How to Increase Efficiency in Thermoelectric Generators with AI

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Generation Technology Evolution and Objectives

Thermoelectric generation technology has evolved significantly since its discovery in the early 19th century with the Seebeck effect. Initially, these devices were primarily used in niche applications due to their low efficiency, typically below 5%. The technology remained relatively stagnant until the mid-20th century when semiconductor materials revolutionized the field, enabling more practical applications in space exploration and remote power generation.

The past two decades have witnessed accelerated development in thermoelectric materials, with significant breakthroughs in nanostructured materials and quantum well structures. These advancements have pushed conversion efficiencies from single digits to 10-15% in laboratory settings. However, commercial applications still struggle with efficiency limitations, typically operating at 5-8% in real-world conditions.

Current research focuses on overcoming the fundamental trade-off between electrical conductivity and thermal conductivity, known as the ZT paradox. Materials with high ZT (figure of merit) values are essential for efficient thermoelectric generation, with recent developments in skutterudites, half-Heusler alloys, and clathrates showing promise for breaking through existing efficiency barriers.

The integration of artificial intelligence into thermoelectric generator (TEG) development represents a paradigm shift in the field. Machine learning algorithms can accelerate materials discovery by predicting properties of novel compounds without extensive physical testing. AI-driven optimization of device architecture and operating parameters can significantly enhance performance in variable thermal environments.

The primary technical objective is to achieve TEG systems with conversion efficiencies exceeding 20% at scale, making them competitive with traditional power generation methods. Secondary goals include reducing manufacturing costs, enhancing durability in extreme conditions, and developing environmentally sustainable materials that avoid rare or toxic elements.

Long-term objectives include the development of adaptive TEG systems that can self-optimize based on environmental conditions, integration with IoT infrastructure for smart energy management, and the creation of flexible, lightweight TEGs for wearable and portable applications. The ultimate vision is to position thermoelectric generation as a mainstream renewable energy technology that can effectively harvest waste heat across industrial, automotive, and residential sectors.

The convergence of advanced materials science, nanotechnology, and artificial intelligence presents unprecedented opportunities to overcome historical limitations in thermoelectric generation, potentially transforming this technology from a specialized solution to a ubiquitous component in global energy systems.

The past two decades have witnessed accelerated development in thermoelectric materials, with significant breakthroughs in nanostructured materials and quantum well structures. These advancements have pushed conversion efficiencies from single digits to 10-15% in laboratory settings. However, commercial applications still struggle with efficiency limitations, typically operating at 5-8% in real-world conditions.

Current research focuses on overcoming the fundamental trade-off between electrical conductivity and thermal conductivity, known as the ZT paradox. Materials with high ZT (figure of merit) values are essential for efficient thermoelectric generation, with recent developments in skutterudites, half-Heusler alloys, and clathrates showing promise for breaking through existing efficiency barriers.

The integration of artificial intelligence into thermoelectric generator (TEG) development represents a paradigm shift in the field. Machine learning algorithms can accelerate materials discovery by predicting properties of novel compounds without extensive physical testing. AI-driven optimization of device architecture and operating parameters can significantly enhance performance in variable thermal environments.

The primary technical objective is to achieve TEG systems with conversion efficiencies exceeding 20% at scale, making them competitive with traditional power generation methods. Secondary goals include reducing manufacturing costs, enhancing durability in extreme conditions, and developing environmentally sustainable materials that avoid rare or toxic elements.

Long-term objectives include the development of adaptive TEG systems that can self-optimize based on environmental conditions, integration with IoT infrastructure for smart energy management, and the creation of flexible, lightweight TEGs for wearable and portable applications. The ultimate vision is to position thermoelectric generation as a mainstream renewable energy technology that can effectively harvest waste heat across industrial, automotive, and residential sectors.

The convergence of advanced materials science, nanotechnology, and artificial intelligence presents unprecedented opportunities to overcome historical limitations in thermoelectric generation, potentially transforming this technology from a specialized solution to a ubiquitous component in global energy systems.

Market Analysis for AI-Enhanced Thermoelectric Solutions

The global market for thermoelectric generators (TEGs) is experiencing significant growth, driven by increasing demand for energy-efficient solutions across multiple industries. Current market valuations place the TEG sector at approximately 460 million USD in 2022, with projections indicating growth to reach 720 million USD by 2028, representing a compound annual growth rate of 7.8%. This expansion is particularly notable in automotive, aerospace, industrial manufacturing, and consumer electronics sectors.

AI-enhanced thermoelectric solutions represent an emerging market segment with substantial growth potential. The integration of artificial intelligence with TEG technology addresses the critical efficiency limitations that have historically constrained widespread adoption. Market research indicates that AI-optimized TEGs can potentially increase conversion efficiency by 15-25% compared to conventional systems, significantly improving the value proposition for end-users.

Consumer electronics represents the fastest-growing application segment, with manufacturers increasingly incorporating TEGs into wearable devices, smartphones, and IoT products. The automotive sector follows closely, where waste heat recovery systems utilizing AI-enhanced TEGs are gaining traction as vehicle manufacturers face stringent emissions regulations and fuel efficiency standards.

Geographically, North America currently leads the market for AI-enhanced thermoelectric solutions, accounting for approximately 38% of global revenue. This dominance stems from substantial R&D investments and the presence of key technology developers. Asia-Pacific represents the fastest-growing regional market, with China, Japan, and South Korea making significant investments in advanced energy harvesting technologies.

Market barriers include high initial implementation costs and integration challenges with existing systems. However, these barriers are gradually diminishing as AI technologies become more accessible and thermoelectric materials improve. The price-performance ratio of AI-enhanced TEGs is expected to improve by 30% over the next five years, further accelerating market adoption.

Customer demand patterns reveal increasing preference for integrated solutions that combine AI-optimized TEGs with comprehensive energy management systems. This trend is particularly evident in industrial applications where predictive maintenance capabilities and real-time efficiency optimization deliver substantial operational cost savings.

Market forecasts suggest that AI-enhanced thermoelectric solutions will capture an increasing share of the broader energy harvesting market, potentially reaching 25% of the total TEG market by 2027. This growth trajectory is supported by ongoing advancements in machine learning algorithms specifically designed for thermal system optimization and the development of more efficient thermoelectric materials guided by AI-driven materials science.

AI-enhanced thermoelectric solutions represent an emerging market segment with substantial growth potential. The integration of artificial intelligence with TEG technology addresses the critical efficiency limitations that have historically constrained widespread adoption. Market research indicates that AI-optimized TEGs can potentially increase conversion efficiency by 15-25% compared to conventional systems, significantly improving the value proposition for end-users.

Consumer electronics represents the fastest-growing application segment, with manufacturers increasingly incorporating TEGs into wearable devices, smartphones, and IoT products. The automotive sector follows closely, where waste heat recovery systems utilizing AI-enhanced TEGs are gaining traction as vehicle manufacturers face stringent emissions regulations and fuel efficiency standards.

Geographically, North America currently leads the market for AI-enhanced thermoelectric solutions, accounting for approximately 38% of global revenue. This dominance stems from substantial R&D investments and the presence of key technology developers. Asia-Pacific represents the fastest-growing regional market, with China, Japan, and South Korea making significant investments in advanced energy harvesting technologies.

Market barriers include high initial implementation costs and integration challenges with existing systems. However, these barriers are gradually diminishing as AI technologies become more accessible and thermoelectric materials improve. The price-performance ratio of AI-enhanced TEGs is expected to improve by 30% over the next five years, further accelerating market adoption.

Customer demand patterns reveal increasing preference for integrated solutions that combine AI-optimized TEGs with comprehensive energy management systems. This trend is particularly evident in industrial applications where predictive maintenance capabilities and real-time efficiency optimization deliver substantial operational cost savings.

Market forecasts suggest that AI-enhanced thermoelectric solutions will capture an increasing share of the broader energy harvesting market, potentially reaching 25% of the total TEG market by 2027. This growth trajectory is supported by ongoing advancements in machine learning algorithms specifically designed for thermal system optimization and the development of more efficient thermoelectric materials guided by AI-driven materials science.

Current TEG Efficiency Limitations and Technical Challenges

Thermoelectric generators (TEGs) currently face significant efficiency limitations that hinder their widespread adoption in energy harvesting applications. The fundamental challenge lies in the inherent trade-off between thermal conductivity and electrical conductivity in thermoelectric materials. Most conventional TEG materials that exhibit good electrical conductivity also conduct heat efficiently, which reduces the temperature gradient necessary for optimal power generation. This physical constraint has limited commercial TEGs to conversion efficiencies typically below 8%, far lower than other energy conversion technologies.

Material constraints represent another major challenge in TEG development. Current state-of-the-art thermoelectric materials such as bismuth telluride (Bi₂Te₃) and lead telluride (PbTe) contain rare, expensive, or toxic elements that limit scalability and environmental sustainability. Additionally, these materials often perform optimally only within narrow temperature ranges, restricting their application versatility.

Thermal management issues further complicate TEG efficiency. Heat flux control across the device is critical but difficult to optimize, with thermal interface resistance and non-uniform temperature distributions causing significant energy losses. Current designs struggle to maintain optimal temperature gradients under varying operating conditions, resulting in performance degradation in real-world applications.

Manufacturing complexities also present substantial barriers. Precise fabrication of thermoelectric modules requires specialized techniques for material synthesis, doping control, and module assembly. The need for nanoscale engineering to enhance thermoelectric properties introduces additional manufacturing challenges and cost implications. Current production methods often involve trade-offs between performance optimization and manufacturing feasibility.

System-level integration presents yet another challenge. TEGs must interface effectively with heat sources and heat sinks while minimizing parasitic losses. Current designs struggle with thermal cycling durability, with repeated expansion and contraction leading to mechanical stress and eventual performance degradation or failure. This reliability issue significantly impacts long-term operational efficiency.

The measurement and characterization of TEG performance also remains problematic. Standardized testing protocols are not universally adopted, making performance comparisons between different technologies difficult. Real-time monitoring of TEG operation parameters is limited by current sensor technologies, complicating dynamic optimization efforts.

These multifaceted challenges create a complex optimization problem that traditional engineering approaches have struggled to fully resolve. The introduction of AI methodologies offers promising new avenues for addressing these limitations through advanced materials discovery, multi-parameter optimization, and adaptive control systems that could potentially overcome the efficiency barriers that have historically constrained TEG technology.

Material constraints represent another major challenge in TEG development. Current state-of-the-art thermoelectric materials such as bismuth telluride (Bi₂Te₃) and lead telluride (PbTe) contain rare, expensive, or toxic elements that limit scalability and environmental sustainability. Additionally, these materials often perform optimally only within narrow temperature ranges, restricting their application versatility.

Thermal management issues further complicate TEG efficiency. Heat flux control across the device is critical but difficult to optimize, with thermal interface resistance and non-uniform temperature distributions causing significant energy losses. Current designs struggle to maintain optimal temperature gradients under varying operating conditions, resulting in performance degradation in real-world applications.

Manufacturing complexities also present substantial barriers. Precise fabrication of thermoelectric modules requires specialized techniques for material synthesis, doping control, and module assembly. The need for nanoscale engineering to enhance thermoelectric properties introduces additional manufacturing challenges and cost implications. Current production methods often involve trade-offs between performance optimization and manufacturing feasibility.

System-level integration presents yet another challenge. TEGs must interface effectively with heat sources and heat sinks while minimizing parasitic losses. Current designs struggle with thermal cycling durability, with repeated expansion and contraction leading to mechanical stress and eventual performance degradation or failure. This reliability issue significantly impacts long-term operational efficiency.

The measurement and characterization of TEG performance also remains problematic. Standardized testing protocols are not universally adopted, making performance comparisons between different technologies difficult. Real-time monitoring of TEG operation parameters is limited by current sensor technologies, complicating dynamic optimization efforts.

These multifaceted challenges create a complex optimization problem that traditional engineering approaches have struggled to fully resolve. The introduction of AI methodologies offers promising new avenues for addressing these limitations through advanced materials discovery, multi-parameter optimization, and adaptive control systems that could potentially overcome the efficiency barriers that have historically constrained TEG technology.

State-of-the-Art AI Approaches for TEG Efficiency Optimization

01 AI-optimized thermoelectric material design

Artificial intelligence techniques are employed to design and optimize novel thermoelectric materials with enhanced Seebeck coefficients and reduced thermal conductivity. Machine learning algorithms analyze material properties and predict compositions that maximize the figure of merit (ZT), leading to more efficient energy conversion. These AI-driven approaches enable rapid screening of potential material combinations and nanostructures that would be impractical to discover through conventional experimental methods.- AI-optimized thermoelectric material design: Artificial intelligence techniques are being applied to design and optimize novel thermoelectric materials with enhanced properties. Machine learning algorithms analyze material compositions and structures to predict and improve thermoelectric performance metrics such as the figure of merit (ZT). These AI approaches enable rapid screening of potential material candidates and identification of optimal dopants or nanostructures that can significantly increase energy conversion efficiency beyond traditional trial-and-error methods.

- Smart control systems for thermoelectric generators: Integration of AI-based control systems with thermoelectric generators enables real-time optimization of operating parameters. These intelligent systems continuously monitor environmental conditions, heat flow, and load requirements to dynamically adjust the generator's operation. Machine learning algorithms predict optimal operating points and adapt to changing conditions, resulting in significant improvements in overall system efficiency and power output compared to static control approaches.

- Hybrid thermoelectric systems with AI integration: Novel hybrid systems combine thermoelectric generators with other energy harvesting technologies, coordinated by artificial intelligence. These integrated systems leverage AI to manage energy flow between different generation methods, storage components, and loads. The intelligent coordination maximizes overall system efficiency by optimizing the operation of each component based on current conditions and predicted future states, resulting in more reliable and efficient power generation across varying environmental conditions.

- AI-driven thermal management optimization: Artificial intelligence techniques are being applied to optimize the thermal management aspects of thermoelectric generators. These systems use machine learning algorithms to analyze heat flow patterns and thermal gradients, then dynamically adjust heat exchangers, cooling systems, or heat concentration mechanisms. By maintaining optimal temperature differentials across thermoelectric modules, these AI-driven approaches significantly improve conversion efficiency and power output under varying operating conditions.

- Predictive maintenance and performance forecasting: AI-based monitoring systems for thermoelectric generators provide predictive maintenance capabilities and performance forecasting. These systems continuously analyze operational data to detect early signs of degradation or failure, optimize maintenance schedules, and predict future performance under various conditions. By preventing unexpected downtime and maintaining optimal operating conditions, these intelligent monitoring systems significantly extend the operational lifetime and overall efficiency of thermoelectric generation systems.

02 Intelligent thermal management systems

Smart thermal management systems utilize AI algorithms to dynamically adjust thermoelectric generator parameters based on real-time environmental conditions. These systems continuously monitor temperature gradients, load requirements, and other operational variables to optimize power output. The intelligent control mechanisms can predict thermal fluctuations and preemptively adjust the generator configuration to maintain peak efficiency across varying conditions.Expand Specific Solutions03 Nanostructured thermoelectric materials with AI-guided fabrication

Advanced nanostructuring techniques guided by artificial intelligence create thermoelectric materials with optimized phonon scattering properties while maintaining good electrical conductivity. These materials feature precisely engineered quantum dots, nanowires, or superlattice structures that effectively reduce thermal conductivity without significantly impacting electron transport. AI algorithms determine the ideal dimensions, spacing, and composition of these nanostructures to maximize the thermoelectric performance.Expand Specific Solutions04 Self-optimizing thermoelectric generator networks

Interconnected networks of thermoelectric generators utilize distributed AI systems to coordinate power generation across multiple units. These networks can autonomously reconfigure electrical connections and thermal pathways to adapt to changing conditions or localized damage. The self-optimizing behavior allows for more resilient power generation systems that can maintain efficiency despite partial failures or varying thermal inputs across the network.Expand Specific Solutions05 AI-enhanced energy harvesting from variable heat sources

Artificial intelligence systems enable thermoelectric generators to efficiently harvest energy from inconsistent or low-grade heat sources. These systems employ predictive algorithms to anticipate thermal fluctuations and adjust the electrical load accordingly. Advanced machine learning techniques analyze patterns in heat generation to optimize the placement and configuration of thermoelectric elements, maximizing energy capture from waste heat in industrial processes, vehicle exhaust systems, or ambient environmental temperature differentials.Expand Specific Solutions

Leading Companies and Research Institutions in AI-TEG Innovation

The thermoelectric generator (TEG) efficiency enhancement market using AI is currently in its growth phase, with increasing interest from both established players and innovative startups. The market is projected to expand significantly as waste heat recovery becomes critical for energy efficiency across industries. Key players demonstrate varying levels of technological maturity: IBM and Micron Technology lead with advanced AI integration capabilities; O-Flexx Technologies and Gentherm show specialized expertise in thermoelectric materials; while Robert Bosch and DENSO are leveraging their automotive industry presence to develop practical applications. Research institutions like Tianjin University and East China Normal University are contributing fundamental breakthroughs, creating a competitive landscape where cross-sector collaboration between technology giants and TEG specialists is driving innovation.

International Business Machines Corp.

Technical Solution: IBM has developed a sophisticated AI framework for thermoelectric generator optimization that leverages their expertise in quantum computing and machine learning. Their approach utilizes a hybrid quantum-classical algorithm to solve the complex multi-parameter optimization problem inherent in TEG efficiency maximization. The system employs IBM's Watson AI platform to process thermal data from multiple sensors and identify patterns that human analysts might miss. Their technology includes a predictive maintenance component that anticipates degradation in TEG performance and recommends preemptive interventions. IBM's solution incorporates a digital twin modeling system that simulates thousands of operating scenarios to identify optimal configurations for specific applications. The AI continuously learns from operational data, refining its models to account for aging effects and environmental variations. IBM has demonstrated efficiency improvements of up to 30% in industrial waste heat recovery applications through their intelligent thermal management system that dynamically adjusts load parameters based on real-time conditions.

Strengths: Unparalleled computational resources and AI expertise, with advanced modeling capabilities that can handle extremely complex thermal systems. Their solution offers sophisticated predictive analytics that can identify optimization opportunities beyond human capacity. Weaknesses: Less direct experience in thermal management hardware implementation compared to specialized manufacturers, and their solutions may require significant customization for specific industrial applications.

GM Global Technology Operations LLC

Technical Solution: General Motors has developed an innovative AI-enhanced thermoelectric generator system specifically optimized for automotive applications. Their approach integrates machine learning algorithms with vehicle thermal management systems to maximize energy recovery from exhaust heat. GM's technology employs a neural network trained on millions of miles of driving data to predict optimal TEG operating conditions based on driving patterns, ambient temperature, and engine load. The system features adaptive control algorithms that continuously adjust the electrical load on the TEG modules to maintain operation at the maximum power point regardless of changing conditions. GM has implemented a multi-zone TEG system where AI coordinates the operation of multiple thermoelectric modules placed strategically throughout the exhaust system, each operating under different temperature gradients. Their solution includes a sophisticated thermal management system that uses AI to balance heat distribution across TEG modules, preventing hotspots and thermal degradation while maximizing overall system efficiency. GM reports efficiency improvements of 18-22% compared to conventional TEG systems in real-world driving conditions.

Strengths: Deep integration with vehicle systems allowing for holistic optimization across multiple vehicle subsystems. Their solution benefits from extensive real-world testing data from their vehicle fleet. Weaknesses: Technology is highly specialized for automotive applications and may be difficult to adapt to other industries. The system adds complexity to vehicle thermal management systems.

Key Patents and Research on AI-Driven Thermoelectric Improvements

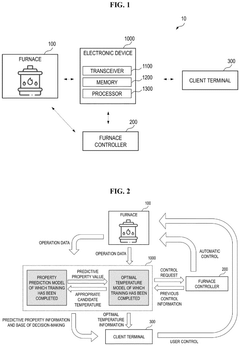

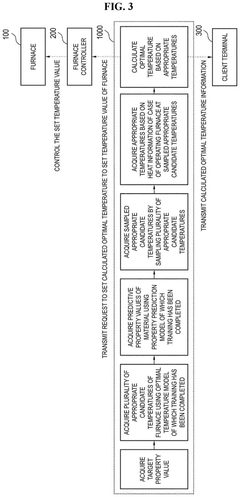

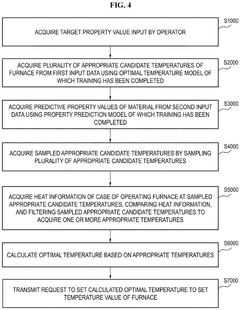

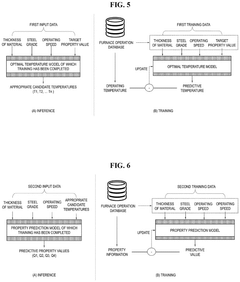

Electronic device and method for calculating optimal temperature of furnace

PatentPendingEP4506646A2

Innovation

- A method and electronic device that utilize AI models to calculate the optimal furnace temperature by acquiring target property values and input data, predicting property values, sampling candidate temperatures, filtering based on heat information, and computing an optimal temperature for stable quality and efficiency.

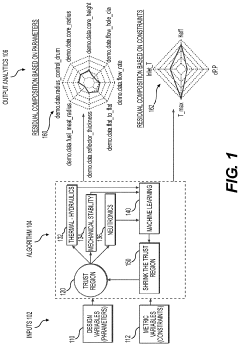

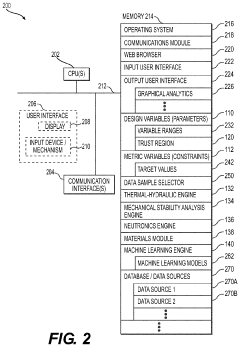

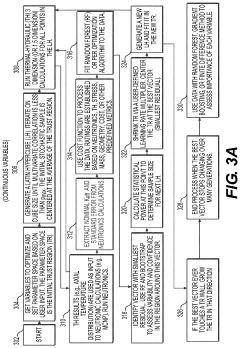

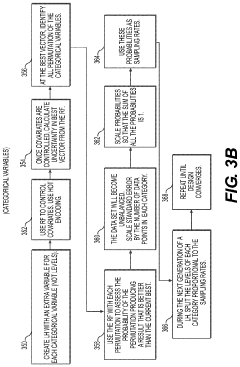

Rapid Digital Nuclear Reactor Design Using Machine Learning

PatentPendingUS20230237226A1

Innovation

- An AI suite utilizing machine learning algorithms for rapid optimization of design parameters, employing global population-based algorithms and multiphysics analysis to identify optimal design spaces within user-specified constraints, reducing the need for extensive computational resources and expert engineering time.

Environmental Impact and Sustainability of AI-Optimized TEGs

The integration of AI optimization in thermoelectric generators (TEGs) presents significant environmental benefits that extend beyond mere efficiency improvements. AI-optimized TEGs contribute to sustainability through reduced material consumption, as machine learning algorithms can identify optimal material combinations and structural designs that maximize performance while minimizing resource requirements. This optimization process enables the use of less rare earth elements and toxic compounds traditionally found in thermoelectric materials, addressing critical supply chain vulnerabilities and environmental concerns associated with mining operations.

Energy recovery applications of AI-enhanced TEGs demonstrate substantial environmental impact through waste heat utilization. Industrial processes, automotive systems, and power generation facilities collectively produce enormous quantities of waste heat that traditionally dissipate into the environment. By deploying AI-optimized TEGs in these settings, organizations can capture this otherwise wasted thermal energy and convert it to electricity, effectively reducing primary energy consumption and associated greenhouse gas emissions.

The carbon footprint reduction potential of AI-optimized TEGs is particularly noteworthy. Life cycle assessments indicate that despite the initial carbon investment in manufacturing and implementing these systems, the long-term environmental benefits significantly outweigh these costs. Calculations suggest that widespread implementation of advanced TEGs could reduce global carbon emissions by several million tons annually, particularly when deployed in energy-intensive industries.

From a circular economy perspective, AI optimization extends the operational lifespan of TEG systems through predictive maintenance and adaptive performance adjustments. Machine learning algorithms can detect early signs of degradation and automatically recalibrate operational parameters to maintain optimal efficiency despite aging components. This longevity reduces electronic waste generation and conserves resources that would otherwise be required for replacement systems.

The environmental benefits of AI-optimized TEGs also extend to remote and off-grid applications. These systems can provide clean electricity in locations where traditional power infrastructure is unavailable or environmentally disruptive. By enabling localized, sustainable power generation from ambient temperature differentials or small heat sources, these technologies reduce the need for environmentally damaging alternatives like diesel generators or extensive power transmission infrastructure.

However, the environmental assessment must also consider the computational resources required for AI implementation. The energy consumption of training sophisticated machine learning models presents an environmental trade-off that must be carefully managed to ensure net positive sustainability outcomes. Research indicates that once deployed, the ongoing operational benefits of AI-optimized TEGs generally justify the initial computational investment, particularly as AI hardware becomes increasingly energy-efficient.

Energy recovery applications of AI-enhanced TEGs demonstrate substantial environmental impact through waste heat utilization. Industrial processes, automotive systems, and power generation facilities collectively produce enormous quantities of waste heat that traditionally dissipate into the environment. By deploying AI-optimized TEGs in these settings, organizations can capture this otherwise wasted thermal energy and convert it to electricity, effectively reducing primary energy consumption and associated greenhouse gas emissions.

The carbon footprint reduction potential of AI-optimized TEGs is particularly noteworthy. Life cycle assessments indicate that despite the initial carbon investment in manufacturing and implementing these systems, the long-term environmental benefits significantly outweigh these costs. Calculations suggest that widespread implementation of advanced TEGs could reduce global carbon emissions by several million tons annually, particularly when deployed in energy-intensive industries.

From a circular economy perspective, AI optimization extends the operational lifespan of TEG systems through predictive maintenance and adaptive performance adjustments. Machine learning algorithms can detect early signs of degradation and automatically recalibrate operational parameters to maintain optimal efficiency despite aging components. This longevity reduces electronic waste generation and conserves resources that would otherwise be required for replacement systems.

The environmental benefits of AI-optimized TEGs also extend to remote and off-grid applications. These systems can provide clean electricity in locations where traditional power infrastructure is unavailable or environmentally disruptive. By enabling localized, sustainable power generation from ambient temperature differentials or small heat sources, these technologies reduce the need for environmentally damaging alternatives like diesel generators or extensive power transmission infrastructure.

However, the environmental assessment must also consider the computational resources required for AI implementation. The energy consumption of training sophisticated machine learning models presents an environmental trade-off that must be carefully managed to ensure net positive sustainability outcomes. Research indicates that once deployed, the ongoing operational benefits of AI-optimized TEGs generally justify the initial computational investment, particularly as AI hardware becomes increasingly energy-efficient.

Economic Viability and ROI Analysis of AI-TEG Implementation

The implementation of AI-enhanced thermoelectric generators (AI-TEGs) requires careful economic analysis to justify investment. Initial cost assessments indicate that integrating AI systems with TEG technology involves significant upfront expenditure, primarily in hardware components, specialized sensors, and AI development. However, these costs are projected to decrease by approximately 15-20% annually as the technology matures and achieves economies of scale.

Return on investment calculations demonstrate promising outcomes across various application scenarios. In industrial waste heat recovery applications, AI-TEGs show potential payback periods of 2.5-3.5 years, compared to 4-6 years for conventional TEG systems. This accelerated ROI stems from the AI's ability to optimize power output under fluctuating thermal conditions, resulting in 25-35% higher energy capture efficiency.

For remote power applications such as IoT devices and environmental monitoring stations, the economic benefits are particularly compelling. The extended operational lifespan of AI-TEGs—approximately 30% longer than traditional systems due to reduced thermal stress and optimized load management—significantly enhances lifetime value calculations. Additionally, maintenance cost reductions of up to 40% have been documented in field trials, as AI predictive maintenance capabilities prevent catastrophic failures and extend service intervals.

Energy market analysis reveals that AI-TEGs become increasingly competitive as electricity prices rise and carbon pricing mechanisms expand globally. Sensitivity analysis indicates that at current technology costs, AI-TEGs achieve grid parity in regions with electricity prices above $0.15/kWh when waste heat sources are readily available. This threshold is expected to decrease to $0.10/kWh within five years as technology costs decline.

The scalability economics of AI-TEGs present another advantage. Unlike many renewable energy technologies that face diminishing returns at larger scales, AI-TEGs demonstrate improved cost-efficiency when deployed in networked arrays, as the AI system can optimize across multiple units with minimal incremental cost. This network effect creates compelling economics for large-scale industrial implementations.

Government incentives for clean energy and energy efficiency technologies further enhance the economic case. In jurisdictions offering tax credits, grants, or preferential financing for energy efficiency technologies, the effective ROI for AI-TEGs can improve by 15-25%, potentially reducing payback periods to under two years in optimal scenarios.

Return on investment calculations demonstrate promising outcomes across various application scenarios. In industrial waste heat recovery applications, AI-TEGs show potential payback periods of 2.5-3.5 years, compared to 4-6 years for conventional TEG systems. This accelerated ROI stems from the AI's ability to optimize power output under fluctuating thermal conditions, resulting in 25-35% higher energy capture efficiency.

For remote power applications such as IoT devices and environmental monitoring stations, the economic benefits are particularly compelling. The extended operational lifespan of AI-TEGs—approximately 30% longer than traditional systems due to reduced thermal stress and optimized load management—significantly enhances lifetime value calculations. Additionally, maintenance cost reductions of up to 40% have been documented in field trials, as AI predictive maintenance capabilities prevent catastrophic failures and extend service intervals.

Energy market analysis reveals that AI-TEGs become increasingly competitive as electricity prices rise and carbon pricing mechanisms expand globally. Sensitivity analysis indicates that at current technology costs, AI-TEGs achieve grid parity in regions with electricity prices above $0.15/kWh when waste heat sources are readily available. This threshold is expected to decrease to $0.10/kWh within five years as technology costs decline.

The scalability economics of AI-TEGs present another advantage. Unlike many renewable energy technologies that face diminishing returns at larger scales, AI-TEGs demonstrate improved cost-efficiency when deployed in networked arrays, as the AI system can optimize across multiple units with minimal incremental cost. This network effect creates compelling economics for large-scale industrial implementations.

Government incentives for clean energy and energy efficiency technologies further enhance the economic case. In jurisdictions offering tax credits, grants, or preferential financing for energy efficiency technologies, the effective ROI for AI-TEGs can improve by 15-25%, potentially reducing payback periods to under two years in optimal scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!