How to Design Thermoelectric Material Properties for Specific Uses

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Background and Design Objectives

Thermoelectric materials have evolved significantly since their discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion between temperature differences and electric voltage. This discovery laid the foundation for thermoelectric technology, which has since progressed through several developmental phases. Initially, metallic conductors were the primary focus, but research shifted to semiconductors in the mid-20th century when it was recognized that these materials offered superior thermoelectric performance due to their unique electronic properties.

The evolution of thermoelectric materials has been marked by the pursuit of higher efficiency, measured by the dimensionless figure of merit ZT. Traditional thermoelectric materials such as bismuth telluride (Bi₂Te₃), lead telluride (PbTe), and silicon-germanium alloys dominated the field for decades with modest ZT values around 1. However, recent advancements in nanotechnology, material science, and computational methods have pushed these values beyond 2, opening new possibilities for practical applications.

Current technological trends in thermoelectric materials research include the development of nanostructured materials, exploration of complex crystal structures, and investigation of organic thermoelectric materials. Nanostructuring has proven particularly effective in reducing thermal conductivity while maintaining electrical conductivity, thereby enhancing ZT values. Additionally, the discovery of new material classes such as skutterudites, clathrates, and half-Heusler alloys has expanded the temperature ranges and application scenarios for thermoelectric devices.

The primary technical objective in thermoelectric material design is to optimize the power factor (S²σ, where S is the Seebeck coefficient and σ is electrical conductivity) while minimizing thermal conductivity (κ). This optimization presents a significant challenge due to the interdependence of these properties—improvements in one often lead to deterioration in another. Therefore, a key goal is to develop strategies for decoupling these properties to achieve the "phonon glass-electron crystal" paradigm, where materials conduct electricity like crystals but conduct heat poorly like glasses.

Another critical objective is to design materials tailored for specific operational conditions and applications. This includes developing high-temperature thermoelectric materials for waste heat recovery in industrial processes and automotive applications, mid-temperature materials for residential cogeneration systems, and low-temperature materials for electronic cooling and portable power generation. Each temperature range requires different material compositions and structures to achieve optimal performance.

Furthermore, sustainability objectives have become increasingly important, driving research toward abundant, non-toxic alternatives to replace traditional thermoelectric materials containing scarce or hazardous elements like tellurium and lead. This shift aligns with global efforts to develop environmentally friendly technologies and ensures the long-term viability of thermoelectric solutions in a resource-constrained world.

The evolution of thermoelectric materials has been marked by the pursuit of higher efficiency, measured by the dimensionless figure of merit ZT. Traditional thermoelectric materials such as bismuth telluride (Bi₂Te₃), lead telluride (PbTe), and silicon-germanium alloys dominated the field for decades with modest ZT values around 1. However, recent advancements in nanotechnology, material science, and computational methods have pushed these values beyond 2, opening new possibilities for practical applications.

Current technological trends in thermoelectric materials research include the development of nanostructured materials, exploration of complex crystal structures, and investigation of organic thermoelectric materials. Nanostructuring has proven particularly effective in reducing thermal conductivity while maintaining electrical conductivity, thereby enhancing ZT values. Additionally, the discovery of new material classes such as skutterudites, clathrates, and half-Heusler alloys has expanded the temperature ranges and application scenarios for thermoelectric devices.

The primary technical objective in thermoelectric material design is to optimize the power factor (S²σ, where S is the Seebeck coefficient and σ is electrical conductivity) while minimizing thermal conductivity (κ). This optimization presents a significant challenge due to the interdependence of these properties—improvements in one often lead to deterioration in another. Therefore, a key goal is to develop strategies for decoupling these properties to achieve the "phonon glass-electron crystal" paradigm, where materials conduct electricity like crystals but conduct heat poorly like glasses.

Another critical objective is to design materials tailored for specific operational conditions and applications. This includes developing high-temperature thermoelectric materials for waste heat recovery in industrial processes and automotive applications, mid-temperature materials for residential cogeneration systems, and low-temperature materials for electronic cooling and portable power generation. Each temperature range requires different material compositions and structures to achieve optimal performance.

Furthermore, sustainability objectives have become increasingly important, driving research toward abundant, non-toxic alternatives to replace traditional thermoelectric materials containing scarce or hazardous elements like tellurium and lead. This shift aligns with global efforts to develop environmentally friendly technologies and ensures the long-term viability of thermoelectric solutions in a resource-constrained world.

Market Analysis for Thermoelectric Applications

The global thermoelectric market is experiencing significant growth, projected to reach $1.7 billion by 2027, with a compound annual growth rate of approximately 8.3% from 2022. This expansion is driven by increasing demand across multiple sectors, particularly automotive, aerospace, industrial manufacturing, and consumer electronics, where waste heat recovery and precision temperature control are becoming critical operational factors.

In the automotive sector, thermoelectric generators (TEGs) are gaining traction as vehicle manufacturers seek to meet stringent emission standards and improve fuel efficiency. These devices convert waste heat from exhaust systems into usable electricity, potentially improving fuel economy by 2-5%. Major automotive companies including BMW, Ford, and Toyota have active research programs exploring thermoelectric integration in their vehicle lines.

The aerospace industry represents another high-value market segment, where thermoelectric cooling systems are utilized for precise temperature regulation of sensitive electronic components and cabin climate control. The reliability and lack of moving parts make thermoelectric solutions particularly attractive in this sector, where maintenance accessibility is limited and system failure is costly.

Consumer electronics constitute a rapidly growing application area, with thermoelectric modules being incorporated into portable coolers, temperature-controlled beverage containers, and computer cooling systems. The miniaturization trend in electronics has created demand for compact cooling solutions that can efficiently manage heat in confined spaces, driving innovation in micro-scale thermoelectric designs.

Medical and healthcare applications represent an emerging market with substantial growth potential. Thermoelectric devices are increasingly used in DNA sequencers, PCR machines, blood analyzers, and patient temperature management systems. The precise temperature control capabilities of thermoelectric technology are particularly valuable in these applications, where even minor temperature variations can significantly impact results or patient outcomes.

Geographic market distribution shows North America and Europe currently leading in thermoelectric technology adoption, particularly in high-end applications requiring premium materials. However, Asia-Pacific regions, especially China, Japan, and South Korea, are experiencing the fastest growth rates due to expanding manufacturing capabilities and increasing investment in renewable energy technologies.

Market challenges include the relatively high cost of high-performance thermoelectric materials and the efficiency limitations of current technologies. The cost-performance ratio remains a significant barrier to widespread adoption in price-sensitive consumer markets. Additionally, competition from alternative technologies such as vapor compression cooling systems and passive heat management solutions continues to constrain market penetration in certain applications.

In the automotive sector, thermoelectric generators (TEGs) are gaining traction as vehicle manufacturers seek to meet stringent emission standards and improve fuel efficiency. These devices convert waste heat from exhaust systems into usable electricity, potentially improving fuel economy by 2-5%. Major automotive companies including BMW, Ford, and Toyota have active research programs exploring thermoelectric integration in their vehicle lines.

The aerospace industry represents another high-value market segment, where thermoelectric cooling systems are utilized for precise temperature regulation of sensitive electronic components and cabin climate control. The reliability and lack of moving parts make thermoelectric solutions particularly attractive in this sector, where maintenance accessibility is limited and system failure is costly.

Consumer electronics constitute a rapidly growing application area, with thermoelectric modules being incorporated into portable coolers, temperature-controlled beverage containers, and computer cooling systems. The miniaturization trend in electronics has created demand for compact cooling solutions that can efficiently manage heat in confined spaces, driving innovation in micro-scale thermoelectric designs.

Medical and healthcare applications represent an emerging market with substantial growth potential. Thermoelectric devices are increasingly used in DNA sequencers, PCR machines, blood analyzers, and patient temperature management systems. The precise temperature control capabilities of thermoelectric technology are particularly valuable in these applications, where even minor temperature variations can significantly impact results or patient outcomes.

Geographic market distribution shows North America and Europe currently leading in thermoelectric technology adoption, particularly in high-end applications requiring premium materials. However, Asia-Pacific regions, especially China, Japan, and South Korea, are experiencing the fastest growth rates due to expanding manufacturing capabilities and increasing investment in renewable energy technologies.

Market challenges include the relatively high cost of high-performance thermoelectric materials and the efficiency limitations of current technologies. The cost-performance ratio remains a significant barrier to widespread adoption in price-sensitive consumer markets. Additionally, competition from alternative technologies such as vapor compression cooling systems and passive heat management solutions continues to constrain market penetration in certain applications.

Current Challenges in Thermoelectric Material Engineering

Despite significant advancements in thermoelectric materials over recent decades, the field continues to face substantial engineering challenges that impede widespread commercial adoption. The fundamental challenge remains the inherent coupling of thermal and electrical properties, making it difficult to optimize the thermoelectric figure of merit (ZT). When attempting to increase electrical conductivity, thermal conductivity often increases proportionally, negating potential efficiency gains.

Material stability presents another critical obstacle, particularly for applications requiring operation at high temperatures or under thermal cycling conditions. Many high-performance thermoelectric materials degrade rapidly when exposed to oxygen at elevated temperatures or experience performance deterioration after repeated thermal cycling, limiting their practical lifespan in real-world applications.

Manufacturing scalability continues to hinder industrial implementation. Current high-performance thermoelectric materials often require precise composition control, expensive elements (such as tellurium, germanium, or rare earth metals), and complex processing techniques. These factors significantly increase production costs and create supply chain vulnerabilities, especially for materials containing geopolitically sensitive elements.

Interface engineering remains problematic in device fabrication. Contact resistance at the junction between thermoelectric materials and metal electrodes can substantially reduce overall device efficiency. Additionally, thermal expansion mismatches between different materials in a thermoelectric module often lead to mechanical stress, cracking, and eventual device failure.

Environmental concerns and toxicity issues pose regulatory challenges. Many current high-performance thermoelectric materials contain toxic elements like lead, tellurium, or antimony, raising concerns about environmental impact and limiting applications in consumer products or medical devices.

Application-specific optimization represents a significant engineering hurdle. Different applications (power generation, refrigeration, sensing) require distinct material property profiles, yet most research focuses on maximizing ZT without considering specific operational requirements such as temperature range, mechanical properties, or form factor constraints.

Theoretical modeling limitations hinder predictive materials design. While computational methods have advanced significantly, accurately predicting thermoelectric performance of complex materials systems remains challenging, particularly for nanostructured materials where quantum effects become significant.

Interdisciplinary knowledge gaps between materials science, electrical engineering, and thermal management often result in suboptimal system designs. Holistic approaches that consider the entire thermoelectric system rather than just material properties are still underdeveloped in both academic research and industrial applications.

Material stability presents another critical obstacle, particularly for applications requiring operation at high temperatures or under thermal cycling conditions. Many high-performance thermoelectric materials degrade rapidly when exposed to oxygen at elevated temperatures or experience performance deterioration after repeated thermal cycling, limiting their practical lifespan in real-world applications.

Manufacturing scalability continues to hinder industrial implementation. Current high-performance thermoelectric materials often require precise composition control, expensive elements (such as tellurium, germanium, or rare earth metals), and complex processing techniques. These factors significantly increase production costs and create supply chain vulnerabilities, especially for materials containing geopolitically sensitive elements.

Interface engineering remains problematic in device fabrication. Contact resistance at the junction between thermoelectric materials and metal electrodes can substantially reduce overall device efficiency. Additionally, thermal expansion mismatches between different materials in a thermoelectric module often lead to mechanical stress, cracking, and eventual device failure.

Environmental concerns and toxicity issues pose regulatory challenges. Many current high-performance thermoelectric materials contain toxic elements like lead, tellurium, or antimony, raising concerns about environmental impact and limiting applications in consumer products or medical devices.

Application-specific optimization represents a significant engineering hurdle. Different applications (power generation, refrigeration, sensing) require distinct material property profiles, yet most research focuses on maximizing ZT without considering specific operational requirements such as temperature range, mechanical properties, or form factor constraints.

Theoretical modeling limitations hinder predictive materials design. While computational methods have advanced significantly, accurately predicting thermoelectric performance of complex materials systems remains challenging, particularly for nanostructured materials where quantum effects become significant.

Interdisciplinary knowledge gaps between materials science, electrical engineering, and thermal management often result in suboptimal system designs. Holistic approaches that consider the entire thermoelectric system rather than just material properties are still underdeveloped in both academic research and industrial applications.

State-of-the-Art Thermoelectric Material Design Approaches

01 Composition and structure of thermoelectric materials

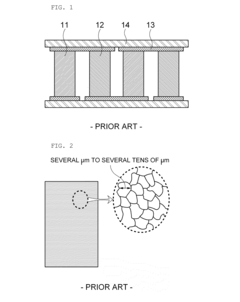

Thermoelectric materials can be composed of various elements and compounds with specific structures that enhance their thermoelectric properties. These materials often include bismuth telluride, lead telluride, silicon-germanium alloys, and other semiconductor materials. The composition and crystal structure significantly influence the material's ability to convert heat into electricity efficiently. Nanostructuring and composite formations are commonly employed to improve thermoelectric performance by optimizing electron transport while reducing thermal conductivity.- Composition and structure of thermoelectric materials: The composition and structure of thermoelectric materials significantly influence their performance. Various materials including bismuth telluride, lead telluride, and skutterudites are commonly used for thermoelectric applications. The crystal structure, grain size, and atomic arrangement affect the material's ability to convert heat into electricity. Nanostructuring and composite formations can enhance thermoelectric properties by optimizing electron transport while reducing thermal conductivity.

- Figure of merit and efficiency optimization: The thermoelectric figure of merit (ZT) is a critical parameter that determines the efficiency of thermoelectric materials. Higher ZT values indicate better conversion efficiency between thermal and electrical energy. Materials with high electrical conductivity, high Seebeck coefficient, and low thermal conductivity achieve optimal ZT values. Various approaches to improve ZT include doping, band engineering, and creating materials with complex crystal structures that scatter phonons while allowing electron transport.

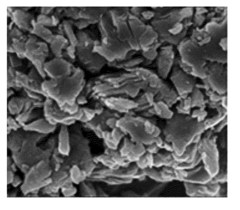

- Nanostructured thermoelectric materials: Nanostructuring has emerged as an effective strategy to enhance thermoelectric performance. By introducing nanoscale features such as quantum dots, nanowires, or nanoparticles, the thermal conductivity can be reduced through increased phonon scattering while maintaining good electrical properties. These nanostructured materials create interfaces that selectively scatter phonons without significantly affecting electron transport, leading to improved thermoelectric efficiency.

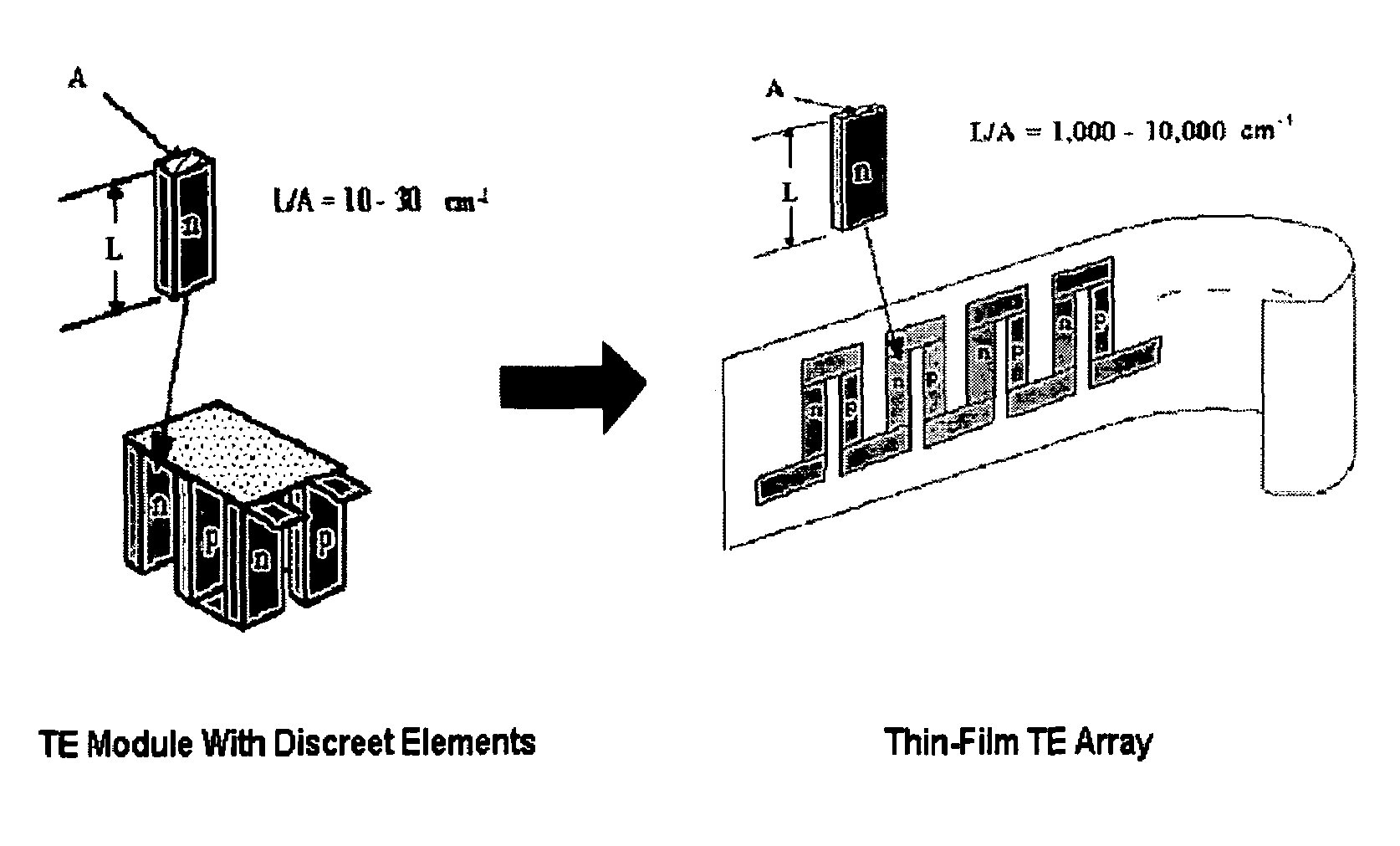

- Flexible and thin-film thermoelectric materials: Flexible and thin-film thermoelectric materials represent an emerging class of materials suitable for wearable electronics and conformal energy harvesting applications. These materials can be fabricated on flexible substrates using techniques such as printing, sputtering, or solution processing. They typically exhibit different properties compared to bulk materials due to size effects and substrate interactions. The mechanical flexibility combined with thermoelectric functionality enables new applications in portable and wearable power generation.

- Environmental stability and durability: The environmental stability and durability of thermoelectric materials are crucial for long-term applications. Factors such as oxidation resistance, thermal cycling stability, and mechanical strength determine the operational lifetime of thermoelectric devices. Materials must maintain their thermoelectric properties under various environmental conditions including high temperatures, humidity, and mechanical stress. Protective coatings, encapsulation techniques, and inherently stable material compositions are developed to enhance the durability of thermoelectric systems.

02 Figure of merit and efficiency optimization

The thermoelectric performance of materials is primarily evaluated by the dimensionless figure of merit ZT, which depends on electrical conductivity, Seebeck coefficient, and thermal conductivity. Materials with high electrical conductivity, high Seebeck coefficient, and low thermal conductivity achieve higher ZT values and better energy conversion efficiency. Various approaches to optimize these properties include doping, band engineering, and creating materials with complex crystal structures that scatter phonons while allowing electrons to flow freely.Expand Specific Solutions03 Temperature-dependent performance characteristics

Thermoelectric materials exhibit different performance characteristics at various temperature ranges. Some materials are optimized for low-temperature applications (below 200°C), while others are designed for medium (200-600°C) or high-temperature (above 600°C) environments. The stability, efficiency, and durability of thermoelectric materials under thermal cycling and at sustained high temperatures are critical properties that determine their practical applications in waste heat recovery, power generation, and cooling systems.Expand Specific Solutions04 Nanostructured thermoelectric materials

Nanostructuring has emerged as a powerful approach to enhance thermoelectric properties by introducing interfaces that scatter phonons more effectively than electrons. Nanoscale features such as quantum dots, nanowires, nanoparticles, and superlattices can significantly reduce thermal conductivity while maintaining good electrical properties. These nanostructured materials often exhibit enhanced ZT values compared to their bulk counterparts due to quantum confinement effects and increased phonon scattering at interfaces.Expand Specific Solutions05 Flexible and printable thermoelectric materials

Recent advances have led to the development of flexible and printable thermoelectric materials that can conform to curved surfaces and be manufactured using cost-effective methods. These materials often incorporate organic compounds, polymer composites, or thin-film inorganic materials deposited on flexible substrates. They enable new applications in wearable electronics, conformal waste heat recovery systems, and self-powered sensors, though they typically have lower efficiency compared to rigid inorganic thermoelectric materials.Expand Specific Solutions

Leading Organizations in Thermoelectric Research and Development

The thermoelectric materials design landscape is currently in a growth phase, with an estimated market size of $600-700 million and projected annual growth of 8-10%. The technology has reached moderate maturity but remains in active development across various application sectors. Leading academic institutions (MIT, Zhejiang University, North Carolina State University) are driving fundamental research, while industrial players demonstrate varying levels of commercial implementation. Toyota and Samsung have established significant patent portfolios in automotive and consumer electronics applications respectively. Research institutes like Shanghai Institute of Ceramics and Korea Institute of Materials Science are bridging the gap between theoretical advances and practical applications. The competitive landscape shows a balanced ecosystem of academic research, government laboratories, and corporate R&D focusing on efficiency improvements and application-specific material optimization.

Korea Institute of Materials Science

Technical Solution: The Korea Institute of Materials Science (KIMS) has developed specialized thermoelectric materials optimized for specific temperature ranges and applications. Their research focuses on environmentally friendly, cost-effective materials that avoid rare or toxic elements. KIMS has pioneered advanced manufacturing techniques for skutterudite-based materials with enhanced ZT values through precise control of nanostructures and interfaces. Their proprietary processing methods include spark plasma sintering and melt spinning to create optimized microstructures that effectively scatter phonons while preserving electron mobility. KIMS researchers have developed materials specifically designed for mid-temperature (200-500°C) applications in industrial settings, achieving ZT values of 1.3-1.8 in this range. They've also created flexible thermoelectric materials using organic-inorganic hybrids for wearable electronics and IoT applications, with demonstrated power densities sufficient for small sensors and monitoring devices.

Strengths: Strong focus on practical, commercially viable materials; excellent balance between performance and manufacturing cost; expertise in both high-temperature and flexible/wearable applications. Weaknesses: Some materials show performance degradation under thermal cycling; international patent protection may be less comprehensive than some competitors.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has developed advanced thermoelectric materials with exceptional thermal stability and efficiency through innovative composition engineering and microstructure control. Their research focuses on oxide-based and silicide-based thermoelectric materials that can operate reliably at high temperatures (600-900°C) for extended periods. Their proprietary manufacturing processes incorporate precise doping strategies and defect engineering to optimize the power factor while minimizing thermal conductivity. The institute has pioneered hierarchical structuring techniques that create multi-scale phonon scattering centers while maintaining electron transport pathways. Their materials demonstrate ZT values of 1.2-1.5 at high temperatures with minimal degradation over thousands of operating hours. The institute has also developed specialized coating technologies that protect thermoelectric modules from oxidation and sublimation in harsh environments, extending operational lifetimes by 300-400% compared to conventional materials.

Strengths: Exceptional expertise in high-temperature materials with outstanding thermal stability; strong capabilities in large-scale manufacturing processes; excellent long-term reliability under harsh conditions. Weaknesses: Materials optimized for high-temperature applications may have lower performance at room temperature; some manufacturing processes require specialized equipment with high capital costs.

Key Patents and Scientific Breakthroughs in Thermoelectric Materials

Thermoelectric material, method for preparing the same, and thermoelectric module including the same

PatentInactiveUS9153763B2

Innovation

- A thermoelectric material with a plate-type layered structure, each layer being 30 nm or less in thickness, aligned in the C-axial direction, is synthesized using a method involving vacuum sealing, dissolution at 600-700°C, and rapid cooling at 0°C or lower, to enhance phonon scattering and crystallinity, thereby improving thermal conductivity and module performance.

Thermoelectric power source utilizing ambient energy harvesting for remote sensing and transmitting

PatentActiveUS7834263B2

Innovation

- A method and apparatus that harness and convert ambient temperature differences in the environment into electrical energy using thermoelectric devices, amplifying temperature gradients through means like heat pipes to generate power for extended periods.

Material Characterization and Testing Methodologies

Effective characterization and testing of thermoelectric materials are essential for designing materials with properties tailored to specific applications. The measurement of thermoelectric properties requires specialized equipment and methodologies to accurately determine the Seebeck coefficient, electrical conductivity, and thermal conductivity—the three key parameters that define the figure of merit (ZT).

For Seebeck coefficient measurements, the most common approach involves creating a temperature gradient across the sample and measuring the resulting voltage difference. Advanced systems like the ZEM-3 apparatus enable simultaneous measurement of both Seebeck coefficient and electrical conductivity under various temperature conditions, providing comprehensive data for material optimization.

Electrical conductivity testing typically employs the four-probe method to eliminate contact resistance effects, which is crucial for accurate measurements in thermoelectric materials where electrical properties are highly temperature-dependent. For thin films and nanoscale materials, specialized techniques such as van der Pauw measurements offer more precise characterization of electrical transport properties.

Thermal conductivity determination presents particular challenges due to the need to isolate heat flow pathways. The laser flash method has emerged as the industry standard, measuring thermal diffusivity which can be converted to thermal conductivity when combined with specific heat capacity and density measurements. For materials with anisotropic properties, direction-dependent measurements are essential to fully characterize performance potential.

Hall effect measurements provide critical insights into carrier concentration and mobility, which directly influence thermoelectric performance. Understanding these carrier transport mechanisms is fundamental when designing materials for specific temperature ranges or operating conditions.

X-ray diffraction (XRD) and electron microscopy techniques offer complementary structural information, revealing crystalline phases, grain boundaries, and defect structures that significantly impact thermoelectric properties. Advanced techniques like scanning thermal microscopy can map thermal transport at the nanoscale, providing insights into local variations in performance.

Stability testing under thermal cycling and in various atmospheres is particularly important for applications involving temperature gradients and potentially reactive environments. Long-term performance degradation assessment through accelerated aging tests helps predict device lifetime and reliability in real-world conditions.

Standardization of testing protocols remains an ongoing challenge in the field, with efforts by organizations like ASTM International working to establish consistent methodologies that enable reliable comparison between materials developed by different research groups and manufacturers.

For Seebeck coefficient measurements, the most common approach involves creating a temperature gradient across the sample and measuring the resulting voltage difference. Advanced systems like the ZEM-3 apparatus enable simultaneous measurement of both Seebeck coefficient and electrical conductivity under various temperature conditions, providing comprehensive data for material optimization.

Electrical conductivity testing typically employs the four-probe method to eliminate contact resistance effects, which is crucial for accurate measurements in thermoelectric materials where electrical properties are highly temperature-dependent. For thin films and nanoscale materials, specialized techniques such as van der Pauw measurements offer more precise characterization of electrical transport properties.

Thermal conductivity determination presents particular challenges due to the need to isolate heat flow pathways. The laser flash method has emerged as the industry standard, measuring thermal diffusivity which can be converted to thermal conductivity when combined with specific heat capacity and density measurements. For materials with anisotropic properties, direction-dependent measurements are essential to fully characterize performance potential.

Hall effect measurements provide critical insights into carrier concentration and mobility, which directly influence thermoelectric performance. Understanding these carrier transport mechanisms is fundamental when designing materials for specific temperature ranges or operating conditions.

X-ray diffraction (XRD) and electron microscopy techniques offer complementary structural information, revealing crystalline phases, grain boundaries, and defect structures that significantly impact thermoelectric properties. Advanced techniques like scanning thermal microscopy can map thermal transport at the nanoscale, providing insights into local variations in performance.

Stability testing under thermal cycling and in various atmospheres is particularly important for applications involving temperature gradients and potentially reactive environments. Long-term performance degradation assessment through accelerated aging tests helps predict device lifetime and reliability in real-world conditions.

Standardization of testing protocols remains an ongoing challenge in the field, with efforts by organizations like ASTM International working to establish consistent methodologies that enable reliable comparison between materials developed by different research groups and manufacturers.

Environmental Impact and Sustainability Considerations

The development and deployment of thermoelectric materials carry significant environmental implications that must be carefully considered throughout their lifecycle. Traditional thermoelectric materials often contain toxic or rare elements such as tellurium, bismuth, lead, and antimony, which pose environmental risks during extraction, processing, and disposal phases. Mining operations for these elements frequently result in habitat destruction, soil contamination, and water pollution, particularly in regions with limited environmental regulations.

Energy consumption during the manufacturing process represents another critical environmental concern. The synthesis of high-performance thermoelectric materials typically requires energy-intensive processes including high-temperature treatments and precision fabrication techniques. This energy footprint must be factored into lifecycle assessments when evaluating the net environmental benefit of thermoelectric applications.

Sustainable design approaches for thermoelectric materials are emerging as a response to these challenges. Research is increasingly focused on developing earth-abundant alternatives that maintain comparable performance while reducing reliance on scarce or toxic elements. Materials systems based on silicides, oxides, and organic compounds show promising potential as environmentally benign alternatives, though they currently lag behind conventional materials in efficiency metrics.

Circular economy principles are becoming essential in thermoelectric material design. Considerations for end-of-life recovery and recycling must be incorporated from the earliest design stages. This includes developing materials with structures that facilitate component separation and recovery processes that can efficiently extract valuable elements for reuse in new thermoelectric devices.

The environmental payback period—the time required for a thermoelectric device to offset the environmental impact of its production through its operation—varies significantly depending on application context. In waste heat recovery applications, thermoelectric generators can potentially deliver substantial net environmental benefits by converting otherwise wasted thermal energy into useful electricity, thereby reducing overall energy consumption and associated emissions.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic materials, including thermoelectrics. Compliance with regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) is becoming mandatory for market access, driving innovation toward more environmentally compatible material compositions and manufacturing processes.

Energy consumption during the manufacturing process represents another critical environmental concern. The synthesis of high-performance thermoelectric materials typically requires energy-intensive processes including high-temperature treatments and precision fabrication techniques. This energy footprint must be factored into lifecycle assessments when evaluating the net environmental benefit of thermoelectric applications.

Sustainable design approaches for thermoelectric materials are emerging as a response to these challenges. Research is increasingly focused on developing earth-abundant alternatives that maintain comparable performance while reducing reliance on scarce or toxic elements. Materials systems based on silicides, oxides, and organic compounds show promising potential as environmentally benign alternatives, though they currently lag behind conventional materials in efficiency metrics.

Circular economy principles are becoming essential in thermoelectric material design. Considerations for end-of-life recovery and recycling must be incorporated from the earliest design stages. This includes developing materials with structures that facilitate component separation and recovery processes that can efficiently extract valuable elements for reuse in new thermoelectric devices.

The environmental payback period—the time required for a thermoelectric device to offset the environmental impact of its production through its operation—varies significantly depending on application context. In waste heat recovery applications, thermoelectric generators can potentially deliver substantial net environmental benefits by converting otherwise wasted thermal energy into useful electricity, thereby reducing overall energy consumption and associated emissions.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic materials, including thermoelectrics. Compliance with regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) is becoming mandatory for market access, driving innovation toward more environmentally compatible material compositions and manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!