Improving Thermoelectric Generator Efficiency Using Nanotechnology

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Nanotechnology Background and Objectives

Thermoelectric power generation has evolved significantly since its discovery in the early 19th century with the Seebeck effect. This phenomenon, where temperature differences are directly converted into electrical voltage, has seen renewed interest due to increasing global energy demands and environmental concerns. Traditional thermoelectric generators (TEGs) have been limited by their low efficiency, typically converting only 5-8% of heat energy into electricity, which has restricted their widespread adoption despite their reliability and lack of moving parts.

Nanotechnology represents a revolutionary approach to enhancing thermoelectric efficiency. By manipulating materials at the nanoscale (1-100 nm), researchers can engineer thermal and electrical properties that are unattainable in bulk materials. The field has witnessed accelerated development since the 1990s, with significant breakthroughs occurring in the past decade as advanced fabrication techniques have matured.

The fundamental challenge in thermoelectric technology lies in simultaneously optimizing three interdependent parameters: electrical conductivity, thermal conductivity, and Seebeck coefficient. These parameters are collectively expressed in the figure of merit ZT, which directly correlates with conversion efficiency. Historically, improving one parameter often degraded others, creating a seemingly insurmountable barrier to achieving high ZT values.

Nanotechnology offers promising pathways to overcome this limitation through quantum confinement effects, phonon scattering at interfaces, and band structure engineering. Recent research has demonstrated that nanostructured materials can achieve ZT values exceeding 2.0, compared to traditional materials that rarely surpass 1.0. This improvement translates to potential efficiency increases from below 10% to theoretical values approaching 20-30%.

The primary objectives of current thermoelectric nanotechnology research include developing scalable fabrication methods for high-performance nanomaterials, creating composite structures that optimize electron and phonon transport, and discovering novel materials with intrinsically favorable thermoelectric properties. Additionally, researchers aim to reduce reliance on rare or toxic elements like tellurium and lead, which are common in today's best-performing thermoelectric materials.

Industry trends indicate growing interest in waste heat recovery applications, particularly in automotive, industrial, and power generation sectors. The global thermoelectric generator market is projected to expand significantly, driven by energy efficiency regulations and sustainability initiatives. Concurrently, emerging applications in wearable technology, IoT devices, and space exploration are creating new opportunities for specialized thermoelectric solutions.

The convergence of advanced computational modeling, novel synthesis techniques, and improved characterization methods is accelerating innovation in this field. As research progresses toward addressing key technical challenges, thermoelectric nanotechnology stands poised to transform how we harvest and utilize waste heat across multiple sectors of the global economy.

Nanotechnology represents a revolutionary approach to enhancing thermoelectric efficiency. By manipulating materials at the nanoscale (1-100 nm), researchers can engineer thermal and electrical properties that are unattainable in bulk materials. The field has witnessed accelerated development since the 1990s, with significant breakthroughs occurring in the past decade as advanced fabrication techniques have matured.

The fundamental challenge in thermoelectric technology lies in simultaneously optimizing three interdependent parameters: electrical conductivity, thermal conductivity, and Seebeck coefficient. These parameters are collectively expressed in the figure of merit ZT, which directly correlates with conversion efficiency. Historically, improving one parameter often degraded others, creating a seemingly insurmountable barrier to achieving high ZT values.

Nanotechnology offers promising pathways to overcome this limitation through quantum confinement effects, phonon scattering at interfaces, and band structure engineering. Recent research has demonstrated that nanostructured materials can achieve ZT values exceeding 2.0, compared to traditional materials that rarely surpass 1.0. This improvement translates to potential efficiency increases from below 10% to theoretical values approaching 20-30%.

The primary objectives of current thermoelectric nanotechnology research include developing scalable fabrication methods for high-performance nanomaterials, creating composite structures that optimize electron and phonon transport, and discovering novel materials with intrinsically favorable thermoelectric properties. Additionally, researchers aim to reduce reliance on rare or toxic elements like tellurium and lead, which are common in today's best-performing thermoelectric materials.

Industry trends indicate growing interest in waste heat recovery applications, particularly in automotive, industrial, and power generation sectors. The global thermoelectric generator market is projected to expand significantly, driven by energy efficiency regulations and sustainability initiatives. Concurrently, emerging applications in wearable technology, IoT devices, and space exploration are creating new opportunities for specialized thermoelectric solutions.

The convergence of advanced computational modeling, novel synthesis techniques, and improved characterization methods is accelerating innovation in this field. As research progresses toward addressing key technical challenges, thermoelectric nanotechnology stands poised to transform how we harvest and utilize waste heat across multiple sectors of the global economy.

Market Analysis for High-Efficiency Thermoelectric Applications

The global thermoelectric generator (TEG) market is experiencing significant growth, driven by increasing demand for waste heat recovery systems and energy-efficient solutions across multiple industries. Current market valuations place the TEG sector at approximately 640 million USD in 2023, with projections indicating a compound annual growth rate of 8.3% through 2030. This growth trajectory is particularly pronounced in automotive, industrial manufacturing, and aerospace sectors where waste heat recovery presents substantial energy-saving opportunities.

Nanotechnology-enhanced thermoelectric materials are creating a distinct high-efficiency market segment that commands premium pricing due to superior performance characteristics. While conventional thermoelectric materials typically achieve conversion efficiencies of 5-8%, nano-engineered solutions have demonstrated laboratory efficiencies approaching 15-20%, representing a step-change in performance that opens new application possibilities.

The automotive industry represents the largest current market for high-efficiency thermoelectric applications, with major manufacturers integrating TEG systems into exhaust systems to improve fuel economy. This segment alone accounts for approximately 35% of the high-efficiency thermoelectric market. Industrial waste heat recovery follows closely at 28%, with particular growth in steel, glass, and cement manufacturing where enormous quantities of waste heat are routinely generated.

Consumer electronics represents an emerging market with substantial growth potential, as miniaturized high-efficiency TEGs enable self-powered wearable devices and IoT sensors. This segment is growing at nearly 12% annually, outpacing the broader market. Aerospace applications, though smaller in volume, command the highest per-unit prices and drive significant research investment.

Geographically, North America and Europe currently lead in high-efficiency thermoelectric adoption, accounting for 38% and 32% of the market respectively. However, Asia-Pacific represents the fastest-growing region with 14% annual growth, driven by rapid industrialization and stringent energy efficiency regulations in China, Japan, and South Korea.

Market barriers include relatively high initial costs compared to conventional power generation technologies, with premium nano-engineered thermoelectric materials costing 3-5 times more than standard bismuth telluride formulations. However, lifecycle cost analyses increasingly favor high-efficiency solutions as energy prices rise and carbon reduction initiatives gain momentum.

Customer demand patterns indicate growing preference for integrated thermoelectric solutions rather than component-level products, with system providers capturing increasing market share. This trend favors companies with both materials expertise and system integration capabilities, driving consolidation among smaller specialized players.

Nanotechnology-enhanced thermoelectric materials are creating a distinct high-efficiency market segment that commands premium pricing due to superior performance characteristics. While conventional thermoelectric materials typically achieve conversion efficiencies of 5-8%, nano-engineered solutions have demonstrated laboratory efficiencies approaching 15-20%, representing a step-change in performance that opens new application possibilities.

The automotive industry represents the largest current market for high-efficiency thermoelectric applications, with major manufacturers integrating TEG systems into exhaust systems to improve fuel economy. This segment alone accounts for approximately 35% of the high-efficiency thermoelectric market. Industrial waste heat recovery follows closely at 28%, with particular growth in steel, glass, and cement manufacturing where enormous quantities of waste heat are routinely generated.

Consumer electronics represents an emerging market with substantial growth potential, as miniaturized high-efficiency TEGs enable self-powered wearable devices and IoT sensors. This segment is growing at nearly 12% annually, outpacing the broader market. Aerospace applications, though smaller in volume, command the highest per-unit prices and drive significant research investment.

Geographically, North America and Europe currently lead in high-efficiency thermoelectric adoption, accounting for 38% and 32% of the market respectively. However, Asia-Pacific represents the fastest-growing region with 14% annual growth, driven by rapid industrialization and stringent energy efficiency regulations in China, Japan, and South Korea.

Market barriers include relatively high initial costs compared to conventional power generation technologies, with premium nano-engineered thermoelectric materials costing 3-5 times more than standard bismuth telluride formulations. However, lifecycle cost analyses increasingly favor high-efficiency solutions as energy prices rise and carbon reduction initiatives gain momentum.

Customer demand patterns indicate growing preference for integrated thermoelectric solutions rather than component-level products, with system providers capturing increasing market share. This trend favors companies with both materials expertise and system integration capabilities, driving consolidation among smaller specialized players.

Current Limitations and Challenges in Thermoelectric Efficiency

Despite significant advancements in thermoelectric technology, current thermoelectric generators (TEGs) face substantial efficiency limitations that hinder their widespread commercial adoption. The fundamental challenge lies in the interdependent nature of the three key parameters that determine thermoelectric performance: electrical conductivity, thermal conductivity, and Seebeck coefficient. These parameters are intrinsically coupled, making simultaneous optimization extremely difficult using conventional materials and approaches.

The figure of merit ZT, which quantifies thermoelectric efficiency, remains below 2 for most commercially viable materials, whereas practical applications typically require values exceeding 3. This efficiency gap represents one of the most significant barriers to widespread implementation of thermoelectric technology in energy recovery systems and power generation applications.

Material constraints present another major challenge. Traditional thermoelectric materials such as bismuth telluride (Bi₂Te₃) and lead telluride (PbTe) contain rare, expensive, or toxic elements that limit scalability and raise environmental concerns. Additionally, these materials often exhibit optimal performance only within narrow temperature ranges, restricting their application versatility.

Thermal management issues further complicate thermoelectric generator design. Maintaining optimal temperature gradients across thermoelectric modules requires sophisticated heat transfer systems that add complexity, weight, and cost to the overall system. Thermal expansion mismatches between different materials in the generator assembly can lead to mechanical stress, reduced durability, and eventual performance degradation over time.

Manufacturing challenges also impede progress in thermoelectric technology. Current production methods for high-performance thermoelectric materials often involve complex, energy-intensive processes that are difficult to scale economically. The precise control required for nanoscale features in advanced thermoelectric materials demands sophisticated fabrication techniques that are not yet optimized for mass production.

Interface engineering represents another critical challenge. Contact resistance at the interfaces between thermoelectric materials and metal electrodes can significantly reduce overall device efficiency. These parasitic resistances become increasingly problematic as device dimensions decrease, particularly in nanostructured thermoelectric systems.

The integration of thermoelectric generators into existing energy systems presents additional hurdles. Compatibility issues with conventional power electronics, system reliability concerns, and the need for specialized control systems add layers of complexity that must be addressed before widespread adoption can occur.

From an economic perspective, the cost-performance ratio of current thermoelectric technology remains unfavorable compared to alternative energy conversion technologies. The high material and manufacturing costs, coupled with modest efficiency levels, result in prohibitively long payback periods for many potential applications.

The figure of merit ZT, which quantifies thermoelectric efficiency, remains below 2 for most commercially viable materials, whereas practical applications typically require values exceeding 3. This efficiency gap represents one of the most significant barriers to widespread implementation of thermoelectric technology in energy recovery systems and power generation applications.

Material constraints present another major challenge. Traditional thermoelectric materials such as bismuth telluride (Bi₂Te₃) and lead telluride (PbTe) contain rare, expensive, or toxic elements that limit scalability and raise environmental concerns. Additionally, these materials often exhibit optimal performance only within narrow temperature ranges, restricting their application versatility.

Thermal management issues further complicate thermoelectric generator design. Maintaining optimal temperature gradients across thermoelectric modules requires sophisticated heat transfer systems that add complexity, weight, and cost to the overall system. Thermal expansion mismatches between different materials in the generator assembly can lead to mechanical stress, reduced durability, and eventual performance degradation over time.

Manufacturing challenges also impede progress in thermoelectric technology. Current production methods for high-performance thermoelectric materials often involve complex, energy-intensive processes that are difficult to scale economically. The precise control required for nanoscale features in advanced thermoelectric materials demands sophisticated fabrication techniques that are not yet optimized for mass production.

Interface engineering represents another critical challenge. Contact resistance at the interfaces between thermoelectric materials and metal electrodes can significantly reduce overall device efficiency. These parasitic resistances become increasingly problematic as device dimensions decrease, particularly in nanostructured thermoelectric systems.

The integration of thermoelectric generators into existing energy systems presents additional hurdles. Compatibility issues with conventional power electronics, system reliability concerns, and the need for specialized control systems add layers of complexity that must be addressed before widespread adoption can occur.

From an economic perspective, the cost-performance ratio of current thermoelectric technology remains unfavorable compared to alternative energy conversion technologies. The high material and manufacturing costs, coupled with modest efficiency levels, result in prohibitively long payback periods for many potential applications.

State-of-the-Art Nanoscale Thermoelectric Solutions

01 Material selection for improved thermoelectric efficiency

The selection of appropriate materials is crucial for enhancing thermoelectric generator efficiency. Materials with high Seebeck coefficient, high electrical conductivity, and low thermal conductivity are preferred. Advanced materials such as nanostructured semiconductors, skutterudites, and bismuth telluride compounds can significantly improve the figure of merit (ZT) of thermoelectric devices, leading to higher conversion efficiency. These materials can be engineered at the nanoscale to optimize their thermoelectric properties.- Material selection for improved thermoelectric efficiency: The selection of appropriate materials is crucial for enhancing thermoelectric generator efficiency. Materials with high Seebeck coefficient, high electrical conductivity, and low thermal conductivity are ideal for thermoelectric applications. Advanced materials such as nanostructured semiconductors, skutterudites, and bismuth telluride compounds have shown significant improvements in thermoelectric performance. These materials can effectively convert temperature differences into electrical energy with higher efficiency compared to conventional materials.

- Structural design optimization for thermoelectric generators: The structural design of thermoelectric generators significantly impacts their efficiency. Optimized designs include segmented or cascaded structures, which utilize different materials for different temperature ranges, and modular configurations that maximize heat transfer while minimizing thermal losses. Advanced geometric arrangements of thermoelectric elements and improved heat exchanger designs can enhance the temperature gradient across the device, leading to higher power output and conversion efficiency.

- Heat management techniques for efficiency enhancement: Effective heat management is essential for maximizing thermoelectric generator efficiency. Techniques include the implementation of advanced heat exchangers, thermal interface materials, and heat spreading technologies to optimize temperature differentials across thermoelectric modules. Proper thermal insulation between hot and cold sides prevents parasitic heat losses, while efficient heat dissipation systems on the cold side maintain the temperature gradient. These approaches collectively contribute to higher conversion efficiency by maximizing the utilizable temperature difference.

- Integration of nanotechnology in thermoelectric systems: Nanotechnology offers significant potential for improving thermoelectric generator efficiency. Nanoscale structures such as quantum dots, nanowires, and superlattices can reduce thermal conductivity while maintaining electrical conductivity, thereby increasing the figure of merit (ZT). Nanostructured materials can create phonon scattering centers that impede heat flow without significantly affecting electron transport. These nanoscale engineering approaches have demonstrated substantial improvements in thermoelectric performance compared to bulk materials.

- System-level optimization and waste heat recovery applications: System-level optimization focuses on integrating thermoelectric generators into broader energy systems for maximum efficiency. This includes coupling thermoelectric devices with waste heat sources from industrial processes, vehicle exhaust systems, or residential heating applications. Advanced control systems that dynamically adjust operating parameters based on temperature conditions can maximize power output. Hybrid systems that combine thermoelectric generators with other energy conversion technologies can also achieve higher overall system efficiency through complementary operation.

02 Structural design optimization for thermoelectric generators

The structural design of thermoelectric generators plays a significant role in determining their efficiency. Optimized designs include segmented or cascaded structures, which utilize different materials for different temperature ranges, and modular configurations that maximize heat transfer and minimize thermal losses. Advanced geometries such as thin films, quantum wells, and superlattice structures can enhance the thermoelectric performance by improving electron transport while restricting phonon propagation. Proper thermal management through heat exchangers and heat sinks is also essential for maintaining temperature gradients.Expand Specific Solutions03 Temperature gradient management techniques

Maintaining an optimal temperature gradient is essential for maximizing thermoelectric generator efficiency. Techniques include the use of heat concentrators, thermal insulation between hot and cold sides, and strategic placement of heat sources and sinks. Advanced heat transfer mechanisms such as phase change materials and heat pipes can help maintain stable temperature differences. Active cooling systems on the cold side and efficient heat capture on the hot side contribute to higher temperature differentials, directly improving conversion efficiency according to the Carnot efficiency principle.Expand Specific Solutions04 Circuit and system integration approaches

The electrical configuration and system integration of thermoelectric generators significantly impact overall efficiency. Approaches include optimized load matching circuits, power conditioning electronics, and maximum power point tracking systems. Series-parallel arrangements of thermoelectric modules can be tailored to specific application requirements. Hybrid systems that combine thermoelectric generators with other energy harvesting technologies can improve overall energy utilization. Advanced control systems that adjust operating parameters based on changing conditions help maintain optimal performance across varying temperature and load scenarios.Expand Specific Solutions05 Novel manufacturing and fabrication techniques

Innovative manufacturing and fabrication methods can enhance thermoelectric generator efficiency. Techniques such as additive manufacturing, thin-film deposition, and precision doping processes enable the creation of optimized thermoelectric structures with reduced contact resistance and improved material interfaces. Nano-engineering approaches allow for the creation of materials with tailored electronic and thermal properties. Advanced bonding and interconnection technologies minimize parasitic losses at junctions. These manufacturing innovations lead to higher quality thermoelectric modules with improved performance characteristics and longer operational lifetimes.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Nanotechnology

The thermoelectric generator (TEG) efficiency improvement market using nanotechnology is currently in its growth phase, with an estimated global market size of $600-700 million and projected annual growth of 8-10%. The technology maturity varies across applications, with automotive and industrial waste heat recovery leading adoption. Key players demonstrate different technological approaches: The Regents of the University of California and Tsinghua University focus on fundamental nanomaterial research; Industrial Technology Research Institute and Toyota Motor Corp. emphasize practical applications; while specialized companies like O-Flexx Technologies and Murata Manufacturing are developing commercial solutions. Samsung Electronics and LG Electronics are integrating TEGs into consumer electronics, while automotive manufacturers (Toyota, Continental Emitec) are exploring vehicle waste heat recovery applications. The competitive landscape shows a balance between academic research institutions advancing theoretical foundations and commercial entities driving practical implementation.

Beijing Institute of Nanoenergy & Nanosystems

Technical Solution: Beijing Institute of Nanoenergy & Nanosystems has developed innovative thermoelectric generators (TEGs) utilizing nanomaterials to enhance the Seebeck effect. Their approach incorporates hierarchically structured nanomaterials with controlled interfaces to reduce thermal conductivity while maintaining electrical conductivity. The institute has pioneered the use of 2D materials like graphene and transition metal dichalcogenides as interlayers in TEG devices, creating quantum confinement effects that enhance the power factor. Their research demonstrates ZT values exceeding 2.0 at room temperature through precise nanostructure engineering. Additionally, they've developed flexible TEGs using nanowire arrays that can conform to curved surfaces while maintaining performance, enabling applications in wearable electronics and IoT devices. The institute has also created hybrid systems combining TEGs with other energy harvesting technologies to maximize overall efficiency in variable temperature environments.

Strengths: Exceptional expertise in nanomaterial synthesis and characterization, with demonstrated high ZT values. Their flexible TEG designs enable new application areas previously inaccessible to rigid TEGs. Weaknesses: Some of their advanced nanomaterials require complex fabrication processes that may limit large-scale manufacturing feasibility and increase production costs.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has developed a groundbreaking approach to thermoelectric materials using nanostructured composites. Their research focuses on creating skutterudite-based nanocomposites with embedded nano-inclusions that effectively scatter phonons across multiple length scales while preserving electron transport. They've pioneered a novel solution-based synthesis method that enables precise control over nanoparticle size distribution and interface characteristics. Their most advanced TEGs incorporate hierarchically structured materials with nanopores, nanoprecipitates, and grain boundaries engineered to create "phonon-glass electron-crystal" behavior. Recent publications demonstrate ZT values approaching 2.2 in their optimized materials. The university has also developed innovative manufacturing techniques including spark plasma sintering and selective laser melting to fabricate complex TEG geometries with preserved nanostructures, enabling more efficient heat capture from irregular heat sources.

Strengths: Their solution-based synthesis methods allow for cost-effective scaling of nanomaterial production compared to vacuum-based techniques. Their multi-scale approach to phonon scattering achieves exceptional thermal conductivity reduction. Weaknesses: The complex nanostructures may suffer from thermal stability issues at elevated temperatures, potentially limiting long-term performance in high-temperature applications.

Key Patents and Breakthroughs in Nanostructured Thermoelectric Materials

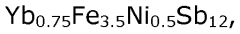

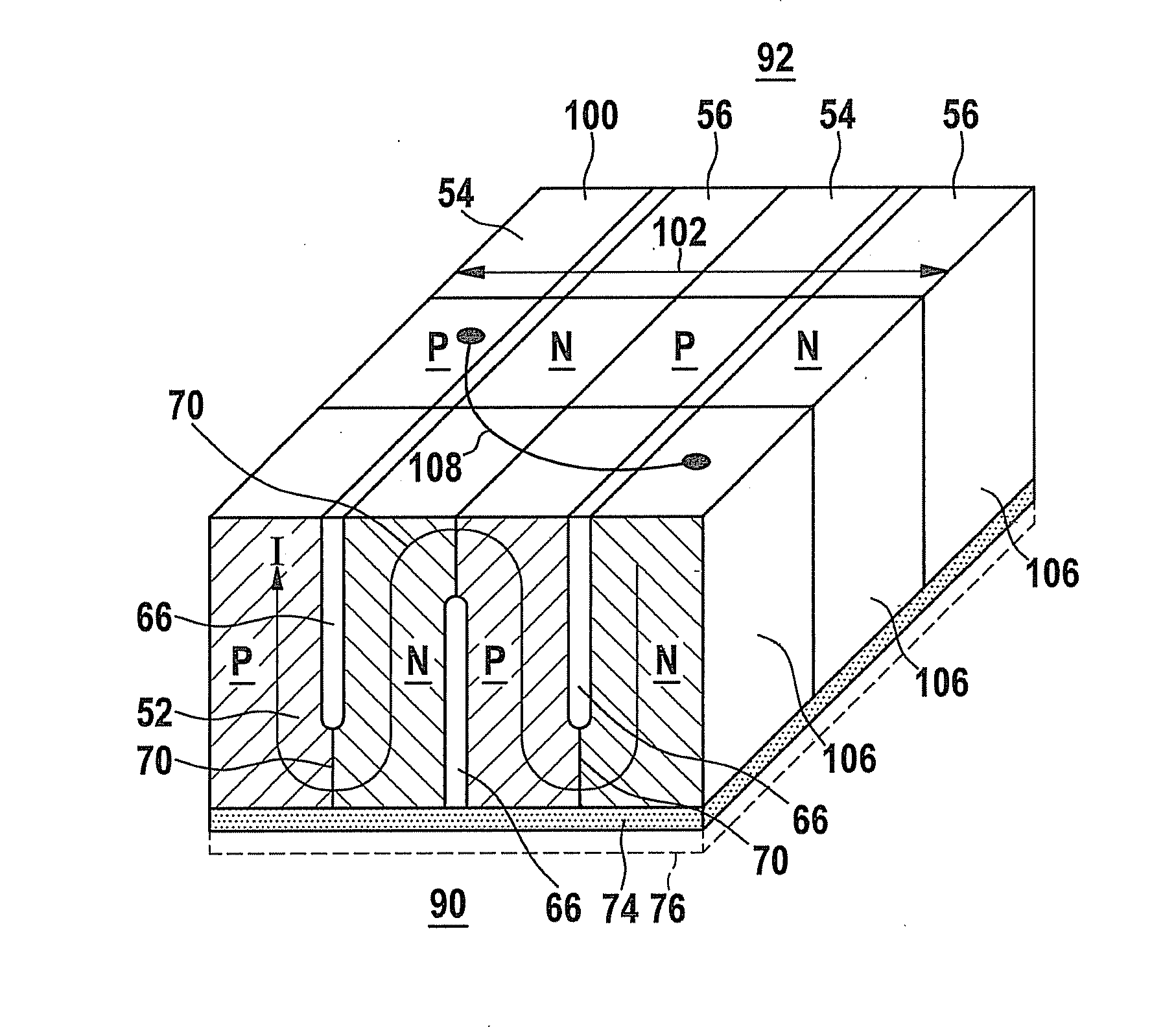

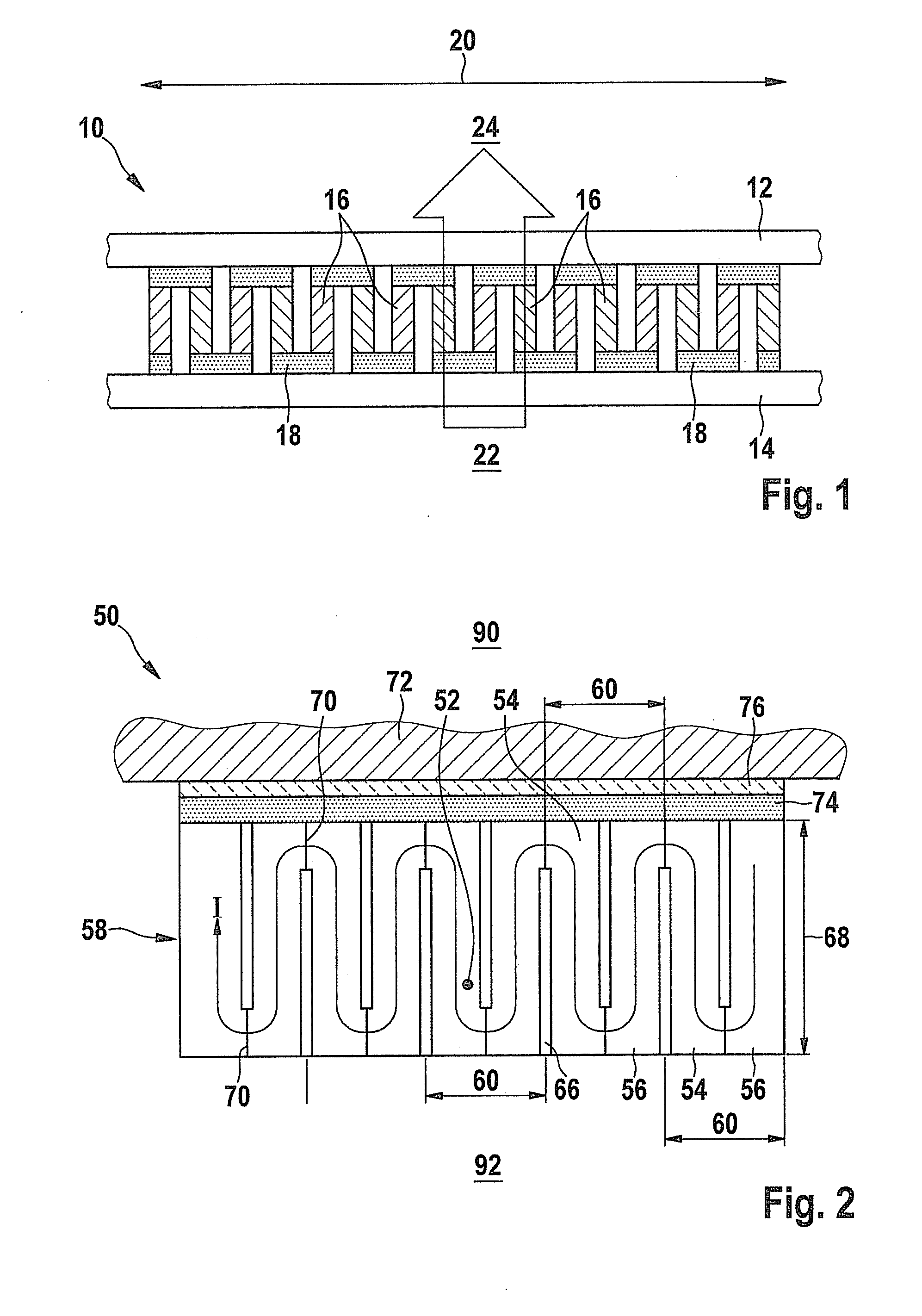

Thermoelectric generator for converting thermal energy into electrical energy

PatentWO2008155406A2

Innovation

- The use of Peltier elements with p-doped and n-doped legs made of different materials, optimized for varying temperature values at the contact points with the heat source, allowing for segmented construction and adaptation to temperature gradients, enhancing the conversion of thermal energy into electrical energy.

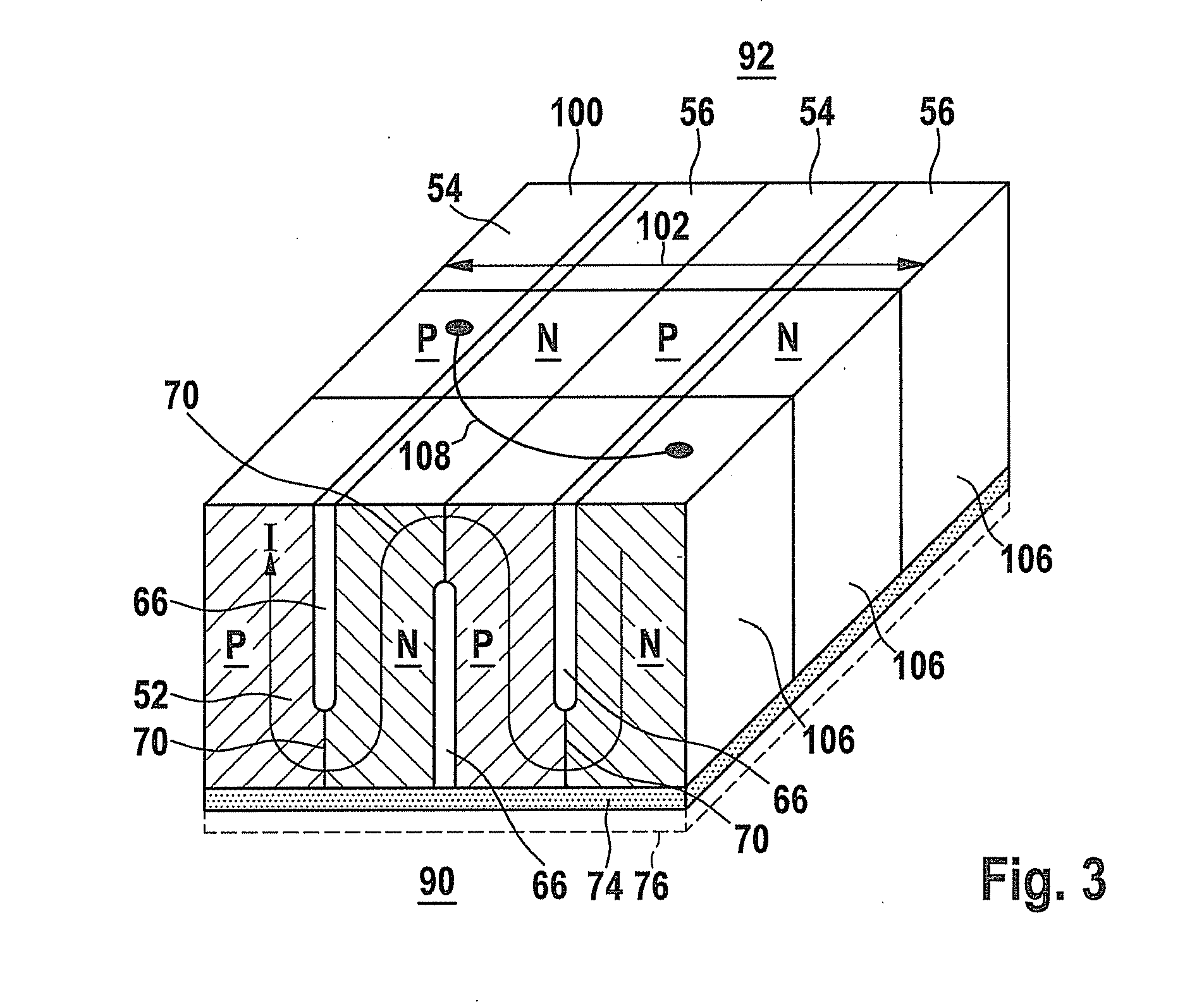

Thermoelectric generator including a thermoelectric module having a meandering p-n system

PatentInactiveUS20120103379A1

Innovation

- A p-n-legs construction without mechanical bracing, where p- and n-conductive semiconductor legs are aligned in series and parallel, with alternating gaps and bridges for electrical and thermal connection, reducing heat transfers and weight while enabling integral thermal and electric connections.

Environmental Impact and Sustainability Considerations

The integration of nanotechnology in thermoelectric generators presents significant environmental benefits that align with global sustainability goals. Thermoelectric generators utilizing nanomaterials can effectively convert waste heat into electricity, potentially reducing global energy consumption by capturing heat that would otherwise be lost to the environment. This waste heat recovery capability is particularly valuable in industrial settings, where approximately 20-50% of energy input is typically dissipated as heat, representing a substantial opportunity for energy reclamation and reduced carbon emissions.

From a lifecycle perspective, thermoelectric generators offer notable advantages compared to conventional power generation technologies. They operate without moving parts, eliminating the need for lubricants and reducing maintenance requirements. Additionally, they produce no direct emissions during operation, contributing to cleaner energy production. However, the environmental impact of nanomaterial production requires careful consideration, as manufacturing processes may involve energy-intensive methods and potentially hazardous chemicals.

The raw materials used in advanced thermoelectric nanomaterials present both challenges and opportunities for sustainability. Some high-performance thermoelectric materials incorporate rare or toxic elements such as tellurium, bismuth, and lead. Concerns regarding resource scarcity and environmental contamination necessitate the development of alternative materials using more abundant and environmentally benign elements. Recent research has shown promising results with silicon-based nanostructures and organic thermoelectric materials, which could provide more sustainable alternatives.

End-of-life management for nano-enhanced thermoelectric devices represents another critical environmental consideration. The potential for nanomaterial leaching or dispersion during disposal poses risks that must be addressed through proper recycling protocols. Developing effective recovery methods for valuable materials within these devices could establish a circular economy approach, minimizing waste while reclaiming scarce resources.

When evaluating the net environmental impact, nano-enhanced thermoelectric generators demonstrate positive potential through their energy recovery capabilities. Studies suggest that widespread implementation could reduce global carbon emissions by 1-2% through waste heat recovery alone. This benefit must be balanced against the environmental footprint of manufacturing and disposal processes, which requires ongoing assessment and optimization to ensure true sustainability.

Regulatory frameworks governing nanomaterial use in thermoelectric applications continue to evolve, with increasing emphasis on environmental protection and human health safeguards. Future development of this technology will likely require adherence to stricter environmental standards, driving innovation toward greener manufacturing processes and more environmentally compatible materials.

From a lifecycle perspective, thermoelectric generators offer notable advantages compared to conventional power generation technologies. They operate without moving parts, eliminating the need for lubricants and reducing maintenance requirements. Additionally, they produce no direct emissions during operation, contributing to cleaner energy production. However, the environmental impact of nanomaterial production requires careful consideration, as manufacturing processes may involve energy-intensive methods and potentially hazardous chemicals.

The raw materials used in advanced thermoelectric nanomaterials present both challenges and opportunities for sustainability. Some high-performance thermoelectric materials incorporate rare or toxic elements such as tellurium, bismuth, and lead. Concerns regarding resource scarcity and environmental contamination necessitate the development of alternative materials using more abundant and environmentally benign elements. Recent research has shown promising results with silicon-based nanostructures and organic thermoelectric materials, which could provide more sustainable alternatives.

End-of-life management for nano-enhanced thermoelectric devices represents another critical environmental consideration. The potential for nanomaterial leaching or dispersion during disposal poses risks that must be addressed through proper recycling protocols. Developing effective recovery methods for valuable materials within these devices could establish a circular economy approach, minimizing waste while reclaiming scarce resources.

When evaluating the net environmental impact, nano-enhanced thermoelectric generators demonstrate positive potential through their energy recovery capabilities. Studies suggest that widespread implementation could reduce global carbon emissions by 1-2% through waste heat recovery alone. This benefit must be balanced against the environmental footprint of manufacturing and disposal processes, which requires ongoing assessment and optimization to ensure true sustainability.

Regulatory frameworks governing nanomaterial use in thermoelectric applications continue to evolve, with increasing emphasis on environmental protection and human health safeguards. Future development of this technology will likely require adherence to stricter environmental standards, driving innovation toward greener manufacturing processes and more environmentally compatible materials.

Manufacturing Scalability and Cost Analysis

The scalability of nanotechnology-enhanced thermoelectric generators (TEGs) represents a critical challenge in transitioning from laboratory success to commercial viability. Current manufacturing processes for nanomaterials used in TEGs often involve complex, multi-step procedures that are difficult to scale up efficiently. Techniques such as molecular beam epitaxy and chemical vapor deposition deliver high-quality nanostructures but remain prohibitively expensive and time-consuming for mass production scenarios.

Cost analysis reveals that material expenses constitute approximately 40-60% of total manufacturing costs for thermoelectric devices. Particularly expensive are rare earth elements and precious metals often incorporated into high-performance TEGs. The specialized equipment required for nanofabrication further elevates capital expenditure, with industrial-scale nanomaterial production facilities typically requiring investments of $50-100 million.

Recent advancements in solution-based processing methods offer promising alternatives for scalable manufacturing. Roll-to-roll printing and spray coating technologies have demonstrated potential for continuous production of nanostructured thermoelectric films at significantly reduced costs. These approaches could potentially decrease manufacturing expenses by 30-45% compared to traditional methods, though often with some trade-offs in performance characteristics.

Energy consumption during manufacturing presents another significant cost factor. Conventional high-temperature sintering processes used to consolidate thermoelectric nanomaterials typically require temperatures exceeding 800°C, resulting in substantial energy expenditure. Emerging cold sintering and spark plasma sintering techniques operate at lower temperatures (200-400°C), potentially reducing energy costs by 50-70% while maintaining material integrity.

Yield rates remain problematic in nanomanufacturing, with current processes achieving only 60-75% yields for complex nanostructured thermoelectric materials. This inefficiency significantly impacts production economics. Improving process control through advanced in-line monitoring systems and machine learning algorithms shows promise for increasing yields to 85-90%, substantially improving cost structures.

Environmental considerations also factor into manufacturing scalability assessments. Many current nanofabrication processes utilize hazardous chemicals requiring specialized handling and disposal procedures. Development of greener synthesis routes using bio-inspired approaches and aqueous processing could reduce environmental impact while simultaneously lowering regulatory compliance costs by an estimated 15-25%.

The economic viability threshold for nanotechnology-enhanced TEGs appears to be approaching. Analysis suggests that with continued manufacturing innovations, production costs could decrease from current levels of $20-30/W to $5-10/W within 5-7 years, potentially enabling mass-market applications beyond current niche deployments.

Cost analysis reveals that material expenses constitute approximately 40-60% of total manufacturing costs for thermoelectric devices. Particularly expensive are rare earth elements and precious metals often incorporated into high-performance TEGs. The specialized equipment required for nanofabrication further elevates capital expenditure, with industrial-scale nanomaterial production facilities typically requiring investments of $50-100 million.

Recent advancements in solution-based processing methods offer promising alternatives for scalable manufacturing. Roll-to-roll printing and spray coating technologies have demonstrated potential for continuous production of nanostructured thermoelectric films at significantly reduced costs. These approaches could potentially decrease manufacturing expenses by 30-45% compared to traditional methods, though often with some trade-offs in performance characteristics.

Energy consumption during manufacturing presents another significant cost factor. Conventional high-temperature sintering processes used to consolidate thermoelectric nanomaterials typically require temperatures exceeding 800°C, resulting in substantial energy expenditure. Emerging cold sintering and spark plasma sintering techniques operate at lower temperatures (200-400°C), potentially reducing energy costs by 50-70% while maintaining material integrity.

Yield rates remain problematic in nanomanufacturing, with current processes achieving only 60-75% yields for complex nanostructured thermoelectric materials. This inefficiency significantly impacts production economics. Improving process control through advanced in-line monitoring systems and machine learning algorithms shows promise for increasing yields to 85-90%, substantially improving cost structures.

Environmental considerations also factor into manufacturing scalability assessments. Many current nanofabrication processes utilize hazardous chemicals requiring specialized handling and disposal procedures. Development of greener synthesis routes using bio-inspired approaches and aqueous processing could reduce environmental impact while simultaneously lowering regulatory compliance costs by an estimated 15-25%.

The economic viability threshold for nanotechnology-enhanced TEGs appears to be approaching. Analysis suggests that with continued manufacturing innovations, production costs could decrease from current levels of $20-30/W to $5-10/W within 5-7 years, potentially enabling mass-market applications beyond current niche deployments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!