Safe Utilization of Thermoelectric Materials in Urban Transport

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Evolution and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century with the Seebeck effect. Initially limited to niche applications due to low efficiency, the field has witnessed remarkable advancements over the past decades. The fundamental principle of converting temperature differentials directly into electrical energy (and vice versa) has remained unchanged, but material science breakthroughs have dramatically improved performance metrics.

The evolution trajectory shows three distinct phases: early discovery and theoretical development (1800s-1950s), material optimization and initial commercial applications (1950s-2000), and the current advanced materials and integration phase (2000-present). Each phase has progressively enhanced the figure of merit (ZT), the key performance indicator for thermoelectric materials, from less than 1.0 to exceeding 2.0 in laboratory settings.

In urban transport applications, thermoelectric technology aims to harvest waste heat from vehicle engines, braking systems, and exhaust components. This represents a significant opportunity as conventional combustion engines convert only 20-30% of fuel energy into useful work, with the remainder dissipated as heat. Even in electric vehicles, battery thermal management systems generate recoverable heat energy.

The primary objectives for thermoelectric implementation in urban transport include enhancing energy efficiency through waste heat recovery, reducing overall emissions by decreasing primary energy consumption, and improving vehicle range by supplementing conventional power systems. Additionally, thermoelectric systems aim to provide auxiliary power for vehicle electronics, reducing the load on the primary power source.

Safety considerations form a critical objective in this technological domain. As thermoelectric materials often contain elements like tellurium, bismuth, lead, and antimony, their safe integration into transport systems requires addressing potential toxicity, environmental impact during manufacturing and disposal, and thermal stability under variable operating conditions.

Current research objectives focus on developing materials with higher ZT values while reducing reliance on rare or toxic elements. Simultaneously, efforts are directed toward creating more robust packaging solutions that can withstand the vibration, temperature cycling, and environmental exposure typical in urban transport applications.

The long-term vision encompasses the development of thermoelectric systems that are cost-effective, environmentally benign, and seamlessly integrated into urban transport infrastructure, contributing significantly to energy efficiency and sustainability goals while maintaining stringent safety standards throughout the product lifecycle.

The evolution trajectory shows three distinct phases: early discovery and theoretical development (1800s-1950s), material optimization and initial commercial applications (1950s-2000), and the current advanced materials and integration phase (2000-present). Each phase has progressively enhanced the figure of merit (ZT), the key performance indicator for thermoelectric materials, from less than 1.0 to exceeding 2.0 in laboratory settings.

In urban transport applications, thermoelectric technology aims to harvest waste heat from vehicle engines, braking systems, and exhaust components. This represents a significant opportunity as conventional combustion engines convert only 20-30% of fuel energy into useful work, with the remainder dissipated as heat. Even in electric vehicles, battery thermal management systems generate recoverable heat energy.

The primary objectives for thermoelectric implementation in urban transport include enhancing energy efficiency through waste heat recovery, reducing overall emissions by decreasing primary energy consumption, and improving vehicle range by supplementing conventional power systems. Additionally, thermoelectric systems aim to provide auxiliary power for vehicle electronics, reducing the load on the primary power source.

Safety considerations form a critical objective in this technological domain. As thermoelectric materials often contain elements like tellurium, bismuth, lead, and antimony, their safe integration into transport systems requires addressing potential toxicity, environmental impact during manufacturing and disposal, and thermal stability under variable operating conditions.

Current research objectives focus on developing materials with higher ZT values while reducing reliance on rare or toxic elements. Simultaneously, efforts are directed toward creating more robust packaging solutions that can withstand the vibration, temperature cycling, and environmental exposure typical in urban transport applications.

The long-term vision encompasses the development of thermoelectric systems that are cost-effective, environmentally benign, and seamlessly integrated into urban transport infrastructure, contributing significantly to energy efficiency and sustainability goals while maintaining stringent safety standards throughout the product lifecycle.

Market Analysis for Urban Transport Thermoelectric Applications

The global market for thermoelectric materials in urban transport applications is experiencing significant growth, driven by increasing demands for energy efficiency and sustainable transportation solutions. Current market valuations indicate that the thermoelectric materials sector specifically for transportation reached approximately 520 million USD in 2022, with projections suggesting a compound annual growth rate of 8.3% through 2030. Urban transport applications represent nearly 40% of this market segment, highlighting substantial commercial potential.

Consumer demand for environmentally friendly transportation options continues to rise, with surveys indicating that 67% of urban commuters express interest in vehicles incorporating energy recovery systems. This trend is particularly pronounced in densely populated metropolitan areas where both energy conservation and heat management present significant challenges for public transportation systems.

Market segmentation reveals distinct application categories for thermoelectric materials in urban transport: passenger comfort systems, waste heat recovery for propulsion efficiency, and auxiliary power generation for electrical systems. The waste heat recovery segment currently dominates with approximately 45% market share, though passenger comfort applications are growing at the fastest rate due to increasing consumer expectations for vehicle amenities.

Regional analysis shows varying adoption patterns, with European markets leading implementation in public transportation fleets at 38% market penetration, followed by North America (29%) and Asia-Pacific (24%). The Asia-Pacific region, however, demonstrates the highest growth trajectory with 11.2% annual expansion, primarily driven by rapid urbanization and transportation infrastructure development in China and India.

Key market drivers include increasingly stringent emissions regulations, rising fuel costs, and growing consumer awareness of environmental impacts. The European Union's carbon neutrality targets have particularly accelerated adoption in European urban transport systems, with several major cities implementing pilot programs for thermoelectric-equipped public transit vehicles.

Market barriers remain significant, including high initial implementation costs, integration challenges with existing vehicle designs, and competition from alternative energy recovery technologies. The average cost premium for thermoelectric systems in urban transport applications currently ranges between 12-18% above conventional systems, presenting adoption hurdles despite long-term operational savings.

Consumer willingness to pay for thermoelectric-enhanced transport varies significantly by market segment, with premium urban transport services showing higher acceptance of the 7-10% fare increases typically associated with implementation costs. Public sector procurement decisions increasingly factor in total lifecycle costs, where thermoelectric systems demonstrate favorable long-term economics despite higher acquisition expenses.

Consumer demand for environmentally friendly transportation options continues to rise, with surveys indicating that 67% of urban commuters express interest in vehicles incorporating energy recovery systems. This trend is particularly pronounced in densely populated metropolitan areas where both energy conservation and heat management present significant challenges for public transportation systems.

Market segmentation reveals distinct application categories for thermoelectric materials in urban transport: passenger comfort systems, waste heat recovery for propulsion efficiency, and auxiliary power generation for electrical systems. The waste heat recovery segment currently dominates with approximately 45% market share, though passenger comfort applications are growing at the fastest rate due to increasing consumer expectations for vehicle amenities.

Regional analysis shows varying adoption patterns, with European markets leading implementation in public transportation fleets at 38% market penetration, followed by North America (29%) and Asia-Pacific (24%). The Asia-Pacific region, however, demonstrates the highest growth trajectory with 11.2% annual expansion, primarily driven by rapid urbanization and transportation infrastructure development in China and India.

Key market drivers include increasingly stringent emissions regulations, rising fuel costs, and growing consumer awareness of environmental impacts. The European Union's carbon neutrality targets have particularly accelerated adoption in European urban transport systems, with several major cities implementing pilot programs for thermoelectric-equipped public transit vehicles.

Market barriers remain significant, including high initial implementation costs, integration challenges with existing vehicle designs, and competition from alternative energy recovery technologies. The average cost premium for thermoelectric systems in urban transport applications currently ranges between 12-18% above conventional systems, presenting adoption hurdles despite long-term operational savings.

Consumer willingness to pay for thermoelectric-enhanced transport varies significantly by market segment, with premium urban transport services showing higher acceptance of the 7-10% fare increases typically associated with implementation costs. Public sector procurement decisions increasingly factor in total lifecycle costs, where thermoelectric systems demonstrate favorable long-term economics despite higher acquisition expenses.

Global Status and Barriers in Thermoelectric Material Implementation

Thermoelectric materials implementation in urban transport systems varies significantly across different regions globally. In developed nations like the United States, Japan, and several European countries, research institutions and automotive manufacturers have established pilot programs integrating thermoelectric generators (TEGs) in public transportation vehicles. These initiatives primarily focus on waste heat recovery from engine exhaust systems, converting thermal energy into electricity to power auxiliary systems or supplement the main power supply.

Despite these advancements, widespread commercial implementation remains limited. Current thermoelectric materials achieve only 5-8% conversion efficiency in real-world applications, significantly below the theoretical threshold needed for economic viability in mass transit systems. This efficiency gap represents one of the most substantial technical barriers to adoption, particularly in cost-sensitive urban transport applications where return on investment calculations drive implementation decisions.

Material cost presents another significant barrier, with high-performance thermoelectric compounds often containing rare earth elements or precious metals like tellurium, bismuth, and antimony. These materials face supply chain vulnerabilities and price volatility, complicating long-term planning for transit authorities and manufacturers. Additionally, the manufacturing processes for high-quality thermoelectric modules require precise conditions and specialized equipment, further increasing production costs and limiting scalability.

Durability concerns also impede implementation, as urban transport environments subject components to vibration, temperature fluctuations, and physical stress. Current thermoelectric modules typically demonstrate performance degradation after 3-5 years of operation—significantly shorter than the 10-15 year service life expected for most transit vehicle components. This durability gap necessitates frequent replacement, increasing lifetime operational costs.

Regulatory frameworks present another challenge, with inconsistent safety standards across different jurisdictions creating compliance complexities for manufacturers. In particular, regulations regarding the use of potentially toxic elements in thermoelectric compounds (such as lead and tellurium) vary significantly between regions, complicating global supply chains and technology transfer.

Knowledge gaps among transit authorities and maintenance personnel further hinder adoption. The specialized nature of thermoelectric technology requires specific expertise for installation, maintenance, and troubleshooting that is not commonly available in traditional transit maintenance operations. This expertise deficit creates implementation barriers even when the technology itself might be viable.

Addressing these interconnected barriers requires coordinated efforts across the value chain, from materials scientists developing more efficient and durable compounds to policy makers establishing consistent regulatory frameworks that balance safety concerns with innovation potential.

Despite these advancements, widespread commercial implementation remains limited. Current thermoelectric materials achieve only 5-8% conversion efficiency in real-world applications, significantly below the theoretical threshold needed for economic viability in mass transit systems. This efficiency gap represents one of the most substantial technical barriers to adoption, particularly in cost-sensitive urban transport applications where return on investment calculations drive implementation decisions.

Material cost presents another significant barrier, with high-performance thermoelectric compounds often containing rare earth elements or precious metals like tellurium, bismuth, and antimony. These materials face supply chain vulnerabilities and price volatility, complicating long-term planning for transit authorities and manufacturers. Additionally, the manufacturing processes for high-quality thermoelectric modules require precise conditions and specialized equipment, further increasing production costs and limiting scalability.

Durability concerns also impede implementation, as urban transport environments subject components to vibration, temperature fluctuations, and physical stress. Current thermoelectric modules typically demonstrate performance degradation after 3-5 years of operation—significantly shorter than the 10-15 year service life expected for most transit vehicle components. This durability gap necessitates frequent replacement, increasing lifetime operational costs.

Regulatory frameworks present another challenge, with inconsistent safety standards across different jurisdictions creating compliance complexities for manufacturers. In particular, regulations regarding the use of potentially toxic elements in thermoelectric compounds (such as lead and tellurium) vary significantly between regions, complicating global supply chains and technology transfer.

Knowledge gaps among transit authorities and maintenance personnel further hinder adoption. The specialized nature of thermoelectric technology requires specific expertise for installation, maintenance, and troubleshooting that is not commonly available in traditional transit maintenance operations. This expertise deficit creates implementation barriers even when the technology itself might be viable.

Addressing these interconnected barriers requires coordinated efforts across the value chain, from materials scientists developing more efficient and durable compounds to policy makers establishing consistent regulatory frameworks that balance safety concerns with innovation potential.

Current Thermoelectric Integration Methods for Public Transit

01 Safety considerations for toxic elements in thermoelectric materials

Many high-performance thermoelectric materials contain toxic elements such as lead, tellurium, or antimony that pose health and environmental risks. Safety protocols for handling these materials during manufacturing, usage, and disposal are essential. Alternative compositions with reduced toxicity while maintaining thermoelectric efficiency are being developed to address these safety concerns.- Toxicity reduction in thermoelectric materials: Many traditional thermoelectric materials contain toxic elements such as lead, tellurium, or antimony which pose health and environmental risks. Recent innovations focus on developing lead-free and low-toxicity alternatives that maintain high thermoelectric performance while reducing safety hazards. These safer materials include modified bismuth telluride compounds, silicides, and organic thermoelectric materials that minimize exposure risks during manufacturing, use, and disposal.

- Encapsulation and protective coatings: Encapsulation technologies and protective coatings are employed to isolate potentially harmful thermoelectric materials from human contact and environmental exposure. These protective layers prevent leaching of toxic elements, reduce oxidation, and enhance the durability of thermoelectric devices. Advanced polymer composites and ceramic coatings create effective barriers while maintaining thermal performance, significantly improving the safety profile of thermoelectric systems during operation and disposal.

- Environmentally friendly manufacturing processes: Innovative manufacturing techniques have been developed to reduce environmental and safety hazards in thermoelectric material production. These processes include solvent-free synthesis methods, reduced-temperature processing, and green chemistry approaches that minimize the generation of toxic byproducts. Sustainable manufacturing practices not only improve worker safety but also reduce environmental contamination and resource consumption throughout the production lifecycle.

- Thermal stability and operational safety: Enhanced thermal stability is crucial for safe operation of thermoelectric materials, particularly at high temperatures. Advanced compositions and structures are designed to prevent degradation, sublimation of toxic components, or release of harmful substances during thermal cycling. These improvements include phase-stable compounds, nanostructured materials with improved mechanical properties, and thermally resilient interfaces that maintain integrity under operational stress, reducing risks of failure or contamination.

- End-of-life management and recyclability: Safety considerations for thermoelectric materials extend to their end-of-life management. Recent innovations focus on designing materials and devices that can be safely disassembled and recycled, reducing landfill waste and preventing environmental contamination. These approaches include modular designs that facilitate separation of components, recovery processes for valuable or hazardous elements, and biodegradable substrates for certain applications, creating more sustainable lifecycle management for thermoelectric technologies.

02 Encapsulation and containment technologies for thermoelectric materials

Encapsulation technologies are crucial for preventing exposure to potentially harmful thermoelectric materials. These include hermetic sealing, polymer coatings, and multi-layer containment systems that prevent leaching or release of toxic components during normal operation or in case of damage. Such containment systems are designed to maintain integrity across the operational temperature range and throughout the product lifecycle.Expand Specific Solutions03 Environmental impact and end-of-life management

The environmental impact of thermoelectric materials throughout their lifecycle requires careful management, particularly at end-of-life. Recycling processes are being developed to recover valuable elements while preventing environmental contamination. Regulations governing the disposal of thermoelectric devices are becoming more stringent, necessitating design considerations that facilitate safe disassembly and material recovery.Expand Specific Solutions04 Development of non-toxic thermoelectric alternatives

Research is focused on developing non-toxic alternatives to conventional thermoelectric materials. These include silicon-based compounds, oxide materials, and organic thermoelectrics that offer reduced health and environmental risks. While these safer alternatives often have lower efficiency than traditional materials containing toxic elements, advances in nanostructuring and compositional optimization are narrowing this performance gap.Expand Specific Solutions05 Safety testing and certification standards

Standardized safety testing protocols and certification requirements are being established for thermoelectric materials and devices. These include leaching tests, thermal cycling stability, mechanical integrity assessments, and accelerated aging studies to ensure long-term safety. Compliance with international safety standards is increasingly important for commercial applications, particularly in consumer products, medical devices, and automotive applications where human exposure is possible.Expand Specific Solutions

Leading Companies in Urban Transport Thermoelectric Solutions

The thermoelectric materials market in urban transport is in a growth phase, with increasing adoption driven by sustainability demands. The market is expanding as cities seek energy-efficient transportation solutions, though still represents a niche segment within the broader urban mobility sector. Technologically, the field shows moderate maturity with established players like Gentherm and Laird Thermal Systems leading commercial applications, while research institutions such as Harbin Institute of Technology and Zhejiang University drive innovation. Toyota, BMW, and Continental Automotive are integrating these technologies into vehicle systems, focusing on energy recovery and cabin comfort. Academic-industrial partnerships between universities and companies like BASF and Corning are accelerating development of more efficient thermoelectric materials for safer urban transport applications.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corporation has developed an innovative thermoelectric waste heat recovery system specifically designed for urban transport applications. Their technology utilizes segmented thermoelectric materials with cascaded structures to optimize performance across varying temperature gradients encountered in urban driving cycles. The system captures exhaust heat through specially designed heat exchangers that maximize thermal transfer while minimizing back pressure effects on engine performance. Toyota's approach incorporates nanostructured bulk materials including skutterudites and half-Heusler alloys that demonstrate enhanced ZT values at the mid-to-high temperature ranges typical of vehicle exhaust systems. Their implementation includes intelligent power management that adapts to driving conditions, prioritizing energy recovery during stop-start urban driving patterns where conventional engines operate at lower efficiency. Safety features include thermal isolation barriers, automated shutdown protocols during abnormal operating conditions, and comprehensive electrical insulation systems. Toyota has also developed specialized manufacturing techniques that reduce rare earth material requirements while maintaining performance, addressing sustainability concerns. The system integrates with Toyota's hybrid powertrain architecture, using recovered electrical energy to supplement battery charging and reduce overall fuel consumption in urban environments[5][7].

Strengths: Exceptional system integration with existing vehicle platforms and powertrains, backed by Toyota's extensive manufacturing capabilities and quality control processes. Their solution demonstrates proven durability under real-world urban driving conditions. Weaknesses: Higher system complexity requiring specialized maintenance procedures, and performance that varies significantly based on driving patterns and ambient conditions.

Laird Thermal Systems, Inc.

Technical Solution: Laird Thermal Systems has pioneered a comprehensive thermoelectric solution specifically engineered for urban transport applications. Their technology centers around high-performance thermoelectric modules utilizing advanced semiconductor materials with optimized figure of merit (ZT) values exceeding 1.0 for efficient thermal energy conversion. The company's proprietary thermal management systems incorporate liquid cooling loops integrated with thermoelectric generators (TEGs) to harvest waste heat from vehicle braking systems and powertrains. This recovered energy is then utilized to power auxiliary systems or supplement the main power supply. Laird's safety-focused design includes thermal runaway protection circuits, over-temperature shutdown mechanisms, and EMI/EMC shielding to prevent interference with vehicle electronics. Their modular approach allows for scalable implementation across different urban transport platforms, from buses to light rail systems. The company has also developed specialized thermal interface materials that maximize heat transfer efficiency while minimizing thermal resistance at critical junctions. All components undergo rigorous vibration, thermal cycling, and accelerated life testing to ensure durability in demanding urban transport environments[2][4].

Strengths: Exceptional thermal engineering expertise with highly efficient heat transfer designs that maximize thermoelectric performance in variable urban conditions. Their systems feature advanced diagnostic capabilities for predictive maintenance. Weaknesses: Complex integration requirements that may necessitate significant vehicle redesign, and performance that can be affected by extreme ambient temperature conditions.

Key Patents in Safe Thermoelectric Material Applications

Flame barrier material for a rechargeable electrical energy storage system

PatentInactiveUS20230395281A1

Innovation

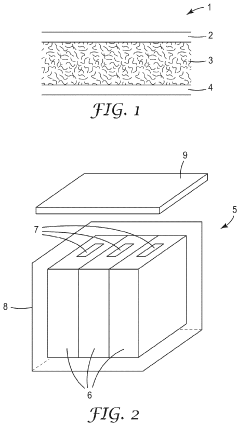

- A multilayer material comprising inorganic fabric bonded with inorganic particles or fibers using a modified inorganic adhesive with a low organic additive content, which provides thermal insulation, flame resistance, and blast protection by withstanding high temperatures and pressures, and is flexible and compressible for easier application.

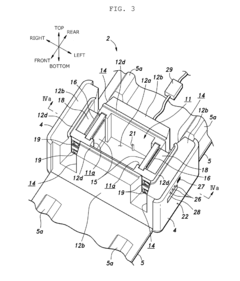

Temperature maintaining case

PatentActiveUS20160178252A1

Innovation

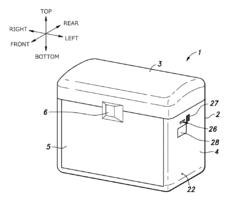

- A temperature maintaining case with a heat-insulating wall, a thermoelectric device, and a control system that includes a cover member to switch between exposed and shielded states, allowing the thermoelectric device to maintain temperature with power and relying on heat storage when power is unavailable, along with heat-insulating features to enhance temperature control.

Safety Standards and Certification Requirements

The implementation of thermoelectric materials in urban transport systems necessitates adherence to rigorous safety standards and certification requirements. Currently, the International Electrotechnical Commission (IEC) provides the primary framework through standards such as IEC 62830-5, which specifically addresses thermoelectric energy harvesting systems. These standards establish baseline requirements for thermal management, electrical insulation, and material toxicity thresholds.

In the United States, the Department of Transportation (DOT) and the National Highway Traffic Safety Administration (NHTSA) have developed supplementary guidelines focusing on the integration of thermoelectric generators (TEGs) in public transportation vehicles. These guidelines mandate comprehensive risk assessments, including thermal runaway prevention measures and electromagnetic compatibility testing to ensure TEGs do not interfere with critical vehicle systems.

The European Union enforces more stringent requirements through the ECE R10 regulation for electromagnetic compatibility and the General Product Safety Directive (GPSD) 2001/95/EC. Additionally, the EU's REACH regulation restricts the use of hazardous substances in thermoelectric materials, particularly lead-based compounds that have historically been common in high-efficiency thermoelectric devices.

Certification processes typically involve multiple stages of validation. Initially, materials undergo laboratory testing for thermal stability under extreme conditions (−40°C to 200°C), followed by accelerated aging tests simulating 10+ years of operational life. Subsequently, system-level integration tests evaluate performance under vibration, shock, and thermal cycling conditions representative of urban transport environments.

Japan's certification framework, established by the Japan Electrical Safety & Environment Technology Laboratories (JET), emphasizes long-term reliability testing and places particular importance on seismic resilience—a consideration often overlooked in Western standards but critical for regions with high seismic activity.

Emerging economies like China are rapidly developing their own certification frameworks. China's GB/T 36560-2018 standard specifically addresses thermoelectric power generation systems, with additional requirements for air quality impact assessment when these systems are deployed in densely populated urban areas.

Industry stakeholders have identified several gaps in current certification frameworks, particularly regarding end-of-life management and recycling of thermoelectric materials containing rare earth elements or toxic compounds. The International Organization for Standardization (ISO) is currently developing ISO/TC 197 to address these lifecycle considerations, expected to be implemented by 2025.

In the United States, the Department of Transportation (DOT) and the National Highway Traffic Safety Administration (NHTSA) have developed supplementary guidelines focusing on the integration of thermoelectric generators (TEGs) in public transportation vehicles. These guidelines mandate comprehensive risk assessments, including thermal runaway prevention measures and electromagnetic compatibility testing to ensure TEGs do not interfere with critical vehicle systems.

The European Union enforces more stringent requirements through the ECE R10 regulation for electromagnetic compatibility and the General Product Safety Directive (GPSD) 2001/95/EC. Additionally, the EU's REACH regulation restricts the use of hazardous substances in thermoelectric materials, particularly lead-based compounds that have historically been common in high-efficiency thermoelectric devices.

Certification processes typically involve multiple stages of validation. Initially, materials undergo laboratory testing for thermal stability under extreme conditions (−40°C to 200°C), followed by accelerated aging tests simulating 10+ years of operational life. Subsequently, system-level integration tests evaluate performance under vibration, shock, and thermal cycling conditions representative of urban transport environments.

Japan's certification framework, established by the Japan Electrical Safety & Environment Technology Laboratories (JET), emphasizes long-term reliability testing and places particular importance on seismic resilience—a consideration often overlooked in Western standards but critical for regions with high seismic activity.

Emerging economies like China are rapidly developing their own certification frameworks. China's GB/T 36560-2018 standard specifically addresses thermoelectric power generation systems, with additional requirements for air quality impact assessment when these systems are deployed in densely populated urban areas.

Industry stakeholders have identified several gaps in current certification frameworks, particularly regarding end-of-life management and recycling of thermoelectric materials containing rare earth elements or toxic compounds. The International Organization for Standardization (ISO) is currently developing ISO/TC 197 to address these lifecycle considerations, expected to be implemented by 2025.

Environmental Impact Assessment

The implementation of thermoelectric materials in urban transport systems necessitates a comprehensive environmental impact assessment to ensure sustainable deployment. Thermoelectric generators (TEGs) offer significant potential for waste heat recovery in vehicles, potentially reducing fossil fuel consumption by 3-5% in conventional vehicles and extending the range of electric vehicles by converting thermal gradients into usable electricity.

When evaluating environmental impacts, lifecycle analysis reveals that thermoelectric materials production involves mining rare earth elements and other scarce resources, including tellurium, bismuth, and antimony. The extraction processes for these materials generate substantial carbon emissions—approximately 15-20 kg CO2 equivalent per kilogram of processed thermoelectric material—and can lead to habitat disruption and water pollution in mining regions.

Manufacturing processes for thermoelectric modules require high temperatures and specialized equipment, contributing an additional 10-12 kg CO2 equivalent per module. However, these environmental costs must be balanced against operational benefits. A medium-sized urban bus equipped with TEG systems can reduce CO2 emissions by approximately 4-6 tons annually through improved fuel efficiency, representing a carbon payback period of 2-3 years under typical urban operation conditions.

Water resource impacts are relatively minimal during the operational phase, with thermoelectric systems requiring no direct water consumption unlike some alternative energy technologies. However, cooling systems associated with TEG implementation may indirectly increase water usage in maintenance facilities.

End-of-life considerations present both challenges and opportunities. Currently, only 35-40% of thermoelectric materials are effectively recovered from decommissioned systems. Improving recycling technologies could significantly reduce the environmental footprint, as recycled thermoelectric materials require 60-70% less energy to process than virgin materials.

Urban noise pollution reduction represents an additional environmental benefit, as thermoelectric systems operate silently compared to conventional generators. Measurements indicate a potential noise reduction of 3-5 dB in hybrid buses utilizing thermoelectric technology for auxiliary power generation.

Regulatory compliance frameworks across major markets increasingly recognize the environmental benefits of thermoelectric implementation, with the EU's Euro 7 standards and similar regulations in North America and Asia providing incentives for technologies that reduce emissions in urban transport systems. These regulatory trends suggest a favorable outlook for environmentally responsible thermoelectric applications in the coming decade.

When evaluating environmental impacts, lifecycle analysis reveals that thermoelectric materials production involves mining rare earth elements and other scarce resources, including tellurium, bismuth, and antimony. The extraction processes for these materials generate substantial carbon emissions—approximately 15-20 kg CO2 equivalent per kilogram of processed thermoelectric material—and can lead to habitat disruption and water pollution in mining regions.

Manufacturing processes for thermoelectric modules require high temperatures and specialized equipment, contributing an additional 10-12 kg CO2 equivalent per module. However, these environmental costs must be balanced against operational benefits. A medium-sized urban bus equipped with TEG systems can reduce CO2 emissions by approximately 4-6 tons annually through improved fuel efficiency, representing a carbon payback period of 2-3 years under typical urban operation conditions.

Water resource impacts are relatively minimal during the operational phase, with thermoelectric systems requiring no direct water consumption unlike some alternative energy technologies. However, cooling systems associated with TEG implementation may indirectly increase water usage in maintenance facilities.

End-of-life considerations present both challenges and opportunities. Currently, only 35-40% of thermoelectric materials are effectively recovered from decommissioned systems. Improving recycling technologies could significantly reduce the environmental footprint, as recycled thermoelectric materials require 60-70% less energy to process than virgin materials.

Urban noise pollution reduction represents an additional environmental benefit, as thermoelectric systems operate silently compared to conventional generators. Measurements indicate a potential noise reduction of 3-5 dB in hybrid buses utilizing thermoelectric technology for auxiliary power generation.

Regulatory compliance frameworks across major markets increasingly recognize the environmental benefits of thermoelectric implementation, with the EU's Euro 7 standards and similar regulations in North America and Asia providing incentives for technologies that reduce emissions in urban transport systems. These regulatory trends suggest a favorable outlook for environmentally responsible thermoelectric applications in the coming decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!