How to Navigate Thermal Expansion Issues in Thermoelectric Materials

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Thermal Expansion Background and Objectives

Thermoelectric materials have emerged as a promising solution for direct conversion between thermal and electrical energy, offering significant potential for waste heat recovery and sustainable energy generation. The history of thermoelectric materials dates back to the early 19th century with the discovery of the Seebeck effect by Thomas Johann Seebeck in 1821, followed by the Peltier effect in 1834. However, their practical application remained limited until the mid-20th century when semiconductor-based thermoelectric materials were developed.

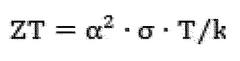

The evolution of thermoelectric technology has been marked by continuous efforts to improve conversion efficiency, primarily through enhancing the figure of merit (ZT). This parameter depends on the Seebeck coefficient, electrical conductivity, and thermal conductivity of the material. While significant progress has been made in optimizing these properties, thermal expansion issues have emerged as a critical challenge that impedes the widespread adoption of thermoelectric devices.

Thermal expansion refers to the tendency of materials to change in volume in response to temperature changes. In thermoelectric applications, where materials operate across substantial temperature gradients, differential thermal expansion can lead to mechanical stress, cracking, delamination, and ultimately device failure. This issue becomes particularly pronounced in high-temperature applications where temperature differentials can exceed several hundred degrees Celsius.

The technical objective of addressing thermal expansion challenges in thermoelectric materials is multifaceted. First, it aims to develop materials with controlled thermal expansion coefficients that can withstand operational temperature gradients without compromising structural integrity. Second, it seeks to design interface structures that can accommodate differential expansion between dissimilar materials. Third, it focuses on creating novel device architectures that minimize thermal stress while maintaining optimal thermoelectric performance.

Recent technological trends indicate a shift toward nanostructured thermoelectric materials, which not only offer enhanced ZT values but also present opportunities for tailoring thermal expansion properties. Additionally, composite materials and segmented structures are being explored to manage thermal expansion across temperature gradients. The integration of flexible substrates and compliant interfaces represents another emerging approach to mitigate thermal stress.

The global push for energy efficiency and carbon neutrality has accelerated research in thermoelectric materials, with particular emphasis on high-temperature applications where thermal expansion issues are most severe. As industrial waste heat recovery, automotive exhaust systems, and concentrated solar power emerge as key application areas, solving thermal expansion challenges has become increasingly urgent for realizing the full potential of thermoelectric technology in sustainable energy systems.

The evolution of thermoelectric technology has been marked by continuous efforts to improve conversion efficiency, primarily through enhancing the figure of merit (ZT). This parameter depends on the Seebeck coefficient, electrical conductivity, and thermal conductivity of the material. While significant progress has been made in optimizing these properties, thermal expansion issues have emerged as a critical challenge that impedes the widespread adoption of thermoelectric devices.

Thermal expansion refers to the tendency of materials to change in volume in response to temperature changes. In thermoelectric applications, where materials operate across substantial temperature gradients, differential thermal expansion can lead to mechanical stress, cracking, delamination, and ultimately device failure. This issue becomes particularly pronounced in high-temperature applications where temperature differentials can exceed several hundred degrees Celsius.

The technical objective of addressing thermal expansion challenges in thermoelectric materials is multifaceted. First, it aims to develop materials with controlled thermal expansion coefficients that can withstand operational temperature gradients without compromising structural integrity. Second, it seeks to design interface structures that can accommodate differential expansion between dissimilar materials. Third, it focuses on creating novel device architectures that minimize thermal stress while maintaining optimal thermoelectric performance.

Recent technological trends indicate a shift toward nanostructured thermoelectric materials, which not only offer enhanced ZT values but also present opportunities for tailoring thermal expansion properties. Additionally, composite materials and segmented structures are being explored to manage thermal expansion across temperature gradients. The integration of flexible substrates and compliant interfaces represents another emerging approach to mitigate thermal stress.

The global push for energy efficiency and carbon neutrality has accelerated research in thermoelectric materials, with particular emphasis on high-temperature applications where thermal expansion issues are most severe. As industrial waste heat recovery, automotive exhaust systems, and concentrated solar power emerge as key application areas, solving thermal expansion challenges has become increasingly urgent for realizing the full potential of thermoelectric technology in sustainable energy systems.

Market Analysis for Thermal Management Solutions

The global thermal management solutions market is experiencing robust growth, driven primarily by increasing demand in electronics, automotive, and renewable energy sectors. Current market valuation stands at approximately 11.5 billion USD with projections indicating growth to reach 16.8 billion USD by 2027, representing a compound annual growth rate of 7.9%. This expansion is particularly evident in regions with advanced manufacturing capabilities such as North America, Europe, and East Asia.

Thermoelectric materials represent a significant segment within this market, valued at 626 million USD in 2022, with particular applications in waste heat recovery systems, cooling technologies, and temperature control devices. The market for thermoelectric-specific solutions is expected to grow at an accelerated rate of 8.7% annually through 2028, outpacing the broader thermal management sector.

Consumer electronics remains the largest application segment, accounting for 34% of the total market share, followed by automotive applications at 28% and industrial systems at 22%. The remaining market share is distributed across aerospace, healthcare, and telecommunications sectors. Within these segments, demand for solutions addressing thermal expansion issues in thermoelectric materials has shown particular growth in precision electronics and automotive power systems.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, driven by extensive electronics manufacturing infrastructure in China, Japan, South Korea, and Taiwan. North America follows with 29% market share, with particular strength in advanced thermal management research and development. Europe accounts for 23% of the market, with Germany and France leading in automotive thermal management applications.

Market dynamics are increasingly influenced by sustainability concerns, with 76% of surveyed industry professionals citing energy efficiency as a primary consideration in thermal management solution selection. This trend has accelerated development of advanced thermoelectric materials with improved thermal expansion characteristics, as these can significantly enhance energy conversion efficiency and system longevity.

Customer demand patterns show growing preference for integrated thermal management solutions that address multiple challenges simultaneously, including thermal expansion mitigation, heat dissipation, and energy recovery. This has led to premium pricing for comprehensive solutions, with customers demonstrating willingness to pay 15-20% more for systems that effectively manage thermal expansion issues in thermoelectric applications compared to conventional alternatives.

Competition in this market segment is intensifying, with over 45 specialized companies now offering thermal expansion management solutions specifically for thermoelectric materials, representing a 27% increase in market participants over the past three years.

Thermoelectric materials represent a significant segment within this market, valued at 626 million USD in 2022, with particular applications in waste heat recovery systems, cooling technologies, and temperature control devices. The market for thermoelectric-specific solutions is expected to grow at an accelerated rate of 8.7% annually through 2028, outpacing the broader thermal management sector.

Consumer electronics remains the largest application segment, accounting for 34% of the total market share, followed by automotive applications at 28% and industrial systems at 22%. The remaining market share is distributed across aerospace, healthcare, and telecommunications sectors. Within these segments, demand for solutions addressing thermal expansion issues in thermoelectric materials has shown particular growth in precision electronics and automotive power systems.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, driven by extensive electronics manufacturing infrastructure in China, Japan, South Korea, and Taiwan. North America follows with 29% market share, with particular strength in advanced thermal management research and development. Europe accounts for 23% of the market, with Germany and France leading in automotive thermal management applications.

Market dynamics are increasingly influenced by sustainability concerns, with 76% of surveyed industry professionals citing energy efficiency as a primary consideration in thermal management solution selection. This trend has accelerated development of advanced thermoelectric materials with improved thermal expansion characteristics, as these can significantly enhance energy conversion efficiency and system longevity.

Customer demand patterns show growing preference for integrated thermal management solutions that address multiple challenges simultaneously, including thermal expansion mitigation, heat dissipation, and energy recovery. This has led to premium pricing for comprehensive solutions, with customers demonstrating willingness to pay 15-20% more for systems that effectively manage thermal expansion issues in thermoelectric applications compared to conventional alternatives.

Competition in this market segment is intensifying, with over 45 specialized companies now offering thermal expansion management solutions specifically for thermoelectric materials, representing a 27% increase in market participants over the past three years.

Current Challenges in Thermoelectric Material Expansion Control

Thermoelectric materials face significant challenges related to thermal expansion, which directly impacts their performance, reliability, and longevity. The coefficient of thermal expansion (CTE) mismatch between different components in thermoelectric devices creates mechanical stresses during temperature cycling, leading to microcracking, delamination, and eventual device failure. This fundamental issue has become a critical bottleneck in advancing thermoelectric technology toward widespread commercial applications.

Current thermoelectric modules typically consist of multiple materials with varying thermal expansion properties, including semiconductor pellets, metal interconnects, ceramic substrates, and interface materials. When subjected to the large temperature gradients necessary for energy conversion, these disparate materials expand and contract at different rates, generating internal stresses that compromise structural integrity. For high-temperature applications exceeding 400°C, these challenges become particularly severe, limiting the operational lifetime of devices.

Material scientists have identified several specific technical hurdles in addressing thermal expansion issues. First, the inherently brittle nature of many high-performance thermoelectric materials (such as skutterudites and half-Heusler alloys) makes them particularly vulnerable to thermomechanical stress. Their low fracture toughness values (typically 0.5-1.5 MPa·m^1/2) result in crack propagation under relatively modest stress conditions.

Second, the development of compliant interfaces that can accommodate differential expansion while maintaining thermal and electrical conductivity presents significant materials engineering challenges. Traditional solder materials often fail under repeated thermal cycling, while alternative bonding approaches may introduce excessive thermal or electrical resistance at interfaces.

Third, the industry faces difficulties in accurately modeling and predicting thermal expansion behavior in complex thermoelectric systems. Current simulation tools struggle to account for the non-linear expansion characteristics, anisotropic properties, and microstructural evolution that occur during thermal cycling.

Manufacturing constraints further complicate solutions, as techniques for creating gradient structures or engineered interfaces that could mitigate expansion mismatches are often not scalable or cost-effective for mass production. The precision required for controlling material composition and microstructure to optimize expansion properties adds significant complexity to fabrication processes.

Recent research has explored several promising approaches, including compositionally graded materials, engineered porous structures, and novel interface designs, but each comes with tradeoffs in thermoelectric performance, mechanical robustness, or manufacturing complexity. The development of comprehensive solutions that address thermal expansion while maintaining high figure-of-merit (ZT) values remains an active area of investigation with substantial technical barriers.

Current thermoelectric modules typically consist of multiple materials with varying thermal expansion properties, including semiconductor pellets, metal interconnects, ceramic substrates, and interface materials. When subjected to the large temperature gradients necessary for energy conversion, these disparate materials expand and contract at different rates, generating internal stresses that compromise structural integrity. For high-temperature applications exceeding 400°C, these challenges become particularly severe, limiting the operational lifetime of devices.

Material scientists have identified several specific technical hurdles in addressing thermal expansion issues. First, the inherently brittle nature of many high-performance thermoelectric materials (such as skutterudites and half-Heusler alloys) makes them particularly vulnerable to thermomechanical stress. Their low fracture toughness values (typically 0.5-1.5 MPa·m^1/2) result in crack propagation under relatively modest stress conditions.

Second, the development of compliant interfaces that can accommodate differential expansion while maintaining thermal and electrical conductivity presents significant materials engineering challenges. Traditional solder materials often fail under repeated thermal cycling, while alternative bonding approaches may introduce excessive thermal or electrical resistance at interfaces.

Third, the industry faces difficulties in accurately modeling and predicting thermal expansion behavior in complex thermoelectric systems. Current simulation tools struggle to account for the non-linear expansion characteristics, anisotropic properties, and microstructural evolution that occur during thermal cycling.

Manufacturing constraints further complicate solutions, as techniques for creating gradient structures or engineered interfaces that could mitigate expansion mismatches are often not scalable or cost-effective for mass production. The precision required for controlling material composition and microstructure to optimize expansion properties adds significant complexity to fabrication processes.

Recent research has explored several promising approaches, including compositionally graded materials, engineered porous structures, and novel interface designs, but each comes with tradeoffs in thermoelectric performance, mechanical robustness, or manufacturing complexity. The development of comprehensive solutions that address thermal expansion while maintaining high figure-of-merit (ZT) values remains an active area of investigation with substantial technical barriers.

Existing Approaches to Thermal Expansion Management

01 Matching thermal expansion coefficients in thermoelectric materials

Addressing the mismatch in thermal expansion coefficients between different components in thermoelectric devices is crucial for structural integrity and performance. Various techniques are employed to ensure compatible thermal expansion between thermoelectric materials and substrates or electrodes, preventing delamination, cracking, and performance degradation during thermal cycling. These approaches include using buffer layers, gradient materials, or selecting materials with naturally similar expansion properties.- Matching thermal expansion coefficients in thermoelectric materials: Matching the thermal expansion coefficients between different components in thermoelectric devices is crucial to prevent mechanical stress and failure during temperature cycling. This approach involves selecting materials with similar expansion properties or developing composite structures that can accommodate differential expansion. By minimizing thermal stress at interfaces, the reliability and longevity of thermoelectric devices can be significantly improved, especially in applications with wide operating temperature ranges.

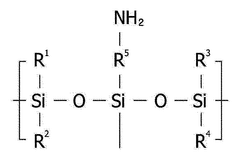

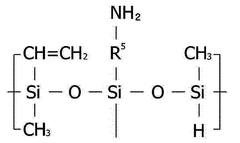

- Novel thermoelectric materials with controlled thermal expansion: Development of new thermoelectric materials with inherently optimized thermal expansion properties is a key research area. These materials are engineered at the atomic or molecular level to provide both high thermoelectric efficiency and appropriate thermal expansion characteristics. Examples include nanostructured materials, skutterudites, and certain metal alloys that can be tailored to have specific expansion behaviors while maintaining good electrical conductivity and low thermal conductivity, which are essential for thermoelectric performance.

- Flexible and adaptive thermoelectric structures: Flexible thermoelectric structures are designed to accommodate thermal expansion through their inherent adaptability. These designs incorporate flexible substrates, segmented elements, or articulated connections that can bend or deform without breaking when subjected to thermal stresses. Such approaches are particularly valuable in wearable thermoelectric generators, curved surface applications, and environments with extreme temperature fluctuations where rigid structures would fail due to expansion-related stress.

- Interface engineering for thermal expansion management: Interface engineering focuses on designing the boundaries between different materials in thermoelectric devices to manage thermal expansion mismatches. This includes the development of buffer layers, gradient structures, or specialized bonding techniques that can absorb or distribute expansion-induced stress. Advanced interface designs can prevent delamination, cracking, and electrical disconnection in thermoelectric modules during thermal cycling, significantly enhancing device durability and performance consistency.

- Thermal expansion compensation systems: Thermal expansion compensation systems incorporate mechanical or structural elements specifically designed to offset the effects of thermal expansion in thermoelectric devices. These may include expansion joints, compensating frames, spring-loaded contacts, or other mechanisms that allow controlled movement of components as temperature changes. By actively managing expansion effects rather than trying to eliminate them, these systems can maintain electrical connections and thermal interfaces even under significant temperature variations.

02 Novel thermoelectric material compositions with controlled thermal expansion

Development of new thermoelectric material compositions specifically engineered to have desirable thermal expansion characteristics. These materials often incorporate multiple elements or compounds to achieve both high thermoelectric performance and appropriate thermal expansion behavior. Examples include complex alloys, nanostructured composites, and materials with tailored microstructures that can withstand thermal stresses while maintaining efficient energy conversion properties.Expand Specific Solutions03 Flexible and adaptive thermoelectric structures to accommodate thermal expansion

Design approaches for thermoelectric devices that can physically accommodate thermal expansion through flexible or adaptive structures. These designs include segmented elements, accordion-like structures, spring-loaded contacts, or elastically deformable components that can absorb dimensional changes during heating and cooling cycles. Such designs help maintain electrical contact and thermal interfaces despite the expansion and contraction of materials.Expand Specific Solutions04 Thermal expansion management in thermoelectric module fabrication

Manufacturing techniques and assembly methods specifically developed to address thermal expansion issues in thermoelectric modules. These include specialized bonding processes, stress-relieving structures, pre-stressing components, and assembly under controlled temperature conditions. The fabrication approaches focus on creating robust interfaces between different materials that can withstand repeated thermal cycling without degradation of electrical or thermal properties.Expand Specific Solutions05 Thermal expansion compensation systems for thermoelectric applications

Systems and methods that actively or passively compensate for thermal expansion in thermoelectric devices during operation. These include heat spreading structures, expansion joints, compensating elements with opposite expansion coefficients, and dynamic mounting systems. Such approaches help maintain optimal contact pressure, electrical connections, and heat transfer efficiency across varying temperature conditions, extending device lifetime and maintaining performance consistency.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Technology

The thermoelectric materials market is currently in a growth phase, with thermal expansion management representing a critical technical challenge. The market is projected to reach approximately $1.5 billion by 2027, driven by waste heat recovery applications in automotive and industrial sectors. Leading automotive manufacturers like BMW, Hyundai, and Continental are advancing thermal expansion solutions through proprietary material formulations. Research institutions including Kyoto University and The University of Sydney collaborate with industrial players such as Bosch, Siemens, and GlobalFoundries to develop composite materials with controlled expansion coefficients. Japanese corporations like Toshiba, NEC, and Kyocera demonstrate technological maturity through patented solutions addressing thermal cycling stability, while specialized companies like O-Flexx Technologies focus exclusively on thermoelectric optimization.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive approach to thermal expansion management in thermoelectric materials through their multi-layer composite structure technology. Their solution incorporates gradient-based material interfaces where the coefficient of thermal expansion (CTE) gradually changes between layers, reducing stress concentration at material boundaries. Bosch's thermoelectric generators (TEGs) utilize specialized buffer layers between the semiconductor elements and metal interconnects that accommodate differential expansion while maintaining electrical conductivity. The company has implemented advanced sintering techniques that create microstructural features capable of absorbing expansion-induced strain without compromising performance. Additionally, Bosch employs proprietary flexible interconnect designs that allow for controlled movement during thermal cycling while maintaining reliable electrical connections. Their systems incorporate active thermal management with precise temperature control algorithms that limit the rate of temperature change during operation, reducing thermal shock and associated mechanical stresses.

Strengths: Exceptional reliability under automotive thermal cycling conditions; integrated system approach combining materials science and electronic control; proven durability in harsh environments. Weaknesses: Higher manufacturing complexity increases production costs; requires specialized materials that may have limited suppliers; system performance optimization requires extensive calibration for each application environment.

Kyoto University

Technical Solution: Kyoto University researchers have developed an innovative nanostructured approach to managing thermal expansion in thermoelectric materials. Their technique involves creating controlled nanopores and precipitates within the thermoelectric matrix that serve as expansion accommodation sites. These engineered voids provide space for material expansion without generating destructive stresses. The university's research team has pioneered advanced powder metallurgy processes that create hierarchical structures with nano, micro, and meso-scale features that collectively manage thermal expansion across multiple length scales. Their materials incorporate specially designed grain boundaries that can slide or deform under thermal stress, effectively acting as internal strain relief mechanisms. Kyoto University has also developed novel composite thermoelectric materials with interpenetrating networks of phases having complementary thermal expansion coefficients, resulting in a bulk material with significantly reduced effective thermal expansion. Their approach includes the use of crystallographically aligned materials where the thermal expansion anisotropy is exploited to minimize expansion in critical directions while allowing it in non-critical directions.

Strengths: Fundamentally addresses thermal expansion at the material structure level rather than through mechanical accommodation; potential for lower manufacturing costs at scale; excellent performance retention after thermal cycling. Weaknesses: Currently at research/prototype stage rather than full commercial implementation; optimization required for specific application environments; may require specialized manufacturing equipment for precise nanostructure control.

Critical Patents and Research on Expansion-Resistant Materials

Thermoelectric element

PatentWO2020004827A1

Innovation

- A thermoelectric element assembly with a first resin layer and first electrodes at a low temperature section, and a second resin layer and second electrodes at a high temperature section, where the bonding strength between the first resin layer and first electrodes is significantly higher than between the second resin layer and second electrodes, with the second electrodes partially embedded in the second resin layer and grooves to accommodate thermal expansion.

Ceramic coating of high thermal expansion coefficient for thermoelectric materials

PatentInactiveUS3833387A

Innovation

- A protective ceramic coating composed of a dispersion of metal oxide in an enamel with high thermal expansion coefficients, where the metal oxide and enamel form a continuous matrix, providing a crystalline, impervious coating that matches the thermal expansion of thermoelectric materials, thus preventing sublimation and maintaining electrical properties for extended periods.

Environmental Impact and Sustainability Considerations

The environmental implications of addressing thermal expansion in thermoelectric materials extend far beyond technical considerations, encompassing significant sustainability dimensions. Thermoelectric materials typically contain elements such as tellurium, bismuth, lead, and antimony, many of which are classified as critical raw materials with limited global reserves. The manufacturing processes developed to mitigate thermal expansion issues often require additional materials and energy inputs, potentially increasing the overall environmental footprint of thermoelectric devices.

When evaluating thermal expansion solutions, lifecycle assessment becomes essential. Materials designed with complex microstructures or multi-layered compositions to manage thermal stress may present end-of-life recycling challenges. For instance, nanostructured thermoelectric materials that effectively manage thermal expansion often prove difficult to separate and recover at disposal stage, reducing circular economy potential.

Energy consumption during manufacturing represents another critical environmental consideration. High-temperature sintering processes commonly employed to create expansion-resistant thermoelectric materials can be energy-intensive, contributing to carbon emissions unless powered by renewable sources. Advanced manufacturing techniques like spark plasma sintering offer more energy-efficient alternatives but may involve trade-offs in material performance or production scale.

The operational environmental benefits of thermoelectric systems must be weighed against their production impacts. While these systems can recover waste heat and reduce fossil fuel consumption, their net environmental benefit depends on manufacturing efficiency and operational lifespan. Thermal expansion solutions that extend device longevity through improved mechanical stability directly enhance sustainability by amortizing production impacts over longer service periods.

Toxicity concerns also merit attention, particularly as many high-performance thermoelectric materials contain hazardous elements. Solutions involving less toxic alternatives like silicides or oxides may offer environmental advantages despite potentially lower thermoelectric performance. The development of lead-free alternatives represents a significant research direction aligned with global environmental regulations such as RoHS and REACH.

Water usage in manufacturing processes addressing thermal expansion should not be overlooked. Certain fabrication techniques require substantial water resources for cooling or chemical processing, raising concerns in water-stressed regions. Dry manufacturing methods and closed-loop water systems offer promising approaches to minimize this environmental impact while maintaining thermal expansion control.

When evaluating thermal expansion solutions, lifecycle assessment becomes essential. Materials designed with complex microstructures or multi-layered compositions to manage thermal stress may present end-of-life recycling challenges. For instance, nanostructured thermoelectric materials that effectively manage thermal expansion often prove difficult to separate and recover at disposal stage, reducing circular economy potential.

Energy consumption during manufacturing represents another critical environmental consideration. High-temperature sintering processes commonly employed to create expansion-resistant thermoelectric materials can be energy-intensive, contributing to carbon emissions unless powered by renewable sources. Advanced manufacturing techniques like spark plasma sintering offer more energy-efficient alternatives but may involve trade-offs in material performance or production scale.

The operational environmental benefits of thermoelectric systems must be weighed against their production impacts. While these systems can recover waste heat and reduce fossil fuel consumption, their net environmental benefit depends on manufacturing efficiency and operational lifespan. Thermal expansion solutions that extend device longevity through improved mechanical stability directly enhance sustainability by amortizing production impacts over longer service periods.

Toxicity concerns also merit attention, particularly as many high-performance thermoelectric materials contain hazardous elements. Solutions involving less toxic alternatives like silicides or oxides may offer environmental advantages despite potentially lower thermoelectric performance. The development of lead-free alternatives represents a significant research direction aligned with global environmental regulations such as RoHS and REACH.

Water usage in manufacturing processes addressing thermal expansion should not be overlooked. Certain fabrication techniques require substantial water resources for cooling or chemical processing, raising concerns in water-stressed regions. Dry manufacturing methods and closed-loop water systems offer promising approaches to minimize this environmental impact while maintaining thermal expansion control.

Reliability Testing and Performance Standards for Thermoelectric Systems

Reliability testing and performance standards are critical components in addressing thermal expansion challenges in thermoelectric materials. The industry has developed comprehensive testing protocols that specifically target the mechanical integrity of thermoelectric systems under thermal cycling conditions. These protocols typically include accelerated aging tests where materials are subjected to rapid temperature fluctuations between operational extremes, often ranging from -40°C to 150°C, to simulate years of service within weeks of testing.

Standard test methods such as ASTM D3045 for thermal stability and ISO 16750 for environmental conditions in automotive applications have been adapted specifically for thermoelectric materials. These standards provide benchmarks for evaluating how materials respond to thermal expansion stresses over time, with particular attention to interface integrity and mechanical fatigue.

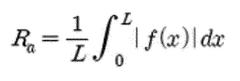

Performance degradation metrics have been established to quantify the impact of thermal expansion on thermoelectric efficiency. Key parameters include the Figure of Merit (ZT) stability under thermal cycling, electrical contact resistance changes, and mechanical strength retention. Industry standards typically require less than 10% degradation in ZT value after 1,000 thermal cycles to qualify materials for commercial applications.

Non-destructive evaluation techniques have become standard practice in reliability assessment. Acoustic emission testing, infrared thermography, and electrical impedance spectroscopy allow manufacturers to detect microcracks and delamination caused by thermal expansion mismatch before catastrophic failure occurs. These techniques have been standardized through organizations like IEEE and IEC to ensure consistency across the industry.

Qualification standards for thermoelectric modules in different application sectors vary significantly. Automotive-grade thermoelectric generators must meet stringent reliability standards such as AEC-Q100 for thermal shock resistance, while consumer electronics applications follow less rigorous JEDEC standards. Aerospace applications demand compliance with NASA outgassing specifications and military standards for thermal cycling resistance.

Accelerated life testing methodologies have been developed specifically for thermoelectric systems, incorporating Weibull statistical analysis to predict service life based on thermal expansion-induced failure modes. These methodologies typically employ the Coffin-Manson relationship to correlate thermal cycling with fatigue life, enabling manufacturers to provide warranty periods with statistical confidence.

International harmonization efforts are underway through organizations like the International Thermoelectric Society to establish unified global standards for reliability testing that specifically address thermal expansion challenges. These efforts aim to create consistent performance metrics and testing protocols that will facilitate global market access for thermoelectric technologies while ensuring reliable operation across diverse environmental conditions.

Standard test methods such as ASTM D3045 for thermal stability and ISO 16750 for environmental conditions in automotive applications have been adapted specifically for thermoelectric materials. These standards provide benchmarks for evaluating how materials respond to thermal expansion stresses over time, with particular attention to interface integrity and mechanical fatigue.

Performance degradation metrics have been established to quantify the impact of thermal expansion on thermoelectric efficiency. Key parameters include the Figure of Merit (ZT) stability under thermal cycling, electrical contact resistance changes, and mechanical strength retention. Industry standards typically require less than 10% degradation in ZT value after 1,000 thermal cycles to qualify materials for commercial applications.

Non-destructive evaluation techniques have become standard practice in reliability assessment. Acoustic emission testing, infrared thermography, and electrical impedance spectroscopy allow manufacturers to detect microcracks and delamination caused by thermal expansion mismatch before catastrophic failure occurs. These techniques have been standardized through organizations like IEEE and IEC to ensure consistency across the industry.

Qualification standards for thermoelectric modules in different application sectors vary significantly. Automotive-grade thermoelectric generators must meet stringent reliability standards such as AEC-Q100 for thermal shock resistance, while consumer electronics applications follow less rigorous JEDEC standards. Aerospace applications demand compliance with NASA outgassing specifications and military standards for thermal cycling resistance.

Accelerated life testing methodologies have been developed specifically for thermoelectric systems, incorporating Weibull statistical analysis to predict service life based on thermal expansion-induced failure modes. These methodologies typically employ the Coffin-Manson relationship to correlate thermal cycling with fatigue life, enabling manufacturers to provide warranty periods with statistical confidence.

International harmonization efforts are underway through organizations like the International Thermoelectric Society to establish unified global standards for reliability testing that specifically address thermal expansion challenges. These efforts aim to create consistent performance metrics and testing protocols that will facilitate global market access for thermoelectric technologies while ensuring reliable operation across diverse environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!