Thermoelectric Materials in Compact Refrigeration Systems

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Cooling Background and Objectives

Thermoelectric cooling technology has evolved significantly since its discovery in the early 19th century when Jean Charles Athanase Peltier first observed the phenomenon of heat absorption or emission at the junction of two different conductors. This effect, later termed the Peltier effect, forms the foundation of modern thermoelectric cooling systems. The subsequent development of semiconductor materials in the mid-20th century revolutionized thermoelectric applications, enabling more efficient energy conversion between thermal and electrical domains.

The progression of thermoelectric materials has been marked by continuous improvements in the figure of merit (ZT), which quantifies cooling efficiency. Traditional bismuth telluride (Bi2Te3) compounds dominated early commercial applications, achieving ZT values around 1. Recent advancements in nanostructured materials, quantum dot superlattices, and skutterudites have pushed theoretical ZT values beyond 2, signaling significant efficiency improvements in thermoelectric performance.

Compact refrigeration systems represent a critical application domain for thermoelectric cooling technology. Unlike conventional vapor-compression refrigeration, thermoelectric systems offer solid-state operation with no moving parts, refrigerants, or complex mechanical components. This simplicity translates to enhanced reliability, miniaturization capabilities, and precise temperature control—attributes particularly valuable in specialized cooling applications where space constraints are paramount.

The primary technical objective in thermoelectric material development for compact refrigeration is achieving higher cooling power density while maintaining or improving energy efficiency. Current commercial thermoelectric modules typically operate at 5-8% of Carnot efficiency, significantly lower than conventional refrigeration systems that achieve 30-40%. Bridging this efficiency gap represents a fundamental challenge and opportunity in the field.

Another critical objective involves addressing thermal management challenges inherent to compact systems. As device dimensions shrink, heat flux densities increase dramatically, necessitating innovative approaches to heat spreading and dissipation. Advanced thermal interface materials and optimized heat exchanger designs are essential components of this technical objective.

Cost-effective manufacturing at scale remains a persistent challenge, particularly for newer high-performance thermoelectric materials. Many advanced materials with promising laboratory performance face significant barriers to commercialization due to complex synthesis requirements, expensive constituent elements, or challenging integration processes. Developing economically viable production methods represents a key objective for widespread adoption.

The convergence of these technical trajectories points toward a future where thermoelectric cooling could potentially disrupt conventional refrigeration in specific application niches, particularly where compactness, reliability, and precise temperature control outweigh pure efficiency considerations.

The progression of thermoelectric materials has been marked by continuous improvements in the figure of merit (ZT), which quantifies cooling efficiency. Traditional bismuth telluride (Bi2Te3) compounds dominated early commercial applications, achieving ZT values around 1. Recent advancements in nanostructured materials, quantum dot superlattices, and skutterudites have pushed theoretical ZT values beyond 2, signaling significant efficiency improvements in thermoelectric performance.

Compact refrigeration systems represent a critical application domain for thermoelectric cooling technology. Unlike conventional vapor-compression refrigeration, thermoelectric systems offer solid-state operation with no moving parts, refrigerants, or complex mechanical components. This simplicity translates to enhanced reliability, miniaturization capabilities, and precise temperature control—attributes particularly valuable in specialized cooling applications where space constraints are paramount.

The primary technical objective in thermoelectric material development for compact refrigeration is achieving higher cooling power density while maintaining or improving energy efficiency. Current commercial thermoelectric modules typically operate at 5-8% of Carnot efficiency, significantly lower than conventional refrigeration systems that achieve 30-40%. Bridging this efficiency gap represents a fundamental challenge and opportunity in the field.

Another critical objective involves addressing thermal management challenges inherent to compact systems. As device dimensions shrink, heat flux densities increase dramatically, necessitating innovative approaches to heat spreading and dissipation. Advanced thermal interface materials and optimized heat exchanger designs are essential components of this technical objective.

Cost-effective manufacturing at scale remains a persistent challenge, particularly for newer high-performance thermoelectric materials. Many advanced materials with promising laboratory performance face significant barriers to commercialization due to complex synthesis requirements, expensive constituent elements, or challenging integration processes. Developing economically viable production methods represents a key objective for widespread adoption.

The convergence of these technical trajectories points toward a future where thermoelectric cooling could potentially disrupt conventional refrigeration in specific application niches, particularly where compactness, reliability, and precise temperature control outweigh pure efficiency considerations.

Market Analysis for Compact Refrigeration Solutions

The global market for compact refrigeration solutions is experiencing robust growth, driven primarily by increasing demand for portable cooling systems across various sectors. The market was valued at approximately 11.2 billion USD in 2022 and is projected to reach 18.7 billion USD by 2030, representing a compound annual growth rate (CAGR) of 6.6%. This growth trajectory is supported by several key factors, including rising consumer preference for energy-efficient cooling solutions, technological advancements in thermoelectric materials, and expanding applications in medical, automotive, and consumer electronics industries.

Thermoelectric cooling technology, particularly utilizing advanced thermoelectric materials, has emerged as a significant segment within this market. Unlike traditional vapor-compression refrigeration systems, thermoelectric coolers offer advantages such as compact size, absence of moving parts, precise temperature control, and environmental friendliness due to the elimination of refrigerants. These benefits have positioned thermoelectric solutions as increasingly attractive alternatives for specialized cooling applications.

The healthcare and pharmaceutical sectors represent the fastest-growing application segments, with a market share of approximately 24% in 2022. The demand is primarily driven by the need for reliable temperature-controlled storage of vaccines, medications, and biological samples. The COVID-19 pandemic further accelerated this trend, highlighting the critical importance of portable and reliable cooling solutions for vaccine distribution chains.

Consumer electronics applications follow closely, accounting for 21% of the market share. The integration of thermoelectric cooling in personal devices, gaming equipment, and portable refrigerators has gained significant traction. Additionally, the automotive sector has shown increasing adoption rates for thermoelectric cooling in vehicle climate control systems and beverage coolers, representing 18% of the current market.

Geographically, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the forecast period, driven by rapid industrialization, increasing disposable income, and growing awareness about energy-efficient technologies in countries like China, Japan, and South Korea.

Key challenges in the market include relatively higher initial costs compared to conventional cooling systems and lower coefficient of performance (COP) values. However, ongoing research in advanced thermoelectric materials, particularly skutterudites, half-Heusler alloys, and nanostructured materials, is expected to address these limitations and further expand market opportunities.

Thermoelectric cooling technology, particularly utilizing advanced thermoelectric materials, has emerged as a significant segment within this market. Unlike traditional vapor-compression refrigeration systems, thermoelectric coolers offer advantages such as compact size, absence of moving parts, precise temperature control, and environmental friendliness due to the elimination of refrigerants. These benefits have positioned thermoelectric solutions as increasingly attractive alternatives for specialized cooling applications.

The healthcare and pharmaceutical sectors represent the fastest-growing application segments, with a market share of approximately 24% in 2022. The demand is primarily driven by the need for reliable temperature-controlled storage of vaccines, medications, and biological samples. The COVID-19 pandemic further accelerated this trend, highlighting the critical importance of portable and reliable cooling solutions for vaccine distribution chains.

Consumer electronics applications follow closely, accounting for 21% of the market share. The integration of thermoelectric cooling in personal devices, gaming equipment, and portable refrigerators has gained significant traction. Additionally, the automotive sector has shown increasing adoption rates for thermoelectric cooling in vehicle climate control systems and beverage coolers, representing 18% of the current market.

Geographically, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the forecast period, driven by rapid industrialization, increasing disposable income, and growing awareness about energy-efficient technologies in countries like China, Japan, and South Korea.

Key challenges in the market include relatively higher initial costs compared to conventional cooling systems and lower coefficient of performance (COP) values. However, ongoing research in advanced thermoelectric materials, particularly skutterudites, half-Heusler alloys, and nanostructured materials, is expected to address these limitations and further expand market opportunities.

Current Thermoelectric Material Limitations and Challenges

Despite significant advancements in thermoelectric technology, current materials used in compact refrigeration systems face substantial limitations that hinder widespread commercial adoption. The primary challenge remains the inherently low efficiency of thermoelectric materials, typically measured by the dimensionless figure of merit ZT. Most commercially available thermoelectric materials operate with ZT values between 0.8 and 1.2, whereas practical applications for compact refrigeration systems ideally require ZT values exceeding 2.0 to compete with conventional vapor-compression systems.

Bismuth telluride (Bi₂Te₃) and its alloys, the most commonly used materials in thermoelectric cooling applications, exhibit maximum ZT values around 1.0 at room temperature. This translates to conversion efficiencies of only 5-7%, significantly lower than the 30-40% efficiency achieved by conventional refrigeration technologies. Additionally, these materials contain tellurium, which is rare, expensive, and faces supply chain vulnerabilities due to its limited global production.

Thermal management presents another critical challenge. The performance of thermoelectric modules degrades significantly when heat is not effectively removed from the hot side, creating a thermal bottleneck that limits cooling capacity. This issue becomes particularly pronounced in compact systems where space constraints restrict the implementation of adequate heat dissipation mechanisms.

Mechanical stability and durability concerns further complicate material development. Thermoelectric materials must withstand thermal cycling and mechanical stresses while maintaining consistent performance. Many high-ZT materials developed in laboratory settings exhibit poor mechanical properties or degrade rapidly under operating conditions, limiting their practical application in commercial refrigeration systems.

Manufacturing scalability represents a significant barrier to widespread implementation. Advanced thermoelectric materials often involve complex synthesis procedures, precise doping requirements, and nanoscale engineering that are difficult to translate to mass production. This results in high manufacturing costs that undermine the economic viability of thermoelectric refrigeration systems compared to conventional alternatives.

Environmental and regulatory challenges also impact material selection. Many high-performance thermoelectric materials contain toxic elements like lead or tellurium, raising concerns about environmental impact and regulatory compliance. This has spurred research into "green" thermoelectric materials, though these alternatives typically offer lower performance characteristics.

Interface thermal resistance between different components of thermoelectric modules constitutes another significant limitation. Poor thermal and electrical contacts between thermoelectric materials and metal interconnects can substantially reduce system efficiency, necessitating advanced interface engineering solutions that add complexity and cost to manufacturing processes.

Bismuth telluride (Bi₂Te₃) and its alloys, the most commonly used materials in thermoelectric cooling applications, exhibit maximum ZT values around 1.0 at room temperature. This translates to conversion efficiencies of only 5-7%, significantly lower than the 30-40% efficiency achieved by conventional refrigeration technologies. Additionally, these materials contain tellurium, which is rare, expensive, and faces supply chain vulnerabilities due to its limited global production.

Thermal management presents another critical challenge. The performance of thermoelectric modules degrades significantly when heat is not effectively removed from the hot side, creating a thermal bottleneck that limits cooling capacity. This issue becomes particularly pronounced in compact systems where space constraints restrict the implementation of adequate heat dissipation mechanisms.

Mechanical stability and durability concerns further complicate material development. Thermoelectric materials must withstand thermal cycling and mechanical stresses while maintaining consistent performance. Many high-ZT materials developed in laboratory settings exhibit poor mechanical properties or degrade rapidly under operating conditions, limiting their practical application in commercial refrigeration systems.

Manufacturing scalability represents a significant barrier to widespread implementation. Advanced thermoelectric materials often involve complex synthesis procedures, precise doping requirements, and nanoscale engineering that are difficult to translate to mass production. This results in high manufacturing costs that undermine the economic viability of thermoelectric refrigeration systems compared to conventional alternatives.

Environmental and regulatory challenges also impact material selection. Many high-performance thermoelectric materials contain toxic elements like lead or tellurium, raising concerns about environmental impact and regulatory compliance. This has spurred research into "green" thermoelectric materials, though these alternatives typically offer lower performance characteristics.

Interface thermal resistance between different components of thermoelectric modules constitutes another significant limitation. Poor thermal and electrical contacts between thermoelectric materials and metal interconnects can substantially reduce system efficiency, necessitating advanced interface engineering solutions that add complexity and cost to manufacturing processes.

State-of-the-Art Thermoelectric Material Solutions

01 Bismuth telluride-based thermoelectric materials

Bismuth telluride (Bi2Te3) and its alloys are among the most widely used thermoelectric materials due to their high figure of merit at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. They are commonly used in cooling applications and low-temperature power generation. Research focuses on improving their efficiency through nanostructuring and compositional optimization.- Bismuth telluride-based thermoelectric materials: Bismuth telluride (Bi2Te3) and its alloys are among the most widely used thermoelectric materials due to their high efficiency at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. The performance of these materials is often measured by the figure of merit ZT, which depends on the Seebeck coefficient, electrical conductivity, and thermal conductivity. Nanostructuring techniques can be applied to bismuth telluride-based materials to reduce thermal conductivity while maintaining electrical conductivity.

- Organic and polymer-based thermoelectric materials: Organic and polymer-based thermoelectric materials offer advantages such as flexibility, low cost, and environmental friendliness. These materials can be processed using solution-based techniques, making them suitable for large-area applications. Conductive polymers, such as PEDOT:PSS, and organic small molecules can be used as thermoelectric materials. The thermoelectric performance of these materials can be enhanced by controlling the doping level, molecular ordering, and composite formation with inorganic materials.

- Nanostructured thermoelectric materials: Nanostructuring is a powerful approach to enhance the thermoelectric performance of materials. By creating nanoscale features such as quantum dots, nanowires, or nanocomposites, the thermal conductivity can be reduced due to increased phonon scattering at interfaces, while maintaining good electrical properties. Various fabrication techniques, including ball milling, hot pressing, and chemical synthesis, can be used to create nanostructured thermoelectric materials. These materials show significantly improved ZT values compared to their bulk counterparts.

- Skutterudite and half-Heusler thermoelectric materials: Skutterudites and half-Heusler compounds are promising thermoelectric materials for mid to high-temperature applications. Skutterudites have a cage-like crystal structure that can accommodate guest atoms (fillers), which scatter phonons and reduce thermal conductivity. Half-Heusler compounds have good mechanical properties and thermal stability, making them suitable for power generation applications. Both material classes can be optimized through compositional tuning and microstructural engineering to achieve high thermoelectric performance.

- Flexible and printable thermoelectric devices: Flexible and printable thermoelectric devices enable new applications such as wearable energy harvesters and conformal cooling systems. These devices can be fabricated using techniques such as screen printing, inkjet printing, or roll-to-roll processing. The materials used in these devices include both organic and inorganic thermoelectric materials, often in the form of inks or pastes. Substrate selection, interface engineering, and device architecture are critical factors affecting the performance and durability of flexible thermoelectric devices.

02 Skutterudite and half-Heusler thermoelectric materials

Skutterudites and half-Heusler alloys represent important classes of mid to high-temperature thermoelectric materials. These materials feature complex crystal structures that inherently reduce thermal conductivity while maintaining good electrical properties. They can be filled with rattling atoms or modified with various dopants to further enhance their thermoelectric performance, making them suitable for waste heat recovery applications in automotive and industrial settings.Expand Specific Solutions03 Nanostructured thermoelectric materials

Nanostructuring has emerged as a powerful approach to enhance the performance of thermoelectric materials. By introducing nanoscale features such as quantum dots, nanowires, or grain boundaries, phonon scattering can be increased without significantly affecting electron transport. This leads to reduced thermal conductivity while maintaining electrical conductivity, thereby improving the overall thermoelectric figure of merit. Various fabrication techniques including ball milling, hot pressing, and thin film deposition are employed to create these nanostructured materials.Expand Specific Solutions04 Organic and flexible thermoelectric materials

Organic and polymer-based thermoelectric materials offer advantages such as flexibility, light weight, and solution processability. These materials can be fabricated into flexible devices that conform to curved surfaces, enabling new applications in wearable electronics and IoT devices. While their efficiency is generally lower than inorganic counterparts, their low thermal conductivity and potential for low-cost manufacturing make them attractive for specific applications. Research focuses on improving their electrical conductivity and stability through various doping strategies and composite formations.Expand Specific Solutions05 Advanced manufacturing techniques for thermoelectric devices

Various manufacturing techniques have been developed to fabricate efficient thermoelectric devices. These include printing technologies for flexible thermoelectrics, thin film deposition for miniaturized devices, and bulk manufacturing methods for industrial applications. Advanced techniques such as spark plasma sintering allow for the creation of highly dense materials with controlled microstructures. Module design and contact engineering are also critical aspects that affect the overall device performance and reliability under thermal cycling conditions.Expand Specific Solutions

Leading Companies in Thermoelectric Cooling Industry

Thermoelectric materials in compact refrigeration systems are currently in a growth phase, with the market expected to expand significantly due to increasing demand for energy-efficient cooling solutions. The global market is projected to reach substantial value as applications diversify beyond traditional sectors. Technologically, the field shows varying maturity levels, with academic institutions like Zhejiang University, California Institute of Technology, and Peking University driving fundamental research, while companies such as Laird Thermal Systems, O-Flexx Technologies, and Gentherm are commercializing applications. Industrial players like Samsung Electronics and 3M are investing in advanced material development, while specialized entities like Industrial Technology Research Institute are bridging research-to-market gaps. Government involvement through research institutes indicates strategic importance in energy efficiency initiatives.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced thermoelectric material solutions for compact refrigeration systems through their Fluorinert™ Electronic Liquid technology. Their approach combines traditional bismuth telluride thermoelectric modules with proprietary heat transfer fluids that enhance thermal management in confined spaces. The company has engineered specialized interface materials with thermal conductivity exceeding 5 W/m·K while maintaining electrical isolation properties critical for thermoelectric system efficiency. 3M's multilayer thin-film thermoelectric materials utilize alternating nanoscale layers of different semiconductor materials to create quantum well structures that enhance the Seebeck coefficient while reducing thermal conductivity, achieving ZT values up to 2.0 in laboratory conditions. Their manufacturing process incorporates precision deposition techniques that enable the creation of thermoelectric modules with thickness under 1mm, ideal for space-constrained cooling applications in electronics and medical devices.

Strengths: Extensive materials science expertise across multiple domains; strong intellectual property portfolio in thermal management; established global manufacturing infrastructure. Weaknesses: Less specialized in thermoelectric technology compared to pure-play thermoelectric companies; solutions often focus on complementary materials rather than core thermoelectric elements.

Laird Thermal Systems, Inc.

Technical Solution: Laird Thermal Systems has developed advanced thermoelectric modules (TEMs) specifically designed for compact refrigeration applications. Their Tunnel Series TEMs utilize bismuth telluride semiconductor material arranged in pellets to create the Peltier effect, achieving temperature differentials up to 78°C in single-stage configurations. The company has pioneered high-performance thin-film thermoelectric materials with enhanced ZT values exceeding 1.5, significantly improving cooling efficiency. Their SuperCool Series incorporates proprietary thermoelectric material compositions with optimized electrical conductivity while minimizing thermal conductivity, achieving up to 10% better performance than standard modules. Laird's manufacturing process includes precision automated assembly techniques that ensure consistent pellet height within ±0.01mm, critical for thermal performance in compact systems.

Strengths: Industry-leading ZT values in commercial products; comprehensive thermal management solutions including heat sinks and controllers; extensive customization capabilities for specific applications. Weaknesses: Higher cost compared to conventional cooling technologies; limited temperature differential capability in extreme environments without multistage configurations.

Key Patents and Research in Thermoelectric Materials

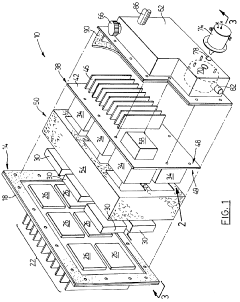

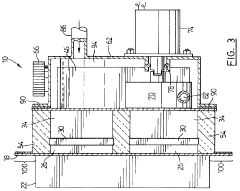

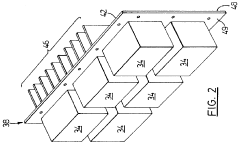

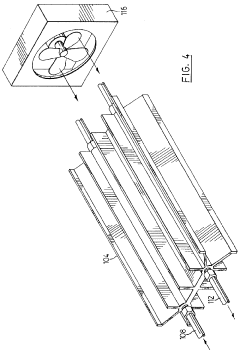

Compact thermoelectric refrigeration drive assembly

PatentInactiveUS5809785A

Innovation

- A compact thermoelectric refrigeration drive assembly featuring a thermoelectric heat transfer device with active surfaces, a collector member, a transfer member forming a vessel for cooling fluid, insulation to inhibit heat transfer, and a control system for efficient heat management, including a thermostatically controlled pump and fan for enhanced heat exchange.

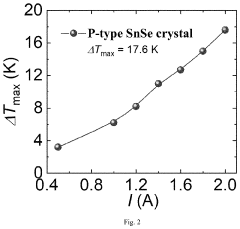

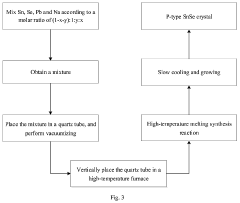

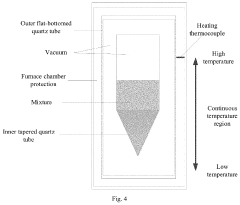

P-type SnSe crystal capable of being used as thermoelectric refrigeration material and preparation method thereof

PatentActiveUS11629431B2

Innovation

- A Na-doped and Pb-alloyed SnSe crystal with a specific molar ratio is synthesized using a high-temperature melting synthesis method, optimizing the energy band structure and carrier mobility through multiple valence band synergistic effects, resulting in enhanced thermoelectric performance.

Energy Efficiency and Sustainability Considerations

The energy efficiency of thermoelectric materials in compact refrigeration systems presents a critical consideration in their commercial viability and environmental impact. Current thermoelectric cooling systems typically operate at 5-10% of Carnot efficiency, significantly lower than conventional vapor-compression refrigeration systems that achieve 30-40% efficiency. This efficiency gap represents both a challenge and an opportunity for technological advancement in the field.

Thermoelectric cooling systems consume electricity directly, making their overall environmental footprint heavily dependent on the electricity generation mix. In regions with high renewable energy penetration, these systems can offer substantial carbon footprint reductions compared to conventional refrigeration technologies that rely on refrigerants with high global warming potential (GWP).

Material selection plays a pivotal role in sustainability considerations. Traditional thermoelectric materials like bismuth telluride contain rare and potentially toxic elements, raising concerns about resource depletion and end-of-life disposal. Recent research has focused on developing alternative materials using earth-abundant elements such as magnesium silicide, skutterudites, and half-Heusler alloys, which promise reduced environmental impact throughout their lifecycle.

Manufacturing processes for thermoelectric modules also present significant energy and resource demands. Current fabrication techniques often require high-temperature processing and precision engineering, contributing to embodied energy costs. Innovations in additive manufacturing and low-temperature synthesis methods are emerging as potential pathways to reduce the energy intensity of production.

Lifecycle assessment studies indicate that the environmental benefits of thermoelectric refrigeration systems are highly application-dependent. In small-scale, intermittent cooling applications, thermoelectric systems can offer net environmental benefits despite lower energy efficiency due to their compact size, lack of moving parts, and absence of refrigerants. However, in continuous, large-scale cooling applications, conventional systems typically maintain an environmental advantage.

The integration of thermoelectric cooling with waste heat recovery systems presents a promising approach to improve overall system efficiency. By capturing and repurposing waste heat from the hot side of thermoelectric modules, hybrid systems can achieve significantly higher effective coefficients of performance, potentially approaching or exceeding those of conventional refrigeration technologies in specific applications.

Regulatory frameworks increasingly emphasize energy efficiency and refrigerant phase-out, creating market drivers for alternative cooling technologies. The Montreal Protocol and subsequent amendments targeting hydrofluorocarbons (HFCs) have accelerated interest in non-vapor compression technologies, including thermoelectric cooling, despite their current efficiency limitations.

Thermoelectric cooling systems consume electricity directly, making their overall environmental footprint heavily dependent on the electricity generation mix. In regions with high renewable energy penetration, these systems can offer substantial carbon footprint reductions compared to conventional refrigeration technologies that rely on refrigerants with high global warming potential (GWP).

Material selection plays a pivotal role in sustainability considerations. Traditional thermoelectric materials like bismuth telluride contain rare and potentially toxic elements, raising concerns about resource depletion and end-of-life disposal. Recent research has focused on developing alternative materials using earth-abundant elements such as magnesium silicide, skutterudites, and half-Heusler alloys, which promise reduced environmental impact throughout their lifecycle.

Manufacturing processes for thermoelectric modules also present significant energy and resource demands. Current fabrication techniques often require high-temperature processing and precision engineering, contributing to embodied energy costs. Innovations in additive manufacturing and low-temperature synthesis methods are emerging as potential pathways to reduce the energy intensity of production.

Lifecycle assessment studies indicate that the environmental benefits of thermoelectric refrigeration systems are highly application-dependent. In small-scale, intermittent cooling applications, thermoelectric systems can offer net environmental benefits despite lower energy efficiency due to their compact size, lack of moving parts, and absence of refrigerants. However, in continuous, large-scale cooling applications, conventional systems typically maintain an environmental advantage.

The integration of thermoelectric cooling with waste heat recovery systems presents a promising approach to improve overall system efficiency. By capturing and repurposing waste heat from the hot side of thermoelectric modules, hybrid systems can achieve significantly higher effective coefficients of performance, potentially approaching or exceeding those of conventional refrigeration technologies in specific applications.

Regulatory frameworks increasingly emphasize energy efficiency and refrigerant phase-out, creating market drivers for alternative cooling technologies. The Montreal Protocol and subsequent amendments targeting hydrofluorocarbons (HFCs) have accelerated interest in non-vapor compression technologies, including thermoelectric cooling, despite their current efficiency limitations.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of thermoelectric materials represents a critical factor in the widespread adoption of compact refrigeration systems. Current production methods for high-performance thermoelectric materials often involve complex processes such as powder metallurgy, spark plasma sintering, and precision machining, which significantly impact production costs and scalability. These specialized manufacturing techniques require substantial capital investment in equipment and skilled labor, creating barriers to mass production.

Material costs constitute a substantial portion of the overall expense in thermoelectric cooling systems. High-performance bismuth telluride (Bi2Te3) compounds, the industry standard for near-room-temperature applications, contain tellurium—a relatively scarce element with fluctuating market prices. Recent market analyses indicate that tellurium prices have experienced volatility, with costs ranging from $30-200 per kilogram depending on purity requirements and market conditions.

Production yield rates present another significant challenge. Manufacturing processes for thermoelectric modules typically experience yield losses of 15-30% due to material defects, dimensional inconsistencies, and electrical performance variations. These yield issues directly impact unit economics and must be addressed through improved process controls and quality assurance protocols.

Economies of scale remain elusive for many thermoelectric material manufacturers. While traditional semiconductor industries benefit from dramatic cost reductions through scaling, thermoelectric material production has not yet achieved comparable economies of scale. Analysis of production data suggests that doubling production volume currently reduces unit costs by only 7-12%, compared to 15-20% in mature semiconductor manufacturing.

Supply chain considerations further complicate the manufacturing landscape. Many high-performance thermoelectric materials require elements with geographically concentrated sources, creating potential supply vulnerabilities. For instance, over 80% of tellurium production occurs in just four countries, exposing manufacturers to geopolitical and market risks.

Recent innovations in manufacturing techniques show promise for improving scalability. Additive manufacturing approaches, including selective laser sintering and direct ink writing, demonstrate potential for reducing material waste and enabling more complex geometries. Additionally, thin-film deposition techniques adapted from the semiconductor industry offer pathways to higher throughput and potentially lower production costs, though these approaches remain primarily in research and development phases.

Cost modeling indicates that achieving price parity with conventional vapor-compression refrigeration requires approximately 40-60% reduction in current manufacturing costs of thermoelectric systems. This target necessitates innovations in both material formulations and manufacturing processes to enable broader market adoption beyond current niche applications.

Material costs constitute a substantial portion of the overall expense in thermoelectric cooling systems. High-performance bismuth telluride (Bi2Te3) compounds, the industry standard for near-room-temperature applications, contain tellurium—a relatively scarce element with fluctuating market prices. Recent market analyses indicate that tellurium prices have experienced volatility, with costs ranging from $30-200 per kilogram depending on purity requirements and market conditions.

Production yield rates present another significant challenge. Manufacturing processes for thermoelectric modules typically experience yield losses of 15-30% due to material defects, dimensional inconsistencies, and electrical performance variations. These yield issues directly impact unit economics and must be addressed through improved process controls and quality assurance protocols.

Economies of scale remain elusive for many thermoelectric material manufacturers. While traditional semiconductor industries benefit from dramatic cost reductions through scaling, thermoelectric material production has not yet achieved comparable economies of scale. Analysis of production data suggests that doubling production volume currently reduces unit costs by only 7-12%, compared to 15-20% in mature semiconductor manufacturing.

Supply chain considerations further complicate the manufacturing landscape. Many high-performance thermoelectric materials require elements with geographically concentrated sources, creating potential supply vulnerabilities. For instance, over 80% of tellurium production occurs in just four countries, exposing manufacturers to geopolitical and market risks.

Recent innovations in manufacturing techniques show promise for improving scalability. Additive manufacturing approaches, including selective laser sintering and direct ink writing, demonstrate potential for reducing material waste and enabling more complex geometries. Additionally, thin-film deposition techniques adapted from the semiconductor industry offer pathways to higher throughput and potentially lower production costs, though these approaches remain primarily in research and development phases.

Cost modeling indicates that achieving price parity with conventional vapor-compression refrigeration requires approximately 40-60% reduction in current manufacturing costs of thermoelectric systems. This target necessitates innovations in both material formulations and manufacturing processes to enable broader market adoption beyond current niche applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!