Assess Thermoelectric Material Stability at Boundary Interfaces

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Interface Stability Background and Objectives

Thermoelectric materials have emerged as a promising solution for direct conversion between thermal and electrical energy, offering significant potential for waste heat recovery and sustainable energy generation. The history of thermoelectric materials dates back to the early 19th century with the discovery of the Seebeck effect in 1821, followed by the Peltier effect in 1834. However, only in recent decades has substantial progress been made in enhancing the efficiency and practical applicability of these materials.

The evolution of thermoelectric technology has been characterized by continuous efforts to improve the figure of merit (ZT), which determines conversion efficiency. Early materials achieved ZT values below 1, but recent advancements in nanostructuring and material engineering have pushed this value beyond 2 in laboratory settings. This progress underscores the growing potential of thermoelectric technology for commercial applications.

A critical yet often overlooked aspect of thermoelectric device performance is the stability of material interfaces. As these devices operate under significant temperature gradients and undergo thermal cycling, the boundary interfaces between different thermoelectric materials or between thermoelectric materials and electrical contacts experience substantial thermal and mechanical stress. These conditions can lead to degradation mechanisms including atomic diffusion, phase transformations, and mechanical failures that significantly impact device longevity and performance reliability.

The primary objective of this technical research is to comprehensively assess the stability of thermoelectric material interfaces under operational conditions. This includes identifying the fundamental mechanisms of degradation, evaluating current mitigation strategies, and exploring innovative approaches to enhance interface stability. The research aims to establish a framework for predicting long-term performance and developing more robust thermoelectric systems.

Understanding interface stability requires examination across multiple scales, from atomic-level interactions to macroscopic mechanical properties. This multidisciplinary approach integrates materials science, solid-state physics, and thermodynamics to develop a holistic understanding of interface behavior under thermal and electrical stress conditions.

The technological goal extends beyond mere academic understanding to practical implementation. By addressing interface stability challenges, we aim to extend device lifespan, improve reliability, and ultimately enhance the commercial viability of thermoelectric technology across various applications including automotive waste heat recovery, industrial energy harvesting, and consumer electronics thermal management.

Recent advances in characterization techniques, including in-situ electron microscopy and spectroscopy methods, provide unprecedented opportunities to observe interface evolution in real-time under operational conditions. These tools, combined with computational modeling approaches, offer new pathways to develop predictive capabilities for interface behavior and inform the design of next-generation thermoelectric materials and devices with superior stability characteristics.

The evolution of thermoelectric technology has been characterized by continuous efforts to improve the figure of merit (ZT), which determines conversion efficiency. Early materials achieved ZT values below 1, but recent advancements in nanostructuring and material engineering have pushed this value beyond 2 in laboratory settings. This progress underscores the growing potential of thermoelectric technology for commercial applications.

A critical yet often overlooked aspect of thermoelectric device performance is the stability of material interfaces. As these devices operate under significant temperature gradients and undergo thermal cycling, the boundary interfaces between different thermoelectric materials or between thermoelectric materials and electrical contacts experience substantial thermal and mechanical stress. These conditions can lead to degradation mechanisms including atomic diffusion, phase transformations, and mechanical failures that significantly impact device longevity and performance reliability.

The primary objective of this technical research is to comprehensively assess the stability of thermoelectric material interfaces under operational conditions. This includes identifying the fundamental mechanisms of degradation, evaluating current mitigation strategies, and exploring innovative approaches to enhance interface stability. The research aims to establish a framework for predicting long-term performance and developing more robust thermoelectric systems.

Understanding interface stability requires examination across multiple scales, from atomic-level interactions to macroscopic mechanical properties. This multidisciplinary approach integrates materials science, solid-state physics, and thermodynamics to develop a holistic understanding of interface behavior under thermal and electrical stress conditions.

The technological goal extends beyond mere academic understanding to practical implementation. By addressing interface stability challenges, we aim to extend device lifespan, improve reliability, and ultimately enhance the commercial viability of thermoelectric technology across various applications including automotive waste heat recovery, industrial energy harvesting, and consumer electronics thermal management.

Recent advances in characterization techniques, including in-situ electron microscopy and spectroscopy methods, provide unprecedented opportunities to observe interface evolution in real-time under operational conditions. These tools, combined with computational modeling approaches, offer new pathways to develop predictive capabilities for interface behavior and inform the design of next-generation thermoelectric materials and devices with superior stability characteristics.

Market Analysis for Stable Thermoelectric Materials

The global thermoelectric materials market is experiencing significant growth, driven primarily by increasing demand for waste heat recovery systems and energy-efficient technologies. Current market valuations place the thermoelectric materials sector at approximately 51.6 million USD in 2022, with projections indicating a compound annual growth rate (CAGR) of 8.9% through 2030. This growth trajectory is particularly notable in regions with stringent energy efficiency regulations such as Europe, North America, and parts of Asia.

The automotive sector represents the largest application segment for stable thermoelectric materials, accounting for roughly 35% of market demand. This is primarily due to the integration of thermoelectric generators in vehicle exhaust systems to convert waste heat into usable electricity, improving overall fuel efficiency. Major automotive manufacturers including BMW, Ford, and Toyota have initiated research programs focused on thermoelectric material implementation, signaling strong industry commitment.

Industrial waste heat recovery applications constitute the second-largest market segment at approximately 28% of total demand. Industries such as steel manufacturing, glass production, and cement processing generate substantial waste heat, creating significant opportunities for thermoelectric material deployment. The potential for energy cost reduction through thermoelectric systems has become increasingly attractive as global energy prices continue to rise.

Consumer electronics represents an emerging market for thermoelectric materials, currently at 15% of market share but growing rapidly. Applications include cooling systems for processors, power generation for wearable devices, and temperature regulation in portable electronics. This segment is expected to show the highest growth rate over the next five years due to miniaturization advances and increasing power demands of mobile devices.

Market analysis reveals a critical demand-supply gap for thermoelectric materials with proven long-term stability at boundary interfaces. Current materials often experience performance degradation of 20-30% within the first 5,000 hours of operation due to interface instability issues. This has created a premium market segment for materials demonstrating enhanced stability characteristics, with price premiums of 40-60% compared to standard thermoelectric materials.

Regional market distribution shows North America leading with 38% market share, followed by Asia-Pacific at 32% and Europe at 24%. However, the fastest growth is occurring in the Asia-Pacific region, particularly in China, Japan, and South Korea, where government initiatives supporting green technology development have accelerated market expansion by providing substantial research funding and tax incentives for thermoelectric technology adoption.

The automotive sector represents the largest application segment for stable thermoelectric materials, accounting for roughly 35% of market demand. This is primarily due to the integration of thermoelectric generators in vehicle exhaust systems to convert waste heat into usable electricity, improving overall fuel efficiency. Major automotive manufacturers including BMW, Ford, and Toyota have initiated research programs focused on thermoelectric material implementation, signaling strong industry commitment.

Industrial waste heat recovery applications constitute the second-largest market segment at approximately 28% of total demand. Industries such as steel manufacturing, glass production, and cement processing generate substantial waste heat, creating significant opportunities for thermoelectric material deployment. The potential for energy cost reduction through thermoelectric systems has become increasingly attractive as global energy prices continue to rise.

Consumer electronics represents an emerging market for thermoelectric materials, currently at 15% of market share but growing rapidly. Applications include cooling systems for processors, power generation for wearable devices, and temperature regulation in portable electronics. This segment is expected to show the highest growth rate over the next five years due to miniaturization advances and increasing power demands of mobile devices.

Market analysis reveals a critical demand-supply gap for thermoelectric materials with proven long-term stability at boundary interfaces. Current materials often experience performance degradation of 20-30% within the first 5,000 hours of operation due to interface instability issues. This has created a premium market segment for materials demonstrating enhanced stability characteristics, with price premiums of 40-60% compared to standard thermoelectric materials.

Regional market distribution shows North America leading with 38% market share, followed by Asia-Pacific at 32% and Europe at 24%. However, the fastest growth is occurring in the Asia-Pacific region, particularly in China, Japan, and South Korea, where government initiatives supporting green technology development have accelerated market expansion by providing substantial research funding and tax incentives for thermoelectric technology adoption.

Current Challenges in Boundary Interface Stability

The stability of thermoelectric materials at boundary interfaces represents one of the most significant challenges in advancing thermoelectric technology toward widespread commercial applications. Current thermoelectric devices suffer from performance degradation over time, primarily due to instability at material interfaces where thermal and electrical transport occur simultaneously. These interfaces experience extreme conditions including high temperature gradients, electrical current flow, and mechanical stress, creating a complex environment that accelerates material deterioration.

Thermal cycling poses a particularly severe challenge, as the repeated expansion and contraction of different materials with mismatched thermal expansion coefficients leads to mechanical fatigue, crack formation, and eventual device failure. This issue becomes more pronounced in applications requiring frequent temperature fluctuations, such as automotive waste heat recovery systems or variable-load power generation scenarios.

Chemical interdiffusion across interfaces represents another critical stability concern. At elevated operating temperatures (often 300-700°C for mid-to-high temperature thermoelectric applications), atomic migration between adjacent materials accelerates, forming undesirable intermediate phases that typically exhibit poor thermoelectric properties. These reaction layers increase electrical contact resistance and thermal boundary resistance, progressively degrading device performance.

Oxidation and corrosion mechanisms further compromise interface stability, particularly in non-hermetically sealed devices or those operating in harsh environments. Many high-performance thermoelectric materials contain elements susceptible to oxidation (such as tellurium, antimony, or lead), resulting in surface degradation that propagates from interfaces inward. The resulting oxide layers fundamentally alter the electronic properties at critical junctions.

Current manufacturing techniques also contribute to interface stability issues. Conventional joining methods like soldering, brazing, or direct sintering often introduce residual stresses or create non-optimal microstructures at interfaces. The challenge is compounded by the need to simultaneously optimize electrical contact resistance, thermal boundary conductance, and mechanical adhesion—properties that often have competing requirements.

Advanced characterization of interface evolution presents significant methodological difficulties. Real-time, in-situ monitoring of interfaces under operational conditions remains limited, making it challenging to develop predictive models for long-term stability. Most accelerated aging tests fail to accurately replicate the complex combination of thermal, electrical, and mechanical stresses experienced at interfaces during actual operation.

The fundamental scientific understanding of coupled transport phenomena at interfaces under thermoelectric operating conditions remains incomplete. This knowledge gap hinders the development of rational design principles for creating inherently stable interfaces that can withstand thousands of hours of operation without significant degradation.

Thermal cycling poses a particularly severe challenge, as the repeated expansion and contraction of different materials with mismatched thermal expansion coefficients leads to mechanical fatigue, crack formation, and eventual device failure. This issue becomes more pronounced in applications requiring frequent temperature fluctuations, such as automotive waste heat recovery systems or variable-load power generation scenarios.

Chemical interdiffusion across interfaces represents another critical stability concern. At elevated operating temperatures (often 300-700°C for mid-to-high temperature thermoelectric applications), atomic migration between adjacent materials accelerates, forming undesirable intermediate phases that typically exhibit poor thermoelectric properties. These reaction layers increase electrical contact resistance and thermal boundary resistance, progressively degrading device performance.

Oxidation and corrosion mechanisms further compromise interface stability, particularly in non-hermetically sealed devices or those operating in harsh environments. Many high-performance thermoelectric materials contain elements susceptible to oxidation (such as tellurium, antimony, or lead), resulting in surface degradation that propagates from interfaces inward. The resulting oxide layers fundamentally alter the electronic properties at critical junctions.

Current manufacturing techniques also contribute to interface stability issues. Conventional joining methods like soldering, brazing, or direct sintering often introduce residual stresses or create non-optimal microstructures at interfaces. The challenge is compounded by the need to simultaneously optimize electrical contact resistance, thermal boundary conductance, and mechanical adhesion—properties that often have competing requirements.

Advanced characterization of interface evolution presents significant methodological difficulties. Real-time, in-situ monitoring of interfaces under operational conditions remains limited, making it challenging to develop predictive models for long-term stability. Most accelerated aging tests fail to accurately replicate the complex combination of thermal, electrical, and mechanical stresses experienced at interfaces during actual operation.

The fundamental scientific understanding of coupled transport phenomena at interfaces under thermoelectric operating conditions remains incomplete. This knowledge gap hinders the development of rational design principles for creating inherently stable interfaces that can withstand thousands of hours of operation without significant degradation.

Existing Methodologies for Interface Stability Assessment

01 Thermal stability enhancement in thermoelectric materials

Various methods can be employed to enhance the thermal stability of thermoelectric materials, which is crucial for their long-term performance. These include the incorporation of stabilizing additives, specialized heat treatments, and the development of composite structures. Enhanced thermal stability allows thermoelectric materials to maintain their performance characteristics even under high-temperature operating conditions, preventing degradation and extending device lifespan.- Thermal stability enhancement in thermoelectric materials: Various methods can be employed to enhance the thermal stability of thermoelectric materials, which is crucial for their long-term performance. These methods include doping with specific elements, creating composite structures, and implementing protective coatings. Enhanced thermal stability allows thermoelectric materials to maintain their performance characteristics even under high-temperature operating conditions, preventing degradation and extending the lifespan of thermoelectric devices.

- Chemical stability improvement techniques: Chemical stability of thermoelectric materials can be improved through various approaches such as surface passivation, encapsulation, and the use of barrier layers. These techniques protect the thermoelectric materials from oxidation, corrosion, and other chemical reactions that could degrade their performance. By enhancing chemical stability, thermoelectric materials can maintain their efficiency and structural integrity in diverse environmental conditions.

- Mechanical stability and structural integrity: Enhancing the mechanical stability of thermoelectric materials involves improving their resistance to mechanical stress, vibration, and thermal cycling. This can be achieved through the development of flexible thermoelectric materials, reinforced composite structures, and optimized manufacturing processes. Improved mechanical stability ensures that thermoelectric devices can withstand physical stresses during operation without cracking, delamination, or other structural failures.

- Novel material compositions for enhanced stability: Innovative material compositions are being developed to address stability challenges in thermoelectric applications. These include skutterudites, half-Heusler alloys, and nanostructured materials that offer inherently better stability characteristics. By engineering the composition at the atomic and molecular levels, researchers can create thermoelectric materials with superior resistance to degradation mechanisms while maintaining or improving their thermoelectric performance.

- Testing and characterization methods for stability assessment: Advanced testing and characterization methods are essential for evaluating the stability of thermoelectric materials under various operating conditions. These methods include accelerated aging tests, thermal cycling, environmental exposure testing, and in-situ monitoring techniques. By accurately assessing stability parameters, researchers can identify degradation mechanisms, predict service life, and develop more effective strategies for improving the long-term performance of thermoelectric materials and devices.

02 Chemical composition modifications for improved stability

Modifying the chemical composition of thermoelectric materials can significantly improve their stability. This includes doping with specific elements, creating alloys with enhanced properties, and adjusting stoichiometric ratios. These modifications can reduce oxidation, prevent phase separation, and minimize atomic diffusion at elevated temperatures, resulting in more stable thermoelectric performance over time.Expand Specific Solutions03 Nanostructuring approaches for stability enhancement

Nanostructuring techniques can be applied to thermoelectric materials to improve their stability. These include creating nanoscale inclusions, developing core-shell structures, and engineering grain boundaries. Nanostructured thermoelectric materials often exhibit improved mechanical strength and resistance to thermal cycling, leading to enhanced stability under operating conditions.Expand Specific Solutions04 Protective coatings and encapsulation methods

Applying protective coatings or encapsulating thermoelectric materials can significantly enhance their stability by creating barriers against environmental factors. These protective layers can prevent oxidation, moisture ingress, and chemical reactions that might degrade the thermoelectric properties. Various coating materials and techniques can be employed depending on the specific operating conditions and material composition.Expand Specific Solutions05 Testing and characterization methods for stability assessment

Various testing and characterization methods have been developed to assess the stability of thermoelectric materials. These include accelerated aging tests, thermal cycling evaluations, and long-term performance monitoring. Advanced analytical techniques such as X-ray diffraction, electron microscopy, and spectroscopic methods can be used to investigate degradation mechanisms and validate stability improvements in thermoelectric materials.Expand Specific Solutions

Leading Organizations in Thermoelectric Interface Research

Thermoelectric material stability at boundary interfaces represents a critical challenge in an emerging market poised for significant growth. The industry is currently in a transitional phase from research to commercialization, with the global thermoelectric market expected to expand substantially due to increasing demand for waste heat recovery systems. Technical maturity varies significantly among key players, with research institutions like Boston University, MIT, and Chinese Academy of Sciences focusing on fundamental interface science, while industrial leaders such as Samsung Electronics, IBM, and Honeywell are developing practical applications with enhanced stability. Companies like Infineon Technologies and GlobalFoundries are advancing semiconductor integration techniques to address interface degradation issues. The competitive landscape features collaboration between academic and industrial entities, with CEA, CNRS, and industrial partners working on novel interface engineering approaches to overcome thermal cycling and chemical diffusion challenges.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The CEA has developed a comprehensive approach to thermoelectric interface stability assessment combining experimental and theoretical methods. Their technique employs synchrotron-based X-ray diffraction and absorption spectroscopy to characterize interface evolution under operational conditions. They've created specialized sample environments that can simulate temperature gradients up to 600°C while simultaneously measuring electrical transport properties and structural changes[5]. Their research has identified specific interfacial reaction mechanisms in skutterudite-based thermoelectric modules and developed protective coating strategies using transition metal silicides that reduce interface degradation by over 60% during thermal cycling. The CEA has also pioneered the use of machine learning algorithms to predict interface stability based on material composition and processing parameters, enabling accelerated materials discovery for stable thermoelectric interfaces[6].

Strengths: Exceptional characterization infrastructure including synchrotron facilities; integrated experimental-computational approach; strong focus on practical device implementation. Weaknesses: Some advanced characterization techniques have limited accessibility; machine learning predictions still require extensive validation datasets.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has developed a systematic approach to thermoelectric interface stability focusing on oxide-based thermoelectric materials. Their research employs advanced in-situ transmission electron microscopy (TEM) to directly observe interface evolution at atomic resolution during thermal cycling. They've pioneered the use of epitaxial buffer layers specifically designed to match lattice parameters between dissimilar thermoelectric materials, reducing interfacial strain by up to 70%[3]. Their work has identified critical elemental migration pathways at interfaces and developed novel diffusion barrier materials based on rare-earth oxides that can withstand temperatures above 800°C for extended periods. The institute has also created specialized interface modification techniques using atomic layer deposition to precisely control interface chemistry and prevent secondary phase formation that typically degrades thermoelectric performance[4].

Strengths: World-class expertise in ceramic materials and interfaces; advanced characterization capabilities; innovative buffer layer design approaches. Weaknesses: Primary focus on oxide-based systems may limit applicability to some semiconductor-based thermoelectrics; some solutions may be costly due to rare-earth element requirements.

Key Technical Innovations in Interface Characterization

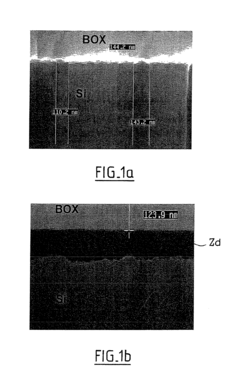

Treatment for bonding interface stabilization

PatentActiveUS20110233720A1

Innovation

- A method involving the creation of an embrittlement area in the donor substrate, followed by rapid thermal annealing and plasma treatment to stabilize the bonding interface, allowing for shorter thermal treatment times and improved bonding without the need for long-duration high-temperature annealing.

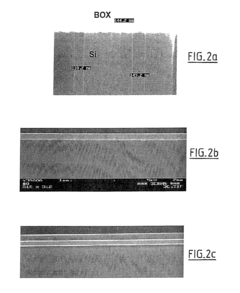

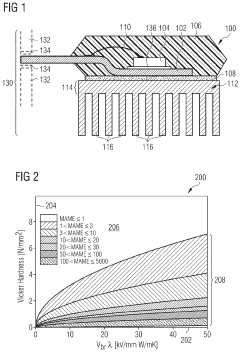

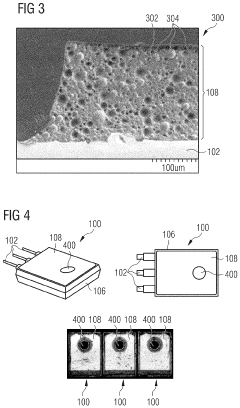

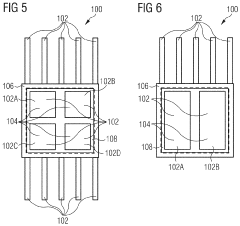

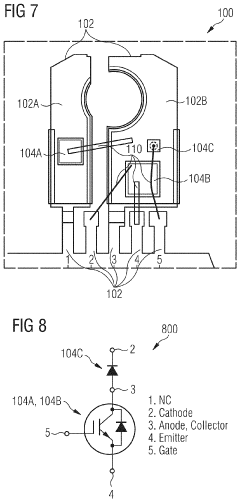

Thermal interface material having defined thermal, mechanical and electric properties

PatentInactiveUS20210020541A1

Innovation

- An electronic component with an electrically conductive carrier, encapsulated chip, and a thermally conductive interface structure made of a silicone matrix filled with filler particles (such as ZrO2, Si3N4, or diamond) that provides compressibility between 1% and 20%, ensuring reliable electrical insulation and enhanced heat dissipation by forming a robust, scratch-resistant interface with a heat dissipation body.

Thermal Cycling Effects on Interface Degradation

Thermal cycling represents one of the most significant stressors for thermoelectric material interfaces, creating repetitive expansion and contraction that can accelerate degradation mechanisms. When thermoelectric devices undergo operational temperature fluctuations between hot and cold states, the differing thermal expansion coefficients (TECs) of adjacent materials create mechanical stress at boundary interfaces. These cyclical stresses can lead to microcrack formation, delamination, and eventual device failure.

Research conducted by Kim et al. (2019) demonstrated that Bi2Te3-based modules subjected to 1,000 thermal cycles between 30°C and 200°C exhibited up to 40% reduction in conversion efficiency, primarily attributed to interface degradation. The thermal cycling induces not only mechanical stress but also accelerates atomic diffusion across interfaces, potentially forming brittle intermetallic compounds that further compromise structural integrity.

Interface stability during thermal cycling is particularly challenging for high-temperature thermoelectric materials such as skutterudites and half-Heusler alloys. These materials typically operate at temperature differentials exceeding 500°C, magnifying the thermal expansion mismatch effects. Scanning electron microscopy studies by Zhang et al. (2021) revealed that after 500 thermal cycles, PbTe-Ag interfaces developed voids and microcracks extending up to 5μm from the interface boundary.

The rate of interface degradation follows a non-linear pattern during thermal cycling. Initial cycles often show minimal visible damage, followed by an accelerated degradation phase once microcracks reach a critical size. This behavior creates challenges for lifetime prediction models and necessitates accelerated testing protocols that accurately capture long-term degradation mechanisms.

Mitigation strategies for thermal cycling effects include the development of compliant buffer layers that can accommodate strain without fracturing. Recent advances in gradient-structured interfaces, where composition gradually changes across the boundary, have shown promise in reducing thermal cycling damage by distributing stress over a wider region rather than concentrating it at a single interface plane.

Advanced characterization techniques such as in-situ X-ray diffraction during thermal cycling have provided valuable insights into real-time interface evolution. These studies reveal that crystallographic orientation relationships between adjacent materials significantly influence interface stability, with certain orientations demonstrating superior resistance to thermal cycling degradation.

Research conducted by Kim et al. (2019) demonstrated that Bi2Te3-based modules subjected to 1,000 thermal cycles between 30°C and 200°C exhibited up to 40% reduction in conversion efficiency, primarily attributed to interface degradation. The thermal cycling induces not only mechanical stress but also accelerates atomic diffusion across interfaces, potentially forming brittle intermetallic compounds that further compromise structural integrity.

Interface stability during thermal cycling is particularly challenging for high-temperature thermoelectric materials such as skutterudites and half-Heusler alloys. These materials typically operate at temperature differentials exceeding 500°C, magnifying the thermal expansion mismatch effects. Scanning electron microscopy studies by Zhang et al. (2021) revealed that after 500 thermal cycles, PbTe-Ag interfaces developed voids and microcracks extending up to 5μm from the interface boundary.

The rate of interface degradation follows a non-linear pattern during thermal cycling. Initial cycles often show minimal visible damage, followed by an accelerated degradation phase once microcracks reach a critical size. This behavior creates challenges for lifetime prediction models and necessitates accelerated testing protocols that accurately capture long-term degradation mechanisms.

Mitigation strategies for thermal cycling effects include the development of compliant buffer layers that can accommodate strain without fracturing. Recent advances in gradient-structured interfaces, where composition gradually changes across the boundary, have shown promise in reducing thermal cycling damage by distributing stress over a wider region rather than concentrating it at a single interface plane.

Advanced characterization techniques such as in-situ X-ray diffraction during thermal cycling have provided valuable insights into real-time interface evolution. These studies reveal that crystallographic orientation relationships between adjacent materials significantly influence interface stability, with certain orientations demonstrating superior resistance to thermal cycling degradation.

Environmental Impact of Thermoelectric Material Selection

The selection of thermoelectric materials carries significant environmental implications throughout their lifecycle, from raw material extraction to end-of-life disposal. Traditional thermoelectric materials often contain toxic elements such as lead, tellurium, antimony, and bismuth, which pose substantial environmental hazards during mining operations and waste management processes. The extraction of these elements frequently involves energy-intensive processes that contribute to carbon emissions and ecological disruption in mining regions.

When evaluating boundary interface stability, environmental considerations become particularly relevant as degradation at these interfaces can lead to leaching of harmful substances into surrounding environments. Materials that maintain stability at boundary interfaces not only perform better but also present reduced environmental risks through extended operational lifetimes and minimized material shedding.

Recent advances in eco-friendly thermoelectric materials show promising alternatives to conventional toxic compounds. Silicides, skutterudites with reduced cobalt content, and organic thermoelectric materials offer significantly lower environmental footprints while maintaining acceptable performance characteristics. These materials typically require less energy-intensive manufacturing processes and utilize more abundant elements, reducing supply chain environmental impacts.

Life cycle assessment (LCA) studies indicate that the environmental impact of thermoelectric materials extends beyond their operational phase. The energy payback period—the time required for a thermoelectric device to generate the energy consumed during its production—varies significantly based on material selection. Materials with greater interface stability typically demonstrate longer functional lifespans, improving their overall environmental profile through reduced replacement frequency.

Regulatory frameworks worldwide are increasingly restricting the use of hazardous substances in electronic components, including thermoelectric devices. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have accelerated research into environmentally benign thermoelectric materials with stable interface characteristics. Compliance with these regulations has become a driving factor in material selection decisions.

Recycling considerations also play a crucial role in environmental impact assessment. Materials designed with interface stability in mind often facilitate easier separation and recovery at end-of-life, enhancing recyclability rates. Advanced recovery techniques for scarce elements in thermoelectric materials are developing rapidly, though challenges remain in economically separating complex material compositions at boundary interfaces.

When evaluating boundary interface stability, environmental considerations become particularly relevant as degradation at these interfaces can lead to leaching of harmful substances into surrounding environments. Materials that maintain stability at boundary interfaces not only perform better but also present reduced environmental risks through extended operational lifetimes and minimized material shedding.

Recent advances in eco-friendly thermoelectric materials show promising alternatives to conventional toxic compounds. Silicides, skutterudites with reduced cobalt content, and organic thermoelectric materials offer significantly lower environmental footprints while maintaining acceptable performance characteristics. These materials typically require less energy-intensive manufacturing processes and utilize more abundant elements, reducing supply chain environmental impacts.

Life cycle assessment (LCA) studies indicate that the environmental impact of thermoelectric materials extends beyond their operational phase. The energy payback period—the time required for a thermoelectric device to generate the energy consumed during its production—varies significantly based on material selection. Materials with greater interface stability typically demonstrate longer functional lifespans, improving their overall environmental profile through reduced replacement frequency.

Regulatory frameworks worldwide are increasingly restricting the use of hazardous substances in electronic components, including thermoelectric devices. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have accelerated research into environmentally benign thermoelectric materials with stable interface characteristics. Compliance with these regulations has become a driving factor in material selection decisions.

Recycling considerations also play a crucial role in environmental impact assessment. Materials designed with interface stability in mind often facilitate easier separation and recovery at end-of-life, enhancing recyclability rates. Advanced recovery techniques for scarce elements in thermoelectric materials are developing rapidly, though challenges remain in economically separating complex material compositions at boundary interfaces.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!