How to Achieve Ultra-High Efficiency in Thermoelectric Modules

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Evolution and Efficiency Goals

Thermoelectric technology has evolved significantly since its discovery in the early 19th century. The Seebeck effect, discovered by Thomas Johann Seebeck in 1821, laid the foundation for thermoelectric power generation. This was followed by Jean Peltier's discovery of the Peltier effect in 1834, which enabled thermoelectric cooling applications. However, for many decades, thermoelectric devices remained primarily laboratory curiosities due to their extremely low efficiency.

The mid-20th century marked a turning point with the development of semiconductor-based thermoelectric materials. In the 1950s, Abram Ioffe pioneered the concept of using semiconductors for thermoelectric applications, introducing the figure of merit ZT as the key parameter for evaluating thermoelectric efficiency. This period saw the first commercial applications of thermoelectric technology, primarily in specialized cooling applications and remote power generation for space missions.

From the 1960s through the 1990s, thermoelectric technology advanced incrementally, with ZT values hovering around 1, limiting conversion efficiency to approximately 4-6%. This plateau represented a significant barrier to widespread commercial adoption beyond niche applications. The fundamental challenge remained the interdependence of thermal conductivity, electrical conductivity, and Seebeck coefficient—improving one parameter often negatively impacted the others.

The early 2000s witnessed a renaissance in thermoelectric research with the introduction of nanostructured materials and quantum confinement effects. Researchers demonstrated that nanostructuring could effectively decouple these interdependent parameters, particularly by reducing thermal conductivity without significantly affecting electrical properties. This led to reported ZT values exceeding 2 in laboratory settings.

Current technological goals focus on achieving commercially viable modules with ZT values consistently above 2, which would enable conversion efficiencies of 15-20%. The ultimate aspiration is to reach ZT values of 3 or higher, potentially enabling efficiencies approaching 30%, which would make thermoelectric technology competitive with traditional mechanical heat engines for many applications.

The evolution trajectory points toward multi-material, multi-scale engineered systems that optimize electron transport while minimizing phonon transport. Research is increasingly focused on earth-abundant, non-toxic materials to ensure sustainability and scalability. Additionally, there is growing interest in flexible thermoelectric generators for wearable applications and integration with IoT devices.

For industrial-scale waste heat recovery, the efficiency target is to achieve cost-effectiveness at $1-2 per watt, requiring both higher ZT values and reduced manufacturing costs. The automotive sector specifically aims for thermoelectric generators that can improve fuel efficiency by 3-5% through waste heat recovery from exhaust systems.

The mid-20th century marked a turning point with the development of semiconductor-based thermoelectric materials. In the 1950s, Abram Ioffe pioneered the concept of using semiconductors for thermoelectric applications, introducing the figure of merit ZT as the key parameter for evaluating thermoelectric efficiency. This period saw the first commercial applications of thermoelectric technology, primarily in specialized cooling applications and remote power generation for space missions.

From the 1960s through the 1990s, thermoelectric technology advanced incrementally, with ZT values hovering around 1, limiting conversion efficiency to approximately 4-6%. This plateau represented a significant barrier to widespread commercial adoption beyond niche applications. The fundamental challenge remained the interdependence of thermal conductivity, electrical conductivity, and Seebeck coefficient—improving one parameter often negatively impacted the others.

The early 2000s witnessed a renaissance in thermoelectric research with the introduction of nanostructured materials and quantum confinement effects. Researchers demonstrated that nanostructuring could effectively decouple these interdependent parameters, particularly by reducing thermal conductivity without significantly affecting electrical properties. This led to reported ZT values exceeding 2 in laboratory settings.

Current technological goals focus on achieving commercially viable modules with ZT values consistently above 2, which would enable conversion efficiencies of 15-20%. The ultimate aspiration is to reach ZT values of 3 or higher, potentially enabling efficiencies approaching 30%, which would make thermoelectric technology competitive with traditional mechanical heat engines for many applications.

The evolution trajectory points toward multi-material, multi-scale engineered systems that optimize electron transport while minimizing phonon transport. Research is increasingly focused on earth-abundant, non-toxic materials to ensure sustainability and scalability. Additionally, there is growing interest in flexible thermoelectric generators for wearable applications and integration with IoT devices.

For industrial-scale waste heat recovery, the efficiency target is to achieve cost-effectiveness at $1-2 per watt, requiring both higher ZT values and reduced manufacturing costs. The automotive sector specifically aims for thermoelectric generators that can improve fuel efficiency by 3-5% through waste heat recovery from exhaust systems.

Market Demand Analysis for High-Efficiency Thermoelectric Solutions

The global market for high-efficiency thermoelectric solutions is experiencing significant growth driven by increasing demand for waste heat recovery systems and sustainable energy solutions. Current market estimates value the thermoelectric generator market at approximately $460 million in 2023, with projections indicating growth to reach $1.2 billion by 2030, representing a compound annual growth rate of 14.7% during the forecast period.

Industrial waste heat recovery represents the largest application segment, accounting for nearly 40% of the total market share. Manufacturing facilities, power plants, and chemical processing industries are increasingly adopting thermoelectric modules to convert waste heat into usable electricity, thereby improving overall energy efficiency and reducing operational costs.

The automotive sector has emerged as a rapidly growing market for thermoelectric solutions, particularly for improving fuel efficiency in internal combustion engines and extending the range of electric vehicles. Major automotive manufacturers are investing in thermoelectric systems that can recover waste heat from exhaust systems, with potential fuel efficiency improvements of 3-5% being reported in field tests.

Consumer electronics and wearable technology markets are also driving demand for miniaturized, high-efficiency thermoelectric modules. The growing trend toward self-powered IoT devices and sensors has created a niche market for thermoelectric generators that can harvest small temperature differentials to power low-energy electronics.

Geographic analysis reveals that North America and Europe currently lead the market adoption of high-efficiency thermoelectric solutions, primarily due to stringent environmental regulations and corporate sustainability initiatives. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization in China and India, coupled with increasing government support for clean energy technologies.

Market research indicates that customers are primarily concerned with three key performance metrics when evaluating thermoelectric solutions: conversion efficiency, cost-effectiveness, and durability. Current commercial thermoelectric modules typically operate at 5-8% efficiency, significantly below the theoretical maximum. Industry surveys suggest that achieving efficiency levels of 15-20% would trigger widespread adoption across multiple sectors.

Price sensitivity varies significantly by application segment. While industrial customers prioritize return on investment and are willing to pay premium prices for solutions with demonstrable energy savings, consumer electronics manufacturers require low-cost solutions to maintain competitive pricing structures. This dichotomy presents both challenges and opportunities for market segmentation strategies.

The regulatory landscape is increasingly favorable for thermoelectric technologies, with government incentives for energy efficiency and carbon reduction creating market pull. Carbon pricing mechanisms in Europe and renewable energy credits in North America are making waste heat recovery solutions more economically attractive, further stimulating market demand for high-efficiency thermoelectric modules.

Industrial waste heat recovery represents the largest application segment, accounting for nearly 40% of the total market share. Manufacturing facilities, power plants, and chemical processing industries are increasingly adopting thermoelectric modules to convert waste heat into usable electricity, thereby improving overall energy efficiency and reducing operational costs.

The automotive sector has emerged as a rapidly growing market for thermoelectric solutions, particularly for improving fuel efficiency in internal combustion engines and extending the range of electric vehicles. Major automotive manufacturers are investing in thermoelectric systems that can recover waste heat from exhaust systems, with potential fuel efficiency improvements of 3-5% being reported in field tests.

Consumer electronics and wearable technology markets are also driving demand for miniaturized, high-efficiency thermoelectric modules. The growing trend toward self-powered IoT devices and sensors has created a niche market for thermoelectric generators that can harvest small temperature differentials to power low-energy electronics.

Geographic analysis reveals that North America and Europe currently lead the market adoption of high-efficiency thermoelectric solutions, primarily due to stringent environmental regulations and corporate sustainability initiatives. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization in China and India, coupled with increasing government support for clean energy technologies.

Market research indicates that customers are primarily concerned with three key performance metrics when evaluating thermoelectric solutions: conversion efficiency, cost-effectiveness, and durability. Current commercial thermoelectric modules typically operate at 5-8% efficiency, significantly below the theoretical maximum. Industry surveys suggest that achieving efficiency levels of 15-20% would trigger widespread adoption across multiple sectors.

Price sensitivity varies significantly by application segment. While industrial customers prioritize return on investment and are willing to pay premium prices for solutions with demonstrable energy savings, consumer electronics manufacturers require low-cost solutions to maintain competitive pricing structures. This dichotomy presents both challenges and opportunities for market segmentation strategies.

The regulatory landscape is increasingly favorable for thermoelectric technologies, with government incentives for energy efficiency and carbon reduction creating market pull. Carbon pricing mechanisms in Europe and renewable energy credits in North America are making waste heat recovery solutions more economically attractive, further stimulating market demand for high-efficiency thermoelectric modules.

Current State and Challenges in Thermoelectric Efficiency

Thermoelectric technology has witnessed significant advancements over the past decades, yet the global state of thermoelectric efficiency remains constrained by fundamental physical limitations. Current commercial thermoelectric modules typically operate at efficiency levels between 5-8%, with laboratory prototypes reaching approximately 10-12% under optimal conditions. This efficiency gap represents one of the most significant barriers to widespread adoption of thermoelectric technology in mainstream energy applications.

The figure of merit ZT, which combines electrical conductivity, thermal conductivity, and Seebeck coefficient, serves as the primary metric for thermoelectric performance. While theoretical models suggest that ZT values exceeding 3 could enable efficiencies approaching 30%, most state-of-the-art materials struggle to maintain ZT values above 2 across practical operating temperature ranges. This discrepancy between theoretical potential and practical achievement constitutes a central challenge in the field.

Material limitations present substantial obstacles to efficiency improvements. The interdependence of electrical and thermal properties creates an inherent trade-off: enhancements in electrical conductivity often lead to corresponding increases in thermal conductivity, which diminishes overall thermoelectric performance. This coupling effect, known as the Wiedemann-Franz law, has proven particularly difficult to circumvent despite extensive research efforts.

Manufacturing challenges further complicate efficiency optimization. Contact resistance at material interfaces can significantly degrade module performance, while achieving consistent quality across large-scale production remains problematic. Current fabrication techniques struggle to maintain the precise nanostructures and material compositions necessary for high-efficiency operation, particularly when scaling beyond laboratory environments.

Geographic distribution of thermoelectric research and development shows notable concentration in East Asia (particularly Japan, China, and South Korea), North America, and Europe. China has emerged as a leader in both research output and manufacturing capacity, while specialized research clusters in Germany, the United States, and Japan continue to produce significant innovations in material science approaches.

Temperature management represents another critical challenge, as most thermoelectric materials exhibit optimal performance only within narrow temperature ranges. The development of segmented modules that incorporate different materials optimized for specific temperature zones has shown promise but introduces additional complexity in manufacturing and reliability.

Durability and lifecycle considerations further constrain practical applications, with thermal cycling, oxidation, and mechanical stress limiting the operational lifespan of high-performance thermoelectric modules. These reliability issues become particularly pronounced in applications requiring sustained operation under variable conditions, such as automotive waste heat recovery systems.

The figure of merit ZT, which combines electrical conductivity, thermal conductivity, and Seebeck coefficient, serves as the primary metric for thermoelectric performance. While theoretical models suggest that ZT values exceeding 3 could enable efficiencies approaching 30%, most state-of-the-art materials struggle to maintain ZT values above 2 across practical operating temperature ranges. This discrepancy between theoretical potential and practical achievement constitutes a central challenge in the field.

Material limitations present substantial obstacles to efficiency improvements. The interdependence of electrical and thermal properties creates an inherent trade-off: enhancements in electrical conductivity often lead to corresponding increases in thermal conductivity, which diminishes overall thermoelectric performance. This coupling effect, known as the Wiedemann-Franz law, has proven particularly difficult to circumvent despite extensive research efforts.

Manufacturing challenges further complicate efficiency optimization. Contact resistance at material interfaces can significantly degrade module performance, while achieving consistent quality across large-scale production remains problematic. Current fabrication techniques struggle to maintain the precise nanostructures and material compositions necessary for high-efficiency operation, particularly when scaling beyond laboratory environments.

Geographic distribution of thermoelectric research and development shows notable concentration in East Asia (particularly Japan, China, and South Korea), North America, and Europe. China has emerged as a leader in both research output and manufacturing capacity, while specialized research clusters in Germany, the United States, and Japan continue to produce significant innovations in material science approaches.

Temperature management represents another critical challenge, as most thermoelectric materials exhibit optimal performance only within narrow temperature ranges. The development of segmented modules that incorporate different materials optimized for specific temperature zones has shown promise but introduces additional complexity in manufacturing and reliability.

Durability and lifecycle considerations further constrain practical applications, with thermal cycling, oxidation, and mechanical stress limiting the operational lifespan of high-performance thermoelectric modules. These reliability issues become particularly pronounced in applications requiring sustained operation under variable conditions, such as automotive waste heat recovery systems.

Current Approaches to Enhance Thermoelectric Efficiency

01 Material selection for thermoelectric efficiency improvement

The choice of materials significantly impacts the efficiency of thermoelectric modules. Advanced semiconductor materials with high Seebeck coefficients and low thermal conductivity can enhance the figure of merit (ZT) of thermoelectric devices. Research focuses on developing novel materials such as bismuth telluride alloys, skutterudites, and nanostructured composites that can operate efficiently across various temperature ranges, thereby improving the overall conversion efficiency of thermoelectric modules.- Material selection for improved thermoelectric efficiency: The selection of appropriate materials is crucial for enhancing the efficiency of thermoelectric modules. Materials with high Seebeck coefficient, high electrical conductivity, and low thermal conductivity are preferred. Advanced semiconductor materials, nanostructured materials, and composite materials have shown significant improvements in thermoelectric performance. These materials can effectively convert temperature differences into electrical energy with minimal energy loss.

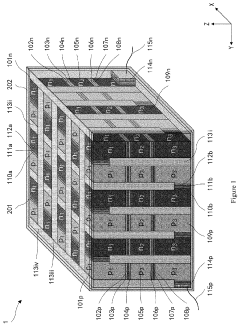

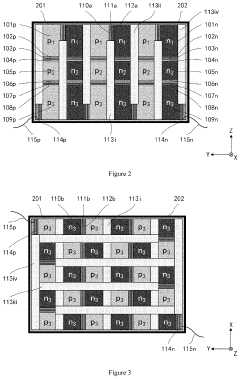

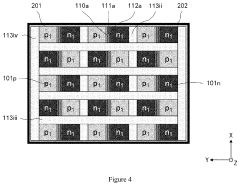

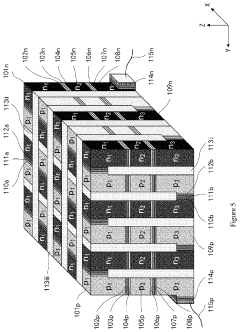

- Structural design optimization of thermoelectric modules: The structural design of thermoelectric modules significantly impacts their efficiency. Optimized geometries, improved contact interfaces, and innovative module architectures can reduce thermal and electrical resistance. Multi-stage designs, segmented structures, and cascaded configurations allow for operation across wider temperature gradients. Advanced manufacturing techniques enable precise fabrication of optimized structures that maximize power output and conversion efficiency.

- Thermal management techniques for efficiency enhancement: Effective thermal management is essential for maximizing thermoelectric module efficiency. This includes optimizing heat transfer at hot and cold sides, minimizing thermal resistance, and maintaining optimal temperature gradients. Heat sink designs, cooling systems, and thermal interface materials play crucial roles in system performance. Techniques such as heat spreading, active cooling, and thermal isolation help maintain temperature differentials and improve overall conversion efficiency.

- Novel junction and interface technologies: Advanced junction and interface technologies significantly impact thermoelectric module efficiency. Improved electrical contacts, reduced contact resistance, and enhanced thermal interfaces minimize energy losses at material boundaries. Novel bonding techniques, interface layers, and contact materials help maintain structural integrity while facilitating efficient energy conversion. These technologies address one of the major efficiency bottlenecks in thermoelectric systems by optimizing the transfer of heat and electricity across material interfaces.

- System-level integration and application-specific optimization: System-level integration approaches focus on optimizing thermoelectric modules for specific applications and operating conditions. This includes power conditioning circuits, control systems, and application-specific designs that maximize efficiency under real-world conditions. Hybrid systems combining thermoelectric modules with other energy technologies can achieve higher overall efficiency. Waste heat recovery systems, automotive applications, and consumer electronics each require tailored optimization strategies to achieve maximum performance.

02 Structural design optimization of thermoelectric modules

The physical configuration and structural design of thermoelectric modules play crucial roles in maximizing efficiency. Innovations include optimized leg geometry, improved electrical contacts, reduced thermal resistance at interfaces, and enhanced heat transfer mechanisms. Advanced designs incorporate segmented or cascaded structures that operate efficiently across temperature gradients, as well as miniaturized or flexible configurations for specific applications, all contributing to higher conversion efficiencies.Expand Specific Solutions03 Thermal management techniques for efficiency enhancement

Effective thermal management is essential for maximizing thermoelectric module efficiency. Techniques include optimized heat sink designs, improved heat spreading mechanisms, and enhanced heat transfer at hot and cold junctions. Advanced cooling methods, thermal interface materials, and heat flow control strategies help maintain optimal temperature gradients across the module, reducing thermal losses and improving overall system performance under various operating conditions.Expand Specific Solutions04 Nanostructuring and interface engineering

Nanostructuring and interface engineering represent cutting-edge approaches to improving thermoelectric efficiency. These techniques involve creating nanoscale features within thermoelectric materials to scatter phonons (reducing thermal conductivity) while maintaining electron transport. Methods include quantum dot superlattices, nanowire arrays, nanocomposites, and engineered interfaces between materials. These approaches help overcome the traditional interdependence of thermal and electrical properties, allowing for higher ZT values and improved conversion efficiencies.Expand Specific Solutions05 System-level integration and power conditioning

System-level integration and power conditioning strategies significantly impact the practical efficiency of thermoelectric modules. This includes optimized electrical load matching, advanced power management circuits, and integration with complementary energy harvesting technologies. Innovations focus on maximum power point tracking, DC-DC conversion optimization, and hybrid system designs that can adapt to varying temperature conditions and power demands, ensuring that thermoelectric modules operate at their peak efficiency points under real-world conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Industry

The thermoelectric module efficiency market is currently in a growth phase, with increasing demand for waste heat recovery solutions driving innovation. The global market size is projected to expand significantly as industries seek sustainable energy solutions. Technologically, the field remains challenging with most commercial modules achieving only 5-8% efficiency. Leading players like Phononic and O-Flexx Technologies are pioneering advanced materials and designs, while established corporations including Intel, LG Innotek, and Toshiba are leveraging their manufacturing expertise to improve scalability. Research institutions such as Industrial Technology Research Institute and Korea Electrotechnology Research Institute are contributing fundamental breakthroughs in material science. The competitive landscape features both specialized thermoelectric companies and diversified electronics manufacturers working to overcome the efficiency barriers that have historically limited widespread adoption.

Yamaha Corp.

Technical Solution:

Intel Corp.

Technical Solution: Intel has developed advanced thermoelectric cooling solutions primarily focused on thermal management for high-performance computing systems. Their approach combines materials science innovations with system-level integration expertise. Intel's thermoelectric technology utilizes nano-engineered semiconductor materials with precisely controlled doping profiles to enhance the Seebeck coefficient while minimizing thermal conductivity. Their modules incorporate thin-film deposition techniques that create superlattice structures with quantum confinement effects, significantly boosting the ZT figure of merit above conventional bulk materials. Intel has also pioneered advanced contact metallization processes that reduce parasitic electrical and thermal resistances at material interfaces. Their integrated approach includes sophisticated power delivery and control systems that optimize the coefficient of performance across varying thermal loads and operating conditions.

Strengths: Exceptional system integration capabilities that optimize the entire thermal management solution; advanced manufacturing infrastructure enables precise material engineering at nanoscale. Weaknesses: Solutions primarily optimized for computing applications rather than broader energy harvesting markets; high development costs limit application to premium market segments.

Key Innovations in High-ZT Materials and Module Design

High performance thermoelectric device and method of manufacturing the same at ultra-high speed

PatentActiveUS11101420B2

Innovation

- A high-performance thermoelectric device is designed with segmented high-temperature, intermediate-temperature, and low-temperature thermoelectric materials, alternated phonon scattering layers, and negative thermal expansion buffering layers, combined with a package structure for enhanced stability and efficiency, and a manufacturing method involving spark plasma sintering and chemical vapor deposition for rapid production.

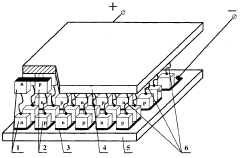

Thermoelectric module

PatentWO2012173519A1

Innovation

- The design separates the substrates by a considerable distance using metal conductors to minimize thermal influence between the hot and cold junctions, allowing for increased temperature differences and efficiency.

Environmental Impact and Sustainability of Thermoelectric Technologies

The pursuit of ultra-high efficiency in thermoelectric modules must be balanced with environmental considerations to ensure sustainable technological advancement. Thermoelectric technologies offer significant environmental benefits through waste heat recovery, potentially reducing global carbon emissions by converting otherwise wasted thermal energy into usable electricity. Studies indicate that industrial waste heat recovery systems utilizing advanced thermoelectric modules could reduce carbon emissions by 5-15% in energy-intensive industries such as steel manufacturing and power generation.

However, the environmental impact of thermoelectric module production presents notable concerns. Many high-efficiency thermoelectric materials contain rare or toxic elements such as tellurium, bismuth, and lead. The mining and processing of these materials contribute to habitat destruction, water pollution, and significant carbon emissions. Life cycle assessments reveal that the production phase of thermoelectric modules can generate substantial environmental footprints, potentially offsetting their operational benefits if not properly managed.

Material sustainability represents a critical challenge for the thermoelectric industry. Current research focuses on developing alternative materials with reduced environmental impact while maintaining high efficiency. Earth-abundant materials such as silicides, oxides, and organic thermoelectric compounds show promising ZT values while significantly reducing reliance on scarce resources. These sustainable alternatives, though currently less efficient than conventional materials, demonstrate the potential for environmentally responsible thermoelectric technologies.

End-of-life management for thermoelectric modules requires careful consideration. The complex composition of these devices complicates recycling efforts, with less than 20% of materials currently recovered from discarded modules. Advanced recycling technologies, including hydrometallurgical and pyrometallurgical processes, are being developed to improve recovery rates of valuable and potentially harmful materials, creating a more circular economy for thermoelectric technologies.

The energy payback period—the time required for a thermoelectric system to generate the energy consumed during its production—varies significantly based on application and materials. High-efficiency modules using sustainable materials can achieve payback periods of 1-3 years in optimal waste heat recovery applications, while less efficient or more environmentally intensive modules may require 5-8 years to offset their production impact.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of thermoelectric technologies. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations impact material selection for thermoelectric modules, driving innovation toward more environmentally benign alternatives while maintaining performance targets.

However, the environmental impact of thermoelectric module production presents notable concerns. Many high-efficiency thermoelectric materials contain rare or toxic elements such as tellurium, bismuth, and lead. The mining and processing of these materials contribute to habitat destruction, water pollution, and significant carbon emissions. Life cycle assessments reveal that the production phase of thermoelectric modules can generate substantial environmental footprints, potentially offsetting their operational benefits if not properly managed.

Material sustainability represents a critical challenge for the thermoelectric industry. Current research focuses on developing alternative materials with reduced environmental impact while maintaining high efficiency. Earth-abundant materials such as silicides, oxides, and organic thermoelectric compounds show promising ZT values while significantly reducing reliance on scarce resources. These sustainable alternatives, though currently less efficient than conventional materials, demonstrate the potential for environmentally responsible thermoelectric technologies.

End-of-life management for thermoelectric modules requires careful consideration. The complex composition of these devices complicates recycling efforts, with less than 20% of materials currently recovered from discarded modules. Advanced recycling technologies, including hydrometallurgical and pyrometallurgical processes, are being developed to improve recovery rates of valuable and potentially harmful materials, creating a more circular economy for thermoelectric technologies.

The energy payback period—the time required for a thermoelectric system to generate the energy consumed during its production—varies significantly based on application and materials. High-efficiency modules using sustainable materials can achieve payback periods of 1-3 years in optimal waste heat recovery applications, while less efficient or more environmentally intensive modules may require 5-8 years to offset their production impact.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of thermoelectric technologies. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations impact material selection for thermoelectric modules, driving innovation toward more environmentally benign alternatives while maintaining performance targets.

Manufacturing Scalability and Cost Optimization Strategies

The scalability of manufacturing processes for thermoelectric modules presents a significant challenge in achieving ultra-high efficiency at commercially viable costs. Current production methods often involve labor-intensive processes that limit mass production capabilities and increase unit costs. Transitioning from laboratory-scale fabrication to industrial-scale manufacturing requires substantial process optimization and automation integration.

Material selection plays a crucial role in cost optimization strategies. Traditional high-performance thermoelectric materials like bismuth telluride contain rare or expensive elements that contribute significantly to overall costs. Developing alternative material systems using earth-abundant elements while maintaining comparable performance metrics represents a promising approach. Recent advances in nanostructured silicon-germanium alloys and magnesium silicide-based compounds demonstrate potential for cost reduction without sacrificing efficiency.

Precision manufacturing techniques require substantial capital investment but offer long-term cost benefits through improved yield rates and performance consistency. Advanced deposition methods such as atomic layer deposition (ALD) and molecular beam epitaxy (MBE) enable precise control over material interfaces and nanostructure formation, critical factors for enhancing ZT values. Implementing these technologies at scale necessitates process standardization and equipment optimization to reduce operational expenses.

Modular design approaches facilitate more efficient manufacturing workflows and reduce material waste. By standardizing component dimensions and connection interfaces, manufacturers can implement parallel production lines that increase throughput while maintaining quality control. This strategy also enables more flexible production scaling in response to market demand fluctuations, optimizing capital utilization and reducing inventory costs.

Supply chain integration represents another critical aspect of cost optimization. Vertical integration of key material processing steps can eliminate intermediary margins and reduce transportation costs. Alternatively, strategic partnerships with specialized material suppliers can leverage economies of scale across multiple applications. Both approaches require careful evaluation of regional manufacturing capabilities, regulatory environments, and intellectual property considerations.

Recycling and circular economy principles offer additional pathways for cost reduction. Developing efficient methods to recover valuable elements from end-of-life thermoelectric modules could significantly offset raw material costs. Current recycling technologies for thermoelectric materials remain limited in efficiency and economic viability, presenting opportunities for innovation in separation techniques and reprocessing methodologies that maintain material purity levels required for high-performance applications.

Material selection plays a crucial role in cost optimization strategies. Traditional high-performance thermoelectric materials like bismuth telluride contain rare or expensive elements that contribute significantly to overall costs. Developing alternative material systems using earth-abundant elements while maintaining comparable performance metrics represents a promising approach. Recent advances in nanostructured silicon-germanium alloys and magnesium silicide-based compounds demonstrate potential for cost reduction without sacrificing efficiency.

Precision manufacturing techniques require substantial capital investment but offer long-term cost benefits through improved yield rates and performance consistency. Advanced deposition methods such as atomic layer deposition (ALD) and molecular beam epitaxy (MBE) enable precise control over material interfaces and nanostructure formation, critical factors for enhancing ZT values. Implementing these technologies at scale necessitates process standardization and equipment optimization to reduce operational expenses.

Modular design approaches facilitate more efficient manufacturing workflows and reduce material waste. By standardizing component dimensions and connection interfaces, manufacturers can implement parallel production lines that increase throughput while maintaining quality control. This strategy also enables more flexible production scaling in response to market demand fluctuations, optimizing capital utilization and reducing inventory costs.

Supply chain integration represents another critical aspect of cost optimization. Vertical integration of key material processing steps can eliminate intermediary margins and reduce transportation costs. Alternatively, strategic partnerships with specialized material suppliers can leverage economies of scale across multiple applications. Both approaches require careful evaluation of regional manufacturing capabilities, regulatory environments, and intellectual property considerations.

Recycling and circular economy principles offer additional pathways for cost reduction. Developing efficient methods to recover valuable elements from end-of-life thermoelectric modules could significantly offset raw material costs. Current recycling technologies for thermoelectric materials remain limited in efficiency and economic viability, presenting opportunities for innovation in separation techniques and reprocessing methodologies that maintain material purity levels required for high-performance applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!