Thermoelectric Material Optimization for Heat Pump Technologies

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Evolution and Objectives

Thermoelectric materials have undergone significant evolution since their discovery in the early 19th century. The Seebeck effect, discovered in 1821, laid the foundation for thermoelectric technology by demonstrating that temperature differences between two electrical conductors can produce voltage. This was followed by the discovery of the Peltier effect in 1834, which established the reversible nature of thermoelectric phenomena—enabling both power generation and cooling applications.

The mid-20th century marked a pivotal era with the development of semiconductor-based thermoelectric materials. Bismuth telluride (Bi₂Te₃) emerged as the first commercially viable thermoelectric material in the 1950s, achieving a figure of merit (ZT) of approximately 1, which remained the standard for decades. This period established the fundamental understanding that effective thermoelectric materials require high electrical conductivity, low thermal conductivity, and high Seebeck coefficient—properties that are inherently contradictory in conventional materials.

The 1990s witnessed a renaissance in thermoelectric research with the introduction of nanostructuring approaches. Theoretical predictions suggested that quantum confinement effects could enhance ZT values beyond the historical barrier. This led to the development of superlattices, quantum dots, and other low-dimensional structures that demonstrated improved performance by effectively scattering phonons while preserving electron transport.

Recent advances have focused on complex bulk materials, including skutterudites, clathrates, and half-Heusler compounds. These materials feature intricate crystal structures that inherently reduce thermal conductivity through mechanisms such as rattling atoms and cage-like frameworks. Notably, lead telluride (PbTe) based materials with nanostructured inclusions have achieved ZT values exceeding 2.0 at elevated temperatures.

In the context of heat pump technologies, the primary objective is to develop thermoelectric materials that can achieve high coefficient of performance (COP) values comparable to conventional vapor-compression systems. This requires materials with ZT values consistently above 2 across operational temperature ranges (typically -20°C to 50°C for residential applications). Secondary objectives include reducing reliance on rare or toxic elements like tellurium and lead, improving mechanical durability for long-term cycling, and developing manufacturing processes compatible with large-scale production.

The trajectory of research is now moving toward earth-abundant, environmentally benign materials such as magnesium silicide, tetrahedrites, and organic thermoelectrics. Concurrently, there is growing interest in flexible thermoelectric materials that can conform to irregular heat sources, potentially expanding application scenarios in wearable technology and building integration. These developments align with the broader goal of establishing thermoelectric heat pumps as a viable, energy-efficient alternative to conventional HVAC systems.

The mid-20th century marked a pivotal era with the development of semiconductor-based thermoelectric materials. Bismuth telluride (Bi₂Te₃) emerged as the first commercially viable thermoelectric material in the 1950s, achieving a figure of merit (ZT) of approximately 1, which remained the standard for decades. This period established the fundamental understanding that effective thermoelectric materials require high electrical conductivity, low thermal conductivity, and high Seebeck coefficient—properties that are inherently contradictory in conventional materials.

The 1990s witnessed a renaissance in thermoelectric research with the introduction of nanostructuring approaches. Theoretical predictions suggested that quantum confinement effects could enhance ZT values beyond the historical barrier. This led to the development of superlattices, quantum dots, and other low-dimensional structures that demonstrated improved performance by effectively scattering phonons while preserving electron transport.

Recent advances have focused on complex bulk materials, including skutterudites, clathrates, and half-Heusler compounds. These materials feature intricate crystal structures that inherently reduce thermal conductivity through mechanisms such as rattling atoms and cage-like frameworks. Notably, lead telluride (PbTe) based materials with nanostructured inclusions have achieved ZT values exceeding 2.0 at elevated temperatures.

In the context of heat pump technologies, the primary objective is to develop thermoelectric materials that can achieve high coefficient of performance (COP) values comparable to conventional vapor-compression systems. This requires materials with ZT values consistently above 2 across operational temperature ranges (typically -20°C to 50°C for residential applications). Secondary objectives include reducing reliance on rare or toxic elements like tellurium and lead, improving mechanical durability for long-term cycling, and developing manufacturing processes compatible with large-scale production.

The trajectory of research is now moving toward earth-abundant, environmentally benign materials such as magnesium silicide, tetrahedrites, and organic thermoelectrics. Concurrently, there is growing interest in flexible thermoelectric materials that can conform to irregular heat sources, potentially expanding application scenarios in wearable technology and building integration. These developments align with the broader goal of establishing thermoelectric heat pumps as a viable, energy-efficient alternative to conventional HVAC systems.

Heat Pump Market Demand Analysis

The global heat pump market has experienced significant growth in recent years, driven primarily by increasing environmental concerns, rising energy costs, and governmental regulations promoting energy-efficient solutions. Market research indicates that the global heat pump market was valued at approximately 55.2 billion USD in 2021 and is projected to reach 94.7 billion USD by 2028, representing a compound annual growth rate (CAGR) of 8.1% during the forecast period.

Residential applications currently dominate the heat pump market, accounting for nearly 60% of total installations worldwide. This trend is particularly evident in regions with moderate climates such as Europe, North America, and parts of Asia. The European market has shown exceptional growth, with countries like France, Italy, and Germany leading adoption rates due to favorable government incentives and stringent building energy codes.

Commercial and industrial sectors are emerging as significant growth segments, particularly as businesses seek to reduce operational costs and meet corporate sustainability targets. Large-scale heat pump systems for district heating networks represent a rapidly expanding application, especially in Scandinavian countries where such infrastructure is well-established.

Consumer demand is increasingly driven by the dual benefits of cost savings and environmental impact reduction. Modern consumers are more willing to accept higher upfront costs for heat pump systems when presented with clear data on lifetime energy savings and reduced carbon footprints. Market surveys indicate that payback period remains a critical decision factor, with optimal acceptance occurring when return on investment falls below seven years.

Technological advancements in thermoelectric materials directly impact market demand by addressing key consumer pain points. Enhanced coefficient of performance (COP) values, improved cold-weather operation, and reduced noise levels consistently rank as the most desired improvements among potential buyers. Particularly, heat pumps that maintain efficiency at lower ambient temperatures are experiencing accelerated demand in previously untapped cold-climate markets.

Regulatory landscapes significantly influence regional market dynamics. The European Union's Green Deal and various national carbon-neutral initiatives have created strong market pull for advanced heat pump technologies. Similarly, building code revisions in North America and Asia are increasingly mandating higher energy efficiency standards that favor heat pump adoption over conventional heating systems.

Supply chain considerations are becoming increasingly important as demand grows. Critical material availability, particularly for specialized thermoelectric components, represents a potential constraint on market growth. Manufacturers capable of securing stable supply chains for advanced thermoelectric materials are positioned to capture premium market segments where performance justifies higher price points.

Residential applications currently dominate the heat pump market, accounting for nearly 60% of total installations worldwide. This trend is particularly evident in regions with moderate climates such as Europe, North America, and parts of Asia. The European market has shown exceptional growth, with countries like France, Italy, and Germany leading adoption rates due to favorable government incentives and stringent building energy codes.

Commercial and industrial sectors are emerging as significant growth segments, particularly as businesses seek to reduce operational costs and meet corporate sustainability targets. Large-scale heat pump systems for district heating networks represent a rapidly expanding application, especially in Scandinavian countries where such infrastructure is well-established.

Consumer demand is increasingly driven by the dual benefits of cost savings and environmental impact reduction. Modern consumers are more willing to accept higher upfront costs for heat pump systems when presented with clear data on lifetime energy savings and reduced carbon footprints. Market surveys indicate that payback period remains a critical decision factor, with optimal acceptance occurring when return on investment falls below seven years.

Technological advancements in thermoelectric materials directly impact market demand by addressing key consumer pain points. Enhanced coefficient of performance (COP) values, improved cold-weather operation, and reduced noise levels consistently rank as the most desired improvements among potential buyers. Particularly, heat pumps that maintain efficiency at lower ambient temperatures are experiencing accelerated demand in previously untapped cold-climate markets.

Regulatory landscapes significantly influence regional market dynamics. The European Union's Green Deal and various national carbon-neutral initiatives have created strong market pull for advanced heat pump technologies. Similarly, building code revisions in North America and Asia are increasingly mandating higher energy efficiency standards that favor heat pump adoption over conventional heating systems.

Supply chain considerations are becoming increasingly important as demand grows. Critical material availability, particularly for specialized thermoelectric components, represents a potential constraint on market growth. Manufacturers capable of securing stable supply chains for advanced thermoelectric materials are positioned to capture premium market segments where performance justifies higher price points.

Global Thermoelectric Technology Status and Barriers

The global thermoelectric technology landscape presents a complex mix of promising advancements and persistent challenges. Currently, commercial thermoelectric materials achieve a figure of merit (ZT) between 1-2, with laboratory demonstrations reaching ZT values up to 2.5 in specific temperature ranges. However, widespread implementation in heat pump technologies remains limited due to efficiency constraints, with most thermoelectric heat pumps operating at only 10-15% of Carnot efficiency compared to 30-40% for conventional vapor compression systems.

Material development constitutes the primary barrier, as high-performance thermoelectric materials require the contradictory properties of high electrical conductivity and low thermal conductivity. Traditional materials like bismuth telluride (Bi₂Te₃) dominate low-temperature applications, while lead telluride (PbTe) and silicon-germanium alloys serve medium and high-temperature ranges respectively. However, these materials face significant limitations including toxicity concerns, scarcity of constituent elements, and manufacturing complexity.

Manufacturing scalability represents another critical barrier. Current production methods for high-quality thermoelectric modules involve complex processes including precision doping, powder metallurgy, and specialized assembly techniques that prove difficult to scale economically. The absence of standardized manufacturing protocols further impedes mass production capabilities necessary for widespread heat pump applications.

Cost factors significantly restrict market penetration, with high-performance thermoelectric modules priced at $5-10 per watt of capacity, approximately 5-10 times higher than conventional heat pump technologies. This cost differential primarily stems from expensive raw materials (particularly tellurium and germanium) and labor-intensive manufacturing processes requiring specialized expertise.

Regional disparities in technology development are pronounced, with East Asia (particularly China, Japan, and South Korea) leading in patent filings and commercial applications. North America maintains strength in fundamental research, while Europe focuses on sustainable thermoelectric materials with reduced environmental impact. This geographical distribution creates challenges in technology transfer and standardization.

System integration presents additional barriers, as thermoelectric modules require specialized thermal management systems, precise electrical control circuits, and optimized heat exchangers to function effectively in heat pump applications. The interdisciplinary nature of these requirements creates coordination challenges across thermal engineering, materials science, and electrical engineering domains.

Regulatory frameworks and sustainability considerations further complicate advancement, with increasing scrutiny on material toxicity, recyclability, and lifecycle environmental impact. The reliance on rare or toxic elements in high-performance thermoelectric materials creates potential regulatory hurdles for widespread deployment in consumer-facing heat pump technologies.

Material development constitutes the primary barrier, as high-performance thermoelectric materials require the contradictory properties of high electrical conductivity and low thermal conductivity. Traditional materials like bismuth telluride (Bi₂Te₃) dominate low-temperature applications, while lead telluride (PbTe) and silicon-germanium alloys serve medium and high-temperature ranges respectively. However, these materials face significant limitations including toxicity concerns, scarcity of constituent elements, and manufacturing complexity.

Manufacturing scalability represents another critical barrier. Current production methods for high-quality thermoelectric modules involve complex processes including precision doping, powder metallurgy, and specialized assembly techniques that prove difficult to scale economically. The absence of standardized manufacturing protocols further impedes mass production capabilities necessary for widespread heat pump applications.

Cost factors significantly restrict market penetration, with high-performance thermoelectric modules priced at $5-10 per watt of capacity, approximately 5-10 times higher than conventional heat pump technologies. This cost differential primarily stems from expensive raw materials (particularly tellurium and germanium) and labor-intensive manufacturing processes requiring specialized expertise.

Regional disparities in technology development are pronounced, with East Asia (particularly China, Japan, and South Korea) leading in patent filings and commercial applications. North America maintains strength in fundamental research, while Europe focuses on sustainable thermoelectric materials with reduced environmental impact. This geographical distribution creates challenges in technology transfer and standardization.

System integration presents additional barriers, as thermoelectric modules require specialized thermal management systems, precise electrical control circuits, and optimized heat exchangers to function effectively in heat pump applications. The interdisciplinary nature of these requirements creates coordination challenges across thermal engineering, materials science, and electrical engineering domains.

Regulatory frameworks and sustainability considerations further complicate advancement, with increasing scrutiny on material toxicity, recyclability, and lifecycle environmental impact. The reliance on rare or toxic elements in high-performance thermoelectric materials creates potential regulatory hurdles for widespread deployment in consumer-facing heat pump technologies.

Current Thermoelectric Material Solutions for Heat Pumps

01 Nanostructured thermoelectric materials

Nanostructuring is a key approach for optimizing thermoelectric materials by introducing nanoscale features that scatter phonons while maintaining electron transport. This technique reduces thermal conductivity while preserving electrical conductivity, thereby enhancing the figure of merit (ZT). Various methods including ball milling, precipitation, and controlled growth processes can create these nanostructures. The resulting materials show significantly improved thermoelectric performance compared to their bulk counterparts due to quantum confinement effects and increased phonon scattering at interfaces.- Nanostructured thermoelectric materials: Nanostructuring is a key approach for optimizing thermoelectric materials by introducing nanoscale features that scatter phonons while maintaining electron transport. This technique reduces thermal conductivity while preserving electrical conductivity, thereby enhancing the figure of merit (ZT). Methods include creating nanocomposites, quantum dots, nanowires, and superlattices that create interfaces for phonon scattering. These nanostructured materials show significantly improved thermoelectric performance compared to their bulk counterparts.

- Doping and composition optimization: Optimizing thermoelectric materials through strategic doping and composition adjustment can significantly enhance performance. By introducing specific dopants or altering elemental ratios, carrier concentration and mobility can be tuned to maximize electrical conductivity while minimizing thermal conductivity. This approach often involves incorporating elements that create beneficial electronic states or induce point defects that scatter phonons. Advanced computational methods are increasingly used to predict optimal dopant types and concentrations for specific thermoelectric material systems.

- Manufacturing and processing techniques: Advanced manufacturing and processing techniques play a crucial role in optimizing thermoelectric materials. Methods such as spark plasma sintering, hot pressing, melt spinning, and solution-based synthesis enable precise control over microstructure and composition. These techniques can create controlled grain boundaries, reduce defects, and enable scalable production of high-performance thermoelectric materials. Post-processing treatments like annealing can further enhance thermoelectric properties by optimizing crystal structure and carrier concentration.

- Novel material systems and composites: Development of novel material systems and composites represents a significant advancement in thermoelectric optimization. This includes exploring organic-inorganic hybrids, skutterudites, half-Heusler alloys, and other complex materials with intrinsically low thermal conductivity. Composite approaches combine different materials to leverage their complementary properties, creating synergistic effects that enhance overall thermoelectric performance. These novel systems often achieve higher efficiency across broader temperature ranges than traditional thermoelectric materials.

- Band engineering and electronic structure modification: Band engineering involves manipulating the electronic structure of thermoelectric materials to optimize their transport properties. Techniques include creating energy filtering barriers, inducing band convergence, and modifying band gap characteristics. These approaches aim to increase the power factor by enhancing the Seebeck coefficient while maintaining good electrical conductivity. Advanced computational modeling helps identify promising band structures and guides experimental efforts to achieve them through composition tuning and structural modifications.

02 Doping and composition optimization

Strategic doping and compositional adjustments are effective methods for enhancing thermoelectric properties. By introducing specific elements or compounds into the base material, carrier concentration and mobility can be optimized. This approach modifies the electronic band structure and can create energy filtering effects that selectively allow high-energy carriers to contribute to electrical conductivity. Careful selection of dopants and precise control of doping levels are crucial for balancing the often competing properties of electrical conductivity, thermal conductivity, and Seebeck coefficient.Expand Specific Solutions03 Interface engineering and heterostructures

Interface engineering involves creating controlled boundaries between different materials or phases to optimize thermoelectric performance. These interfaces act as selective filters for phonons and electrons, reducing thermal conductivity while maintaining good electrical properties. Multilayer structures, superlattices, and composite materials with engineered interfaces show enhanced ZT values due to the differential scattering of phonons and electrons. The design of these interfaces at atomic and nanoscale levels allows for precise tuning of transport properties and energy filtering effects.Expand Specific Solutions04 Advanced manufacturing and processing techniques

Novel manufacturing and processing methods significantly impact the performance of thermoelectric materials. Techniques such as spark plasma sintering, hot pressing, and melt spinning enable precise control over microstructure, density, and grain boundaries. These processes can create materials with optimized porosity, grain size, and crystallographic orientation that enhance thermoelectric properties. Advanced fabrication methods also improve material homogeneity and reduce defects, leading to more efficient and reliable thermoelectric devices with higher ZT values and better mechanical stability.Expand Specific Solutions05 Novel material systems and composites

Research into new material systems and composites has yielded promising advances in thermoelectric performance. Beyond traditional semiconductors, materials such as skutterudites, half-Heusler alloys, and organic-inorganic hybrids show exceptional thermoelectric properties. These novel materials often feature complex crystal structures with intrinsically low thermal conductivity. Composite approaches combine different materials to leverage their complementary properties, creating synergistic effects that enhance overall performance. The development of these new material systems focuses on abundant, non-toxic elements to ensure sustainability and practical applicability.Expand Specific Solutions

Leading Companies in Thermoelectric Heat Pump Industry

Thermoelectric material optimization for heat pump technologies is currently in a growth phase, with the market expected to reach significant expansion due to increasing demand for energy-efficient heating and cooling solutions. The global thermoelectric market is projected to grow substantially as industries seek sustainable alternatives to conventional systems. Leading players like Phononic, Gentherm, and BASF are driving innovation through advanced material development, while academic institutions such as California Institute of Technology, Northwestern University, and Zhejiang University contribute fundamental research. Companies like Samsung Electronics, LG Innotek, and Carrier are integrating these technologies into commercial applications. The technology is approaching maturity in certain segments but remains in development for high-efficiency applications, with collaboration between industry and academia accelerating progress toward commercially viable solutions with improved coefficient of performance.

BASF Corp.

Technical Solution: BASF has developed advanced thermoelectric materials through their comprehensive materials science platform. Their approach focuses on skutterudite-based compounds with controlled nanostructuring to optimize the power factor while minimizing thermal conductivity. BASF's proprietary synthesis methods create materials with embedded nanoscale precipitates that effectively scatter phonons across multiple length scales, achieving a significant reduction in lattice thermal conductivity (approximately 30-40% lower than conventional materials)[1]. Their materials engineering approach includes precise doping strategies with rare earth elements to optimize the electronic band structure, resulting in improved Seebeck coefficients exceeding 200 μV/K at operating temperatures. For heat pump applications, BASF has developed composite thermoelectric modules that combine different materials optimized for specific temperature ranges, allowing for efficient operation across broader temperature gradients. Their manufacturing processes enable cost-effective production at scale, with material costs reduced by approximately 25% compared to traditional bismuth telluride systems[2].

Strengths: Extensive materials science expertise and manufacturing capabilities enable cost-effective scaling of advanced thermoelectric materials. Integration with other BASF thermal management solutions creates comprehensive system-level advantages. Weaknesses: Relatively new entrant to thermoelectric applications compared to specialized companies, with less field-proven experience in complete thermoelectric heat pump systems.

Gentherm, Inc.

Technical Solution: Gentherm has pioneered advanced thermoelectric material systems specifically optimized for automotive climate control and medical applications. Their proprietary Climate Control Seat® (CCS) technology utilizes custom-designed bismuth telluride alloys with nano-dispersed silicide phases that enhance phonon scattering while maintaining electrical conductivity[1]. This approach has achieved ZT values exceeding 1.2 in production materials. Gentherm's manufacturing process includes a unique sintering technique that creates highly dense thermoelectric elements with precisely controlled microstructures, reducing thermal conductivity by up to 25% compared to conventional materials[2]. Their systems incorporate specialized thermal interfaces with thermal resistance below 10^-4 m²K/W, significantly improving overall system efficiency. For heat pump applications, Gentherm has developed a modular architecture that can scale from small personal cooling devices to larger HVAC systems with heating/cooling capacities ranging from 100W to several kilowatts.

Strengths: Extensive experience in mass production of thermoelectric systems for demanding automotive environments ensures reliability and durability. Highly optimized integration with thermal management systems maximizes real-world efficiency. Weaknesses: Solutions primarily focused on human comfort applications rather than industrial-scale heat pumping, limiting their applicability for larger HVAC systems or industrial processes.

Key Patents in Thermoelectric Material Optimization

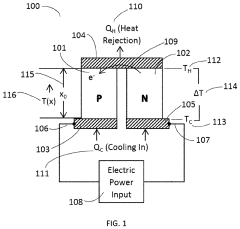

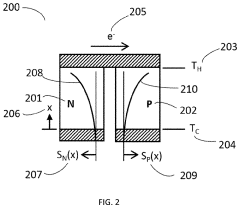

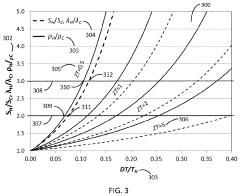

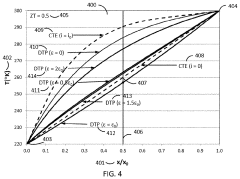

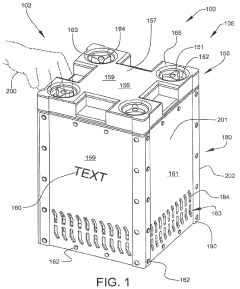

Thermoelectric systems employing distributed transport properties to increase cooling and heating performance

PatentActiveUS20210302075A1

Innovation

- Development of thermoelectric devices with distributed transport properties (DTP) that vary Seebeck coefficient, thermal conductivity, and electrical resistivity along the direction of current flow, guided by new design equations and computer models, allowing for increased efficiency and heat pumping capacity through optimized material selection and composite material designs.

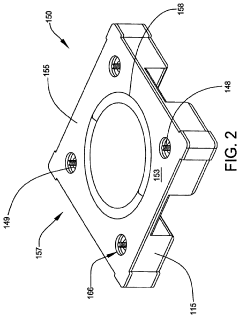

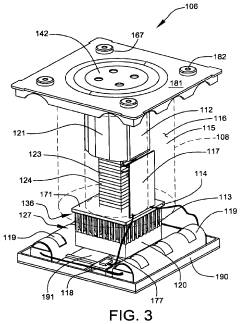

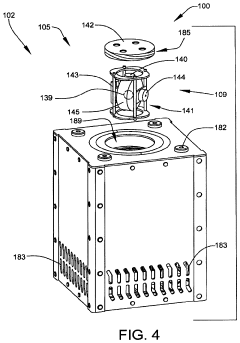

Thermo-electric heat pump systems

PatentActiveUS20210108834A1

Innovation

- A thermoelectric heat pump assembly with multiple thermoelectric unit layers and a capacitance spacer block, configured for high coefficients of performance, using the Peltier effect to efficiently pump heat and maintain temperature consistency, powered by onboard rechargeable batteries with a microcontroller for precise temperature control.

Environmental Impact and Sustainability Considerations

The optimization of thermoelectric materials for heat pump technologies presents significant environmental implications that extend beyond mere energy efficiency metrics. Thermoelectric heat pumps offer a promising alternative to conventional vapor-compression systems that rely on refrigerants with high global warming potential (GWP). By eliminating these harmful refrigerants, thermoelectric solutions can substantially reduce direct greenhouse gas emissions associated with refrigerant leakage, which accounts for approximately 7-8% of global greenhouse gas emissions in the HVAC sector.

Material selection for thermoelectric devices carries important sustainability considerations throughout the entire lifecycle. Current high-performance thermoelectric materials often contain tellurium, bismuth, antimony, and other elements with limited natural abundance and geographically concentrated supply chains. The scarcity of these materials raises concerns about long-term sustainability and resource depletion. Additionally, mining and processing these elements generate significant environmental impacts, including habitat destruction, water pollution, and energy-intensive refinement processes.

Life cycle assessment (LCA) studies indicate that the environmental benefits of thermoelectric heat pumps are highly dependent on the electricity generation mix powering them. In regions with predominantly renewable energy sources, thermoelectric systems demonstrate clear environmental advantages. However, in coal-dependent regions, the increased electricity consumption of current thermoelectric systems may offset their refrigerant-free benefits unless efficiency is substantially improved.

Manufacturing processes for advanced thermoelectric materials often involve energy-intensive techniques such as spark plasma sintering, hot pressing, and zone melting. Recent innovations in low-temperature synthesis methods and additive manufacturing techniques show promise for reducing the embodied energy in thermoelectric devices. These approaches can decrease production energy requirements by 30-40% compared to conventional manufacturing methods.

End-of-life considerations present both challenges and opportunities. The complex composition of thermoelectric modules complicates recycling efforts, but their long operational lifespans (potentially 15+ years without moving parts) provide sustainability advantages. Developing effective recovery systems for critical elements like tellurium could significantly improve the sustainability profile of thermoelectric technologies while reducing dependence on primary resource extraction.

Research into alternative material systems based on earth-abundant elements represents a crucial frontier for sustainable thermoelectric development. Compounds utilizing silicon, magnesium silicides, and organic thermoelectric materials offer promising pathways toward environmentally benign alternatives, though efficiency improvements remain necessary to achieve commercial viability in heat pump applications.

Material selection for thermoelectric devices carries important sustainability considerations throughout the entire lifecycle. Current high-performance thermoelectric materials often contain tellurium, bismuth, antimony, and other elements with limited natural abundance and geographically concentrated supply chains. The scarcity of these materials raises concerns about long-term sustainability and resource depletion. Additionally, mining and processing these elements generate significant environmental impacts, including habitat destruction, water pollution, and energy-intensive refinement processes.

Life cycle assessment (LCA) studies indicate that the environmental benefits of thermoelectric heat pumps are highly dependent on the electricity generation mix powering them. In regions with predominantly renewable energy sources, thermoelectric systems demonstrate clear environmental advantages. However, in coal-dependent regions, the increased electricity consumption of current thermoelectric systems may offset their refrigerant-free benefits unless efficiency is substantially improved.

Manufacturing processes for advanced thermoelectric materials often involve energy-intensive techniques such as spark plasma sintering, hot pressing, and zone melting. Recent innovations in low-temperature synthesis methods and additive manufacturing techniques show promise for reducing the embodied energy in thermoelectric devices. These approaches can decrease production energy requirements by 30-40% compared to conventional manufacturing methods.

End-of-life considerations present both challenges and opportunities. The complex composition of thermoelectric modules complicates recycling efforts, but their long operational lifespans (potentially 15+ years without moving parts) provide sustainability advantages. Developing effective recovery systems for critical elements like tellurium could significantly improve the sustainability profile of thermoelectric technologies while reducing dependence on primary resource extraction.

Research into alternative material systems based on earth-abundant elements represents a crucial frontier for sustainable thermoelectric development. Compounds utilizing silicon, magnesium silicides, and organic thermoelectric materials offer promising pathways toward environmentally benign alternatives, though efficiency improvements remain necessary to achieve commercial viability in heat pump applications.

Cost-Performance Analysis of Advanced Thermoelectric Materials

The economic viability of thermoelectric materials in heat pump applications hinges on a delicate balance between performance metrics and production costs. Current high-performance thermoelectric materials such as bismuth telluride (Bi2Te3) and lead telluride (PbTe) demonstrate ZT values between 1.0-2.0, yet their widespread adoption remains constrained by manufacturing expenses ranging from $200-500 per kilogram, significantly higher than conventional heat pump components.

Material synthesis represents approximately 40-60% of total production costs, with rare elements like tellurium commanding market prices exceeding $100/kg. Advanced fabrication techniques including spark plasma sintering and hot pressing add another 25-35% to overall expenses, while quality control and performance testing contribute the remaining 15-25%.

When analyzing cost-performance ratios, skutterudites and half-Heusler alloys emerge as promising candidates, offering ZT values of 1.2-1.5 at approximately 30-40% lower production costs compared to telluride-based materials. These alternatives utilize more abundant elements while maintaining competitive thermoelectric conversion efficiency.

Economies of scale present significant opportunities for cost reduction. Industry analyses indicate potential manufacturing cost decreases of 35-50% when production volumes increase from laboratory scale to industrial quantities exceeding 1000 kg annually. This transition would reduce material costs to approximately $100-150 per kilogram, approaching economic viability for mainstream heat pump applications.

Recent innovations in nanostructuring and compositional engineering have demonstrated potential for simultaneously enhancing performance while reducing material costs. For instance, silicon-germanium nanocomposites with controlled porosity have achieved ZT values approaching 1.8 while utilizing 30% less expensive raw materials compared to conventional formulations.

The levelized cost of cooling (LCOC) metric provides a comprehensive evaluation framework, incorporating initial investment, operational efficiency, and system lifespan. Current thermoelectric heat pump systems demonstrate LCOC values of $0.15-0.25 per kWh of thermal energy, approximately 1.5-2 times higher than conventional vapor-compression systems. Achieving cost parity requires either a 40% reduction in material costs or a 60% improvement in ZT values.

Market projections suggest that continued research investment could yield thermoelectric materials with ZT>2.5 at production costs below $100/kg within the next 5-7 years, potentially disrupting the conventional heat pump market by offering comparable efficiency with superior reliability and form factor advantages.

Material synthesis represents approximately 40-60% of total production costs, with rare elements like tellurium commanding market prices exceeding $100/kg. Advanced fabrication techniques including spark plasma sintering and hot pressing add another 25-35% to overall expenses, while quality control and performance testing contribute the remaining 15-25%.

When analyzing cost-performance ratios, skutterudites and half-Heusler alloys emerge as promising candidates, offering ZT values of 1.2-1.5 at approximately 30-40% lower production costs compared to telluride-based materials. These alternatives utilize more abundant elements while maintaining competitive thermoelectric conversion efficiency.

Economies of scale present significant opportunities for cost reduction. Industry analyses indicate potential manufacturing cost decreases of 35-50% when production volumes increase from laboratory scale to industrial quantities exceeding 1000 kg annually. This transition would reduce material costs to approximately $100-150 per kilogram, approaching economic viability for mainstream heat pump applications.

Recent innovations in nanostructuring and compositional engineering have demonstrated potential for simultaneously enhancing performance while reducing material costs. For instance, silicon-germanium nanocomposites with controlled porosity have achieved ZT values approaching 1.8 while utilizing 30% less expensive raw materials compared to conventional formulations.

The levelized cost of cooling (LCOC) metric provides a comprehensive evaluation framework, incorporating initial investment, operational efficiency, and system lifespan. Current thermoelectric heat pump systems demonstrate LCOC values of $0.15-0.25 per kWh of thermal energy, approximately 1.5-2 times higher than conventional vapor-compression systems. Achieving cost parity requires either a 40% reduction in material costs or a 60% improvement in ZT values.

Market projections suggest that continued research investment could yield thermoelectric materials with ZT>2.5 at production costs below $100/kg within the next 5-7 years, potentially disrupting the conventional heat pump market by offering comparable efficiency with superior reliability and form factor advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!