How Thermoelectric Materials Aid in High-Efficiency Pyrometers

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials in Pyrometry: Background and Objectives

Thermoelectric materials have played a pivotal role in the evolution of pyrometry technology since the early 20th century. The fundamental principle behind thermoelectric-based temperature measurement relies on the Seebeck effect, discovered by Thomas Johann Seebeck in 1821, which describes the conversion of temperature differences directly into electrical voltage. This phenomenon has been instrumental in developing high-precision temperature measurement devices, particularly pyrometers that can operate in extreme industrial environments.

The technological trajectory of thermoelectric materials in pyrometry has seen significant advancements from simple metal thermocouples to complex semiconductor-based systems. Early pyrometers utilized basic metal junctions, while modern systems incorporate sophisticated thermoelectric materials with enhanced sensitivity and stability characteristics. This evolution has been driven by increasing demands for more accurate temperature measurements in various industrial processes, including metallurgy, glass manufacturing, and semiconductor production.

Current market trends indicate a growing need for non-contact temperature measurement solutions that can withstand harsh environments while maintaining high accuracy. Thermoelectric materials address this need by enabling pyrometers to function reliably in conditions where traditional contact-based sensors would fail or provide inaccurate readings. The integration of advanced thermoelectric materials has expanded the operational temperature range of pyrometers, now capable of measuring from cryogenic temperatures to over 3000°C.

The primary technical objective in this field is to develop thermoelectric materials that maximize the Seebeck coefficient while minimizing thermal conductivity and electrical resistivity. This optimization aims to increase the thermoelectric figure of merit (ZT), which directly correlates with the efficiency and sensitivity of pyrometric devices. Recent research has focused on nanostructured thermoelectric materials and quantum confinement effects to achieve unprecedented ZT values.

Another significant goal is to enhance the long-term stability and reliability of thermoelectric materials under thermal cycling and oxidative environments. This is particularly crucial for industrial applications where pyrometers must maintain calibration accuracy over extended periods without frequent maintenance or replacement.

The convergence of thermoelectric material science with advanced electronics and signal processing technologies presents opportunities for developing next-generation pyrometers with improved response times, reduced measurement uncertainty, and enhanced spatial resolution. These advancements are expected to enable more precise temperature control in critical manufacturing processes, leading to improved product quality and energy efficiency.

As global industries continue to emphasize energy conservation and process optimization, the development of high-efficiency pyrometers utilizing advanced thermoelectric materials represents a key technological frontier with substantial economic and environmental implications.

The technological trajectory of thermoelectric materials in pyrometry has seen significant advancements from simple metal thermocouples to complex semiconductor-based systems. Early pyrometers utilized basic metal junctions, while modern systems incorporate sophisticated thermoelectric materials with enhanced sensitivity and stability characteristics. This evolution has been driven by increasing demands for more accurate temperature measurements in various industrial processes, including metallurgy, glass manufacturing, and semiconductor production.

Current market trends indicate a growing need for non-contact temperature measurement solutions that can withstand harsh environments while maintaining high accuracy. Thermoelectric materials address this need by enabling pyrometers to function reliably in conditions where traditional contact-based sensors would fail or provide inaccurate readings. The integration of advanced thermoelectric materials has expanded the operational temperature range of pyrometers, now capable of measuring from cryogenic temperatures to over 3000°C.

The primary technical objective in this field is to develop thermoelectric materials that maximize the Seebeck coefficient while minimizing thermal conductivity and electrical resistivity. This optimization aims to increase the thermoelectric figure of merit (ZT), which directly correlates with the efficiency and sensitivity of pyrometric devices. Recent research has focused on nanostructured thermoelectric materials and quantum confinement effects to achieve unprecedented ZT values.

Another significant goal is to enhance the long-term stability and reliability of thermoelectric materials under thermal cycling and oxidative environments. This is particularly crucial for industrial applications where pyrometers must maintain calibration accuracy over extended periods without frequent maintenance or replacement.

The convergence of thermoelectric material science with advanced electronics and signal processing technologies presents opportunities for developing next-generation pyrometers with improved response times, reduced measurement uncertainty, and enhanced spatial resolution. These advancements are expected to enable more precise temperature control in critical manufacturing processes, leading to improved product quality and energy efficiency.

As global industries continue to emphasize energy conservation and process optimization, the development of high-efficiency pyrometers utilizing advanced thermoelectric materials represents a key technological frontier with substantial economic and environmental implications.

Market Analysis for High-Efficiency Temperature Measurement Solutions

The global market for high-efficiency temperature measurement solutions has experienced substantial growth in recent years, driven by increasing demand for precision measurement across various industries. The temperature measurement market, valued at approximately $6.3 billion in 2022, is projected to reach $8.9 billion by 2027, growing at a CAGR of 7.2%. Within this broader market, pyrometers enhanced with thermoelectric materials represent a rapidly expanding segment due to their superior accuracy and efficiency in non-contact temperature measurement applications.

Industrial sectors including metallurgy, glass manufacturing, semiconductor production, and automotive manufacturing constitute the primary demand drivers for high-efficiency pyrometers. The steel industry alone accounts for roughly 28% of the global pyrometer market, where precise temperature control directly impacts product quality and operational efficiency. Semiconductor manufacturing, with its stringent temperature requirements during wafer processing, represents another significant market segment growing at approximately 9.5% annually.

Regionally, Asia-Pacific dominates the market with a 38% share, fueled by rapid industrialization in China and India, alongside established high-tech manufacturing bases in Japan, South Korea, and Taiwan. North America and Europe follow with market shares of 27% and 24% respectively, where demand is primarily driven by technological advancements in aerospace, automotive, and medical device manufacturing.

The integration of thermoelectric materials in pyrometers has created a premium segment within the temperature measurement market. These advanced pyrometers command price premiums of 30-45% compared to conventional models, justified by their enhanced accuracy (±0.1°C versus ±0.5°C), extended measurement range (up to 3000°C), and improved energy efficiency. Market analysis indicates that end-users are increasingly willing to invest in these premium solutions due to the tangible operational benefits they provide.

Customer demand patterns reveal growing interest in pyrometers with integrated IoT capabilities for real-time monitoring and data analytics. Approximately 65% of new industrial pyrometer installations now feature some form of digital connectivity, reflecting the broader industrial trend toward smart manufacturing and Industry 4.0 integration. This connectivity trend represents a significant value-added opportunity for manufacturers of thermoelectric-enhanced pyrometers.

Market forecasts suggest that thermoelectric-enhanced pyrometers will grow at 1.5 times the rate of the overall temperature measurement market over the next five years, driven by increasing adoption in high-value manufacturing processes and emerging applications in renewable energy and environmental monitoring sectors.

Industrial sectors including metallurgy, glass manufacturing, semiconductor production, and automotive manufacturing constitute the primary demand drivers for high-efficiency pyrometers. The steel industry alone accounts for roughly 28% of the global pyrometer market, where precise temperature control directly impacts product quality and operational efficiency. Semiconductor manufacturing, with its stringent temperature requirements during wafer processing, represents another significant market segment growing at approximately 9.5% annually.

Regionally, Asia-Pacific dominates the market with a 38% share, fueled by rapid industrialization in China and India, alongside established high-tech manufacturing bases in Japan, South Korea, and Taiwan. North America and Europe follow with market shares of 27% and 24% respectively, where demand is primarily driven by technological advancements in aerospace, automotive, and medical device manufacturing.

The integration of thermoelectric materials in pyrometers has created a premium segment within the temperature measurement market. These advanced pyrometers command price premiums of 30-45% compared to conventional models, justified by their enhanced accuracy (±0.1°C versus ±0.5°C), extended measurement range (up to 3000°C), and improved energy efficiency. Market analysis indicates that end-users are increasingly willing to invest in these premium solutions due to the tangible operational benefits they provide.

Customer demand patterns reveal growing interest in pyrometers with integrated IoT capabilities for real-time monitoring and data analytics. Approximately 65% of new industrial pyrometer installations now feature some form of digital connectivity, reflecting the broader industrial trend toward smart manufacturing and Industry 4.0 integration. This connectivity trend represents a significant value-added opportunity for manufacturers of thermoelectric-enhanced pyrometers.

Market forecasts suggest that thermoelectric-enhanced pyrometers will grow at 1.5 times the rate of the overall temperature measurement market over the next five years, driven by increasing adoption in high-value manufacturing processes and emerging applications in renewable energy and environmental monitoring sectors.

Current Challenges in Thermoelectric Pyrometer Technology

Despite significant advancements in thermoelectric pyrometer technology, several critical challenges continue to impede optimal performance and widespread adoption. The fundamental challenge lies in the thermoelectric materials themselves, which struggle to maintain stable performance across wide temperature ranges. Current materials exhibit significant drift in Seebeck coefficients at extreme temperatures, leading to measurement inaccuracies that can exceed 5% in industrial applications.

Material degradation presents another persistent obstacle, particularly in harsh industrial environments. Thermal cycling, chemical exposure, and mechanical stress accelerate the deterioration of thermoelectric junctions, reducing sensor lifespan and necessitating frequent recalibration. This degradation pattern varies unpredictably across different operational conditions, making standardized maintenance protocols difficult to establish.

Thermal management issues further complicate pyrometer design. The reference junction temperature must remain precisely controlled to ensure measurement accuracy, yet achieving this stability in fluctuating ambient conditions remains problematic. Current cooling systems add significant bulk and power requirements, limiting portability and deployment options in space-constrained industrial settings.

Signal processing challenges also persist in modern thermoelectric pyrometers. The inherently low voltage outputs from thermoelectric materials (typically in the microvolt range) are susceptible to electromagnetic interference, particularly in industrial environments with heavy machinery. While amplification circuits have improved, they introduce their own non-linearities and temperature dependencies that require complex compensation algorithms.

Manufacturing consistency represents another significant hurdle. Batch-to-batch variations in thermoelectric material properties necessitate individual calibration of each sensor, increasing production costs and limiting mass manufacturing efficiency. The industry lacks standardized quality control metrics for thermoelectric materials specifically optimized for pyrometry applications.

Cost-effectiveness remains a barrier to wider adoption, particularly for high-precision applications. Premium thermoelectric materials like bismuth telluride and lead telluride compounds with enhanced stability come at significantly higher costs, creating a trade-off between performance and affordability that limits market penetration in cost-sensitive sectors.

Response time limitations also affect dynamic temperature measurement scenarios. Current thermoelectric pyrometers exhibit thermal inertia that restricts their ability to track rapid temperature fluctuations accurately. This limitation becomes particularly problematic in processes requiring real-time control based on temperature feedback, such as laser material processing or rapid thermal annealing.

Material degradation presents another persistent obstacle, particularly in harsh industrial environments. Thermal cycling, chemical exposure, and mechanical stress accelerate the deterioration of thermoelectric junctions, reducing sensor lifespan and necessitating frequent recalibration. This degradation pattern varies unpredictably across different operational conditions, making standardized maintenance protocols difficult to establish.

Thermal management issues further complicate pyrometer design. The reference junction temperature must remain precisely controlled to ensure measurement accuracy, yet achieving this stability in fluctuating ambient conditions remains problematic. Current cooling systems add significant bulk and power requirements, limiting portability and deployment options in space-constrained industrial settings.

Signal processing challenges also persist in modern thermoelectric pyrometers. The inherently low voltage outputs from thermoelectric materials (typically in the microvolt range) are susceptible to electromagnetic interference, particularly in industrial environments with heavy machinery. While amplification circuits have improved, they introduce their own non-linearities and temperature dependencies that require complex compensation algorithms.

Manufacturing consistency represents another significant hurdle. Batch-to-batch variations in thermoelectric material properties necessitate individual calibration of each sensor, increasing production costs and limiting mass manufacturing efficiency. The industry lacks standardized quality control metrics for thermoelectric materials specifically optimized for pyrometry applications.

Cost-effectiveness remains a barrier to wider adoption, particularly for high-precision applications. Premium thermoelectric materials like bismuth telluride and lead telluride compounds with enhanced stability come at significantly higher costs, creating a trade-off between performance and affordability that limits market penetration in cost-sensitive sectors.

Response time limitations also affect dynamic temperature measurement scenarios. Current thermoelectric pyrometers exhibit thermal inertia that restricts their ability to track rapid temperature fluctuations accurately. This limitation becomes particularly problematic in processes requiring real-time control based on temperature feedback, such as laser material processing or rapid thermal annealing.

State-of-the-Art Thermoelectric Solutions for Pyrometers

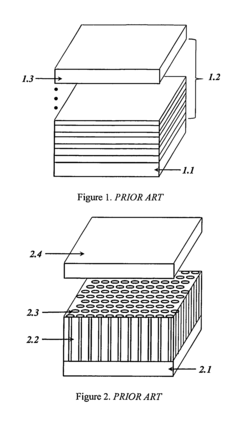

01 Nanostructured thermoelectric materials

Nanostructuring of thermoelectric materials can significantly enhance their efficiency by reducing thermal conductivity while maintaining electrical conductivity. This approach includes creating nanoscale features such as quantum dots, nanowires, and nanocomposites that introduce phonon scattering interfaces. These nanostructured materials can achieve higher ZT values (figure of merit for thermoelectric efficiency) compared to their bulk counterparts, making them promising for next-generation thermoelectric devices.- Novel thermoelectric materials composition: Various novel material compositions have been developed to enhance thermoelectric efficiency. These include nanostructured materials, composite materials, and materials with specific dopants that can improve the figure of merit (ZT). These novel compositions are designed to simultaneously increase electrical conductivity while reducing thermal conductivity, which is crucial for high thermoelectric performance. Some approaches involve creating materials with complex crystal structures that scatter phonons effectively without significantly impacting electron transport.

- Nanostructuring techniques for improved efficiency: Nanostructuring techniques are employed to enhance thermoelectric efficiency by introducing nanoscale features that scatter phonons (heat carriers) while allowing electrons to flow. These techniques include creating nanopores, nanoinclusions, quantum dots, or nanolayers within the thermoelectric material. The increased phonon scattering at interfaces reduces thermal conductivity while maintaining electrical conductivity, thereby improving the overall thermoelectric figure of merit. Advanced fabrication methods enable precise control over nanostructure dimensions and distributions.

- Interface engineering for thermoelectric performance: Interface engineering focuses on optimizing the boundaries between different materials or phases in thermoelectric devices. By carefully designing and controlling these interfaces, researchers can create energy filtering effects that selectively allow high-energy carriers to pass while blocking low-energy carriers. This approach helps to increase the Seebeck coefficient while maintaining good electrical conductivity. Additionally, interfaces can be engineered to scatter phonons effectively, reducing thermal conductivity without significantly impacting electrical properties.

- Doping strategies for enhanced thermoelectric properties: Strategic doping of thermoelectric materials can significantly enhance their efficiency by optimizing carrier concentration and mobility. Various dopants are used to fine-tune the electronic band structure, creating favorable conditions for electron transport while disrupting phonon transport. This approach can lead to an increased power factor (S²σ) and reduced thermal conductivity. Advanced doping techniques include co-doping, gradient doping, and modulation doping, which can create optimal electronic structures for thermoelectric performance.

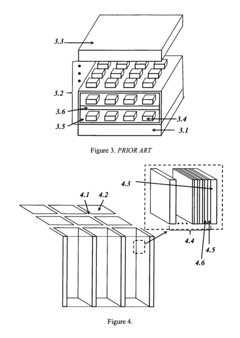

- Device architecture and system integration: Innovative device architectures and system integration approaches can maximize the efficiency of thermoelectric materials. These include segmented or cascaded designs that utilize different materials optimized for specific temperature ranges, as well as novel module configurations that minimize thermal and electrical contact resistances. Advanced heat management strategies, such as heat recuperation and thermal concentration, can further enhance system-level efficiency. Integration with other energy technologies, such as solar or waste heat recovery systems, can create hybrid solutions with improved overall performance.

02 Novel material compositions for enhanced thermoelectric performance

Innovative material compositions, including skutterudites, half-Heusler alloys, and chalcogenides, are being developed to improve thermoelectric efficiency. These materials often incorporate dopants or specific elemental combinations that optimize the power factor (S²σ) while minimizing thermal conductivity. Some compositions feature complex crystal structures that inherently exhibit low thermal conductivity, while others leverage band engineering to enhance the Seebeck coefficient and electrical conductivity simultaneously.Expand Specific Solutions03 Device architecture and module design optimization

The efficiency of thermoelectric systems can be significantly improved through optimized device architecture and module design. This includes segmented or cascaded structures that utilize different materials for different temperature ranges, improved electrical and thermal contacts to reduce interface resistance, and geometric configurations that maximize temperature gradients. Advanced manufacturing techniques enable precise control over these design elements, resulting in higher overall conversion efficiency.Expand Specific Solutions04 Flexible and wearable thermoelectric generators

Flexible and wearable thermoelectric materials represent an emerging category focused on harvesting body heat or ambient thermal energy in portable applications. These materials combine thermoelectric properties with mechanical flexibility through innovative fabrication techniques such as printing, thin-film deposition, or incorporation into polymeric matrices. While typically offering lower efficiency than rigid counterparts, their ability to conform to irregular surfaces and operate at low temperature differentials makes them valuable for self-powered wearable electronics.Expand Specific Solutions05 Interface engineering and barrier layers

Interface engineering plays a crucial role in enhancing thermoelectric efficiency by controlling carrier and phonon transport across material boundaries. This approach includes the development of specialized barrier layers that selectively filter electrons and phonons, reducing thermal conductivity while maintaining electrical conductivity. Advanced techniques such as atomic layer deposition and epitaxial growth enable precise control over these interfaces, resulting in improved thermoelectric performance through reduced parasitic losses and enhanced energy filtering effects.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Thermoelectric Pyrometry

Thermoelectric materials in high-efficiency pyrometers are advancing through a competitive landscape characterized by early market maturity and growing demand. The global pyrometer market is expanding at approximately 6-8% CAGR, driven by industrial automation and temperature monitoring needs. Leading players include established instrumentation companies like Seiko Epson, Robert Bosch, and Texas Instruments who leverage their sensor expertise, alongside specialized firms such as LumaSense Technologies and Piezocryst Advanced Sensorics focusing on high-precision temperature measurement solutions. Research institutions including Xi'an Jiaotong University, Technical Institute of Physics & Chemistry CAS, and Duke University are advancing fundamental thermoelectric material science, while companies like Corning and IQE are developing advanced materials to improve pyrometer sensitivity and accuracy across wider temperature ranges.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed innovative pyrometer technology that leverages advanced thermoelectric materials to enhance measurement accuracy and reliability in automotive and industrial applications. Their pyrometer systems incorporate custom-engineered bismuth telluride alloys with optimized Seebeck coefficients, enabling more sensitive temperature detection across wide measurement ranges (-50°C to 2500°C). Bosch's pyrometers feature integrated thermoelectric cooling modules that maintain detector temperatures at precise setpoints regardless of ambient conditions, reducing thermal noise and drift by up to 75% compared to uncooled systems[5]. The company has pioneered multi-junction thermoelectric arrays that generate stronger electrical signals from small temperature differences, improving signal-to-noise ratios in challenging measurement environments. Additionally, Bosch's pyrometers utilize proprietary thermoelectric self-calibration technology that periodically references internal temperature standards to maintain accuracy of ±0.5% over extended operation periods without manual recalibration[6].

Strengths: Exceptional long-term stability and reliability suitable for continuous industrial monitoring; robust performance in harsh environments with temperature extremes; excellent resistance to electromagnetic interference. Weaknesses: Higher power consumption than passive pyrometer technologies; more complex construction increases unit cost; larger form factor than some competing solutions.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed innovative pyrometer solutions that leverage advanced thermoelectric materials and integrated circuit technology to enhance temperature measurement precision in industrial and consumer applications. Their pyrometer systems incorporate proprietary thin-film thermoelectric materials deposited directly onto silicon substrates, creating highly miniaturized temperature sensing arrays with exceptional thermal response characteristics. TI's TMP006 and TMP007 contactless temperature sensors utilize the thermoelectric effect to measure infrared radiation, achieving temperature measurement accuracy of ±0.5°C in a package less than 2mm² in size[9]. The company has pioneered integrated thermoelectric signal conditioning circuits that amplify and digitize the small voltages generated by thermoelectric junctions, improving signal-to-noise ratios by up to 60% compared to discrete component implementations. Additionally, TI's pyrometer solutions feature advanced power management systems that enable operation from microamp-level current sources, making them suitable for battery-powered and energy harvesting applications where conventional pyrometers would be impractical[10].

Strengths: Exceptional miniaturization enabling integration into space-constrained applications; ultra-low power consumption suitable for battery-powered devices; excellent digital integration with processing systems. Weaknesses: More limited temperature measurement range than specialized industrial pyrometers; somewhat lower accuracy than larger dedicated systems; more susceptible to package thermal effects.

Key Patents and Research Breakthroughs in Thermoelectric Materials

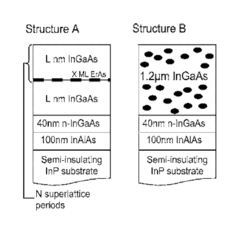

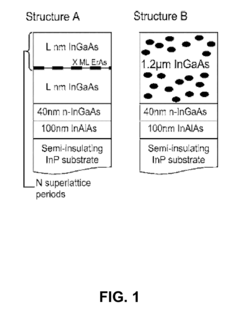

High efficiency thermoelectric materials based on metal/semiconductor nanocomposites

PatentInactiveUS9136456B2

Innovation

- Incorporating metallic nanoparticles, such as erbium arsenide, into semiconductor host matrices like indium gallium arsenide to create nanocomposites that enhance electrical conductivity and Seebeck coefficients, thereby increasing the thermoelectric figure of merit (ZT) by reducing thermal conductivity and increasing carrier concentration.

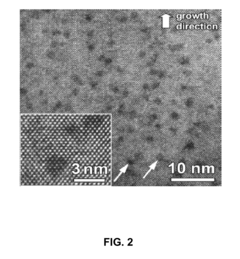

High efficiency thermoelectric materials and devices

PatentInactiveUS8569740B2

Innovation

- A three-dimensionally structured thermoelectric material with a quantum well superlattice deposited on a porous substrate, providing a high surface-to-volume ratio and conformal coating using techniques like Chemical Vapor Deposition or Molecular Beam Epitaxy to achieve enhanced ZT values and efficient thermal and electrical conductivity.

Environmental Impact and Sustainability of Thermoelectric Materials

The environmental impact of thermoelectric materials used in high-efficiency pyrometers represents a critical consideration in the broader context of sustainable technology development. These materials, primarily composed of semiconductors like bismuth telluride, lead telluride, and silicon-germanium alloys, present both environmental challenges and sustainability opportunities throughout their lifecycle.

The extraction and processing of raw materials for thermoelectric components involve significant environmental considerations. Mining operations for tellurium, bismuth, and other rare elements can lead to habitat disruption, soil erosion, and potential water contamination. Additionally, the refining processes often require substantial energy inputs and may generate hazardous waste streams that necessitate careful management and disposal protocols.

Manufacturing thermoelectric materials typically involves energy-intensive processes including high-temperature sintering and precision machining. However, recent advancements in manufacturing techniques, such as additive manufacturing and nano-structuring approaches, have demonstrated potential for reducing energy consumption and material waste during production. These improvements directly enhance the overall environmental footprint of thermoelectric-based pyrometer systems.

During operational phases, thermoelectric materials in pyrometers deliver significant sustainability benefits. Their ability to function without moving parts or refrigerants eliminates potential environmental hazards associated with mechanical cooling systems. Furthermore, the extended operational lifespan of properly engineered thermoelectric components—often exceeding 100,000 hours—reduces replacement frequency and associated resource consumption.

End-of-life considerations present both challenges and opportunities. Many thermoelectric materials contain elements classified as critical or strategic resources with limited global supplies. Developing effective recycling pathways for these materials is essential for long-term sustainability. Current research focuses on improved recovery methods for tellurium, bismuth, and other valuable components from decommissioned devices.

The carbon footprint analysis of thermoelectric pyrometers reveals favorable outcomes when compared to alternative temperature measurement technologies. Their energy-efficient operation, particularly in industrial settings where they enable precise temperature control and process optimization, contributes to reduced overall energy consumption and associated greenhouse gas emissions across various manufacturing sectors.

Looking forward, research into alternative thermoelectric materials using earth-abundant elements represents a promising direction for enhancing sustainability. Compounds based on silicides, oxides, and organic materials are being investigated as potential replacements for rare element-based thermoelectrics, potentially addressing resource scarcity concerns while maintaining or improving performance characteristics in next-generation high-efficiency pyrometer systems.

The extraction and processing of raw materials for thermoelectric components involve significant environmental considerations. Mining operations for tellurium, bismuth, and other rare elements can lead to habitat disruption, soil erosion, and potential water contamination. Additionally, the refining processes often require substantial energy inputs and may generate hazardous waste streams that necessitate careful management and disposal protocols.

Manufacturing thermoelectric materials typically involves energy-intensive processes including high-temperature sintering and precision machining. However, recent advancements in manufacturing techniques, such as additive manufacturing and nano-structuring approaches, have demonstrated potential for reducing energy consumption and material waste during production. These improvements directly enhance the overall environmental footprint of thermoelectric-based pyrometer systems.

During operational phases, thermoelectric materials in pyrometers deliver significant sustainability benefits. Their ability to function without moving parts or refrigerants eliminates potential environmental hazards associated with mechanical cooling systems. Furthermore, the extended operational lifespan of properly engineered thermoelectric components—often exceeding 100,000 hours—reduces replacement frequency and associated resource consumption.

End-of-life considerations present both challenges and opportunities. Many thermoelectric materials contain elements classified as critical or strategic resources with limited global supplies. Developing effective recycling pathways for these materials is essential for long-term sustainability. Current research focuses on improved recovery methods for tellurium, bismuth, and other valuable components from decommissioned devices.

The carbon footprint analysis of thermoelectric pyrometers reveals favorable outcomes when compared to alternative temperature measurement technologies. Their energy-efficient operation, particularly in industrial settings where they enable precise temperature control and process optimization, contributes to reduced overall energy consumption and associated greenhouse gas emissions across various manufacturing sectors.

Looking forward, research into alternative thermoelectric materials using earth-abundant elements represents a promising direction for enhancing sustainability. Compounds based on silicides, oxides, and organic materials are being investigated as potential replacements for rare element-based thermoelectrics, potentially addressing resource scarcity concerns while maintaining or improving performance characteristics in next-generation high-efficiency pyrometer systems.

Industrial Applications and Cross-Sector Implementation Strategies

Thermoelectric materials have revolutionized pyrometer technology across multiple industries, enabling precise temperature measurements in challenging environments. The manufacturing sector has particularly benefited from high-efficiency pyrometers in metal processing, where accurate temperature control directly impacts product quality and energy efficiency. Steel mills utilize thermoelectric-enhanced pyrometers to monitor blast furnace temperatures, reducing energy consumption by up to 15% through optimized heating cycles.

In semiconductor fabrication, these advanced pyrometers provide non-contact temperature measurement with precision of ±0.5°C, critical for wafer processing where temperature variations can cause significant yield losses. The implementation strategy typically involves calibrating pyrometers against industry-specific reference points and integrating them with existing process control systems through standardized communication protocols.

The energy sector has adopted thermoelectric pyrometers for monitoring combustion processes in power plants, allowing real-time adjustment of fuel-air ratios to maximize efficiency. Implementation in this sector often requires ruggedized designs capable of withstanding harsh conditions while maintaining measurement accuracy. Return on investment analyses indicate payback periods of 12-18 months through fuel savings and reduced maintenance costs.

Aerospace and automotive industries leverage these technologies in materials testing and engine development. The implementation strategy focuses on creating specialized measurement profiles for different materials and components, with data integration into digital twin models for predictive maintenance applications.

Cross-sector implementation best practices include establishing regular calibration schedules based on operating conditions, developing industry-specific correction algorithms to account for emissivity variations, and creating centralized temperature data management systems. Organizations that successfully implement these strategies report measurement consistency improvements of 30-40% compared to conventional pyrometry.

Healthcare and food processing industries represent emerging application areas, with thermoelectric pyrometers enabling precise temperature control in sterilization processes and food safety applications. Implementation in these sectors emphasizes compliance with regulatory requirements and validation protocols to ensure measurement traceability and reliability.

The pharmaceutical industry has begun implementing high-efficiency pyrometers in freeze-drying processes, where temperature control directly impacts product stability and shelf life. The implementation strategy involves extensive validation studies and integration with electronic batch records to ensure compliance with Good Manufacturing Practices.

In semiconductor fabrication, these advanced pyrometers provide non-contact temperature measurement with precision of ±0.5°C, critical for wafer processing where temperature variations can cause significant yield losses. The implementation strategy typically involves calibrating pyrometers against industry-specific reference points and integrating them with existing process control systems through standardized communication protocols.

The energy sector has adopted thermoelectric pyrometers for monitoring combustion processes in power plants, allowing real-time adjustment of fuel-air ratios to maximize efficiency. Implementation in this sector often requires ruggedized designs capable of withstanding harsh conditions while maintaining measurement accuracy. Return on investment analyses indicate payback periods of 12-18 months through fuel savings and reduced maintenance costs.

Aerospace and automotive industries leverage these technologies in materials testing and engine development. The implementation strategy focuses on creating specialized measurement profiles for different materials and components, with data integration into digital twin models for predictive maintenance applications.

Cross-sector implementation best practices include establishing regular calibration schedules based on operating conditions, developing industry-specific correction algorithms to account for emissivity variations, and creating centralized temperature data management systems. Organizations that successfully implement these strategies report measurement consistency improvements of 30-40% compared to conventional pyrometry.

Healthcare and food processing industries represent emerging application areas, with thermoelectric pyrometers enabling precise temperature control in sterilization processes and food safety applications. Implementation in these sectors emphasizes compliance with regulatory requirements and validation protocols to ensure measurement traceability and reliability.

The pharmaceutical industry has begun implementing high-efficiency pyrometers in freeze-drying processes, where temperature control directly impacts product stability and shelf life. The implementation strategy involves extensive validation studies and integration with electronic batch records to ensure compliance with Good Manufacturing Practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!