thermoelectric compounds exhibit optimal performance only within narrow temperature ranges, limiting their practical application across diverse thermal environments.

Manufacturing challenges further complicate module development. Precise control of material composition, doping levels, and microstructure is essential for consistent performance but difficult to maintain in mass production. Interface engineering between different materials in the module stack remains problematic, with contact resistance and thermal expansion mismatches causing reliability issues and performance degradation over time.

Thermal management within modules represents another critical challenge. Maintaining optimal temperature gradients while minimizing parasitic heat losses requires sophisticated design approaches. Current module architectures struggle to balance mechanical robustness with thermal efficiency, particularly when scaling to larger systems or integrating with existing infrastructure.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Current manufacturing processes for high-performance thermoelectric modules are complex and expensive, with material costs alone often prohibitive for many applications. The performance-to-cost ratio of thermoelectric systems continues to lag behind competing technologies for both power generation and cooling applications.

Reliability and longevity issues further complicate commercial deployment. Thermoelectric modules must withstand thermal cycling, mechanical stress, and environmental factors while maintaining consistent performance over extended periods. Current modules often experience performance degradation due to diffusion, oxidation, or mechanical failure at interfaces.

Standardization and testing methodologies present additional challenges. The lack of universally accepted protocols for characterizing module performance makes comparative analysis difficult and slows industry-wide progress. This absence of standardization also complicates integration with existing systems and regulatory compliance across different markets and applications.

Material selection presents another significant hurdle. Current high-performance thermoelectric materials often contain rare, expensive, or toxic elements such as tellurium, lead, or bismuth. This dependency on critical materials restricts large-scale production and raises sustainability concerns. Additionally, many promising thermoelectric compounds exhibit optimal performance only within narrow temperature ranges, limiting their practical application across diverse thermal environments.

Manufacturing challenges further complicate module development. Precise control of material composition, doping levels, and microstructure is essential for consistent performance but difficult to maintain in mass production. Interface engineering between different materials in the module stack remains problematic, with contact resistance and thermal expansion mismatches causing reliability issues and performance degradation over time.

Thermal management within modules represents another critical challenge. Maintaining optimal temperature gradients while minimizing parasitic heat losses requires sophisticated design approaches. Current module architectures struggle to balance mechanical robustness with thermal efficiency, particularly when scaling to larger systems or integrating with existing infrastructure.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Current manufacturing processes for high-performance thermoelectric modules are complex and expensive, with material costs alone often prohibitive for many applications. The performance-to-cost ratio of thermoelectric systems continues to lag behind competing technologies for both power generation and cooling applications.

Reliability and longevity issues further complicate commercial deployment. Thermoelectric modules must withstand thermal cycling, mechanical stress, and environmental factors while maintaining consistent performance over extended periods. Current modules often experience performance degradation due to diffusion, oxidation, or mechanical failure at interfaces.

Standardization and testing methodologies present additional challenges. The lack of universally accepted protocols for characterizing module performance makes comparative analysis difficult and slows industry-wide progress. This absence of standardization also complicates integration with existing systems and regulatory compliance across different markets and applications.

State-of-the-Art Thermoelectric Module Construction Methods

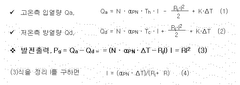

01 Material selection for thermoelectric efficiency

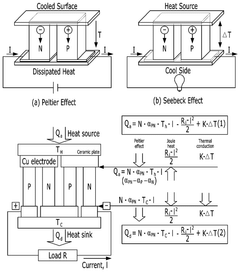

The choice of materials significantly impacts the efficiency of thermoelectric modules. High-performance thermoelectric materials with optimal electrical conductivity, thermal conductivity, and Seebeck coefficient can enhance the figure of merit (ZT) and overall conversion efficiency. Advanced semiconductor materials, nanostructured compounds, and novel alloys are being developed to improve the thermoelectric properties and increase the temperature differential that can be maintained across the module.- Material selection for thermoelectric efficiency: The choice of materials significantly impacts the efficiency of thermoelectric modules. Advanced semiconductor materials with high Seebeck coefficients and low thermal conductivity can improve the figure of merit (ZT) of thermoelectric devices. Nanostructured materials and alloys can further enhance performance by reducing thermal conductivity while maintaining electrical conductivity. These material innovations are crucial for achieving higher conversion efficiencies in thermoelectric power generation.

- Structural design optimization: The physical configuration and structural design of thermoelectric modules significantly affect their efficiency. Optimized geometries, improved contact interfaces, and novel module architectures can reduce thermal and electrical resistance. Multi-stage cascaded designs and segmented leg structures allow for operation across wider temperature gradients. Advanced manufacturing techniques enable precise fabrication of optimized structures that maximize power output and conversion efficiency.

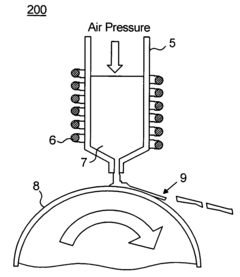

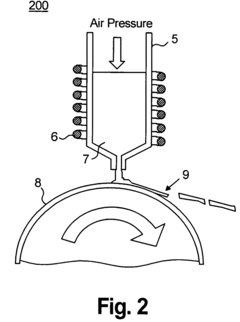

- Thermal management techniques: Effective thermal management is essential for maximizing thermoelectric module efficiency. Heat dissipation systems, including heat sinks, heat pipes, and active cooling mechanisms, help maintain optimal temperature gradients across the module. Thermal interface materials reduce contact resistance between components. Controlling heat flow paths and minimizing parasitic heat losses ensures that more thermal energy is converted to electrical power, thereby improving overall system efficiency.

- Circuit and electrical optimization: Electrical circuit design plays a crucial role in extracting maximum power from thermoelectric modules. Maximum power point tracking systems, optimized load matching, and efficient power conditioning circuits help maximize energy harvesting. Advanced interconnection methods reduce electrical resistance between thermoelectric elements. Hybrid systems that combine thermoelectric modules with other power generation or storage technologies can improve overall system efficiency and reliability.

- Novel cooling and heating applications: Innovative applications of thermoelectric modules in cooling and heating systems demonstrate improved efficiency through application-specific optimizations. Thermoelectric modules integrated into waste heat recovery systems, automotive applications, and consumer electronics show enhanced performance through specialized designs. Bidirectional operation capabilities allow modules to function efficiently in both cooling and power generation modes. These application-focused approaches often yield higher practical efficiencies than conventional implementations.

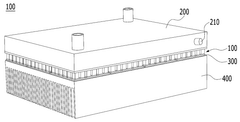

02 Structural design optimization

The physical configuration and structural design of thermoelectric modules play a crucial role in their efficiency. Optimized geometries, improved contact interfaces, and innovative module architectures can reduce thermal and electrical resistance. Multi-stage cascaded designs, segmented leg structures, and miniaturized modules with enhanced heat transfer characteristics help maximize power output and conversion efficiency across various operating conditions.Expand Specific Solutions03 Thermal management techniques

Effective thermal management is essential for maximizing thermoelectric module efficiency. Advanced heat sink designs, improved heat exchangers, and optimized thermal interfaces help maintain larger temperature differentials across the module. Techniques such as active cooling, heat spreading, and thermal isolation between hot and cold sides enhance energy conversion and prevent efficiency losses due to parasitic heat flow.Expand Specific Solutions04 Manufacturing process improvements

Advanced manufacturing techniques significantly impact thermoelectric module efficiency. Precision fabrication methods, improved electrical contacts, and enhanced bonding technologies reduce internal resistance and thermal losses. Novel approaches such as thin-film deposition, additive manufacturing, and nanofabrication enable better control over material properties and module geometry, resulting in higher performance and reliability.Expand Specific Solutions05 System-level integration and control

System-level integration and intelligent control strategies can optimize thermoelectric module performance under varying conditions. Power conditioning circuits, maximum power point tracking, and adaptive control algorithms help extract maximum energy from temperature differentials. Hybrid systems combining thermoelectric modules with other energy technologies, along with optimized load matching and operational parameters, enhance overall system efficiency and practical application performance.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectrics

The thermoelectric module efficiency market is currently in a growth phase, with increasing demand driven by waste heat recovery applications across automotive, industrial, and consumer electronics sectors. The global market size is projected to reach approximately $750 million by 2026, growing at a CAGR of 8%. Technologically, the field is advancing from mid to high maturity, with key players pursuing different approaches. Industry leaders like Toyota, Murata, and Kyocera are focusing on materials optimization, while specialized firms such as O-Flexx Technologies and Novus Energy Technologies concentrate on innovative module designs. Research institutions including ITRI, KIST, and the Industrial Technology Research Institute are advancing fundamental thermoelectric materials science. Automotive manufacturers (Continental Emitec, MAHLE, Aisin) are particularly active in integrating these technologies for vehicle waste heat recovery applications.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing has developed compact, high-efficiency thermoelectric modules using their expertise in ceramic components and precision manufacturing. Their approach centers on miniaturized modules with optimized thermal interfaces that achieve superior performance in limited spaces. Murata's technology employs bismuth-telluride semiconductor materials with precisely controlled doping profiles that maximize the Seebeck coefficient while minimizing electrical resistance. Their manufacturing process utilizes advanced thin-film deposition techniques that create exceptionally uniform thermoelectric elements with thicknesses below 100 micrometers. This enables higher element density and reduced thermal resistance. Murata has also pioneered specialized ceramic substrates with tailored thermal expansion properties that match their thermoelectric materials, minimizing mechanical stress during operation. Their modules incorporate proprietary electrode designs that reduce contact resistance to below 10^-6 Ω·cm², significantly improving overall conversion efficiency.

Strengths: Exceptional miniaturization capabilities and precision manufacturing enable high-performance modules for space-constrained applications. Weaknesses: Current designs are optimized for small-scale applications and may face challenges in scaling to higher-power industrial uses.

Advanced Industrial Science & Technology

Technical Solution: Advanced Industrial Science & Technology (AIST) has developed innovative nanostructured thermoelectric materials that significantly enhance ZT values through phonon scattering mechanisms. Their approach involves creating controlled nanostructures in bulk materials, particularly focusing on silicon-germanium alloys and skutterudites. AIST has pioneered the development of segmented thermoelectric modules that utilize different materials optimized for specific temperature ranges, allowing for maximum efficiency across broad temperature gradients. Their manufacturing process incorporates precision sintering techniques and automated assembly systems that ensure uniform contact resistance and thermal interfaces between thermoelectric elements. AIST has also developed specialized electrode materials and bonding techniques that minimize parasitic electrical and thermal losses at junctions, resulting in modules with conversion efficiencies exceeding 9% in laboratory settings.

Strengths: Superior material science expertise and advanced manufacturing capabilities enable higher ZT values than conventional approaches. Weaknesses: Higher production costs and complexity in mass manufacturing may limit widespread commercial adoption.

Key Patents and Breakthroughs in Thermoelectric Efficiency

Synthesis of High-Efficiency Thermoelectric Materials

PatentInactiveUS20110120517A1

Innovation

- A non-equilibrium synthesis method involving rapid solidification and sintering techniques, such as melt spinning and spark plasma sintering, is employed to inhibit phase segregation and grain growth, allowing for precise control over microstructure and the formation of fully dense thermoelectric materials with enhanced thermoelectric properties.

High-efficiency thermoelectric generation module

PatentWO2022107958A1

Innovation

- A high-efficiency thermoelectric power generation module is designed with a series-parallel mixing structure, connecting thermoelectric elements in parallel and series configurations, and incorporating a water jacket and ceramic panel to optimize temperature differences and reduce internal resistance, allowing for maximum power generation without additional load control devices.

Material Science Advancements for Thermoelectric Applications

Recent advancements in material science have revolutionized the field of thermoelectric applications, enabling significant improvements in the efficiency and performance of thermoelectric modules. The development of novel materials with enhanced thermoelectric properties has been a key focus area for researchers and industry professionals alike. These materials exhibit superior Seebeck coefficients, electrical conductivity, and thermal resistance characteristics, which are essential parameters for high-efficiency thermoelectric conversion.

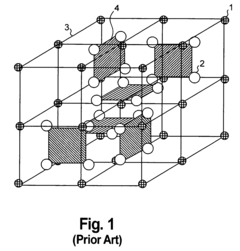

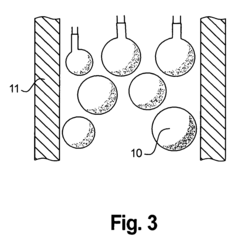

Nanostructured materials have emerged as particularly promising candidates for thermoelectric applications. By manipulating material structures at the nanoscale, researchers have successfully reduced thermal conductivity while maintaining or even improving electrical conductivity. This approach effectively addresses one of the fundamental challenges in thermoelectric material design: the interdependence of thermal and electrical properties.

Skutterudites, half-Heusler alloys, and clathrates represent a class of complex materials that have demonstrated exceptional thermoelectric performance. These materials feature intricate crystal structures that create natural phonon scattering centers, thereby reducing thermal conductivity without significantly compromising electrical transport properties. Recent innovations in doping techniques and compositional optimization have further enhanced their figure of merit (ZT) values.

Organic and polymer-based thermoelectric materials have also gained attention due to their flexibility, low cost, and environmental friendliness. While traditionally exhibiting lower efficiency compared to inorganic counterparts, recent breakthroughs in molecular design and doping strategies have significantly improved their performance metrics. These materials offer unique advantages for wearable and flexible thermoelectric applications.

Two-dimensional materials, including graphene derivatives and transition metal dichalcogenides, represent another frontier in thermoelectric material development. Their unique electronic band structures and quantum confinement effects contribute to enhanced Seebeck coefficients. Additionally, their layered structures can be engineered to create phonon scattering interfaces, effectively reducing thermal conductivity.

Composite and hybrid materials that combine different material classes have shown promising results by leveraging the complementary properties of their constituents. For instance, nanocomposites incorporating metallic nanoparticles within semiconductor matrices have demonstrated enhanced electrical conductivity while maintaining low thermal conductivity due to interface scattering effects.

Advanced manufacturing techniques, such as additive manufacturing and precision deposition methods, have enabled the fabrication of complex material architectures with precisely controlled compositions and structures. These techniques allow for the practical implementation of theoretically optimized material designs, bridging the gap between laboratory research and commercial applications in high-efficiency thermoelectric modules.

Nanostructured materials have emerged as particularly promising candidates for thermoelectric applications. By manipulating material structures at the nanoscale, researchers have successfully reduced thermal conductivity while maintaining or even improving electrical conductivity. This approach effectively addresses one of the fundamental challenges in thermoelectric material design: the interdependence of thermal and electrical properties.

Skutterudites, half-Heusler alloys, and clathrates represent a class of complex materials that have demonstrated exceptional thermoelectric performance. These materials feature intricate crystal structures that create natural phonon scattering centers, thereby reducing thermal conductivity without significantly compromising electrical transport properties. Recent innovations in doping techniques and compositional optimization have further enhanced their figure of merit (ZT) values.

Organic and polymer-based thermoelectric materials have also gained attention due to their flexibility, low cost, and environmental friendliness. While traditionally exhibiting lower efficiency compared to inorganic counterparts, recent breakthroughs in molecular design and doping strategies have significantly improved their performance metrics. These materials offer unique advantages for wearable and flexible thermoelectric applications.

Two-dimensional materials, including graphene derivatives and transition metal dichalcogenides, represent another frontier in thermoelectric material development. Their unique electronic band structures and quantum confinement effects contribute to enhanced Seebeck coefficients. Additionally, their layered structures can be engineered to create phonon scattering interfaces, effectively reducing thermal conductivity.

Composite and hybrid materials that combine different material classes have shown promising results by leveraging the complementary properties of their constituents. For instance, nanocomposites incorporating metallic nanoparticles within semiconductor matrices have demonstrated enhanced electrical conductivity while maintaining low thermal conductivity due to interface scattering effects.

Advanced manufacturing techniques, such as additive manufacturing and precision deposition methods, have enabled the fabrication of complex material architectures with precisely controlled compositions and structures. These techniques allow for the practical implementation of theoretically optimized material designs, bridging the gap between laboratory research and commercial applications in high-efficiency thermoelectric modules.

Environmental Impact and Sustainability of Thermoelectric Solutions

The development of thermoelectric modules presents significant environmental implications that must be considered alongside efficiency improvements. Traditional energy generation methods often produce substantial greenhouse gas emissions and environmental pollutants, whereas thermoelectric technology offers a cleaner alternative by directly converting waste heat into usable electricity without moving parts or harmful emissions.

Thermoelectric modules contribute to sustainability through waste heat recovery in various industrial processes. Manufacturing facilities, power plants, and automotive systems generate considerable thermal energy that typically dissipates into the environment. High-efficiency thermoelectric modules can capture this otherwise wasted energy, improving overall system efficiency and reducing the carbon footprint of industrial operations.

The materials used in thermoelectric modules present both challenges and opportunities for environmental sustainability. Conventional thermoelectric materials often contain scarce or toxic elements such as tellurium, bismuth, and lead. The mining and processing of these materials can result in habitat destruction, water pollution, and energy-intensive extraction processes. However, recent research has focused on developing alternative thermoelectric materials using earth-abundant elements with reduced environmental impact.

Life cycle assessment studies indicate that the environmental benefits of thermoelectric modules generally outweigh their production impacts when deployed in appropriate applications. The long operational lifespan of thermoelectric devices, typically exceeding 100,000 hours with minimal maintenance, enhances their sustainability profile compared to alternatives with shorter service lives or higher maintenance requirements.

The recyclability of thermoelectric modules represents another important sustainability consideration. Current manufacturing methods often result in composite structures that are challenging to disassemble and recycle. Developing design-for-disassembly approaches and establishing specialized recycling processes for thermoelectric materials could significantly improve their end-of-life environmental profile and support circular economy principles.

Energy payback time—the period required for a thermoelectric module to generate the same amount of energy used in its production—varies considerably depending on application and efficiency. High-efficiency modules in continuous waste heat recovery applications may achieve energy payback within months, while less optimal implementations might require years. Improving module efficiency directly enhances this sustainability metric.

As global environmental regulations become increasingly stringent, thermoelectric solutions that minimize hazardous substances and maximize resource efficiency will gain competitive advantage. The RoHS and REACH regulations in Europe already restrict certain substances commonly used in thermoelectric devices, driving innovation toward more environmentally benign alternatives.

Thermoelectric modules contribute to sustainability through waste heat recovery in various industrial processes. Manufacturing facilities, power plants, and automotive systems generate considerable thermal energy that typically dissipates into the environment. High-efficiency thermoelectric modules can capture this otherwise wasted energy, improving overall system efficiency and reducing the carbon footprint of industrial operations.

The materials used in thermoelectric modules present both challenges and opportunities for environmental sustainability. Conventional thermoelectric materials often contain scarce or toxic elements such as tellurium, bismuth, and lead. The mining and processing of these materials can result in habitat destruction, water pollution, and energy-intensive extraction processes. However, recent research has focused on developing alternative thermoelectric materials using earth-abundant elements with reduced environmental impact.

Life cycle assessment studies indicate that the environmental benefits of thermoelectric modules generally outweigh their production impacts when deployed in appropriate applications. The long operational lifespan of thermoelectric devices, typically exceeding 100,000 hours with minimal maintenance, enhances their sustainability profile compared to alternatives with shorter service lives or higher maintenance requirements.

The recyclability of thermoelectric modules represents another important sustainability consideration. Current manufacturing methods often result in composite structures that are challenging to disassemble and recycle. Developing design-for-disassembly approaches and establishing specialized recycling processes for thermoelectric materials could significantly improve their end-of-life environmental profile and support circular economy principles.

Energy payback time—the period required for a thermoelectric module to generate the same amount of energy used in its production—varies considerably depending on application and efficiency. High-efficiency modules in continuous waste heat recovery applications may achieve energy payback within months, while less optimal implementations might require years. Improving module efficiency directly enhances this sustainability metric.

As global environmental regulations become increasingly stringent, thermoelectric solutions that minimize hazardous substances and maximize resource efficiency will gain competitive advantage. The RoHS and REACH regulations in Europe already restrict certain substances commonly used in thermoelectric devices, driving innovation toward more environmentally benign alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!