Thermoelectric Materials in Heat Source Temperature Condition Tests

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Development Background and Objectives

Thermoelectric materials have emerged as a promising solution for direct conversion of thermal energy into electrical power, representing a significant advancement in sustainable energy technologies. The development of these materials dates back to the early 19th century with the discovery of the Seebeck effect by Thomas Johann Seebeck in 1821, followed by the Peltier effect in 1834. However, it wasn't until the mid-20th century that substantial progress was made in developing practical thermoelectric materials with improved efficiency.

The evolution of thermoelectric technology has been characterized by three distinct generations. First-generation materials, primarily based on bismuth telluride (Bi₂Te₃) and lead telluride (PbTe), established the foundation for commercial applications but were limited by relatively low conversion efficiencies. Second-generation materials introduced nanostructuring techniques to enhance performance, while current third-generation materials explore complex crystal structures and novel material compositions to achieve higher figure of merit (ZT) values.

Recent advancements in material science, nanotechnology, and computational modeling have accelerated the development of high-performance thermoelectric materials. The integration of these materials into heat source temperature condition tests represents a critical step in evaluating their practical applicability across various thermal environments, from low-temperature waste heat recovery to high-temperature industrial applications.

The primary objective of thermoelectric materials research in heat source temperature condition testing is to develop materials with optimized performance across diverse temperature ranges. This includes enhancing the ZT value, which directly correlates with conversion efficiency, while ensuring material stability and reliability under varying thermal conditions. Specifically, researchers aim to achieve ZT values exceeding 2.0 for commercial viability, compared to current typical values of 1.0-1.5.

Additional technical goals include reducing material costs through the utilization of earth-abundant elements, minimizing environmental impact by replacing toxic components like lead and tellurium, and improving manufacturing scalability to facilitate widespread industrial adoption. The development of flexible thermoelectric materials capable of operating efficiently under dynamic temperature fluctuations represents another frontier in this field.

Understanding how thermoelectric materials perform under controlled temperature conditions is essential for bridging the gap between laboratory research and practical applications. These tests provide crucial data on thermal stability, degradation mechanisms, and long-term performance—factors that significantly influence the commercial viability of thermoelectric technologies in waste heat recovery systems, automotive applications, and distributed power generation.

The evolution of thermoelectric technology has been characterized by three distinct generations. First-generation materials, primarily based on bismuth telluride (Bi₂Te₃) and lead telluride (PbTe), established the foundation for commercial applications but were limited by relatively low conversion efficiencies. Second-generation materials introduced nanostructuring techniques to enhance performance, while current third-generation materials explore complex crystal structures and novel material compositions to achieve higher figure of merit (ZT) values.

Recent advancements in material science, nanotechnology, and computational modeling have accelerated the development of high-performance thermoelectric materials. The integration of these materials into heat source temperature condition tests represents a critical step in evaluating their practical applicability across various thermal environments, from low-temperature waste heat recovery to high-temperature industrial applications.

The primary objective of thermoelectric materials research in heat source temperature condition testing is to develop materials with optimized performance across diverse temperature ranges. This includes enhancing the ZT value, which directly correlates with conversion efficiency, while ensuring material stability and reliability under varying thermal conditions. Specifically, researchers aim to achieve ZT values exceeding 2.0 for commercial viability, compared to current typical values of 1.0-1.5.

Additional technical goals include reducing material costs through the utilization of earth-abundant elements, minimizing environmental impact by replacing toxic components like lead and tellurium, and improving manufacturing scalability to facilitate widespread industrial adoption. The development of flexible thermoelectric materials capable of operating efficiently under dynamic temperature fluctuations represents another frontier in this field.

Understanding how thermoelectric materials perform under controlled temperature conditions is essential for bridging the gap between laboratory research and practical applications. These tests provide crucial data on thermal stability, degradation mechanisms, and long-term performance—factors that significantly influence the commercial viability of thermoelectric technologies in waste heat recovery systems, automotive applications, and distributed power generation.

Market Analysis for Thermoelectric Energy Harvesting Applications

The thermoelectric energy harvesting market is experiencing significant growth, driven by increasing demand for sustainable energy solutions and the advancement of Internet of Things (IoT) technologies. Current market valuations place the global thermoelectric energy harvesting sector at approximately $626 million in 2023, with projections indicating a compound annual growth rate of 11.7% through 2030, potentially reaching $1.38 billion by the end of the decade.

Industrial applications represent the largest market segment, accounting for nearly 40% of the total market share. These applications primarily focus on waste heat recovery from manufacturing processes, power plants, and automotive systems. The automotive sector specifically has shown remarkable adoption rates, with thermoelectric generators being integrated into exhaust systems to convert waste heat into usable electricity, improving overall vehicle efficiency by 3-5%.

Consumer electronics constitute the fastest-growing segment, with a projected growth rate of 14.2% annually. This surge is attributed to the increasing integration of thermoelectric materials in wearable devices, portable chargers, and smart home systems. The miniaturization of thermoelectric modules has enabled their incorporation into devices where traditional power sources are impractical.

Geographically, North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 28%. However, the Asia-Pacific region is expected to overtake other regions by 2027, driven by rapid industrialization in China and India, coupled with substantial government investments in green technologies.

Customer demand patterns reveal a growing preference for thermoelectric solutions that operate efficiently across wider temperature differentials. This trend directly relates to the importance of heat source temperature condition testing, as materials that can maintain performance across variable temperature conditions command premium market positioning.

Key market drivers include stringent environmental regulations promoting energy efficiency, rising energy costs incentivizing waste heat recovery solutions, and the proliferation of wireless sensor networks requiring autonomous power sources. The increasing focus on decarbonization across industries has created favorable conditions for thermoelectric technologies that can convert otherwise wasted thermal energy into valuable electrical power.

Market barriers include the relatively high cost of high-performance thermoelectric materials, limited conversion efficiency compared to some alternative technologies, and challenges in system integration. However, recent advancements in material science, particularly in skutterudites and half-Heusler alloys, are gradually addressing these limitations, expanding the practical application range of thermoelectric energy harvesting solutions.

Industrial applications represent the largest market segment, accounting for nearly 40% of the total market share. These applications primarily focus on waste heat recovery from manufacturing processes, power plants, and automotive systems. The automotive sector specifically has shown remarkable adoption rates, with thermoelectric generators being integrated into exhaust systems to convert waste heat into usable electricity, improving overall vehicle efficiency by 3-5%.

Consumer electronics constitute the fastest-growing segment, with a projected growth rate of 14.2% annually. This surge is attributed to the increasing integration of thermoelectric materials in wearable devices, portable chargers, and smart home systems. The miniaturization of thermoelectric modules has enabled their incorporation into devices where traditional power sources are impractical.

Geographically, North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 28%. However, the Asia-Pacific region is expected to overtake other regions by 2027, driven by rapid industrialization in China and India, coupled with substantial government investments in green technologies.

Customer demand patterns reveal a growing preference for thermoelectric solutions that operate efficiently across wider temperature differentials. This trend directly relates to the importance of heat source temperature condition testing, as materials that can maintain performance across variable temperature conditions command premium market positioning.

Key market drivers include stringent environmental regulations promoting energy efficiency, rising energy costs incentivizing waste heat recovery solutions, and the proliferation of wireless sensor networks requiring autonomous power sources. The increasing focus on decarbonization across industries has created favorable conditions for thermoelectric technologies that can convert otherwise wasted thermal energy into valuable electrical power.

Market barriers include the relatively high cost of high-performance thermoelectric materials, limited conversion efficiency compared to some alternative technologies, and challenges in system integration. However, recent advancements in material science, particularly in skutterudites and half-Heusler alloys, are gradually addressing these limitations, expanding the practical application range of thermoelectric energy harvesting solutions.

Current Challenges in Heat Source Temperature Testing

Testing thermoelectric materials under realistic heat source temperature conditions presents several significant challenges that impede accurate performance evaluation and material optimization. The primary difficulty lies in creating stable and uniform temperature distributions across test samples. Temperature gradients within test chambers can lead to inconsistent measurements, particularly when evaluating materials intended for high-temperature applications exceeding 500°C, where even minor fluctuations significantly impact the Seebeck coefficient and thermal conductivity readings.

Measurement accuracy represents another critical challenge, as thermoelectric performance metrics require simultaneous precise measurement of electrical properties and thermal gradients. Current instrumentation often struggles to maintain calibration accuracy across wide temperature ranges, introducing systematic errors that compound when calculating the figure of merit (ZT). These measurement uncertainties become particularly problematic when comparing materials from different research groups or when attempting to replicate published results.

Long-term stability testing presents unique difficulties, as many thermoelectric materials undergo compositional or structural changes during extended exposure to operational temperatures. Accelerated aging tests frequently fail to accurately simulate real-world degradation mechanisms, leading to overly optimistic performance projections. The lack of standardized testing protocols for long-term stability assessment further complicates material comparison and selection for commercial applications.

Interface effects between thermoelectric materials and heat sources introduce additional complexities. Contact resistance at these interfaces can significantly degrade overall system performance, yet standard testing methodologies often focus exclusively on bulk material properties while neglecting these critical boundary conditions. This disconnect between laboratory testing and practical implementation has contributed to the performance gap observed when scaling from material samples to functional devices.

Simulating dynamic temperature conditions poses another substantial challenge. Real-world heat sources rarely maintain constant temperatures, yet most testing protocols employ steady-state conditions that fail to capture performance under thermal cycling or rapid temperature fluctuations. This limitation is particularly relevant for waste heat recovery applications in automotive or industrial settings, where heat source temperatures can vary substantially during normal operation.

Standardization issues further complicate the field, as different research groups and manufacturers employ varied testing methodologies, making direct comparisons between published results difficult. The lack of universally accepted testing protocols has hindered technology transfer from research laboratories to commercial applications and slowed industry adoption of promising new thermoelectric materials.

Measurement accuracy represents another critical challenge, as thermoelectric performance metrics require simultaneous precise measurement of electrical properties and thermal gradients. Current instrumentation often struggles to maintain calibration accuracy across wide temperature ranges, introducing systematic errors that compound when calculating the figure of merit (ZT). These measurement uncertainties become particularly problematic when comparing materials from different research groups or when attempting to replicate published results.

Long-term stability testing presents unique difficulties, as many thermoelectric materials undergo compositional or structural changes during extended exposure to operational temperatures. Accelerated aging tests frequently fail to accurately simulate real-world degradation mechanisms, leading to overly optimistic performance projections. The lack of standardized testing protocols for long-term stability assessment further complicates material comparison and selection for commercial applications.

Interface effects between thermoelectric materials and heat sources introduce additional complexities. Contact resistance at these interfaces can significantly degrade overall system performance, yet standard testing methodologies often focus exclusively on bulk material properties while neglecting these critical boundary conditions. This disconnect between laboratory testing and practical implementation has contributed to the performance gap observed when scaling from material samples to functional devices.

Simulating dynamic temperature conditions poses another substantial challenge. Real-world heat sources rarely maintain constant temperatures, yet most testing protocols employ steady-state conditions that fail to capture performance under thermal cycling or rapid temperature fluctuations. This limitation is particularly relevant for waste heat recovery applications in automotive or industrial settings, where heat source temperatures can vary substantially during normal operation.

Standardization issues further complicate the field, as different research groups and manufacturers employ varied testing methodologies, making direct comparisons between published results difficult. The lack of universally accepted testing protocols has hindered technology transfer from research laboratories to commercial applications and slowed industry adoption of promising new thermoelectric materials.

Current Testing Protocols for Thermoelectric Performance

01 Temperature gradient optimization in thermoelectric materials

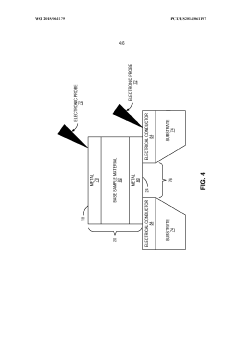

Thermoelectric materials require specific temperature conditions to operate efficiently. The performance of these materials is directly related to the temperature gradient across them. By optimizing the temperature difference between the hot and cold sides, the thermoelectric conversion efficiency can be significantly improved. Various designs and configurations are employed to maintain optimal temperature gradients for maximum power generation or cooling effects.- Temperature conditions for thermoelectric material performance: The performance of thermoelectric materials is highly dependent on temperature conditions. These materials exhibit different efficiency levels at various temperature ranges, with some materials optimized for high-temperature applications and others for low-temperature use. The temperature gradient across the material directly affects the Seebeck coefficient and overall energy conversion efficiency. Understanding these temperature dependencies is crucial for selecting appropriate materials for specific applications.

- High-temperature thermoelectric materials: Specialized thermoelectric materials designed for high-temperature applications can operate efficiently in extreme thermal environments. These materials often incorporate elements like silicon-germanium alloys, skutterudites, or half-Heusler compounds that maintain structural stability and electrical properties at elevated temperatures. High-temperature thermoelectric materials are particularly valuable in waste heat recovery systems for industrial processes, automotive applications, and power generation where heat sources exceed several hundred degrees Celsius.

- Temperature-dependent fabrication methods: The manufacturing processes for thermoelectric materials often require specific temperature conditions to achieve optimal crystal structure and electrical properties. Techniques such as hot pressing, spark plasma sintering, and zone melting are employed under controlled temperature conditions to enhance thermoelectric performance. The thermal history during fabrication significantly impacts carrier concentration, mobility, and thermal conductivity of the final material, which directly affects the figure of merit (ZT) value.

- Temperature cycling and stability: Thermoelectric materials must maintain performance stability under repeated temperature cycling conditions in practical applications. Material degradation, phase changes, or interface delamination can occur due to thermal expansion mismatches during cycling. Advanced thermoelectric materials incorporate nanostructuring, compositional gradients, or protective coatings to enhance thermal stability and prevent performance deterioration over time when subjected to fluctuating temperature conditions.

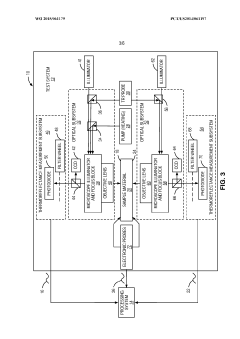

- Temperature measurement and control systems: Precise temperature measurement and control systems are essential for optimizing thermoelectric device performance. These systems monitor temperature gradients across thermoelectric modules and adjust operating parameters accordingly. Advanced control algorithms can maintain optimal temperature conditions to maximize power generation or cooling efficiency. Temperature sensors, heat flux meters, and electronic control units work together to ensure thermoelectric materials operate within their ideal temperature ranges for specific applications.

02 High-temperature thermoelectric materials

Certain thermoelectric materials are specifically designed to operate under high-temperature conditions. These materials maintain their thermoelectric properties and structural integrity at elevated temperatures, making them suitable for applications such as waste heat recovery in industrial processes, automotive exhaust systems, and power plants. Advanced compositions and manufacturing techniques are employed to enhance the stability and performance of these materials at high temperatures.Expand Specific Solutions03 Low-temperature thermoelectric applications

Thermoelectric materials designed for low-temperature applications have unique compositions and structures that enable efficient energy conversion at reduced temperatures. These materials are particularly useful for cooling applications, refrigeration systems, and energy harvesting from low-grade heat sources. The performance of these materials is optimized for temperature ranges typically below 200°C, with specific dopants and manufacturing processes tailored to enhance their low-temperature efficiency.Expand Specific Solutions04 Temperature-dependent phase transitions in thermoelectric materials

Many thermoelectric materials undergo phase transitions at specific temperature conditions, which can significantly affect their performance. These transitions can be utilized to enhance the thermoelectric properties or can be detrimental if not properly managed. Research focuses on understanding and controlling these phase transitions to develop materials with stable performance across wider temperature ranges. Some advanced materials are designed to take advantage of these transitions to achieve higher efficiency at specific operating temperatures.Expand Specific Solutions05 Temperature cycling and thermal stability

Thermoelectric materials must maintain their performance under repeated temperature cycling conditions in practical applications. The thermal stability of these materials is crucial for long-term reliability and efficiency. Various approaches are employed to enhance thermal stability, including the development of composite structures, protective coatings, and novel material compositions that resist degradation under thermal stress. Testing protocols involve subjecting materials to numerous heating and cooling cycles to evaluate their durability and performance retention.Expand Specific Solutions

Leading Research Institutions and Industrial Players

Thermoelectric materials testing for heat source temperature conditions is currently in a growth phase, with the market expected to reach significant expansion due to increasing demand for waste heat recovery solutions. The competitive landscape features a mix of academic institutions (MIT, Northwestern University, Ohio State University), major corporations (Toyota, Apple, Caterpillar), and specialized companies (Phononic, Gentherm, ZT Plus). Research leadership is distributed across North America, Europe, and Asia, with notable contributions from national laboratories like the National Institute for Materials Science and Industrial Technology Research Institute. The technology is approaching commercial maturity in certain applications, though efficiency improvements remain a key focus area for most players, with automotive and industrial sectors showing the strongest adoption potential.

The Ohio State University

Technical Solution: Ohio State University has established a sophisticated thermoelectric materials testing laboratory focused on dynamic temperature condition evaluation. Their approach centers on a custom-designed apparatus that can rapidly cycle between different temperature regimes to simulate real-world operating environments. The university's testing methodology incorporates impedance spectroscopy techniques to characterize material properties under transient temperature conditions, providing insights into performance under fluctuating heat sources. Their system employs multiple temperature sensors positioned strategically throughout test samples to create detailed thermal mapping during operation. OSU researchers have developed specialized algorithms for data processing that account for thermal lag and other time-dependent phenomena that affect thermoelectric performance measurements. Their testing capabilities extend to evaluating materials under mechanical stress while simultaneously subjected to temperature gradients, simulating actual device operating conditions. The university has also pioneered non-destructive evaluation techniques that allow for repeated testing of the same sample under different temperature profiles[4][7].

Strengths: Excellent capabilities for evaluating dynamic temperature performance; comprehensive data collection under realistic operating conditions; innovative approaches to transient thermal analysis. Weaknesses: Complex testing methodology requires significant expertise to implement correctly; testing equipment has higher maintenance requirements due to thermal cycling capabilities.

Northwestern University

Technical Solution: Northwestern University has developed a comprehensive thermoelectric material testing platform that focuses on high-temperature performance evaluation. Their system employs simultaneous measurement of Seebeck coefficient, electrical conductivity, and thermal conductivity under identical temperature conditions to ensure accurate ZT value determination. The university's approach includes custom-built apparatus capable of creating precise temperature gradients while minimizing measurement errors from thermal and electrical contact resistances. Northwestern researchers have implemented flash diffusivity methods combined with laser-based thermal conductivity measurements to characterize materials at temperatures ranging from ambient to over 800°C. Their testing protocols incorporate long-term stability assessments, where materials are subjected to extended thermal cycling to evaluate performance degradation over time. Additionally, they've developed specialized sample preparation techniques that minimize interfacial thermal resistance issues that commonly plague thermoelectric testing accuracy[2][5].

Strengths: Holistic measurement approach capturing all relevant thermoelectric parameters simultaneously; excellent reproducibility of results; specialized expertise in high-temperature applications. Weaknesses: Testing methodology prioritizes accuracy over testing speed; requires highly specialized equipment and expertise to operate effectively.

Key Patents and Research in Temperature Condition Testing

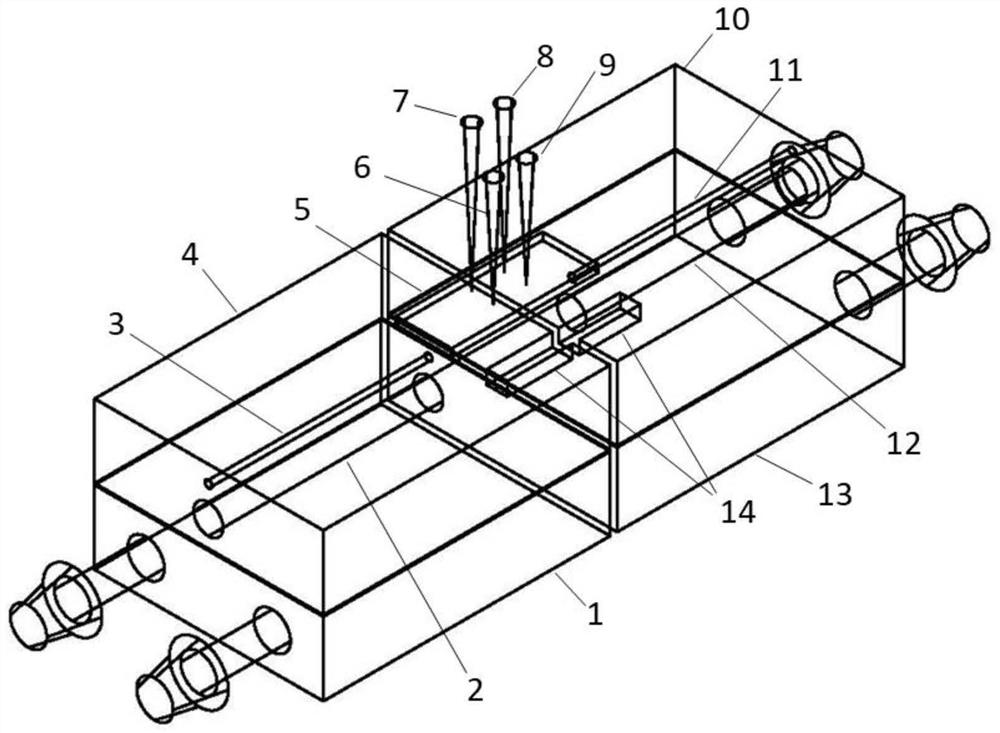

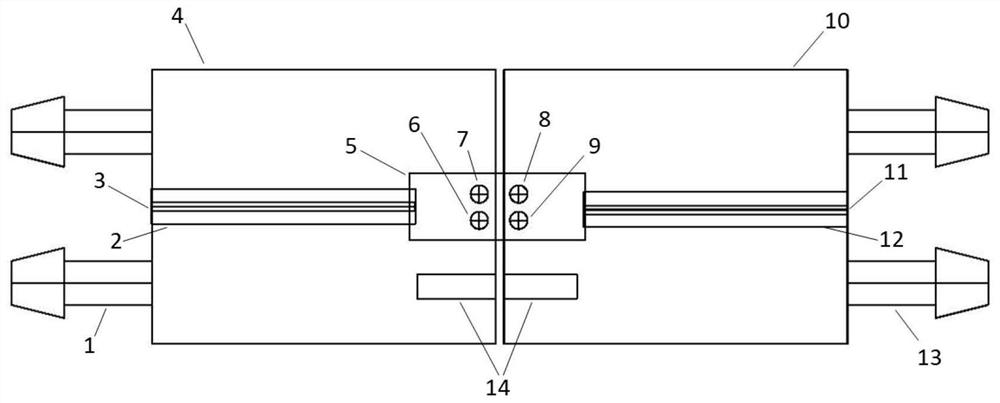

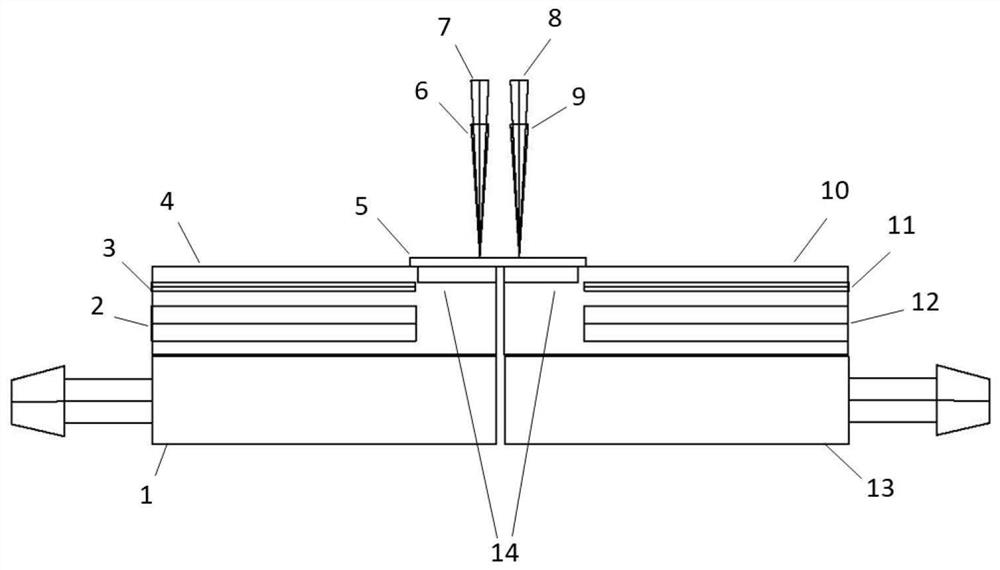

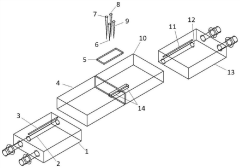

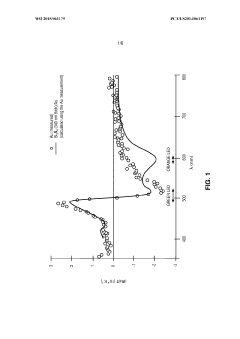

Horizontal test device and method for Seebeck coefficient and conductivity of thermoelectric material

PatentPendingCN113758961A

Innovation

- A horizontal test equipment consisting of two parallel test units is designed. Each test unit contains a heating block, heating element, temperature sensor, voltage and current test probe and cooling system, using contact heating and cooling to support the block. and film samples, and tested conductivity through linear four-probe method and Vanderbilt method to adapt to different temperature conditions.

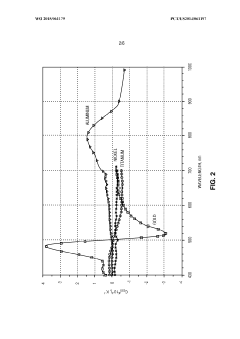

Thermoreflectance-based characterization of thermoelectric material properties

PatentWO2015061179A1

Innovation

- The use of thermoreflectance-based temperature measurements in conjunction with electrical measurements to characterize thermal, thermoelectric, and thermomagnetic properties of materials, allowing for non-contact characterization suitable for small sample sizes, including the application of a material with a high thermoreflectance coefficient to enhance measurement accuracy.

Environmental Impact and Sustainability Considerations

The environmental impact of thermoelectric materials testing extends beyond laboratory boundaries, affecting broader ecological systems. Traditional testing methods often involve significant energy consumption, particularly when simulating various heat source temperature conditions. These processes typically require continuous operation of high-temperature furnaces and cooling systems, contributing to substantial carbon emissions. Recent studies indicate that a standard thermoelectric material testing facility can consume between 50-200 kWh daily, equivalent to the electricity usage of multiple households.

Material selection presents another critical environmental consideration. Many high-performance thermoelectric materials contain rare earth elements or toxic components such as tellurium, lead, and antimony. The mining and processing of these elements generate considerable environmental degradation, including habitat destruction, water pollution, and soil contamination. Furthermore, improper disposal of test specimens containing these materials can lead to long-term environmental contamination.

Water usage in cooling systems during temperature condition tests represents a significant sustainability challenge. Conventional testing setups may consume thousands of liters of water annually, particularly in continuous testing environments. This consumption becomes increasingly problematic in regions facing water scarcity issues, necessitating the development of closed-loop cooling systems and alternative cooling technologies.

The life cycle assessment (LCA) of thermoelectric material testing reveals substantial opportunities for sustainability improvements. Implementing energy recovery systems can capture and repurpose waste heat generated during high-temperature testing phases. Several research institutions have successfully reduced energy consumption by 30-40% through such recovery systems, demonstrating their practical viability.

Emerging sustainable practices include the development of bio-based or recyclable thermoelectric materials that maintain performance while reducing environmental impact. Silicon-based alternatives and organic thermoelectric compounds show particular promise, offering comparable efficiency with significantly reduced toxicity profiles. Additionally, computational modeling and simulation technologies can substantially decrease the number of physical tests required, minimizing material waste and energy consumption.

International standards for sustainable thermoelectric testing are gradually evolving, with organizations like IEEE and ISO developing frameworks that incorporate environmental considerations. These standards increasingly emphasize closed-loop testing systems, energy efficiency metrics, and responsible material sourcing guidelines, driving industry-wide improvements in environmental performance.

Material selection presents another critical environmental consideration. Many high-performance thermoelectric materials contain rare earth elements or toxic components such as tellurium, lead, and antimony. The mining and processing of these elements generate considerable environmental degradation, including habitat destruction, water pollution, and soil contamination. Furthermore, improper disposal of test specimens containing these materials can lead to long-term environmental contamination.

Water usage in cooling systems during temperature condition tests represents a significant sustainability challenge. Conventional testing setups may consume thousands of liters of water annually, particularly in continuous testing environments. This consumption becomes increasingly problematic in regions facing water scarcity issues, necessitating the development of closed-loop cooling systems and alternative cooling technologies.

The life cycle assessment (LCA) of thermoelectric material testing reveals substantial opportunities for sustainability improvements. Implementing energy recovery systems can capture and repurpose waste heat generated during high-temperature testing phases. Several research institutions have successfully reduced energy consumption by 30-40% through such recovery systems, demonstrating their practical viability.

Emerging sustainable practices include the development of bio-based or recyclable thermoelectric materials that maintain performance while reducing environmental impact. Silicon-based alternatives and organic thermoelectric compounds show particular promise, offering comparable efficiency with significantly reduced toxicity profiles. Additionally, computational modeling and simulation technologies can substantially decrease the number of physical tests required, minimizing material waste and energy consumption.

International standards for sustainable thermoelectric testing are gradually evolving, with organizations like IEEE and ISO developing frameworks that incorporate environmental considerations. These standards increasingly emphasize closed-loop testing systems, energy efficiency metrics, and responsible material sourcing guidelines, driving industry-wide improvements in environmental performance.

Standardization and Quality Control Frameworks

The standardization of testing protocols for thermoelectric materials under varying heat source conditions represents a critical framework for ensuring reliable and comparable research outcomes across the industry. Current quality control frameworks exhibit significant variations between laboratories, leading to inconsistent performance evaluations and hindering technological advancement in the field. Establishing unified testing standards requires addressing multiple parameters including temperature gradient measurement accuracy, thermal interface management, and electrical contact resistance minimization.

International organizations such as ASTM International, ISO, and IEEE have begun developing specialized standards for thermoelectric material characterization, though comprehensive frameworks specifically addressing heat source temperature condition tests remain underdeveloped. The ASTM E2716 standard provides partial guidance for thermoelectric material testing, but lacks specific protocols for dynamic temperature conditions that more accurately reflect real-world applications.

Quality assurance methodologies for thermoelectric testing must incorporate statistical validation approaches, uncertainty quantification, and calibration procedures for measurement equipment. Round-robin testing initiatives among leading research institutions have demonstrated that measurement discrepancies of up to 15% in ZT values can occur when standardized protocols are absent, highlighting the urgent need for harmonized testing frameworks.

Reference materials with well-characterized thermoelectric properties present a promising solution for cross-laboratory calibration. Materials such as bismuth telluride and silicon-germanium alloys with certified thermoelectric properties could serve as benchmarks against which testing equipment and methodologies can be validated. Several national metrology institutes have initiated programs to develop and distribute such reference materials, though wider adoption remains limited.

Digital data management systems integrated with testing equipment offer opportunities for automated quality control and enhanced reproducibility. These systems can implement real-time statistical process control, flagging anomalous measurements and ensuring adherence to standardized testing protocols. Machine learning algorithms are increasingly being deployed to identify subtle testing inconsistencies that might otherwise go undetected through conventional quality control methods.

Certification programs for testing facilities represent another important component of quality frameworks. Organizations like the National Institute of Standards and Technology (NIST) have proposed certification criteria for thermoelectric testing laboratories, though implementation remains voluntary. Industry consortia are increasingly recognizing the value of certified testing capabilities as thermoelectric technologies move toward commercialization in automotive, industrial waste heat recovery, and consumer electronics applications.

International organizations such as ASTM International, ISO, and IEEE have begun developing specialized standards for thermoelectric material characterization, though comprehensive frameworks specifically addressing heat source temperature condition tests remain underdeveloped. The ASTM E2716 standard provides partial guidance for thermoelectric material testing, but lacks specific protocols for dynamic temperature conditions that more accurately reflect real-world applications.

Quality assurance methodologies for thermoelectric testing must incorporate statistical validation approaches, uncertainty quantification, and calibration procedures for measurement equipment. Round-robin testing initiatives among leading research institutions have demonstrated that measurement discrepancies of up to 15% in ZT values can occur when standardized protocols are absent, highlighting the urgent need for harmonized testing frameworks.

Reference materials with well-characterized thermoelectric properties present a promising solution for cross-laboratory calibration. Materials such as bismuth telluride and silicon-germanium alloys with certified thermoelectric properties could serve as benchmarks against which testing equipment and methodologies can be validated. Several national metrology institutes have initiated programs to develop and distribute such reference materials, though wider adoption remains limited.

Digital data management systems integrated with testing equipment offer opportunities for automated quality control and enhanced reproducibility. These systems can implement real-time statistical process control, flagging anomalous measurements and ensuring adherence to standardized testing protocols. Machine learning algorithms are increasingly being deployed to identify subtle testing inconsistencies that might otherwise go undetected through conventional quality control methods.

Certification programs for testing facilities represent another important component of quality frameworks. Organizations like the National Institute of Standards and Technology (NIST) have proposed certification criteria for thermoelectric testing laboratories, though implementation remains voluntary. Industry consortia are increasingly recognizing the value of certified testing capabilities as thermoelectric technologies move toward commercialization in automotive, industrial waste heat recovery, and consumer electronics applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!