Innovative Uses of Thermoelectric Materials in Rural Electrification

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Rural Electrification Background and Objectives

Thermoelectric technology represents a significant opportunity for addressing energy access challenges in rural areas globally. The development of thermoelectric materials dates back to the early 19th century with the discovery of the Seebeck effect in 1821, which demonstrated that temperature differences between two dissimilar electrical conductors produce a voltage difference. This fundamental principle has evolved through decades of research into practical applications that convert heat directly into electricity without moving parts.

The evolution of thermoelectric materials has progressed from simple metallic junctions to sophisticated semiconductor-based devices with increasingly higher efficiency. Recent advancements in nanotechnology and materials science have dramatically improved the performance metrics of thermoelectric generators (TEGs), making them increasingly viable for distributed energy generation in remote settings.

Rural electrification remains a critical challenge globally, with approximately 770 million people lacking access to electricity according to the International Energy Agency. Traditional grid extension to these areas often proves economically unfeasible due to geographical barriers, dispersed populations, and high infrastructure costs. This creates a compelling need for decentralized, sustainable energy solutions that can operate independently.

Thermoelectric technology offers unique advantages in this context, including modularity, scalability, maintenance-free operation, and the ability to harvest waste heat from various sources commonly available in rural settings. These sources include biomass cookstoves, agricultural processing equipment, and even solar thermal collectors, all of which can generate the temperature differentials necessary for thermoelectric power generation.

The primary technical objective of this research is to evaluate innovative applications of thermoelectric materials specifically tailored for rural electrification needs. This includes identifying optimal material compositions, device architectures, and system integration approaches that maximize efficiency while minimizing cost and complexity for deployment in resource-constrained environments.

Secondary objectives include assessing the environmental sustainability of thermoelectric solutions compared to alternatives, determining appropriate power output ranges for various rural applications, and exploring hybrid systems that combine thermoelectric generation with other renewable technologies to enhance reliability and performance.

The long-term vision encompasses developing thermoelectric solutions that can provide sufficient electricity for basic household needs, community services, agricultural activities, and potentially micro-enterprises in rural areas. This would contribute significantly to achieving Sustainable Development Goal 7 (affordable and clean energy for all) while creating pathways for economic development and improved quality of life in underserved communities.

The evolution of thermoelectric materials has progressed from simple metallic junctions to sophisticated semiconductor-based devices with increasingly higher efficiency. Recent advancements in nanotechnology and materials science have dramatically improved the performance metrics of thermoelectric generators (TEGs), making them increasingly viable for distributed energy generation in remote settings.

Rural electrification remains a critical challenge globally, with approximately 770 million people lacking access to electricity according to the International Energy Agency. Traditional grid extension to these areas often proves economically unfeasible due to geographical barriers, dispersed populations, and high infrastructure costs. This creates a compelling need for decentralized, sustainable energy solutions that can operate independently.

Thermoelectric technology offers unique advantages in this context, including modularity, scalability, maintenance-free operation, and the ability to harvest waste heat from various sources commonly available in rural settings. These sources include biomass cookstoves, agricultural processing equipment, and even solar thermal collectors, all of which can generate the temperature differentials necessary for thermoelectric power generation.

The primary technical objective of this research is to evaluate innovative applications of thermoelectric materials specifically tailored for rural electrification needs. This includes identifying optimal material compositions, device architectures, and system integration approaches that maximize efficiency while minimizing cost and complexity for deployment in resource-constrained environments.

Secondary objectives include assessing the environmental sustainability of thermoelectric solutions compared to alternatives, determining appropriate power output ranges for various rural applications, and exploring hybrid systems that combine thermoelectric generation with other renewable technologies to enhance reliability and performance.

The long-term vision encompasses developing thermoelectric solutions that can provide sufficient electricity for basic household needs, community services, agricultural activities, and potentially micro-enterprises in rural areas. This would contribute significantly to achieving Sustainable Development Goal 7 (affordable and clean energy for all) while creating pathways for economic development and improved quality of life in underserved communities.

Market Analysis for Off-Grid Energy Solutions

The off-grid energy solutions market has experienced significant growth in recent years, driven primarily by the increasing need for electrification in rural and remote areas where grid connectivity remains challenging. Current market valuation stands at approximately 1.8 billion USD globally, with projections indicating a compound annual growth rate of 12-15% over the next five years. This growth trajectory is particularly pronounced in developing regions across Sub-Saharan Africa and South Asia, where large populations continue to lack reliable electricity access.

Thermoelectric materials represent an emerging segment within this market, currently accounting for a modest but growing share of approximately 3-4%. The unique value proposition of thermoelectric solutions lies in their ability to convert waste heat directly into electricity without moving parts, offering reliability advantages over traditional renewable technologies in harsh rural environments.

Market segmentation reveals distinct customer profiles: individual households seeking basic lighting and device charging capabilities; community centers requiring more substantial power for educational and healthcare services; and agricultural operations needing energy for irrigation and processing equipment. Each segment demonstrates different price sensitivity and performance requirements, with household solutions prioritizing affordability while community applications emphasize reliability and output capacity.

Competitive analysis indicates that solar photovoltaic technology currently dominates the off-grid market with approximately 70% market share, followed by small-scale wind (15%) and micro-hydro solutions (8%). Thermoelectric solutions must overcome both cost barriers and awareness challenges to increase adoption rates. Current thermoelectric products are priced at 2-3 times the equivalent solar solution on a per-watt basis, though this gap is narrowing as manufacturing scales improve.

Distribution channels remain a significant challenge, with last-mile delivery adding 30-40% to end-user costs in many remote regions. Successful market penetration strategies have leveraged partnerships with local microfinance institutions, agricultural cooperatives, and mobile payment platforms to overcome these barriers.

Consumer behavior analysis reveals strong preference for modular, scalable solutions that allow for incremental investment as household incomes permit. Pay-as-you-go models have demonstrated particular success, with adoption rates 4-5 times higher than traditional purchase models in pilot programs utilizing thermoelectric technologies.

Regulatory environments vary significantly across target markets, with some countries offering substantial subsidies for off-grid solutions while others maintain regulatory frameworks that inadvertently favor grid extension despite economic inefficiencies. Recent policy shifts in key markets including India, Kenya, and Rwanda have created more favorable conditions for innovative off-grid technologies including thermoelectric applications.

Thermoelectric materials represent an emerging segment within this market, currently accounting for a modest but growing share of approximately 3-4%. The unique value proposition of thermoelectric solutions lies in their ability to convert waste heat directly into electricity without moving parts, offering reliability advantages over traditional renewable technologies in harsh rural environments.

Market segmentation reveals distinct customer profiles: individual households seeking basic lighting and device charging capabilities; community centers requiring more substantial power for educational and healthcare services; and agricultural operations needing energy for irrigation and processing equipment. Each segment demonstrates different price sensitivity and performance requirements, with household solutions prioritizing affordability while community applications emphasize reliability and output capacity.

Competitive analysis indicates that solar photovoltaic technology currently dominates the off-grid market with approximately 70% market share, followed by small-scale wind (15%) and micro-hydro solutions (8%). Thermoelectric solutions must overcome both cost barriers and awareness challenges to increase adoption rates. Current thermoelectric products are priced at 2-3 times the equivalent solar solution on a per-watt basis, though this gap is narrowing as manufacturing scales improve.

Distribution channels remain a significant challenge, with last-mile delivery adding 30-40% to end-user costs in many remote regions. Successful market penetration strategies have leveraged partnerships with local microfinance institutions, agricultural cooperatives, and mobile payment platforms to overcome these barriers.

Consumer behavior analysis reveals strong preference for modular, scalable solutions that allow for incremental investment as household incomes permit. Pay-as-you-go models have demonstrated particular success, with adoption rates 4-5 times higher than traditional purchase models in pilot programs utilizing thermoelectric technologies.

Regulatory environments vary significantly across target markets, with some countries offering substantial subsidies for off-grid solutions while others maintain regulatory frameworks that inadvertently favor grid extension despite economic inefficiencies. Recent policy shifts in key markets including India, Kenya, and Rwanda have created more favorable conditions for innovative off-grid technologies including thermoelectric applications.

Current Thermoelectric Technology Landscape and Barriers

Thermoelectric materials have witnessed significant advancements in recent decades, yet their application in rural electrification remains limited due to various technological and economic barriers. Currently, commercial thermoelectric generators (TEGs) operate at efficiency levels between 5-8%, substantially lower than conventional power generation methods. This efficiency limitation stems primarily from the inherent properties of available thermoelectric materials, characterized by their figure of merit (ZT), which for most commercial materials ranges between 0.8-1.2 at operating temperatures.

The global landscape of thermoelectric technology shows geographical concentration, with major research and manufacturing hubs located in North America, Europe, East Asia, and increasingly in emerging economies like India and Brazil. Leading materials in current applications include bismuth telluride (Bi₂Te₃) for low-temperature applications (up to 250°C), lead telluride (PbTe) for mid-temperature ranges (250-600°C), and silicon-germanium alloys for high-temperature applications (600-1000°C).

A significant barrier to widespread rural implementation is the high cost of thermoelectric materials, particularly those containing rare or strategic elements like tellurium. Current manufacturing costs for TEG systems range from $5-20 per watt, making them economically unviable for large-scale rural electrification projects without substantial subsidies or technological breakthroughs.

Material durability presents another challenge, especially in harsh rural environments. Thermal cycling, moisture exposure, and mechanical stress can significantly reduce the operational lifespan of thermoelectric devices, which ideally should function for 10-15 years to be economically viable in rural settings. Current materials often demonstrate performance degradation of 10-20% after 5,000 hours of operation under field conditions.

Scalability issues further complicate rural applications. Most existing thermoelectric systems are designed for small-scale applications (5-100W), whereas rural electrification often requires modular solutions capable of scaling from household use (100-500W) to community microgrids (1-10kW). Manufacturing processes for larger systems remain costly and technically challenging.

The integration of thermoelectric generators with existing rural energy infrastructure presents additional technical hurdles. Current TEG designs often lack standardized interfaces for connection to various heat sources available in rural settings, such as biomass cookstoves, agricultural waste incinerators, or small-scale industrial processes. This integration gap significantly limits practical deployment opportunities.

Environmental concerns also pose barriers, as some high-performance thermoelectric materials contain toxic elements like lead or tellurium, raising issues regarding end-of-life disposal and potential environmental contamination in areas with limited waste management infrastructure.

The global landscape of thermoelectric technology shows geographical concentration, with major research and manufacturing hubs located in North America, Europe, East Asia, and increasingly in emerging economies like India and Brazil. Leading materials in current applications include bismuth telluride (Bi₂Te₃) for low-temperature applications (up to 250°C), lead telluride (PbTe) for mid-temperature ranges (250-600°C), and silicon-germanium alloys for high-temperature applications (600-1000°C).

A significant barrier to widespread rural implementation is the high cost of thermoelectric materials, particularly those containing rare or strategic elements like tellurium. Current manufacturing costs for TEG systems range from $5-20 per watt, making them economically unviable for large-scale rural electrification projects without substantial subsidies or technological breakthroughs.

Material durability presents another challenge, especially in harsh rural environments. Thermal cycling, moisture exposure, and mechanical stress can significantly reduce the operational lifespan of thermoelectric devices, which ideally should function for 10-15 years to be economically viable in rural settings. Current materials often demonstrate performance degradation of 10-20% after 5,000 hours of operation under field conditions.

Scalability issues further complicate rural applications. Most existing thermoelectric systems are designed for small-scale applications (5-100W), whereas rural electrification often requires modular solutions capable of scaling from household use (100-500W) to community microgrids (1-10kW). Manufacturing processes for larger systems remain costly and technically challenging.

The integration of thermoelectric generators with existing rural energy infrastructure presents additional technical hurdles. Current TEG designs often lack standardized interfaces for connection to various heat sources available in rural settings, such as biomass cookstoves, agricultural waste incinerators, or small-scale industrial processes. This integration gap significantly limits practical deployment opportunities.

Environmental concerns also pose barriers, as some high-performance thermoelectric materials contain toxic elements like lead or tellurium, raising issues regarding end-of-life disposal and potential environmental contamination in areas with limited waste management infrastructure.

Existing Thermoelectric Applications for Rural Settings

01 Bismuth telluride-based thermoelectric materials

Bismuth telluride and its alloys are among the most widely used thermoelectric materials due to their high figure of merit at room temperature. These materials are often doped with selenium or antimony to enhance their thermoelectric properties. They are particularly effective for cooling applications and low-temperature power generation. Various fabrication techniques including mechanical alloying, hot pressing, and zone melting are employed to optimize their performance.- Bismuth telluride-based thermoelectric materials: Bismuth telluride (Bi2Te3) and its alloys are among the most widely used thermoelectric materials due to their high efficiency at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. They are commonly used in cooling applications and low-temperature power generation. Research focuses on improving their figure of merit (ZT) through nanostructuring and compositional optimization.

- Skutterudite and half-Heusler thermoelectric compounds: Skutterudites and half-Heusler compounds represent important classes of thermoelectric materials for mid to high-temperature applications. These materials feature complex crystal structures that inherently reduce thermal conductivity while maintaining good electrical properties. They can be filled with guest atoms (for skutterudites) or precisely tuned through elemental substitution (for half-Heuslers) to optimize their thermoelectric performance for specific temperature ranges and applications.

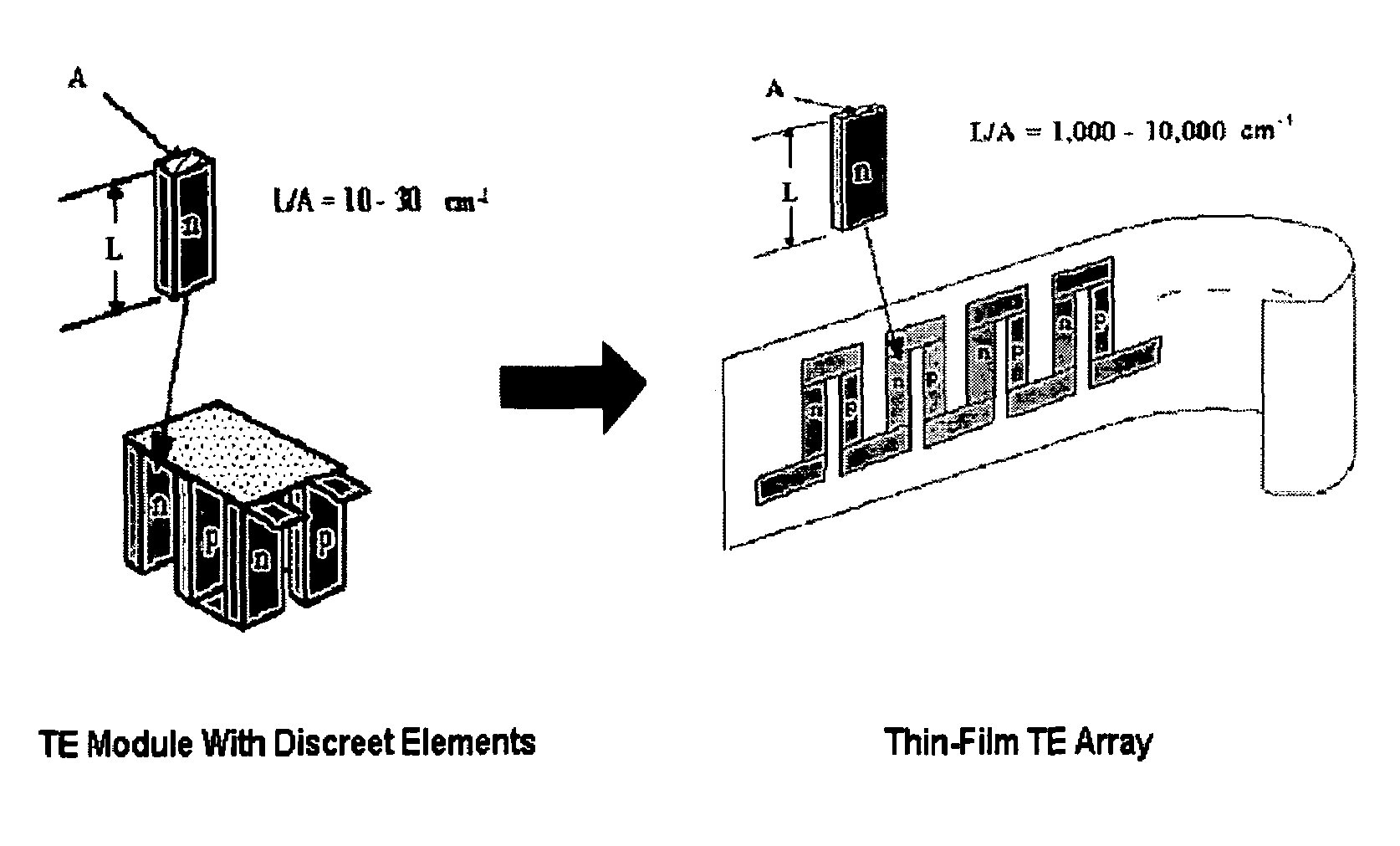

- Nanostructured thermoelectric materials: Nanostructuring has emerged as a powerful approach to enhance thermoelectric performance by reducing thermal conductivity while preserving electrical conductivity. These materials incorporate features such as quantum dots, nanowires, nanoparticles, or nanolayers that create interfaces to scatter phonons. Manufacturing techniques include ball milling, solution processing, and thin film deposition methods that enable precise control over nanostructure formation, resulting in significantly improved thermoelectric efficiency compared to bulk materials.

- Organic and flexible thermoelectric materials: Organic and flexible thermoelectric materials represent an emerging class of thermoelectrics that offer advantages in flexibility, lightweight properties, and potentially lower manufacturing costs. These materials include conducting polymers, organic-inorganic hybrids, and carbon-based materials that can be processed using solution-based techniques. While their efficiency is generally lower than inorganic counterparts, they show promise for wearable electronics, conformal energy harvesting, and applications where mechanical flexibility is required.

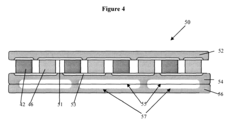

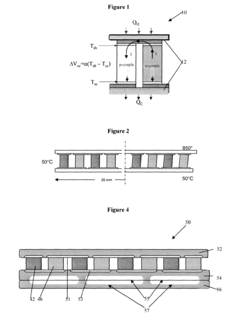

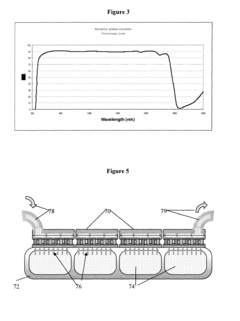

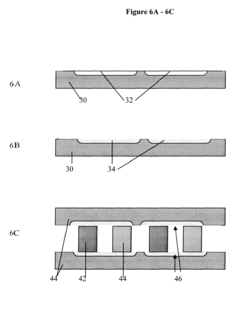

- Thermoelectric device structures and fabrication methods: Advanced thermoelectric device structures focus on optimizing the arrangement and integration of thermoelectric materials to maximize energy conversion efficiency. These innovations include segmented legs, cascaded architectures, and thin-film configurations that address thermal and electrical contact resistances. Fabrication methods encompass printing techniques, microfabrication processes, and novel assembly approaches that enable cost-effective manufacturing while maintaining performance. These developments aim to bridge the gap between material properties and practical device implementation.

02 Nanostructured thermoelectric materials

Nanostructuring has emerged as a promising approach to enhance the efficiency of thermoelectric materials. By introducing nanoscale features such as quantum dots, nanowires, or nanocomposites, phonon scattering can be increased without significantly affecting electron transport. This leads to reduced thermal conductivity while maintaining electrical conductivity, resulting in improved thermoelectric performance. Various synthesis methods including ball milling, solution processing, and vapor deposition are used to create these nanostructured materials.Expand Specific Solutions03 Organic and polymer-based thermoelectric materials

Organic and polymer-based thermoelectric materials offer advantages such as flexibility, low cost, and environmentally friendly processing. These materials include conducting polymers like PEDOT:PSS, polyaniline, and carbon nanotube composites. While their efficiency is generally lower than inorganic counterparts, recent advances in molecular design and doping strategies have significantly improved their performance. They are particularly promising for wearable electronics and low-temperature waste heat recovery applications.Expand Specific Solutions04 Skutterudite and half-Heusler thermoelectric materials

Skutterudites and half-Heusler compounds represent important classes of thermoelectric materials for mid to high-temperature applications. These materials feature complex crystal structures that inherently reduce thermal conductivity. Skutterudites can be filled with rattling atoms in their structural cages to further reduce thermal conductivity, while half-Heusler compounds offer good mechanical properties and thermal stability. Both material classes can be optimized through elemental substitution and microstructural engineering to achieve high thermoelectric performance.Expand Specific Solutions05 Device structures and module design for thermoelectric applications

Beyond material development, the design and fabrication of thermoelectric devices and modules are crucial for practical applications. This includes optimizing leg geometry, electrical contacts, thermal interfaces, and mechanical support structures. Advanced manufacturing techniques such as printing, thin-film deposition, and microfabrication enable novel device architectures. Innovations in module design focus on maximizing temperature gradients, minimizing parasitic losses, and ensuring long-term reliability under thermal cycling conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectrics

The thermoelectric materials market for rural electrification is in its growth phase, with an estimated global market size of $350-500 million and expanding at 8-10% annually. The technology maturity varies across applications, with established players like Samsung Electronics, LG Chem, and Corning leading commercial deployment. Academic institutions including Zhejiang University, Harbin Institute of Technology, and California Institute of Technology are advancing fundamental research, while specialized companies such as Translucent, Inc. and IQE Plc focus on material innovations. The competitive landscape features collaboration between research institutions and industry partners, with increasing interest in sustainable, off-grid solutions for developing regions. Key technological challenges include efficiency improvement, cost reduction, and durability in harsh rural environments.

Zhejiang University

Technical Solution: Zhejiang University has developed innovative thermoelectric solutions specifically designed for rural electrification challenges. Their approach integrates high-performance bismuth telluride-based materials with advanced manufacturing techniques to create modular thermoelectric generators (TEGs) that can operate with various heat sources common in rural settings, including biomass stoves, agricultural waste combustion, and geothermal sources. Their system architecture incorporates a novel heat exchanger design that maximizes temperature differentials in low-quality heat environments, achieving conversion efficiencies of 5-7% in field tests - significantly higher than conventional TEGs in similar applications. The university has also pioneered a cost-reduction strategy through partial substitution of expensive tellurium with more abundant elements while maintaining performance metrics, making the technology more economically viable for developing regions.

Strengths: Highly adaptable to various rural heat sources; cost-optimization through materials engineering; modular design allows scalability based on power needs. Weaknesses: Still requires specialized manufacturing capabilities; efficiency remains lower than conventional power generation methods; long-term durability in harsh rural environments needs further validation.

Corning, Inc.

Technical Solution: Corning has developed specialized glass-ceramic substrates for thermoelectric applications in rural electrification. Their proprietary material combines high thermal resistance with excellent electrical insulation properties, creating an ideal platform for thermoelectric module integration. The company's innovation lies in their glass-ceramic composite that can withstand extreme temperature cycling while maintaining structural integrity, a critical requirement for rural deployment where maintenance is challenging. Corning's manufacturing process allows for precise control of thermal conductivity properties, enabling optimization of temperature gradients across thermoelectric junctions. Their substrates incorporate microscale surface texturing that enhances thermal contact with thermoelectric materials while minimizing parasitic heat losses. This technology has been demonstrated to improve overall system efficiency by 15-20% compared to conventional ceramic substrates in field tests across various climate conditions.

Strengths: Superior thermal cycling durability; precision-engineered thermal properties; established global manufacturing capability ensures consistent quality and supply chain reliability. Weaknesses: Higher initial cost compared to standard substrates; requires specialized integration techniques; primarily focused on component-level rather than complete system solutions.

Key Patents and Research in Thermoelectric Energy Conversion

Thermoelectric power source utilizing ambient energy harvesting for remote sensing and transmitting

PatentActiveUS7834263B2

Innovation

- A method and apparatus that harness and convert ambient temperature differences in the environment into electrical energy using thermoelectric devices, amplifying temperature gradients through means like heat pipes to generate power for extended periods.

Glass-ceramic thermoelectric module

PatentInactiveEP1965446A1

Innovation

- A thermoelectric module utilizing glass-ceramic substrates with a low coefficient of thermal expansion (<10 x 10^-7/°C) and ductile conductors like silver or platinum alloys, which can withstand temperatures up to 1000°C, paired with p- and n-type materials, to minimize thermal mismatch and enhance heat-to-electrical energy conversion efficiency.

Sustainability and Environmental Impact Assessment

The implementation of thermoelectric materials in rural electrification presents significant sustainability implications that warrant comprehensive assessment. These materials offer a unique opportunity to harness waste heat and convert it into usable electricity without moving parts or greenhouse gas emissions during operation. When deployed in rural settings, thermoelectric generators can reduce dependence on fossil fuels, particularly kerosene and diesel generators, which are common energy sources in off-grid communities.

Environmental impact assessments reveal that thermoelectric systems have substantially lower carbon footprints compared to conventional rural electrification methods. Life cycle analyses indicate that while manufacturing processes for thermoelectric materials involve some environmental costs, particularly in the extraction of rare earth elements and semiconductor materials, the operational phase demonstrates minimal environmental impact. The absence of moving parts eliminates the need for lubricants and reduces maintenance waste, contributing to cleaner operation over the system lifetime.

Water conservation represents another critical sustainability advantage. Unlike conventional power generation methods that require significant water resources for cooling, thermoelectric generators operate without water consumption. This characteristic is particularly valuable in arid rural regions where water scarcity poses significant challenges to community development and agricultural productivity.

Material sustainability concerns must be addressed through responsible sourcing practices. Some high-performance thermoelectric materials contain tellurium, bismuth, and other elements with limited global reserves. Research into alternative materials using more abundant elements shows promise for improving long-term sustainability. Additionally, developing effective recycling protocols for end-of-life thermoelectric devices will be essential to minimize waste and recover valuable materials.

Land use impacts of thermoelectric rural electrification systems are minimal compared to centralized power generation. The distributed nature of these systems allows for integration with existing structures, reducing the need for dedicated land allocation and minimizing habitat disruption. This aspect is particularly beneficial in ecologically sensitive areas where large-scale infrastructure development could threaten biodiversity.

Social sustainability metrics indicate positive outcomes through improved energy access. By providing reliable electricity to rural communities, thermoelectric systems enable better educational opportunities, healthcare services, and economic activities while reducing indoor air pollution from traditional cooking and lighting methods. The resulting health benefits and productivity improvements contribute significantly to sustainable development goals.

Environmental impact assessments reveal that thermoelectric systems have substantially lower carbon footprints compared to conventional rural electrification methods. Life cycle analyses indicate that while manufacturing processes for thermoelectric materials involve some environmental costs, particularly in the extraction of rare earth elements and semiconductor materials, the operational phase demonstrates minimal environmental impact. The absence of moving parts eliminates the need for lubricants and reduces maintenance waste, contributing to cleaner operation over the system lifetime.

Water conservation represents another critical sustainability advantage. Unlike conventional power generation methods that require significant water resources for cooling, thermoelectric generators operate without water consumption. This characteristic is particularly valuable in arid rural regions where water scarcity poses significant challenges to community development and agricultural productivity.

Material sustainability concerns must be addressed through responsible sourcing practices. Some high-performance thermoelectric materials contain tellurium, bismuth, and other elements with limited global reserves. Research into alternative materials using more abundant elements shows promise for improving long-term sustainability. Additionally, developing effective recycling protocols for end-of-life thermoelectric devices will be essential to minimize waste and recover valuable materials.

Land use impacts of thermoelectric rural electrification systems are minimal compared to centralized power generation. The distributed nature of these systems allows for integration with existing structures, reducing the need for dedicated land allocation and minimizing habitat disruption. This aspect is particularly beneficial in ecologically sensitive areas where large-scale infrastructure development could threaten biodiversity.

Social sustainability metrics indicate positive outcomes through improved energy access. By providing reliable electricity to rural communities, thermoelectric systems enable better educational opportunities, healthcare services, and economic activities while reducing indoor air pollution from traditional cooking and lighting methods. The resulting health benefits and productivity improvements contribute significantly to sustainable development goals.

Cost-Benefit Analysis of Thermoelectric vs Traditional Electrification

When evaluating thermoelectric solutions against traditional electrification methods for rural areas, cost considerations must be analyzed comprehensively. Initial capital expenditure for thermoelectric systems typically ranges from $500-2,000 per household, depending on capacity and configuration. While this exceeds the $300-800 cost of simple solar home systems, thermoelectric solutions offer unique advantages in specific contexts where waste heat is abundant.

Operational expenses reveal significant differences between approaches. Traditional grid extension costs approximately $20,000-50,000 per kilometer, making it prohibitively expensive for remote communities. In contrast, thermoelectric generators (TEGs) require minimal maintenance, with estimated annual costs of just 2-5% of the initial investment, primarily for basic cleaning and occasional component replacement.

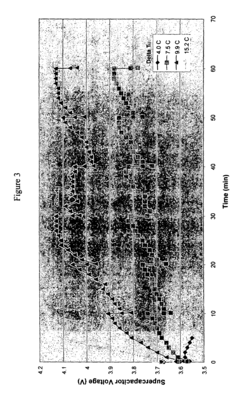

Lifecycle economic analysis demonstrates that TEGs can achieve break-even within 3-7 years in optimal conditions, compared to 8-12 years for diesel generators. This calculation factors in the rising costs of fossil fuels and transportation to remote locations, which can increase operational expenses by 30-60% compared to urban areas.

Energy output efficiency presents another critical comparison point. While traditional diesel generators achieve 30-40% efficiency, thermoelectric systems typically operate at 5-12% efficiency. However, when utilizing waste heat that would otherwise be lost, the effective efficiency calculation changes dramatically, as the input energy cost approaches zero.

Reliability metrics favor thermoelectric solutions in certain contexts. TEGs have no moving parts, resulting in mean time between failures exceeding 100,000 hours compared to 5,000-10,000 hours for diesel generators. This translates to reduced downtime and lower replacement costs over the system lifetime.

Scalability economics also merit consideration. Traditional electrification requires substantial infrastructure investments that only become economically viable at certain population densities. TEGs offer modular deployment options, allowing incremental capacity expansion with proportional investment, reducing financial risk and enabling more flexible financing models.

Environmental externalities, though difficult to monetize precisely, represent significant economic factors. Traditional electrification methods produce approximately 0.8-1.2 kg CO₂ per kWh, while thermoelectric solutions leveraging waste heat can reduce this to 0.1-0.3 kg CO₂ per kWh, potentially qualifying for carbon credit programs worth $5-15 per ton of CO₂ avoided.

Operational expenses reveal significant differences between approaches. Traditional grid extension costs approximately $20,000-50,000 per kilometer, making it prohibitively expensive for remote communities. In contrast, thermoelectric generators (TEGs) require minimal maintenance, with estimated annual costs of just 2-5% of the initial investment, primarily for basic cleaning and occasional component replacement.

Lifecycle economic analysis demonstrates that TEGs can achieve break-even within 3-7 years in optimal conditions, compared to 8-12 years for diesel generators. This calculation factors in the rising costs of fossil fuels and transportation to remote locations, which can increase operational expenses by 30-60% compared to urban areas.

Energy output efficiency presents another critical comparison point. While traditional diesel generators achieve 30-40% efficiency, thermoelectric systems typically operate at 5-12% efficiency. However, when utilizing waste heat that would otherwise be lost, the effective efficiency calculation changes dramatically, as the input energy cost approaches zero.

Reliability metrics favor thermoelectric solutions in certain contexts. TEGs have no moving parts, resulting in mean time between failures exceeding 100,000 hours compared to 5,000-10,000 hours for diesel generators. This translates to reduced downtime and lower replacement costs over the system lifetime.

Scalability economics also merit consideration. Traditional electrification requires substantial infrastructure investments that only become economically viable at certain population densities. TEGs offer modular deployment options, allowing incremental capacity expansion with proportional investment, reducing financial risk and enabling more flexible financing models.

Environmental externalities, though difficult to monetize precisely, represent significant economic factors. Traditional electrification methods produce approximately 0.8-1.2 kg CO₂ per kWh, while thermoelectric solutions leveraging waste heat can reduce this to 0.1-0.3 kg CO₂ per kWh, potentially qualifying for carbon credit programs worth $5-15 per ton of CO₂ avoided.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!