Thermoelectric Materials and Graphene Composites: Analysis

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Evolution and Research Objectives

Thermoelectric materials have evolved significantly since their discovery in the early 19th century. The Seebeck effect, discovered by Thomas Johann Seebeck in 1821, laid the foundation for thermoelectric technology by demonstrating that a temperature difference between two dissimilar electrical conductors produces a voltage difference. This fundamental principle has driven research in thermoelectric materials for nearly two centuries, with significant advancements occurring particularly in the last few decades.

The evolution of thermoelectric materials can be categorized into three distinct generations. First-generation materials, primarily based on bismuth telluride (Bi₂Te₃) and lead telluride (PbTe), dominated the field until the 1990s with modest efficiency values (ZT~1). Second-generation materials emerged with the introduction of nanostructuring techniques, which significantly enhanced phonon scattering while maintaining electron transport, pushing ZT values to approximately 1.5-2.0.

Current third-generation thermoelectric materials incorporate complex crystal structures and advanced material engineering approaches, including hierarchical architectures and band engineering. These innovations have resulted in materials with ZT values exceeding 2.0 in laboratory settings, representing a substantial improvement in conversion efficiency.

Graphene's discovery in 2004 opened new avenues for thermoelectric research. Its exceptional electrical conductivity, coupled with the ability to manipulate its thermal properties through various composite formations, has positioned graphene-based composites as promising candidates for next-generation thermoelectric applications. Recent research has demonstrated that graphene/polymer composites can achieve enhanced power factors while maintaining low thermal conductivity, addressing the fundamental challenge in thermoelectric material development.

The primary research objectives in thermoelectric materials and graphene composites focus on several key areas. First, increasing the figure of merit (ZT) beyond current limitations through novel material combinations and nanostructuring approaches. Second, developing environmentally friendly alternatives to traditional thermoelectric materials that often contain toxic or rare elements. Third, enhancing the mechanical flexibility and durability of thermoelectric devices to expand their application range.

Additionally, research aims to reduce production costs to make thermoelectric technology economically viable for widespread commercial applications. This includes exploring scalable manufacturing processes for graphene-based thermoelectric composites. Finally, there is significant interest in developing materials optimized for specific temperature ranges, particularly for room-temperature applications where most waste heat is generated in industrial and consumer settings.

The convergence of thermoelectric research with graphene technology represents a promising frontier with potential applications ranging from wearable electronics to industrial waste heat recovery systems, driving continued innovation in this field.

The evolution of thermoelectric materials can be categorized into three distinct generations. First-generation materials, primarily based on bismuth telluride (Bi₂Te₃) and lead telluride (PbTe), dominated the field until the 1990s with modest efficiency values (ZT~1). Second-generation materials emerged with the introduction of nanostructuring techniques, which significantly enhanced phonon scattering while maintaining electron transport, pushing ZT values to approximately 1.5-2.0.

Current third-generation thermoelectric materials incorporate complex crystal structures and advanced material engineering approaches, including hierarchical architectures and band engineering. These innovations have resulted in materials with ZT values exceeding 2.0 in laboratory settings, representing a substantial improvement in conversion efficiency.

Graphene's discovery in 2004 opened new avenues for thermoelectric research. Its exceptional electrical conductivity, coupled with the ability to manipulate its thermal properties through various composite formations, has positioned graphene-based composites as promising candidates for next-generation thermoelectric applications. Recent research has demonstrated that graphene/polymer composites can achieve enhanced power factors while maintaining low thermal conductivity, addressing the fundamental challenge in thermoelectric material development.

The primary research objectives in thermoelectric materials and graphene composites focus on several key areas. First, increasing the figure of merit (ZT) beyond current limitations through novel material combinations and nanostructuring approaches. Second, developing environmentally friendly alternatives to traditional thermoelectric materials that often contain toxic or rare elements. Third, enhancing the mechanical flexibility and durability of thermoelectric devices to expand their application range.

Additionally, research aims to reduce production costs to make thermoelectric technology economically viable for widespread commercial applications. This includes exploring scalable manufacturing processes for graphene-based thermoelectric composites. Finally, there is significant interest in developing materials optimized for specific temperature ranges, particularly for room-temperature applications where most waste heat is generated in industrial and consumer settings.

The convergence of thermoelectric research with graphene technology represents a promising frontier with potential applications ranging from wearable electronics to industrial waste heat recovery systems, driving continued innovation in this field.

Market Analysis for Thermoelectric and Graphene Applications

The thermoelectric materials market is experiencing significant growth, driven by increasing demand for energy-efficient technologies and waste heat recovery systems. Current market valuations place the global thermoelectric materials sector at approximately 55 million USD in 2023, with projections indicating growth to reach 95 million USD by 2028, representing a compound annual growth rate (CAGR) of 11.6%. This growth trajectory is supported by expanding applications across automotive, industrial, consumer electronics, and aerospace sectors.

The automotive industry represents the largest application segment, accounting for nearly 35% of the total market share. Thermoelectric generators (TEGs) are increasingly being integrated into vehicle exhaust systems to convert waste heat into usable electricity, improving fuel efficiency by 3-5% in conventional vehicles. Major automotive manufacturers including BMW, Ford, and Toyota have active development programs for thermoelectric systems.

In the industrial sector, thermoelectric solutions for waste heat recovery from manufacturing processes, power plants, and industrial furnaces represent a rapidly growing market segment with 15% annual growth. The ability to convert low-grade waste heat (below 200°C) into electricity provides significant energy savings and supports sustainability initiatives.

Consumer electronics applications, particularly in cooling solutions for processors and portable refrigeration, constitute approximately 20% of the market. The miniaturization trend in electronics has created demand for compact, reliable cooling solutions without moving parts, where thermoelectric modules excel.

The graphene composites market intersects with thermoelectric applications, showing promising growth with current valuations at 38 million USD and expected to reach 87 million USD by 2028 (CAGR of 18%). Graphene-enhanced thermoelectric materials demonstrate 25-40% higher figure of merit (ZT) values compared to conventional materials, significantly improving conversion efficiency.

Regional analysis reveals North America leads the market with 38% share, followed by Asia-Pacific at 35%, which is growing at the fastest rate due to increasing industrial activities and electronics manufacturing. Europe accounts for 22% of the market, with particular focus on automotive applications.

Key market challenges include high material costs, with high-performance thermoelectric materials like bismuth telluride costing 200-300 USD per kilogram, and manufacturing complexities that limit mass production capabilities. Additionally, efficiency limitations of current materials (ZT values typically below 2) restrict broader commercial adoption.

Market opportunities are emerging in wearable thermoelectric generators, building energy management systems, and space applications, where the reliability and longevity of thermoelectric systems provide distinct advantages over alternative technologies.

The automotive industry represents the largest application segment, accounting for nearly 35% of the total market share. Thermoelectric generators (TEGs) are increasingly being integrated into vehicle exhaust systems to convert waste heat into usable electricity, improving fuel efficiency by 3-5% in conventional vehicles. Major automotive manufacturers including BMW, Ford, and Toyota have active development programs for thermoelectric systems.

In the industrial sector, thermoelectric solutions for waste heat recovery from manufacturing processes, power plants, and industrial furnaces represent a rapidly growing market segment with 15% annual growth. The ability to convert low-grade waste heat (below 200°C) into electricity provides significant energy savings and supports sustainability initiatives.

Consumer electronics applications, particularly in cooling solutions for processors and portable refrigeration, constitute approximately 20% of the market. The miniaturization trend in electronics has created demand for compact, reliable cooling solutions without moving parts, where thermoelectric modules excel.

The graphene composites market intersects with thermoelectric applications, showing promising growth with current valuations at 38 million USD and expected to reach 87 million USD by 2028 (CAGR of 18%). Graphene-enhanced thermoelectric materials demonstrate 25-40% higher figure of merit (ZT) values compared to conventional materials, significantly improving conversion efficiency.

Regional analysis reveals North America leads the market with 38% share, followed by Asia-Pacific at 35%, which is growing at the fastest rate due to increasing industrial activities and electronics manufacturing. Europe accounts for 22% of the market, with particular focus on automotive applications.

Key market challenges include high material costs, with high-performance thermoelectric materials like bismuth telluride costing 200-300 USD per kilogram, and manufacturing complexities that limit mass production capabilities. Additionally, efficiency limitations of current materials (ZT values typically below 2) restrict broader commercial adoption.

Market opportunities are emerging in wearable thermoelectric generators, building energy management systems, and space applications, where the reliability and longevity of thermoelectric systems provide distinct advantages over alternative technologies.

Current Challenges in Thermoelectric-Graphene Composite Development

Despite significant advancements in thermoelectric-graphene composite development, several critical challenges continue to impede widespread commercial adoption and optimal performance. One of the primary obstacles remains the interface engineering between graphene and thermoelectric materials. The thermal and electrical contact resistance at these interfaces significantly reduces overall energy conversion efficiency, with current composites achieving only 30-40% of their theoretical performance potential.

Manufacturing scalability presents another substantial hurdle. Laboratory-scale production methods for high-quality graphene-thermoelectric composites often involve complex, multi-step processes that are difficult to scale industrially. Techniques such as chemical vapor deposition produce high-quality graphene but remain prohibitively expensive for mass production, while solution-based methods yield materials with higher defect densities that compromise thermoelectric performance.

Thermal stability and long-term reliability under operational conditions continue to challenge researchers. Many thermoelectric-graphene composites exhibit performance degradation when subjected to thermal cycling or sustained high-temperature operation. This degradation often stems from microstructural changes, interfacial delamination, or oxidation of graphene sheets, particularly in non-vacuum environments typical of real-world applications.

Material compatibility issues further complicate development efforts. The chemical and physical interactions between graphene and various thermoelectric materials (such as Bi2Te3, PbTe, or skutterudites) vary significantly, requiring tailored synthesis approaches for each material system. This diversity hampers the development of standardized manufacturing protocols and increases production complexity.

Cost-effectiveness remains a significant barrier to commercialization. Current production methods for high-performance thermoelectric-graphene composites involve expensive precursors, energy-intensive processing, and sophisticated equipment. The resulting materials often cannot compete economically with conventional technologies, despite their superior technical performance in laboratory settings.

Characterization and modeling challenges also persist. The multi-scale nature of these composites—from atomic-level interfaces to macroscopic device properties—makes comprehensive characterization difficult. Existing theoretical models often fail to accurately predict composite behavior, particularly regarding phonon and electron transport across interfaces, limiting design optimization capabilities.

Environmental and regulatory concerns present additional obstacles. Some high-performance thermoelectric materials contain toxic or restricted elements like lead or tellurium, while graphene nanomaterials face evolving regulatory scrutiny regarding potential environmental and health impacts, creating uncertainty for commercial development pathways.

Manufacturing scalability presents another substantial hurdle. Laboratory-scale production methods for high-quality graphene-thermoelectric composites often involve complex, multi-step processes that are difficult to scale industrially. Techniques such as chemical vapor deposition produce high-quality graphene but remain prohibitively expensive for mass production, while solution-based methods yield materials with higher defect densities that compromise thermoelectric performance.

Thermal stability and long-term reliability under operational conditions continue to challenge researchers. Many thermoelectric-graphene composites exhibit performance degradation when subjected to thermal cycling or sustained high-temperature operation. This degradation often stems from microstructural changes, interfacial delamination, or oxidation of graphene sheets, particularly in non-vacuum environments typical of real-world applications.

Material compatibility issues further complicate development efforts. The chemical and physical interactions between graphene and various thermoelectric materials (such as Bi2Te3, PbTe, or skutterudites) vary significantly, requiring tailored synthesis approaches for each material system. This diversity hampers the development of standardized manufacturing protocols and increases production complexity.

Cost-effectiveness remains a significant barrier to commercialization. Current production methods for high-performance thermoelectric-graphene composites involve expensive precursors, energy-intensive processing, and sophisticated equipment. The resulting materials often cannot compete economically with conventional technologies, despite their superior technical performance in laboratory settings.

Characterization and modeling challenges also persist. The multi-scale nature of these composites—from atomic-level interfaces to macroscopic device properties—makes comprehensive characterization difficult. Existing theoretical models often fail to accurately predict composite behavior, particularly regarding phonon and electron transport across interfaces, limiting design optimization capabilities.

Environmental and regulatory concerns present additional obstacles. Some high-performance thermoelectric materials contain toxic or restricted elements like lead or tellurium, while graphene nanomaterials face evolving regulatory scrutiny regarding potential environmental and health impacts, creating uncertainty for commercial development pathways.

Current Thermoelectric-Graphene Composite Solutions

01 Graphene-based thermoelectric composites for enhanced performance

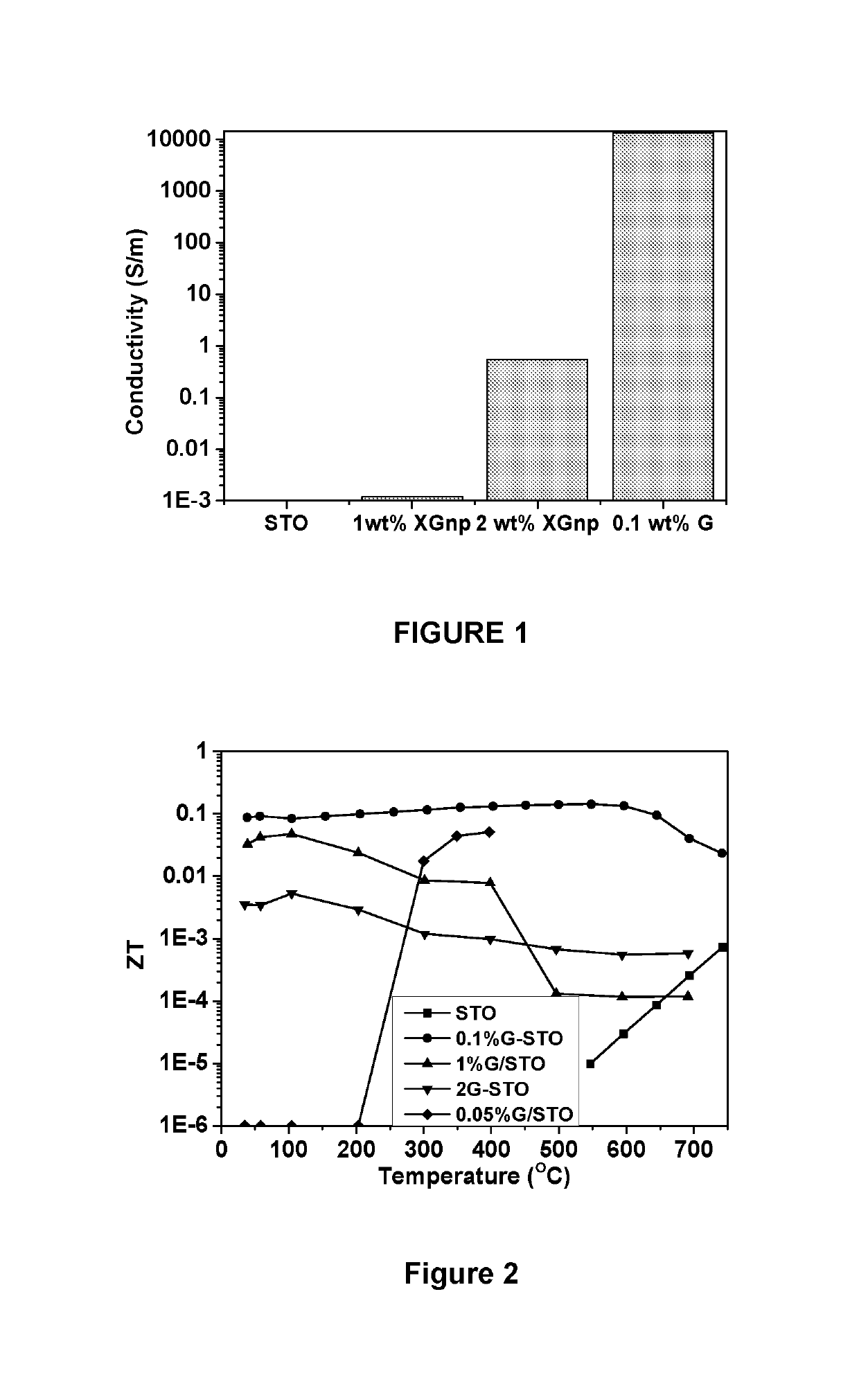

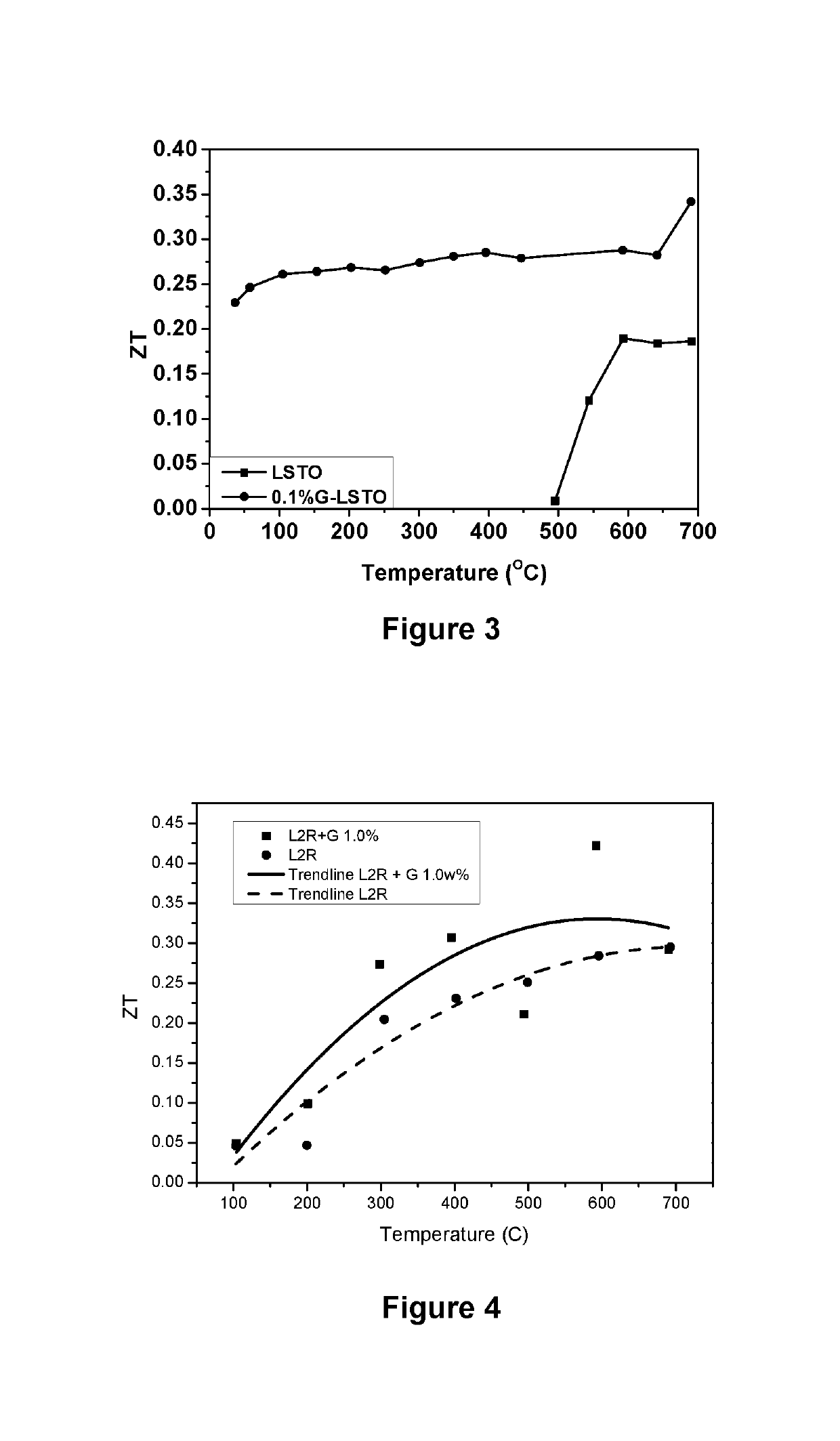

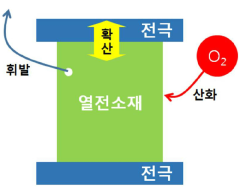

Graphene can be incorporated into thermoelectric materials to enhance their performance by improving electrical conductivity while maintaining low thermal conductivity. These composites leverage graphene's unique two-dimensional structure and excellent electron transport properties to increase the power factor of thermoelectric devices. The addition of graphene can also create interfaces that scatter phonons, reducing thermal conductivity and thereby improving the overall figure of merit (ZT) of thermoelectric materials.- Graphene-based thermoelectric composites for enhanced efficiency: Graphene can be incorporated into thermoelectric materials to enhance their efficiency by improving electrical conductivity while maintaining low thermal conductivity. These composites leverage graphene's unique two-dimensional structure and exceptional electron mobility to optimize the power factor of thermoelectric devices. The addition of graphene can significantly increase the figure of merit (ZT) of thermoelectric materials, making them more effective for power generation applications.

- Nanostructured graphene composites for thermal management: Nanostructured graphene composites can be engineered to control thermal transport properties, which is crucial for thermoelectric applications. By creating specific nanostructures within graphene-based materials, phonon scattering can be enhanced while preserving electron transport, leading to improved thermoelectric performance. These materials can be designed with controlled interfaces, defects, and grain boundaries to optimize the thermal conductivity for specific thermoelectric applications.

- Hybrid thermoelectric materials combining graphene with semiconductors: Hybrid materials that combine graphene with traditional semiconductor thermoelectric materials can achieve synergistic effects that enhance overall performance. These composites often incorporate materials such as bismuth telluride, lead telluride, or silicon with graphene to create structures with optimized electrical and thermal transport properties. The interface between graphene and semiconductor materials plays a crucial role in determining the thermoelectric efficiency of these hybrid systems.

- Functionalized graphene for thermoelectric applications: Chemical functionalization of graphene can be used to tailor its properties specifically for thermoelectric applications. By attaching functional groups or dopants to graphene sheets, researchers can modify the electronic structure, create energy filtering effects, and introduce phonon scattering centers. These modifications help optimize the Seebeck coefficient and electrical conductivity while reducing thermal conductivity, leading to enhanced thermoelectric performance in the resulting composite materials.

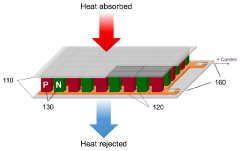

- Manufacturing processes for graphene-based thermoelectric devices: Various manufacturing techniques have been developed to produce graphene-based thermoelectric devices with consistent properties and performance. These processes include solution processing, chemical vapor deposition, thermal reduction, and various printing techniques that enable the scalable production of graphene-thermoelectric composites. Advanced fabrication methods focus on controlling the microstructure, orientation, and integration of graphene within the thermoelectric matrix to maximize energy conversion efficiency and device durability.

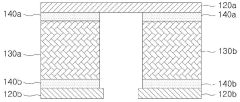

02 Nanostructured graphene-thermoelectric material interfaces

Nanostructuring at the interfaces between graphene and thermoelectric materials can significantly enhance energy conversion efficiency. These nanostructured interfaces create phonon scattering centers that reduce thermal conductivity while maintaining electrical conductivity. Various techniques such as chemical vapor deposition, solution processing, and mechanical exfoliation are used to create these nanostructured interfaces, resulting in improved thermoelectric performance across a wide temperature range.Expand Specific Solutions03 Functionalized graphene for thermoelectric applications

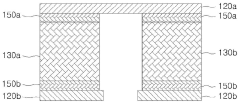

Chemical functionalization of graphene can be used to tune its electronic and thermal properties for specific thermoelectric applications. By attaching functional groups or dopants to the graphene surface, the Seebeck coefficient and electrical conductivity can be optimized. This approach allows for precise control over the thermoelectric properties of the resulting composites, enabling the development of materials with enhanced figure of merit for energy harvesting and cooling applications.Expand Specific Solutions04 3D graphene architectures in thermoelectric materials

Three-dimensional graphene architectures, such as aerogels, foams, and hierarchical structures, can be integrated with thermoelectric materials to create composites with improved performance. These 3D structures provide continuous electron transport pathways while introducing nanoscale porosity that disrupts phonon transport. The resulting materials exhibit enhanced power factors and reduced thermal conductivity, leading to higher thermoelectric efficiency across various temperature ranges.Expand Specific Solutions05 Hybrid graphene-inorganic thermoelectric composites

Hybrid composites combining graphene with inorganic thermoelectric materials such as bismuth telluride, lead telluride, or silicon-germanium alloys show synergistic effects that enhance overall thermoelectric performance. These hybrids leverage the high electrical conductivity of graphene and the good Seebeck coefficient of inorganic materials. Various synthesis methods including solution mixing, spark plasma sintering, and hot pressing are used to create these hybrid materials with optimized interfaces for improved energy conversion efficiency.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Materials

Thermoelectric materials and graphene composites market is currently in a growth phase, with increasing research activities and commercial applications emerging. The global market size for thermoelectric materials is projected to reach $1.5 billion by 2026, driven by demand for waste heat recovery systems and cooling applications. Technologically, the field is advancing rapidly with research institutions like Shanghai Institute of Ceramics (CAS), Centre National de la Recherche Scientifique, and The University of Manchester leading fundamental research, while companies such as Samsung Electronics, RTX Corp., and Micron Technology are developing commercial applications. Korean research institutes (KIMM, KICET) are making significant contributions in material optimization, while Chinese universities (Zhejiang University, Southeast University) focus on novel composite structures. The integration of graphene into thermoelectric materials represents a promising frontier, with improved thermal and electrical conductivity properties being actively explored by industry leaders.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has developed innovative thermoelectric graphene composites through a unique ceramic-matrix approach. Their technology integrates precisely controlled amounts of graphene (typically 0.5-2 wt%) into ceramic-based thermoelectric materials like skutterudites and half-Heusler compounds using advanced powder processing and spark plasma sintering techniques. This creates a network of graphene at grain boundaries that enhances electrical conductivity while introducing nanoscale phonon scattering interfaces[5]. Their proprietary processing method includes surface functionalization of graphene to improve compatibility with ceramic matrices and prevent agglomeration during sintering. The institute has demonstrated ZT values exceeding 1.7 at mid-to-high temperatures (500-800K) for these composites, with significantly improved mechanical properties and thermal stability compared to conventional thermoelectric materials[6]. They've also developed specialized coating technologies that protect these materials from oxidation and sublimation at elevated temperatures, extending operational lifetimes in waste heat recovery applications.

Strengths: World-class expertise in ceramic processing and sintering technologies; demonstrated high-temperature stability of composites; excellent mechanical properties suitable for demanding applications. Weaknesses: Complex manufacturing process with multiple steps; challenges in achieving uniform graphene distribution in large-scale production; higher costs compared to conventional thermoelectric materials.

Corning, Inc.

Technical Solution: Corning has developed advanced glass-ceramic thermoelectric materials enhanced with graphene for high-temperature waste heat recovery applications. Their proprietary technology combines specially formulated glass-ceramic matrices with precisely dispersed graphene nanoplatelets to create composites with enhanced thermoelectric performance. Corning's manufacturing process involves a unique melt-processing technique followed by controlled crystallization and graphene incorporation, resulting in hierarchically structured materials with optimized electron and phonon transport properties[9]. Their glass-ceramic graphene composites demonstrate exceptional thermal stability at temperatures up to 800°C while maintaining ZT values above 1.2, making them particularly suitable for industrial waste heat recovery and automotive applications. The company has also developed specialized coating technologies that protect these materials from oxidation and chemical degradation in harsh environments. Corning's research indicates that their materials can achieve conversion efficiencies of 9-12% in high-temperature differential applications, significantly higher than conventional thermoelectric materials operating in similar conditions[10].

Strengths: Exceptional expertise in glass and ceramic materials processing; materials demonstrate superior high-temperature stability and durability; established manufacturing infrastructure capable of large-scale production. Weaknesses: Higher production costs compared to conventional thermoelectric materials; limited flexibility (primarily rigid materials); optimization primarily focused on high-temperature applications rather than room-temperature performance.

Key Patents and Breakthroughs in Thermoelectric-Graphene Integration

Thermoelectric materials and devices comprising graphene

PatentInactiveUS10950774B2

Innovation

- Development of thermoelectric composite materials comprising metal oxides doped with graphene or modified graphene, which enhance ZT values significantly and extend the operational temperature range, enabling more efficient power generation and cooling across a broader temperature spectrum.

Thermoelectric module using graphene-thermoelectric material composite

PatentActiveKR1020160126558A

Innovation

- A graphene-thermoelectric material composite is introduced, where graphene is uniformly distributed at grain boundaries of thermoelectric materials, forming a matrix to suppress mass transfer and enhance reliability by reducing thermal conductivity through phonon scattering.

Environmental Impact and Sustainability of Thermoelectric Materials

The environmental impact of thermoelectric materials and their graphene composites represents a critical consideration in their development and deployment. Traditional thermoelectric materials often contain toxic or rare elements such as tellurium, bismuth, and lead, raising significant environmental concerns regarding their extraction, processing, and disposal. Mining operations for these elements typically generate substantial waste, consume large amounts of energy, and may lead to habitat destruction and water pollution.

Graphene incorporation into thermoelectric materials offers promising pathways toward more sustainable alternatives. The carbon-based nature of graphene presents lower toxicity profiles compared to heavy metal-based thermoelectrics. Additionally, the exceptional thermal and electrical properties of graphene enable the development of thermoelectric devices that can operate efficiently with reduced quantities of scarce or environmentally problematic elements.

Life cycle assessments of thermoelectric materials reveal varying environmental footprints depending on material composition and manufacturing processes. Conventional bismuth telluride-based devices demonstrate higher environmental impacts during production phases, while graphene composite alternatives show reduced impacts during manufacturing but may present challenges in end-of-life management due to the difficulty in separating nanomaterials for recycling.

Energy payback periods represent another crucial sustainability metric for thermoelectric technologies. Current generation devices typically require 1-3 years to generate the energy consumed during their production, depending on application scenarios and operating conditions. Graphene-enhanced thermoelectrics potentially offer improved energy payback periods through extended device lifespans and higher conversion efficiencies.

Recycling and circular economy approaches for thermoelectric materials remain underdeveloped. The complex nature of these composites presents technical challenges for material recovery, particularly for nanomaterial components. Research into design-for-disassembly approaches and specialized recycling technologies specifically tailored for thermoelectric composites shows promise but requires further development before commercial implementation.

Regulatory frameworks governing thermoelectric materials vary significantly across regions, with the European Union's RoHS and REACH regulations imposing stricter controls on hazardous substances than those found in many developing economies. These regulatory disparities influence global manufacturing patterns and material selection decisions, potentially driving innovation toward more environmentally benign compositions incorporating graphene and other carbon nanomaterials.

Graphene incorporation into thermoelectric materials offers promising pathways toward more sustainable alternatives. The carbon-based nature of graphene presents lower toxicity profiles compared to heavy metal-based thermoelectrics. Additionally, the exceptional thermal and electrical properties of graphene enable the development of thermoelectric devices that can operate efficiently with reduced quantities of scarce or environmentally problematic elements.

Life cycle assessments of thermoelectric materials reveal varying environmental footprints depending on material composition and manufacturing processes. Conventional bismuth telluride-based devices demonstrate higher environmental impacts during production phases, while graphene composite alternatives show reduced impacts during manufacturing but may present challenges in end-of-life management due to the difficulty in separating nanomaterials for recycling.

Energy payback periods represent another crucial sustainability metric for thermoelectric technologies. Current generation devices typically require 1-3 years to generate the energy consumed during their production, depending on application scenarios and operating conditions. Graphene-enhanced thermoelectrics potentially offer improved energy payback periods through extended device lifespans and higher conversion efficiencies.

Recycling and circular economy approaches for thermoelectric materials remain underdeveloped. The complex nature of these composites presents technical challenges for material recovery, particularly for nanomaterial components. Research into design-for-disassembly approaches and specialized recycling technologies specifically tailored for thermoelectric composites shows promise but requires further development before commercial implementation.

Regulatory frameworks governing thermoelectric materials vary significantly across regions, with the European Union's RoHS and REACH regulations imposing stricter controls on hazardous substances than those found in many developing economies. These regulatory disparities influence global manufacturing patterns and material selection decisions, potentially driving innovation toward more environmentally benign compositions incorporating graphene and other carbon nanomaterials.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for thermoelectric materials incorporating graphene composites presents significant challenges and opportunities for commercial viability. Current production methods predominantly rely on laboratory-scale techniques such as hydrothermal synthesis, chemical vapor deposition (CVD), and solution-based processing, which yield high-quality materials but at prohibitively high costs for mass production. The transition from laboratory to industrial scale requires substantial process optimization to maintain material performance while reducing production expenses.

Cost analysis reveals that raw material expenses constitute approximately 40-60% of total production costs, with high-purity graphene being particularly expensive at $200-1000 per gram for research-grade material. Recent advancements in graphene production have reduced costs to $50-100 per gram for industrial applications, though this remains a significant barrier to widespread adoption. Processing costs, including equipment depreciation, energy consumption, and specialized handling requirements, account for an additional 25-35% of total expenses.

Economies of scale present promising pathways for cost reduction. Industry projections suggest that scaling production volumes from kilograms to tons could potentially reduce unit costs by 60-70% over five years. Several manufacturers have demonstrated pilot-scale production capabilities, with companies like Haydale and XG Sciences leading efforts to develop scalable graphene-enhanced thermoelectric materials.

Manufacturing yield rates currently average 65-75% for high-performance thermoelectric-graphene composites, significantly lower than the 90%+ yields achieved in conventional semiconductor manufacturing. This yield gap represents a critical area for improvement, as each percentage point increase in yield can translate to approximately 1-2% reduction in overall production costs.

Automation and process integration offer additional avenues for enhancing scalability. Continuous flow manufacturing systems, currently being developed by several equipment manufacturers, could replace batch processing methods, potentially reducing labor costs by 30-40% while improving consistency in material properties. Roll-to-roll processing techniques show particular promise for thin-film thermoelectric applications, enabling production rates orders of magnitude higher than traditional methods.

Environmental considerations also impact manufacturing scalability, with regulatory compliance costs estimated at 5-10% of production expenses. Sustainable manufacturing approaches, including solvent recovery systems and closed-loop material recycling, are being developed to address these challenges while simultaneously reducing raw material costs through reclamation of high-value components.

The integration of thermoelectric-graphene composites into existing manufacturing infrastructure represents perhaps the most significant near-term opportunity for cost reduction, leveraging established supply chains and production facilities to accelerate commercialization while minimizing capital investment requirements.

Cost analysis reveals that raw material expenses constitute approximately 40-60% of total production costs, with high-purity graphene being particularly expensive at $200-1000 per gram for research-grade material. Recent advancements in graphene production have reduced costs to $50-100 per gram for industrial applications, though this remains a significant barrier to widespread adoption. Processing costs, including equipment depreciation, energy consumption, and specialized handling requirements, account for an additional 25-35% of total expenses.

Economies of scale present promising pathways for cost reduction. Industry projections suggest that scaling production volumes from kilograms to tons could potentially reduce unit costs by 60-70% over five years. Several manufacturers have demonstrated pilot-scale production capabilities, with companies like Haydale and XG Sciences leading efforts to develop scalable graphene-enhanced thermoelectric materials.

Manufacturing yield rates currently average 65-75% for high-performance thermoelectric-graphene composites, significantly lower than the 90%+ yields achieved in conventional semiconductor manufacturing. This yield gap represents a critical area for improvement, as each percentage point increase in yield can translate to approximately 1-2% reduction in overall production costs.

Automation and process integration offer additional avenues for enhancing scalability. Continuous flow manufacturing systems, currently being developed by several equipment manufacturers, could replace batch processing methods, potentially reducing labor costs by 30-40% while improving consistency in material properties. Roll-to-roll processing techniques show particular promise for thin-film thermoelectric applications, enabling production rates orders of magnitude higher than traditional methods.

Environmental considerations also impact manufacturing scalability, with regulatory compliance costs estimated at 5-10% of production expenses. Sustainable manufacturing approaches, including solvent recovery systems and closed-loop material recycling, are being developed to address these challenges while simultaneously reducing raw material costs through reclamation of high-value components.

The integration of thermoelectric-graphene composites into existing manufacturing infrastructure represents perhaps the most significant near-term opportunity for cost reduction, leveraging established supply chains and production facilities to accelerate commercialization while minimizing capital investment requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!