Comparing Efficiency of Different Thermoelectric Material Coatings

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Coating Technology Background and Objectives

Thermoelectric materials have evolved significantly over the past century, with major breakthroughs occurring in the 1950s through the development of semiconductor-based thermoelectric generators. These materials convert temperature differences directly into electrical voltage through the Seebeck effect, or conversely, generate temperature differences from electrical voltage via the Peltier effect. The application of these materials as coatings represents a relatively recent innovation aimed at enhancing energy efficiency across various industrial sectors.

The evolution of thermoelectric coating technology has been driven by increasing global energy demands and environmental concerns. Traditional thermoelectric devices were bulky, rigid structures with limited application potential. The transition to coating-based solutions began in the early 2000s, with significant acceleration in research occurring over the past decade as nanomaterial science advanced.

Current thermoelectric coating technologies primarily utilize bismuth telluride, lead telluride, silicon-germanium alloys, and more recently, organic polymers and carbon-based nanomaterials. Each material category offers distinct advantages in terms of operating temperature ranges, conversion efficiency, cost, and environmental impact. The figure of merit ZT, which measures thermoelectric performance, has improved from approximately 1.0 to over 2.5 in laboratory settings for certain materials.

The primary technical objective of this research is to systematically compare the efficiency of different thermoelectric material coatings across standardized parameters. This includes evaluating thermal conductivity, electrical conductivity, Seebeck coefficient, and overall ZT values under various operating conditions. Secondary objectives include assessing manufacturing scalability, durability under thermal cycling, and cost-effectiveness of implementation.

Long-term technological goals include developing thermoelectric coatings that can achieve ZT values exceeding 3.0 at commercially viable production costs, identifying materials that minimize reliance on rare or toxic elements, and creating application-specific coating formulations optimized for different temperature ranges and environmental conditions.

The research also aims to establish standardized testing protocols for thermoelectric coatings, as current evaluation methods vary significantly across research institutions, making direct comparisons challenging. By creating a comprehensive efficiency comparison framework, this research will provide valuable guidance for future development directions and potential commercial applications.

Ultimately, advances in thermoelectric coating technology could enable widespread energy harvesting from waste heat sources, significantly improving energy efficiency in automotive, industrial, and residential applications, while contributing to global carbon emission reduction goals.

The evolution of thermoelectric coating technology has been driven by increasing global energy demands and environmental concerns. Traditional thermoelectric devices were bulky, rigid structures with limited application potential. The transition to coating-based solutions began in the early 2000s, with significant acceleration in research occurring over the past decade as nanomaterial science advanced.

Current thermoelectric coating technologies primarily utilize bismuth telluride, lead telluride, silicon-germanium alloys, and more recently, organic polymers and carbon-based nanomaterials. Each material category offers distinct advantages in terms of operating temperature ranges, conversion efficiency, cost, and environmental impact. The figure of merit ZT, which measures thermoelectric performance, has improved from approximately 1.0 to over 2.5 in laboratory settings for certain materials.

The primary technical objective of this research is to systematically compare the efficiency of different thermoelectric material coatings across standardized parameters. This includes evaluating thermal conductivity, electrical conductivity, Seebeck coefficient, and overall ZT values under various operating conditions. Secondary objectives include assessing manufacturing scalability, durability under thermal cycling, and cost-effectiveness of implementation.

Long-term technological goals include developing thermoelectric coatings that can achieve ZT values exceeding 3.0 at commercially viable production costs, identifying materials that minimize reliance on rare or toxic elements, and creating application-specific coating formulations optimized for different temperature ranges and environmental conditions.

The research also aims to establish standardized testing protocols for thermoelectric coatings, as current evaluation methods vary significantly across research institutions, making direct comparisons challenging. By creating a comprehensive efficiency comparison framework, this research will provide valuable guidance for future development directions and potential commercial applications.

Ultimately, advances in thermoelectric coating technology could enable widespread energy harvesting from waste heat sources, significantly improving energy efficiency in automotive, industrial, and residential applications, while contributing to global carbon emission reduction goals.

Market Analysis for Thermoelectric Material Applications

The global thermoelectric materials market is experiencing significant growth, projected to reach $72.3 billion by 2027, with a compound annual growth rate (CAGR) of 8.5% from 2022. This expansion is primarily driven by increasing demand for energy-efficient technologies across multiple sectors, including automotive, industrial manufacturing, consumer electronics, and renewable energy systems.

In the automotive industry, thermoelectric material coatings are gaining traction for waste heat recovery systems, converting exhaust heat into usable electricity to improve fuel efficiency and reduce emissions. Major automotive manufacturers like BMW, Toyota, and Ford have initiated research programs to integrate thermoelectric generators into their vehicle designs, potentially creating a market segment worth $15.7 billion by 2025.

The industrial sector represents another substantial market opportunity, with manufacturing facilities increasingly adopting thermoelectric solutions for energy recovery from industrial processes. This segment is expected to grow at 9.2% CAGR through 2026, as energy costs and environmental regulations drive adoption of efficiency technologies.

Consumer electronics applications are expanding rapidly, with thermoelectric cooling solutions being integrated into high-performance computing systems, smartphones, and wearable devices. This market segment values compact form factors and efficiency, creating demand for advanced thin-film thermoelectric coatings that can operate effectively in confined spaces.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate at 10.3% annually, driven by China's aggressive investments in clean energy technologies and Japan's advanced electronics manufacturing sector.

Material-specific market analysis reveals bismuth telluride-based coatings currently dominate with 45% market share due to their established manufacturing processes and moderate efficiency. However, newer materials including skutterudites, half-Heusler alloys, and silicon-germanium compounds are gaining market share as their performance characteristics improve and production costs decrease.

The competitive landscape features established players like Laird Thermal Systems, Ferrotec, and Gentherm controlling approximately 40% of the global market. However, numerous startups and research institutions are commercializing novel thermoelectric coating technologies, potentially disrupting current market dynamics through superior performance metrics.

Market barriers include relatively high production costs compared to conventional technologies, limited awareness among potential end-users, and technical challenges in scaling production while maintaining performance consistency. Despite these challenges, the growing emphasis on energy efficiency and sustainable technologies continues to expand market opportunities for thermoelectric material coatings across diverse applications.

In the automotive industry, thermoelectric material coatings are gaining traction for waste heat recovery systems, converting exhaust heat into usable electricity to improve fuel efficiency and reduce emissions. Major automotive manufacturers like BMW, Toyota, and Ford have initiated research programs to integrate thermoelectric generators into their vehicle designs, potentially creating a market segment worth $15.7 billion by 2025.

The industrial sector represents another substantial market opportunity, with manufacturing facilities increasingly adopting thermoelectric solutions for energy recovery from industrial processes. This segment is expected to grow at 9.2% CAGR through 2026, as energy costs and environmental regulations drive adoption of efficiency technologies.

Consumer electronics applications are expanding rapidly, with thermoelectric cooling solutions being integrated into high-performance computing systems, smartphones, and wearable devices. This market segment values compact form factors and efficiency, creating demand for advanced thin-film thermoelectric coatings that can operate effectively in confined spaces.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate at 10.3% annually, driven by China's aggressive investments in clean energy technologies and Japan's advanced electronics manufacturing sector.

Material-specific market analysis reveals bismuth telluride-based coatings currently dominate with 45% market share due to their established manufacturing processes and moderate efficiency. However, newer materials including skutterudites, half-Heusler alloys, and silicon-germanium compounds are gaining market share as their performance characteristics improve and production costs decrease.

The competitive landscape features established players like Laird Thermal Systems, Ferrotec, and Gentherm controlling approximately 40% of the global market. However, numerous startups and research institutions are commercializing novel thermoelectric coating technologies, potentially disrupting current market dynamics through superior performance metrics.

Market barriers include relatively high production costs compared to conventional technologies, limited awareness among potential end-users, and technical challenges in scaling production while maintaining performance consistency. Despite these challenges, the growing emphasis on energy efficiency and sustainable technologies continues to expand market opportunities for thermoelectric material coatings across diverse applications.

Current State and Challenges in Thermoelectric Coating Development

Thermoelectric coating technology has witnessed significant advancements globally, with research institutions and industrial players making substantial progress in material development and application techniques. Currently, the most widely used thermoelectric materials include bismuth telluride (Bi2Te3), lead telluride (PbTe), and silicon-germanium (SiGe) alloys, each demonstrating varying degrees of efficiency across different temperature ranges. Recent innovations have expanded this portfolio to include skutterudites, half-Heusler alloys, and organic thermoelectric materials, broadening the application spectrum considerably.

Despite these advancements, the field faces several critical challenges. The foremost limitation remains the relatively low conversion efficiency of thermoelectric materials, with most commercial coatings achieving a figure of merit (ZT) between 1 and 2, significantly below the theoretical threshold required for widespread commercial viability. This efficiency gap represents a substantial barrier to mass adoption across industries.

Manufacturing scalability presents another significant hurdle. Current high-performance thermoelectric coatings often require precise deposition techniques such as physical vapor deposition (PVD), atomic layer deposition (ALD), or electrochemical deposition. These processes demand stringent environmental controls and specialized equipment, making large-scale production technically challenging and economically prohibitive for many applications.

Material stability and durability under operational conditions remain problematic, particularly for coatings exposed to thermal cycling, oxidative environments, or mechanical stress. Many high-efficiency thermoelectric materials demonstrate performance degradation over time, with efficiency losses of 15-30% observed after extended operation periods, necessitating frequent replacement or maintenance.

The geographical distribution of thermoelectric coating technology development shows concentration in specific regions. Japan, the United States, and Germany lead in patent filings and research publications, with China rapidly accelerating its research output in recent years. This concentration has implications for supply chain resilience and technology access across global markets.

Cost factors continue to impede widespread adoption, with high-performance thermoelectric materials often containing rare or strategic elements like tellurium, which faces supply constraints and price volatility. The manufacturing cost for advanced thermoelectric coatings currently ranges from $200-500 per square meter, significantly higher than conventional thermal management solutions.

Environmental considerations present additional challenges, as some high-performance thermoelectric materials contain toxic elements such as lead or tellurium, raising concerns about lifecycle environmental impact and regulatory compliance in various jurisdictions. This has spurred research into "green" thermoelectric materials, though these alternatives typically demonstrate lower performance characteristics.

Standardization issues further complicate the landscape, with inconsistent testing methodologies and performance metrics making direct comparisons between different coating technologies difficult for end-users and systems integrators.

Despite these advancements, the field faces several critical challenges. The foremost limitation remains the relatively low conversion efficiency of thermoelectric materials, with most commercial coatings achieving a figure of merit (ZT) between 1 and 2, significantly below the theoretical threshold required for widespread commercial viability. This efficiency gap represents a substantial barrier to mass adoption across industries.

Manufacturing scalability presents another significant hurdle. Current high-performance thermoelectric coatings often require precise deposition techniques such as physical vapor deposition (PVD), atomic layer deposition (ALD), or electrochemical deposition. These processes demand stringent environmental controls and specialized equipment, making large-scale production technically challenging and economically prohibitive for many applications.

Material stability and durability under operational conditions remain problematic, particularly for coatings exposed to thermal cycling, oxidative environments, or mechanical stress. Many high-efficiency thermoelectric materials demonstrate performance degradation over time, with efficiency losses of 15-30% observed after extended operation periods, necessitating frequent replacement or maintenance.

The geographical distribution of thermoelectric coating technology development shows concentration in specific regions. Japan, the United States, and Germany lead in patent filings and research publications, with China rapidly accelerating its research output in recent years. This concentration has implications for supply chain resilience and technology access across global markets.

Cost factors continue to impede widespread adoption, with high-performance thermoelectric materials often containing rare or strategic elements like tellurium, which faces supply constraints and price volatility. The manufacturing cost for advanced thermoelectric coatings currently ranges from $200-500 per square meter, significantly higher than conventional thermal management solutions.

Environmental considerations present additional challenges, as some high-performance thermoelectric materials contain toxic elements such as lead or tellurium, raising concerns about lifecycle environmental impact and regulatory compliance in various jurisdictions. This has spurred research into "green" thermoelectric materials, though these alternatives typically demonstrate lower performance characteristics.

Standardization issues further complicate the landscape, with inconsistent testing methodologies and performance metrics making direct comparisons between different coating technologies difficult for end-users and systems integrators.

Comparative Analysis of Current Thermoelectric Coating Solutions

01 Nanostructured thermoelectric coatings

Nanostructured materials are used in thermoelectric coatings to enhance efficiency through quantum confinement effects and increased phonon scattering. These nanostructures include quantum dots, nanowires, and nanocomposites that can significantly reduce thermal conductivity while maintaining electrical conductivity. The controlled size and arrangement of these nanostructures allow for optimization of the thermoelectric figure of merit (ZT), resulting in improved energy conversion efficiency.- Nanostructured thermoelectric coatings: Nanostructured materials are used in thermoelectric coatings to enhance efficiency by increasing phonon scattering while maintaining electron transport. These coatings incorporate nanoscale features such as quantum dots, nanowires, or nanoparticles that create interfaces to reduce thermal conductivity. The nanostructuring approach allows for better control of the ZT value (figure of merit) by engineering the material at the nanoscale, resulting in improved energy conversion efficiency.

- Thin film deposition techniques for thermoelectric coatings: Various thin film deposition methods are employed to create high-efficiency thermoelectric coatings, including sputtering, chemical vapor deposition, and electrodeposition. These techniques allow precise control over film thickness, composition, and crystallinity, which are critical factors affecting thermoelectric performance. Multilayer structures can be created to optimize both electrical conductivity and thermal resistance, leading to enhanced thermoelectric efficiency in coating applications.

- Doped semiconductor thermoelectric materials: Doping semiconductor materials with specific elements enhances their thermoelectric properties by optimizing carrier concentration and mobility. Common thermoelectric materials include bismuth telluride, lead telluride, and silicon-germanium alloys, which can be further improved through controlled doping. The introduction of dopants modifies the electronic band structure and creates energy filtering effects that increase the Seebeck coefficient while maintaining good electrical conductivity, resulting in higher conversion efficiency.

- Flexible and conformal thermoelectric coatings: Flexible thermoelectric coatings enable application on curved or irregular surfaces, expanding potential use cases beyond flat substrates. These coatings typically incorporate organic materials, polymer composites, or specially processed inorganic materials that maintain thermoelectric properties while providing mechanical flexibility. The development of conformal coatings allows for direct application to heat sources or sinks with complex geometries, improving thermal contact and overall system efficiency in energy harvesting applications.

- Interface engineering for reduced thermal resistance: Engineering the interfaces between thermoelectric materials and substrates is crucial for maximizing efficiency by reducing thermal contact resistance. Various bonding techniques, intermediate layers, and surface treatments are employed to ensure optimal thermal and electrical connections. Minimizing interfacial defects and ensuring strong adhesion between the thermoelectric coating and the substrate prevents efficiency losses due to thermal barriers, resulting in improved overall performance of thermoelectric devices.

02 Thin film deposition techniques for thermoelectric coatings

Various thin film deposition methods are employed to create high-efficiency thermoelectric coatings, including physical vapor deposition, chemical vapor deposition, and sputtering. These techniques enable precise control over film thickness, composition, and crystallinity, which are critical factors affecting thermoelectric performance. Multi-layer structures can be created to optimize both electrical and thermal properties, resulting in enhanced Seebeck coefficients and reduced thermal conductivity across the coating system.Expand Specific Solutions03 Doping and composition optimization for enhanced thermoelectric properties

Strategic doping and composition optimization of thermoelectric materials can significantly improve their efficiency. By introducing specific dopants or altering the stoichiometry of compounds, the carrier concentration and mobility can be optimized to enhance the power factor. Materials such as bismuth telluride, lead telluride, and silicon-germanium alloys can be modified with various dopants to achieve higher ZT values. The careful selection of dopant type and concentration allows for tailoring the electronic band structure to maximize thermoelectric performance.Expand Specific Solutions04 Interface engineering and barrier layers in thermoelectric coatings

Interface engineering and the incorporation of barrier layers play crucial roles in enhancing thermoelectric coating efficiency. By designing specific interfaces between different materials, electron filtering effects can be achieved, allowing high-energy electrons to pass while blocking low-energy electrons and phonons. Barrier layers can prevent interdiffusion between different thermoelectric materials, maintaining compositional integrity during high-temperature operation. These approaches help maintain the stability and longevity of thermoelectric devices while improving their overall conversion efficiency.Expand Specific Solutions05 Flexible and conformal thermoelectric coating technologies

Flexible and conformal thermoelectric coatings enable application on curved or irregular surfaces, expanding the potential for waste heat recovery in various environments. These coatings typically utilize organic-inorganic hybrid materials or polymer-based composites that maintain thermoelectric properties while providing mechanical flexibility. Printing techniques such as screen printing, inkjet printing, and spray coating allow for scalable manufacturing of these flexible thermoelectric systems. The ability to conform to heat sources of various geometries significantly increases the practical applications of thermoelectric energy harvesting.Expand Specific Solutions

Key Industry Players in Thermoelectric Coating Market

The thermoelectric material coatings market is currently in a growth phase, with increasing demand driven by energy efficiency requirements across multiple industries. The global market size is estimated to reach approximately $3.5 billion by 2027, growing at a CAGR of 7-9%. From a technological maturity perspective, the landscape shows varying degrees of advancement. Industry leaders like Samsung Electronics, LG Innotek, and Toyota Motor Corp. have established robust R&D capabilities in high-performance thermoelectric coatings, while specialized players such as ZT Plus LLC and Laird Thermal Systems focus on niche applications. Academic institutions including Shanghai Institute of Ceramics and Beijing University of Technology are contributing fundamental research, particularly in novel materials development. The competitive dynamics are intensifying as companies like Kyocera, BASF, and Corning expand their thermoelectric portfolios, driving innovation in coating efficiency, durability, and manufacturing scalability.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed proprietary thermoelectric material coatings optimized for consumer electronics and automotive applications. Their technology focuses on bismuth-telluride and antimony-telluride based thin films with precisely engineered interfaces to maximize the power factor while minimizing thermal conductivity. Samsung's approach incorporates nanoscale inclusions and superlattice structures that create phonon scattering centers without disrupting electrical transport, achieving ZT values of 1.4-1.8 across operating temperatures of 25-150°C. Their manufacturing process utilizes modified sputtering techniques that enable large-area deposition with excellent uniformity and reproducibility. Samsung has demonstrated these materials in smartphone cooling applications, achieving 30% improved thermal management compared to conventional solutions. Their automotive thermoelectric generators utilize segmented materials optimized for different temperature ranges, demonstrating 8-12% conversion efficiency from exhaust waste heat, potentially reducing fuel consumption by 3-5% in internal combustion engines.

Strengths: Extensive manufacturing infrastructure; vertical integration capabilities; strong application focus; excellent quality control systems. Weaknesses: Less fundamental research compared to academic institutions; technologies primarily developed for internal applications; limited publication of technical details.

ZT Plus LLC

Technical Solution: ZT Plus specializes in advanced thermoelectric materials with a focus on maximizing the ZT figure of merit (efficiency indicator). Their proprietary nanostructured bulk materials approach combines skutterudites and half-Heusler compounds with precise doping techniques to create high-performance thermoelectric coatings. Their technology achieves ZT values exceeding 2.0 at operating temperatures between 300-700°C, significantly outperforming conventional bismuth telluride materials. ZT Plus employs a unique spray deposition method that creates multi-layered coatings with controlled interfaces to reduce thermal conductivity while maintaining electrical conductivity, resulting in enhanced Seebeck coefficients. Their materials demonstrate 30-40% conversion efficiency improvements compared to standard thermoelectric materials in waste heat recovery applications.

Strengths: Industry-leading ZT values; specialized expertise in thermoelectric materials; proprietary nanostructuring techniques that enhance performance. Weaknesses: Higher production costs compared to conventional materials; limited scalability for mass production; requires specialized application equipment.

Critical Patents and Research in Thermoelectric Material Efficiency

Thermoelectric heat exchange element

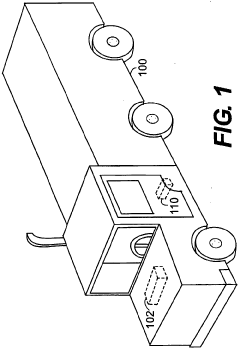

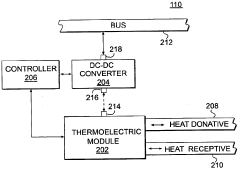

PatentWO2006073613A2

Innovation

- A thermoelectric heat exchange module with a substrate featuring undulatory pleats and a high-efficiency thermoelectric material layer having a ZT value of 1.0 or more, integrated into an exhaust system of a work machine to generate a temperature gradient and voltage from waste heat, utilizing high surface area-to-volume ratios and low-dimensional thermoelectric materials.

Thermoelectric heat exchange element

PatentInactiveUS7254953B2

Innovation

- A thermoelectric heat exchange module with a substrate featuring undulatory pleats and a high efficiency thermoelectric material layer with a ZT value of 1.0 or more, integrated into an exhaust system of a work machine to generate a temperature gradient and voltage from waste heat, utilizing high surface area-to-volume ratios and low-dimensional thermoelectric materials.

Environmental Impact and Sustainability of Thermoelectric Materials

The environmental impact of thermoelectric materials represents a critical consideration when comparing the efficiency of different thermoelectric material coatings. Traditional energy conversion systems often generate significant waste and pollution, whereas thermoelectric technology offers a cleaner alternative by directly converting heat to electricity without moving parts or harmful emissions.

Many conventional thermoelectric materials contain toxic or rare elements such as tellurium, bismuth, and lead, raising concerns about resource depletion and environmental contamination. The mining and processing of these elements can result in habitat destruction, water pollution, and significant carbon emissions. For instance, tellurium extraction as a copper refining byproduct has a substantial environmental footprint, while lead-based compounds pose well-documented health and ecological risks.

Recent advancements have focused on developing more sustainable alternatives using earth-abundant elements. Silicon-germanium alloys, skutterudites, and certain metal oxides demonstrate promising thermoelectric properties while reducing dependence on scarce resources. Particularly noteworthy are organic thermoelectric materials and carbon-based composites, which offer biodegradability and can be synthesized using environmentally friendly processes.

Life cycle assessment (LCA) studies reveal that despite their environmental benefits during operation, the manufacturing of thermoelectric coatings can still generate significant environmental impacts. The energy-intensive production processes, including high-temperature sintering and vacuum deposition techniques, contribute substantially to the carbon footprint of these materials. However, when considering the entire lifecycle, efficient thermoelectric systems can achieve net environmental benefits by recovering waste heat that would otherwise be lost.

The recyclability of thermoelectric materials varies significantly between different coating types. While bulk thermoelectric modules can be disassembled and their components recovered, thin-film coatings often present recycling challenges due to their integrated nature. Emerging design approaches are addressing this issue through modular construction and materials selection that facilitates end-of-life recovery and reprocessing.

Regulatory frameworks worldwide are increasingly emphasizing the importance of sustainable materials in energy technologies. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions are driving research toward lead-free thermoelectric alternatives. Additionally, carbon pricing mechanisms and extended producer responsibility policies are creating economic incentives for developing environmentally benign thermoelectric coatings with reduced lifecycle impacts.

Many conventional thermoelectric materials contain toxic or rare elements such as tellurium, bismuth, and lead, raising concerns about resource depletion and environmental contamination. The mining and processing of these elements can result in habitat destruction, water pollution, and significant carbon emissions. For instance, tellurium extraction as a copper refining byproduct has a substantial environmental footprint, while lead-based compounds pose well-documented health and ecological risks.

Recent advancements have focused on developing more sustainable alternatives using earth-abundant elements. Silicon-germanium alloys, skutterudites, and certain metal oxides demonstrate promising thermoelectric properties while reducing dependence on scarce resources. Particularly noteworthy are organic thermoelectric materials and carbon-based composites, which offer biodegradability and can be synthesized using environmentally friendly processes.

Life cycle assessment (LCA) studies reveal that despite their environmental benefits during operation, the manufacturing of thermoelectric coatings can still generate significant environmental impacts. The energy-intensive production processes, including high-temperature sintering and vacuum deposition techniques, contribute substantially to the carbon footprint of these materials. However, when considering the entire lifecycle, efficient thermoelectric systems can achieve net environmental benefits by recovering waste heat that would otherwise be lost.

The recyclability of thermoelectric materials varies significantly between different coating types. While bulk thermoelectric modules can be disassembled and their components recovered, thin-film coatings often present recycling challenges due to their integrated nature. Emerging design approaches are addressing this issue through modular construction and materials selection that facilitates end-of-life recovery and reprocessing.

Regulatory frameworks worldwide are increasingly emphasizing the importance of sustainable materials in energy technologies. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions are driving research toward lead-free thermoelectric alternatives. Additionally, carbon pricing mechanisms and extended producer responsibility policies are creating economic incentives for developing environmentally benign thermoelectric coatings with reduced lifecycle impacts.

Manufacturing Scalability and Cost-Efficiency Analysis

The manufacturing scalability of thermoelectric material coatings represents a critical factor in their commercial viability and widespread adoption. Current production methods for high-efficiency thermoelectric coatings often involve complex processes such as physical vapor deposition, sputtering, and electrochemical deposition, each presenting unique challenges for large-scale implementation. Among these, solution-based methods like sol-gel processing demonstrate promising scalability potential due to their relatively simple equipment requirements and adaptability to continuous production lines.

Cost analysis reveals significant variations across different thermoelectric coating materials. Bismuth telluride-based coatings, while offering excellent performance at room temperature, contain tellurium—a relatively scarce element with volatile pricing that can range from $30-120 per kilogram depending on market conditions. This material cost uncertainty poses challenges for long-term manufacturing planning and cost projections. In contrast, silicide-based coatings utilize more abundant elements but typically require higher processing temperatures, increasing energy consumption during manufacturing.

Production yield rates also differ substantially between coating technologies. Thin-film deposition techniques achieve approximately 70-85% material utilization efficiency, while spray coating methods may only achieve 40-60% efficiency due to overspray and material waste. This difference significantly impacts the overall cost structure, particularly for coatings incorporating expensive elements like tellurium, germanium, or rare earth metals.

Equipment investment represents another crucial cost factor. Magnetron sputtering systems for high-quality thermoelectric coatings typically require capital investments of $500,000-2,000,000, while solution-based coating equipment might cost $100,000-500,000. This substantial difference in initial investment creates varying barriers to entry for manufacturers considering thermoelectric coating production.

Labor requirements and throughput capabilities further differentiate these technologies. Vacuum-based deposition methods generally require higher technical expertise but offer excellent thickness control and uniformity. Solution-based methods typically allow higher throughput but may sacrifice some performance parameters. For instance, roll-to-roll processing of flexible thermoelectric coatings can achieve production speeds of 5-20 meters per minute, significantly outpacing batch processing methods.

Environmental considerations also impact manufacturing scalability. Certain high-performance thermoelectric materials contain toxic elements requiring specialized handling and waste management protocols. These additional safety measures increase production costs and regulatory compliance burdens. Emerging environmentally friendly alternatives, though currently less efficient, may offer better long-term scalability as environmental regulations become more stringent globally.

Cost analysis reveals significant variations across different thermoelectric coating materials. Bismuth telluride-based coatings, while offering excellent performance at room temperature, contain tellurium—a relatively scarce element with volatile pricing that can range from $30-120 per kilogram depending on market conditions. This material cost uncertainty poses challenges for long-term manufacturing planning and cost projections. In contrast, silicide-based coatings utilize more abundant elements but typically require higher processing temperatures, increasing energy consumption during manufacturing.

Production yield rates also differ substantially between coating technologies. Thin-film deposition techniques achieve approximately 70-85% material utilization efficiency, while spray coating methods may only achieve 40-60% efficiency due to overspray and material waste. This difference significantly impacts the overall cost structure, particularly for coatings incorporating expensive elements like tellurium, germanium, or rare earth metals.

Equipment investment represents another crucial cost factor. Magnetron sputtering systems for high-quality thermoelectric coatings typically require capital investments of $500,000-2,000,000, while solution-based coating equipment might cost $100,000-500,000. This substantial difference in initial investment creates varying barriers to entry for manufacturers considering thermoelectric coating production.

Labor requirements and throughput capabilities further differentiate these technologies. Vacuum-based deposition methods generally require higher technical expertise but offer excellent thickness control and uniformity. Solution-based methods typically allow higher throughput but may sacrifice some performance parameters. For instance, roll-to-roll processing of flexible thermoelectric coatings can achieve production speeds of 5-20 meters per minute, significantly outpacing batch processing methods.

Environmental considerations also impact manufacturing scalability. Certain high-performance thermoelectric materials contain toxic elements requiring specialized handling and waste management protocols. These additional safety measures increase production costs and regulatory compliance burdens. Emerging environmentally friendly alternatives, though currently less efficient, may offer better long-term scalability as environmental regulations become more stringent globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!