Selecting Thermoelectric Elements for Improved Energy Harvesting

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Energy Harvesting Background and Objectives

Thermoelectric energy harvesting represents a significant frontier in sustainable energy technologies, with roots dating back to the early 19th century when Thomas Johann Seebeck first discovered the thermoelectric effect in 1821. This phenomenon, where temperature differences are directly converted into electrical voltage, has evolved from a scientific curiosity into a practical energy solution over the past two centuries. The field has experienced accelerated development since the 1950s with the introduction of semiconductor-based thermoelectric materials, followed by significant breakthroughs in the 1990s with the advent of nanostructured thermoelectric materials.

The evolution of thermoelectric technology has been characterized by continuous improvements in conversion efficiency, primarily measured by the dimensionless figure of merit ZT. Historical values of ZT remained below 1 for many decades, but recent advancements in material science and nanotechnology have pushed this value beyond 2 for certain materials under specific conditions, signaling a new era of potential applications.

Current technological trajectories indicate a shift from traditional bulk thermoelectric materials toward more sophisticated nanostructured and quantum-engineered materials. These advanced materials exploit quantum confinement effects and phonon scattering mechanisms to enhance the power factor while reducing thermal conductivity, thereby improving overall conversion efficiency.

The primary objective of thermoelectric element selection research is to identify and develop materials with optimized thermoelectric properties for specific temperature ranges and application scenarios. This includes maximizing the Seebeck coefficient and electrical conductivity while minimizing thermal conductivity—a challenging triad of properties often referred to as the "thermoelectric paradox."

Secondary objectives include enhancing mechanical stability for long-term operation, reducing manufacturing costs to improve commercial viability, and minimizing environmental impact through the use of earth-abundant, non-toxic materials. The development of flexible thermoelectric generators represents another important goal, particularly for wearable technology applications.

From a broader perspective, thermoelectric energy harvesting aims to capture and convert waste heat from industrial processes, automotive exhaust systems, and even body heat into usable electricity. This technology holds particular promise for powering distributed sensor networks, Internet of Things (IoT) devices, and remote monitoring systems where conventional power sources are impractical.

The ultimate technological goal is to achieve self-powered electronic systems that can operate indefinitely by harvesting ambient thermal energy, thereby eliminating the need for battery replacement and reducing electronic waste. This aligns with global sustainability objectives and the growing demand for energy-autonomous systems in an increasingly connected world.

The evolution of thermoelectric technology has been characterized by continuous improvements in conversion efficiency, primarily measured by the dimensionless figure of merit ZT. Historical values of ZT remained below 1 for many decades, but recent advancements in material science and nanotechnology have pushed this value beyond 2 for certain materials under specific conditions, signaling a new era of potential applications.

Current technological trajectories indicate a shift from traditional bulk thermoelectric materials toward more sophisticated nanostructured and quantum-engineered materials. These advanced materials exploit quantum confinement effects and phonon scattering mechanisms to enhance the power factor while reducing thermal conductivity, thereby improving overall conversion efficiency.

The primary objective of thermoelectric element selection research is to identify and develop materials with optimized thermoelectric properties for specific temperature ranges and application scenarios. This includes maximizing the Seebeck coefficient and electrical conductivity while minimizing thermal conductivity—a challenging triad of properties often referred to as the "thermoelectric paradox."

Secondary objectives include enhancing mechanical stability for long-term operation, reducing manufacturing costs to improve commercial viability, and minimizing environmental impact through the use of earth-abundant, non-toxic materials. The development of flexible thermoelectric generators represents another important goal, particularly for wearable technology applications.

From a broader perspective, thermoelectric energy harvesting aims to capture and convert waste heat from industrial processes, automotive exhaust systems, and even body heat into usable electricity. This technology holds particular promise for powering distributed sensor networks, Internet of Things (IoT) devices, and remote monitoring systems where conventional power sources are impractical.

The ultimate technological goal is to achieve self-powered electronic systems that can operate indefinitely by harvesting ambient thermal energy, thereby eliminating the need for battery replacement and reducing electronic waste. This aligns with global sustainability objectives and the growing demand for energy-autonomous systems in an increasingly connected world.

Market Analysis for Thermoelectric Energy Harvesting Applications

The global market for thermoelectric energy harvesting applications has been experiencing significant growth, driven by increasing demand for sustainable energy solutions and the proliferation of IoT devices. The market was valued at approximately $460 million in 2022 and is projected to reach $750 million by 2027, representing a compound annual growth rate of 10.3%. This growth trajectory is supported by advancements in thermoelectric materials and manufacturing techniques that have improved conversion efficiencies and reduced production costs.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the market share. The integration of thermoelectric generators (TEGs) in wearable devices, smartphones, and other portable electronics has gained traction due to the ability to extend battery life by harvesting waste heat. The automotive sector follows closely, with applications in vehicle waste heat recovery systems showing promising growth potential as automotive manufacturers seek to improve fuel efficiency and reduce emissions.

Industrial applications constitute another significant market segment, where thermoelectric generators are increasingly deployed to harvest waste heat from manufacturing processes, power plants, and industrial equipment. This segment is expected to witness the highest growth rate over the forecast period, driven by stringent environmental regulations and corporate sustainability initiatives.

Geographically, North America leads the market with approximately 40% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to register the highest growth rate due to rapid industrialization, increasing adoption of IoT technologies, and supportive government policies promoting clean energy solutions.

The market landscape is characterized by both established players and innovative startups. Key market participants include Gentherm Inc., Laird Thermal Systems, Ferrotec Corporation, and Kelk Ltd., who collectively hold about 45% of the market share. These companies are investing heavily in R&D to develop more efficient thermoelectric materials and innovative product designs.

Customer demand is increasingly shifting toward miniaturized, flexible, and high-efficiency thermoelectric solutions that can be easily integrated into various applications. The price sensitivity varies across application segments, with consumer electronics being highly price-sensitive, while industrial and automotive applications prioritize performance and reliability over cost.

Emerging market opportunities include the integration of thermoelectric energy harvesting in smart buildings, medical devices, and remote sensing applications. The growing trend toward energy-autonomous sensors and edge computing devices presents a particularly promising market segment for thermoelectric energy harvesting technologies.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the market share. The integration of thermoelectric generators (TEGs) in wearable devices, smartphones, and other portable electronics has gained traction due to the ability to extend battery life by harvesting waste heat. The automotive sector follows closely, with applications in vehicle waste heat recovery systems showing promising growth potential as automotive manufacturers seek to improve fuel efficiency and reduce emissions.

Industrial applications constitute another significant market segment, where thermoelectric generators are increasingly deployed to harvest waste heat from manufacturing processes, power plants, and industrial equipment. This segment is expected to witness the highest growth rate over the forecast period, driven by stringent environmental regulations and corporate sustainability initiatives.

Geographically, North America leads the market with approximately 40% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to register the highest growth rate due to rapid industrialization, increasing adoption of IoT technologies, and supportive government policies promoting clean energy solutions.

The market landscape is characterized by both established players and innovative startups. Key market participants include Gentherm Inc., Laird Thermal Systems, Ferrotec Corporation, and Kelk Ltd., who collectively hold about 45% of the market share. These companies are investing heavily in R&D to develop more efficient thermoelectric materials and innovative product designs.

Customer demand is increasingly shifting toward miniaturized, flexible, and high-efficiency thermoelectric solutions that can be easily integrated into various applications. The price sensitivity varies across application segments, with consumer electronics being highly price-sensitive, while industrial and automotive applications prioritize performance and reliability over cost.

Emerging market opportunities include the integration of thermoelectric energy harvesting in smart buildings, medical devices, and remote sensing applications. The growing trend toward energy-autonomous sensors and edge computing devices presents a particularly promising market segment for thermoelectric energy harvesting technologies.

Current Thermoelectric Materials and Technical Challenges

Thermoelectric materials currently employed in energy harvesting applications primarily include bismuth telluride (Bi2Te3), lead telluride (PbTe), silicon-germanium alloys (SiGe), and various skutterudites. Bi2Te3-based materials dominate the commercial market due to their relatively high figure of merit (ZT) values around 1 at room temperature, making them suitable for near-ambient temperature applications. PbTe compounds demonstrate better performance at intermediate temperatures (400-700K), while SiGe alloys excel in high-temperature environments (>700K).

Despite decades of research, thermoelectric materials face significant technical challenges that limit their widespread adoption. The primary limitation remains their low conversion efficiency, typically below 10% in practical applications. This inefficiency stems from the fundamental interdependence of key material properties: electrical conductivity, thermal conductivity, and Seebeck coefficient. Enhancing one parameter often adversely affects others, creating an optimization paradox that has proven difficult to overcome.

Material cost and availability present additional barriers, particularly for tellurium-based compounds, as tellurium is among the rarest elements in the earth's crust. Environmental concerns also arise with lead-containing thermoelectrics, prompting research into lead-free alternatives. Manufacturing challenges include difficulties in producing consistent, high-quality materials at scale and creating reliable electrical and thermal contacts that can withstand thermal cycling without degradation.

Recent advancements in nanostructured thermoelectric materials have shown promise in decoupling the interdependent properties through quantum confinement effects and phonon scattering at interfaces. Materials such as quantum dot superlattices, nanowires, and nanocomposites have demonstrated improved ZT values exceeding 2 in laboratory settings. However, translating these laboratory successes to commercially viable manufacturing processes remains challenging.

Organic and flexible thermoelectric materials represent another emerging frontier, offering potential for low-cost, large-area applications despite their currently lower efficiency. Polymer-based thermoelectrics and organic-inorganic hybrids are being explored for wearable energy harvesting applications where mechanical flexibility is crucial.

The geographical distribution of thermoelectric technology development shows concentration in East Asia (particularly Japan, China, and South Korea), North America, and Europe. China leads in manufacturing capacity, while the United States and Europe focus more on fundamental research and specialized applications. This distribution reflects both resource availability and strategic national interests in energy technology.

Addressing these technical challenges requires interdisciplinary approaches combining materials science, solid-state physics, chemistry, and engineering. Computational materials design and high-throughput screening methodologies are increasingly employed to accelerate the discovery of new thermoelectric compounds with improved properties, potentially offering pathways to overcome the current limitations.

Despite decades of research, thermoelectric materials face significant technical challenges that limit their widespread adoption. The primary limitation remains their low conversion efficiency, typically below 10% in practical applications. This inefficiency stems from the fundamental interdependence of key material properties: electrical conductivity, thermal conductivity, and Seebeck coefficient. Enhancing one parameter often adversely affects others, creating an optimization paradox that has proven difficult to overcome.

Material cost and availability present additional barriers, particularly for tellurium-based compounds, as tellurium is among the rarest elements in the earth's crust. Environmental concerns also arise with lead-containing thermoelectrics, prompting research into lead-free alternatives. Manufacturing challenges include difficulties in producing consistent, high-quality materials at scale and creating reliable electrical and thermal contacts that can withstand thermal cycling without degradation.

Recent advancements in nanostructured thermoelectric materials have shown promise in decoupling the interdependent properties through quantum confinement effects and phonon scattering at interfaces. Materials such as quantum dot superlattices, nanowires, and nanocomposites have demonstrated improved ZT values exceeding 2 in laboratory settings. However, translating these laboratory successes to commercially viable manufacturing processes remains challenging.

Organic and flexible thermoelectric materials represent another emerging frontier, offering potential for low-cost, large-area applications despite their currently lower efficiency. Polymer-based thermoelectrics and organic-inorganic hybrids are being explored for wearable energy harvesting applications where mechanical flexibility is crucial.

The geographical distribution of thermoelectric technology development shows concentration in East Asia (particularly Japan, China, and South Korea), North America, and Europe. China leads in manufacturing capacity, while the United States and Europe focus more on fundamental research and specialized applications. This distribution reflects both resource availability and strategic national interests in energy technology.

Addressing these technical challenges requires interdisciplinary approaches combining materials science, solid-state physics, chemistry, and engineering. Computational materials design and high-throughput screening methodologies are increasingly employed to accelerate the discovery of new thermoelectric compounds with improved properties, potentially offering pathways to overcome the current limitations.

State-of-the-Art Thermoelectric Element Selection Methodologies

01 Thermoelectric material compositions for energy harvesting

Various material compositions can enhance the efficiency of thermoelectric energy harvesting. These include specialized semiconductor materials, nanostructured composites, and doped materials that improve the Seebeck coefficient while reducing thermal conductivity. These advanced materials enable better conversion of temperature differentials into usable electrical energy, making them suitable for various energy harvesting applications.- Thermoelectric material compositions for energy harvesting: Various material compositions can be used in thermoelectric elements to improve energy harvesting efficiency. These materials typically have high Seebeck coefficients and low thermal conductivity to maximize the conversion of thermal energy to electrical energy. Advanced semiconductor materials, doped compounds, and nanostructured materials are being developed to enhance the figure of merit (ZT) of thermoelectric generators, allowing for more efficient energy harvesting from temperature differentials.

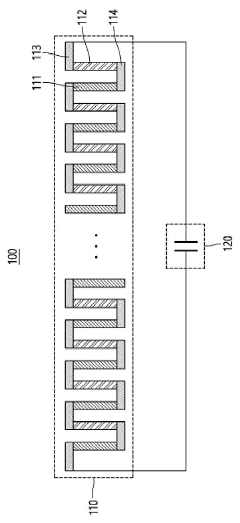

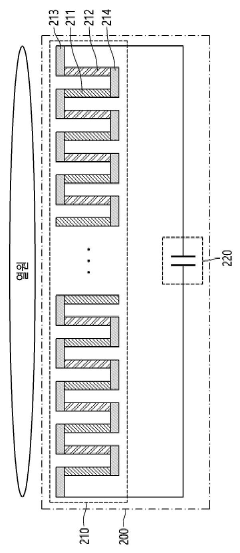

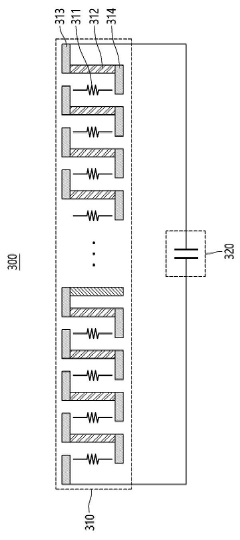

- Structural designs of thermoelectric generators: The physical configuration and arrangement of thermoelectric elements significantly impact energy harvesting performance. Innovative designs include flexible thermoelectric generators, multi-stage configurations, and miniaturized arrays that can be adapted to various heat sources. These structural innovations focus on maximizing the temperature gradient across the thermoelectric elements while minimizing thermal losses, thereby improving overall energy conversion efficiency.

- Integration with energy storage and power management systems: Thermoelectric energy harvesting systems often incorporate power management circuits and energy storage components to handle the typically low and variable output power. These integrated systems include voltage regulators, DC-DC converters, and energy storage devices such as supercapacitors or batteries. The integration enables efficient collection, conversion, and storage of harvested energy for powering electronic devices, particularly in applications where conventional power sources are impractical.

- Wearable and portable thermoelectric energy harvesters: Thermoelectric elements are being incorporated into wearable and portable devices to harvest energy from body heat or environmental temperature differences. These applications include smart textiles, wearable health monitors, and portable electronics that can generate power from the temperature difference between the human body and ambient air. The designs focus on flexibility, comfort, and maximizing the temperature gradient while maintaining user comfort.

- Industrial and automotive waste heat recovery systems: Large-scale thermoelectric systems are being developed to harvest energy from waste heat in industrial processes and automotive applications. These systems capture heat that would otherwise be lost from exhaust gases, cooling systems, or industrial processes, converting it into usable electrical energy. The designs focus on durability under harsh conditions, scalability, and integration with existing infrastructure to improve overall energy efficiency of industrial and transportation systems.

02 Wearable thermoelectric energy harvesting devices

Thermoelectric elements can be integrated into wearable devices to harvest body heat and convert it into electrical energy. These flexible and conformable systems can power small electronic devices such as health monitors, smart textiles, and IoT sensors. The designs focus on maximizing the temperature gradient between body heat and ambient temperature while maintaining user comfort and flexibility.Expand Specific Solutions03 Structural design of thermoelectric generators

Innovative structural designs of thermoelectric generators can significantly improve energy harvesting efficiency. These designs include multi-stage configurations, cascaded systems, and optimized heat exchanger geometries that maximize temperature differentials. Advanced manufacturing techniques like 3D printing allow for complex geometries that enhance thermal management and electrical connectivity between thermoelectric elements.Expand Specific Solutions04 Waste heat recovery systems using thermoelectric elements

Thermoelectric elements can be deployed in industrial settings to recover waste heat from processes and convert it into useful electrical energy. These systems can be integrated with exhaust systems, cooling towers, or other heat-generating industrial equipment. The recovered energy can be used to power sensors, control systems, or fed back into the grid, improving overall energy efficiency of industrial operations.Expand Specific Solutions05 Power management circuits for thermoelectric energy harvesting

Specialized power management circuits are essential for efficiently utilizing the energy generated by thermoelectric elements. These circuits include DC-DC converters, maximum power point tracking systems, and energy storage solutions that can handle the typically low and variable voltage outputs from thermoelectric generators. Advanced circuit designs can operate with ultra-low voltage inputs and provide stable power output for various applications.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Industry

The thermoelectric energy harvesting market is currently in a growth phase, with increasing adoption across automotive, industrial, and consumer electronics sectors. The global market size is projected to reach approximately $750 million by 2025, growing at a CAGR of 8-10%. Technologically, the field is advancing from early commercial maturity toward optimization and integration phases. Leading players include established electronics manufacturers like Toshiba Corp., Analog Devices, and Texas Instruments who focus on commercial applications, while research institutions such as MIT, Shanghai Institute of Ceramics, and Lawrence Livermore National Laboratory drive fundamental materials innovation. Automotive companies (GM, Ford, Boeing) are increasingly investing in thermoelectric solutions for waste heat recovery, while specialized materials firms like Corning and Toshiba Materials are developing advanced thermoelectric elements with improved efficiency coefficients.

Toshiba Corp.

Technical Solution: Toshiba has developed advanced thermoelectric materials based on skutterudite compounds that demonstrate high ZT values (figure of merit) exceeding 1.5 at operating temperatures. Their technology focuses on optimizing the microstructure of thermoelectric elements through nano-inclusions and grain boundary engineering to reduce thermal conductivity while maintaining electrical conductivity. Toshiba's approach includes the development of segmented thermoelectric modules that utilize different materials optimized for specific temperature ranges, allowing for efficient energy harvesting across broader temperature gradients. Their proprietary manufacturing process enables mass production of high-performance modules with improved mechanical stability and thermal cycling resistance, critical for industrial waste heat recovery applications.

Strengths: Superior ZT values in mid-to-high temperature ranges; excellent manufacturing scalability; robust module design for industrial environments. Weaknesses: Higher cost compared to conventional materials; limited performance in low-temperature applications; requires precise temperature control for optimal efficiency.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered breakthrough research in nanostructured thermoelectric materials, focusing on quantum dot superlattices and two-dimensional materials that demonstrate significantly enhanced Seebeck coefficients while maintaining low thermal conductivity. Their innovative approach involves engineering phonon scattering mechanisms at multiple length scales to create "phonon-glass electron-crystal" structures. MIT researchers have developed novel thin-film thermoelectric materials with enhanced power factors through energy filtering techniques and band engineering. Their recent work includes flexible thermoelectric generators utilizing organic-inorganic hybrid materials that can conform to irregular heat sources, enabling energy harvesting from low-grade waste heat (< 100°C) with unprecedented efficiency. Additionally, MIT has developed computational models for optimizing thermoelectric element geometry and electrical contact resistance to maximize power output under variable temperature conditions.

Strengths: Cutting-edge fundamental research in quantum-engineered materials; innovative approaches to low-temperature energy harvesting; interdisciplinary expertise combining materials science, physics, and electrical engineering. Weaknesses: Many technologies remain at laboratory scale; commercialization pathways require significant investment; some advanced materials involve rare or expensive elements.

Key Patents and Innovations in Thermoelectric Materials

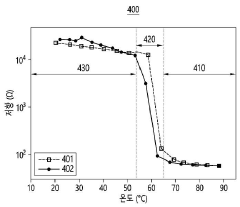

Energy harvesting system using thermoelectric device including phase change material

PatentPendingKR1020230062082A

Innovation

- An energy harvesting system utilizing a thermoelectric element with phase change material channels that operate as thermoelectric channels when a heat source is present and as resistance channels when absent, effectively blocking reverse current without additional components like diodes.

Energy harvesting using a thermoelectric material

PatentInactiveUS20050205125A1

Innovation

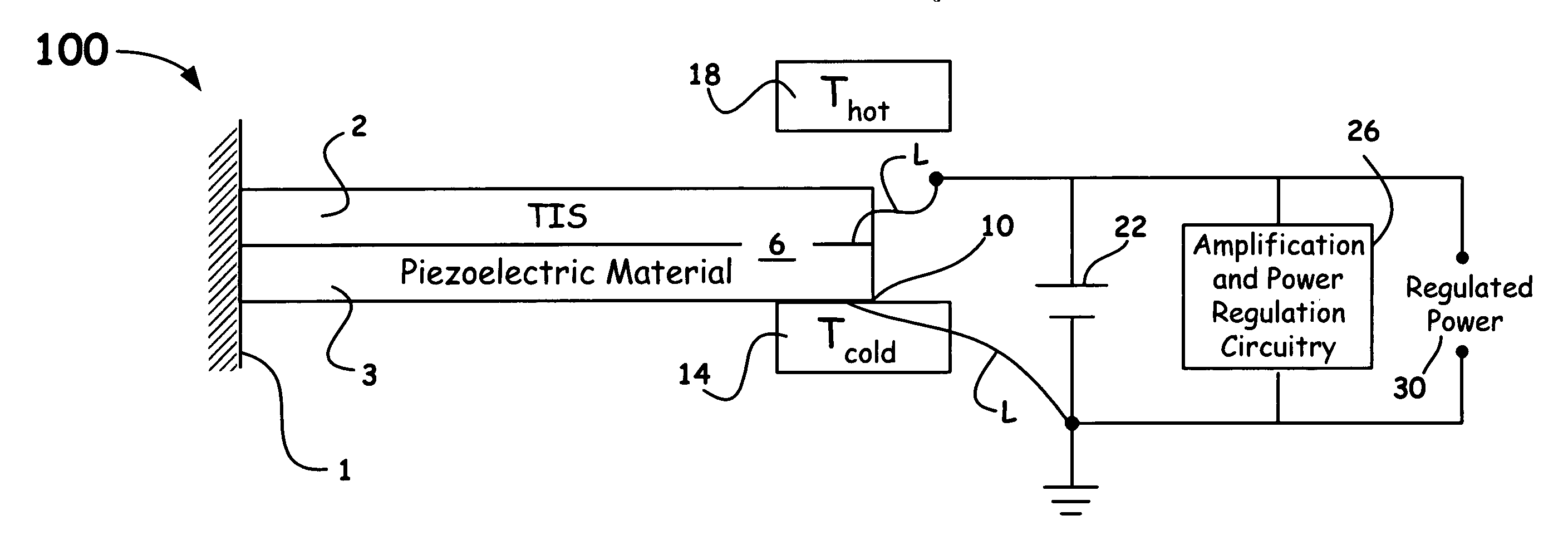

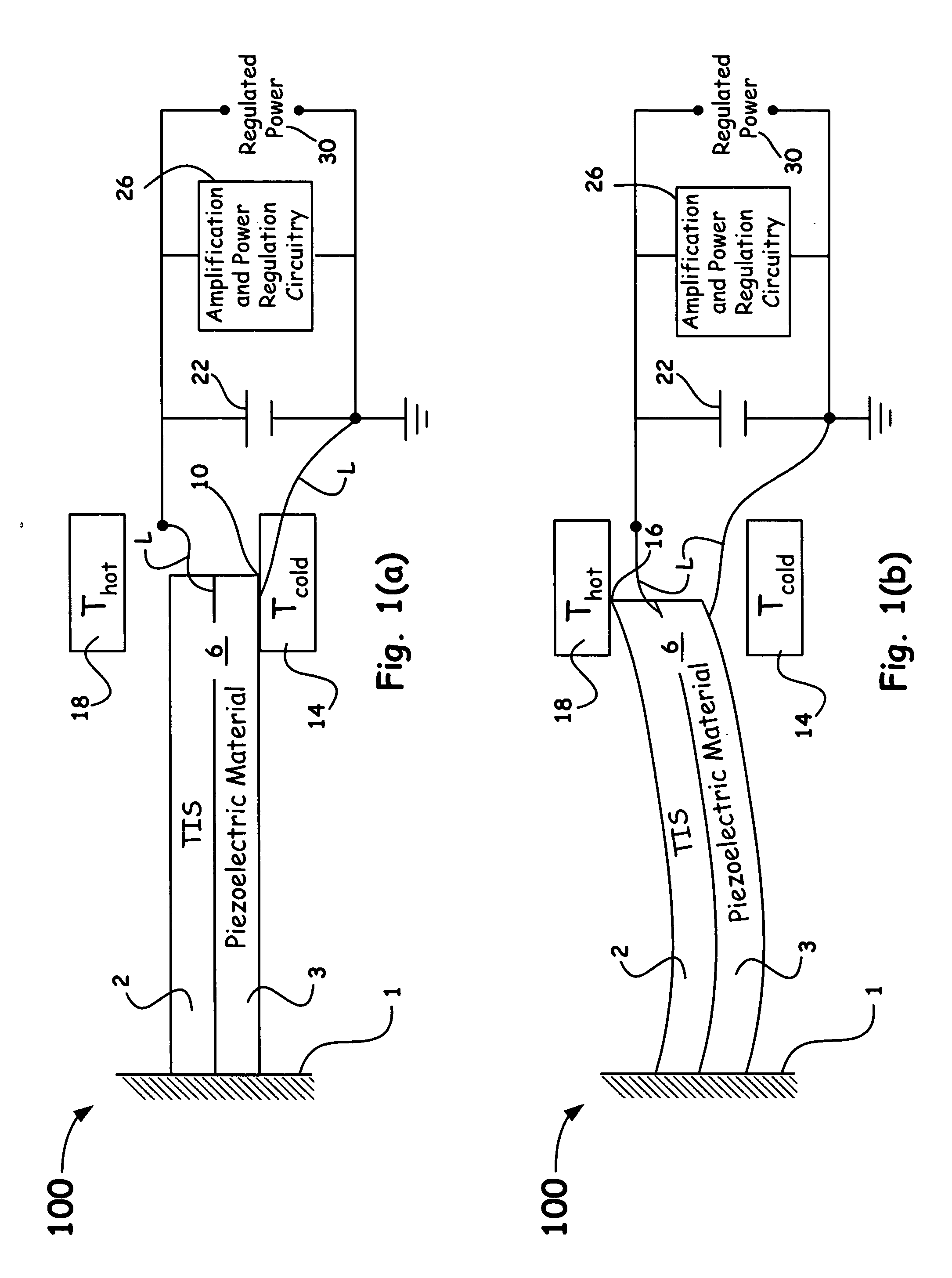

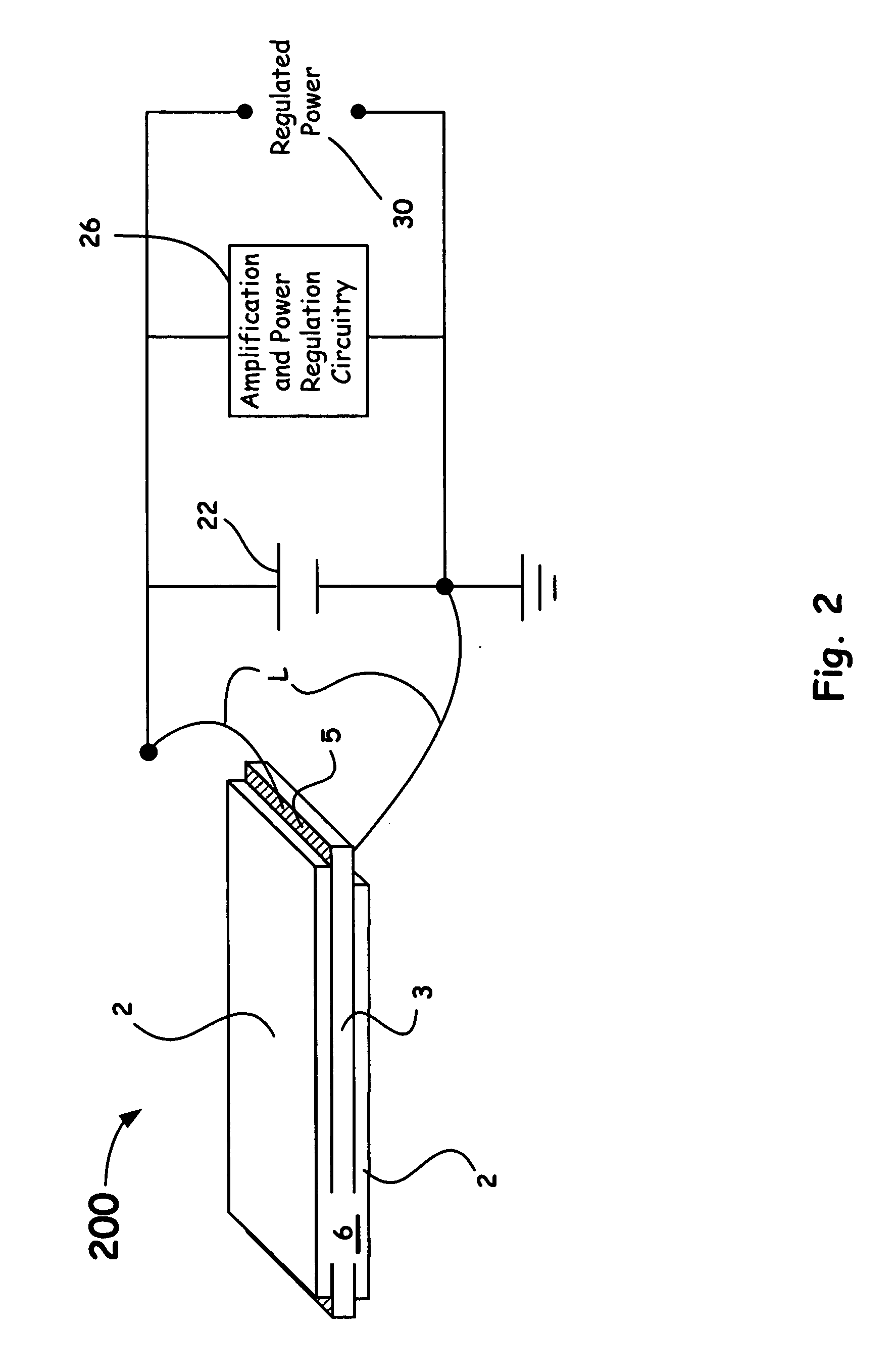

- An energy harvesting system utilizing a thermoelectric material with large thermally induced strain (TIS) and a piezoelectric material to generate a stress-induced electric field, allowing for the conversion of waste heat into electrical energy through a phase transformation-induced strain and voltage production.

Environmental Impact and Sustainability of Thermoelectric Materials

The environmental impact of thermoelectric materials represents a critical consideration in the advancement of energy harvesting technologies. Traditional thermoelectric materials often contain toxic or rare elements such as tellurium, bismuth, and lead, raising significant environmental concerns regarding their extraction, processing, and disposal. The mining operations required to obtain these elements frequently result in habitat destruction, soil contamination, and water pollution, while manufacturing processes may generate hazardous waste and consume substantial energy.

Recent research has focused on developing more sustainable alternatives, including organic thermoelectric materials and abundant element-based compounds. These materials, such as silicides, oxides, and conductive polymers, offer reduced environmental footprints while maintaining acceptable performance characteristics. Silicon-germanium alloys and magnesium silicide, for instance, utilize more abundant elements and demonstrate promising thermoelectric properties for specific temperature ranges.

Life cycle assessment (LCA) studies of thermoelectric systems reveal that despite initial environmental costs in production, the net environmental benefit can be positive when these systems effectively harvest waste heat that would otherwise be lost. The energy payback period—the time required for a thermoelectric system to generate the energy equivalent to that consumed during its production—varies significantly based on material selection and application context, typically ranging from 1-5 years for optimized systems.

The recyclability of thermoelectric materials presents both challenges and opportunities. While traditional bismuth telluride compounds pose recycling difficulties due to their complex composition, newer materials are being designed with end-of-life considerations. Recovery processes for valuable elements from decommissioned thermoelectric devices are advancing, though industrial-scale implementation remains limited.

From a sustainability perspective, thermoelectric energy harvesting contributes to circular economy principles by converting waste heat—an otherwise discarded resource—into useful electricity. This capability is particularly valuable in industrial settings where substantial thermal energy is routinely lost. The carbon footprint reduction potential of thermoelectric systems depends heavily on the specific application and the carbon intensity of the displaced energy source.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic materials, including thermoelectrics. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions are driving manufacturers toward less toxic material formulations. This regulatory landscape is accelerating research into environmentally benign thermoelectric compounds that can meet performance requirements while adhering to stricter environmental standards.

Recent research has focused on developing more sustainable alternatives, including organic thermoelectric materials and abundant element-based compounds. These materials, such as silicides, oxides, and conductive polymers, offer reduced environmental footprints while maintaining acceptable performance characteristics. Silicon-germanium alloys and magnesium silicide, for instance, utilize more abundant elements and demonstrate promising thermoelectric properties for specific temperature ranges.

Life cycle assessment (LCA) studies of thermoelectric systems reveal that despite initial environmental costs in production, the net environmental benefit can be positive when these systems effectively harvest waste heat that would otherwise be lost. The energy payback period—the time required for a thermoelectric system to generate the energy equivalent to that consumed during its production—varies significantly based on material selection and application context, typically ranging from 1-5 years for optimized systems.

The recyclability of thermoelectric materials presents both challenges and opportunities. While traditional bismuth telluride compounds pose recycling difficulties due to their complex composition, newer materials are being designed with end-of-life considerations. Recovery processes for valuable elements from decommissioned thermoelectric devices are advancing, though industrial-scale implementation remains limited.

From a sustainability perspective, thermoelectric energy harvesting contributes to circular economy principles by converting waste heat—an otherwise discarded resource—into useful electricity. This capability is particularly valuable in industrial settings where substantial thermal energy is routinely lost. The carbon footprint reduction potential of thermoelectric systems depends heavily on the specific application and the carbon intensity of the displaced energy source.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic materials, including thermoelectrics. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions are driving manufacturers toward less toxic material formulations. This regulatory landscape is accelerating research into environmentally benign thermoelectric compounds that can meet performance requirements while adhering to stricter environmental standards.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of thermoelectric elements represents a critical factor in their widespread adoption for energy harvesting applications. Current manufacturing processes primarily utilize bulk material production methods, including hot pressing, spark plasma sintering, and zone melting. These techniques, while effective for laboratory-scale production, face significant challenges when scaled to industrial volumes. The capital equipment costs for high-temperature processing facilities can range from $500,000 to several million dollars, creating substantial barriers to entry for smaller manufacturers.

Material availability and processing complexity further impact manufacturing scalability. High-performance thermoelectric materials often incorporate tellurium, bismuth, and antimony—elements with limited global supply chains and significant price volatility. For instance, tellurium prices have fluctuated between $30-200/kg over the past decade, creating uncertainty in production cost forecasting. Additionally, the precise doping requirements for optimal thermoelectric performance necessitate stringent quality control measures that become increasingly challenging at larger production scales.

Cost analysis reveals that material expenses typically constitute 40-60% of total production costs for thermoelectric modules. Labor costs represent approximately 15-25%, while equipment depreciation and energy consumption account for the remainder. The current market price for commercial thermoelectric modules ranges from $5-15 per watt of generating capacity, significantly higher than competing energy technologies. This price point limits market penetration to specialized applications where conventional power sources are impractical.

Recent advancements in manufacturing techniques show promise for improved scalability. Thin-film deposition methods, including sputtering and electrodeposition, enable material usage reduction by up to 90% compared to bulk processing. Additionally, printing technologies for thermoelectric materials are emerging, with potential for roll-to-roll processing that could dramatically reduce production costs. These approaches could potentially reduce module costs to $1-3 per watt, expanding the viable application space considerably.

Economies of scale present significant opportunities for cost reduction. Analysis of existing production facilities indicates that increasing production volume from 10,000 to 100,000 units annually can reduce per-unit costs by 30-40%. However, achieving these economies requires substantial initial investment and market development. The establishment of dedicated supply chains for thermoelectric materials could further reduce costs by 15-20% through improved material sourcing and processing efficiency.

Material availability and processing complexity further impact manufacturing scalability. High-performance thermoelectric materials often incorporate tellurium, bismuth, and antimony—elements with limited global supply chains and significant price volatility. For instance, tellurium prices have fluctuated between $30-200/kg over the past decade, creating uncertainty in production cost forecasting. Additionally, the precise doping requirements for optimal thermoelectric performance necessitate stringent quality control measures that become increasingly challenging at larger production scales.

Cost analysis reveals that material expenses typically constitute 40-60% of total production costs for thermoelectric modules. Labor costs represent approximately 15-25%, while equipment depreciation and energy consumption account for the remainder. The current market price for commercial thermoelectric modules ranges from $5-15 per watt of generating capacity, significantly higher than competing energy technologies. This price point limits market penetration to specialized applications where conventional power sources are impractical.

Recent advancements in manufacturing techniques show promise for improved scalability. Thin-film deposition methods, including sputtering and electrodeposition, enable material usage reduction by up to 90% compared to bulk processing. Additionally, printing technologies for thermoelectric materials are emerging, with potential for roll-to-roll processing that could dramatically reduce production costs. These approaches could potentially reduce module costs to $1-3 per watt, expanding the viable application space considerably.

Economies of scale present significant opportunities for cost reduction. Analysis of existing production facilities indicates that increasing production volume from 10,000 to 100,000 units annually can reduce per-unit costs by 30-40%. However, achieving these economies requires substantial initial investment and market development. The establishment of dedicated supply chains for thermoelectric materials could further reduce costs by 15-20% through improved material sourcing and processing efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!