Increasing Lifespan of Thermoelectric Installations: Proven Techniques

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Evolution and Longevity Goals

Thermoelectric technology has evolved significantly since its discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion between temperature differences and electric voltage. The initial applications were limited due to low efficiency and material constraints. However, the past few decades have witnessed remarkable advancements in thermoelectric materials, design methodologies, and manufacturing techniques, leading to more efficient and durable installations.

The evolution trajectory shows three distinct phases: the discovery and theoretical foundation phase (1800s-1950s), the material innovation phase (1960s-2000s), and the current system optimization phase (2010s-present). Each phase has contributed significantly to enhancing both the performance and longevity of thermoelectric systems, with recent developments focusing particularly on extending operational lifespan while maintaining efficiency.

Current thermoelectric installations face several longevity challenges, including thermal cycling stress, material degradation at high temperatures, contact degradation between thermoelectric elements and electrodes, and oxidation issues. These factors collectively reduce system efficiency over time and ultimately lead to premature failure, necessitating costly replacements and maintenance.

The primary technical goals for increasing thermoelectric installation lifespan include developing more thermally stable materials that can withstand repeated thermal cycling without significant property degradation. Research aims to achieve systems capable of maintaining at least 90% of initial efficiency after 10,000 operational hours under standard conditions, representing a significant improvement over current systems that typically show 15-20% degradation within the same timeframe.

Another critical objective is the enhancement of interface stability between different components, particularly at the critical junctions between thermoelectric materials and electrical contacts. Advanced bonding techniques and interface materials are being explored to minimize thermal expansion mismatch effects and reduce electrical contact resistance over extended operational periods.

The industry is also pursuing improved encapsulation and protection systems to shield thermoelectric elements from environmental factors such as moisture, oxygen, and contaminants that accelerate degradation. Hermetic sealing technologies and advanced protective coatings represent promising approaches in this direction.

From a system-level perspective, the development of intelligent thermal management strategies and predictive maintenance protocols aims to optimize operational conditions and intervene before critical degradation occurs. These approaches leverage advances in sensor technology and data analytics to monitor system health in real-time and adjust parameters accordingly.

The evolution trajectory shows three distinct phases: the discovery and theoretical foundation phase (1800s-1950s), the material innovation phase (1960s-2000s), and the current system optimization phase (2010s-present). Each phase has contributed significantly to enhancing both the performance and longevity of thermoelectric systems, with recent developments focusing particularly on extending operational lifespan while maintaining efficiency.

Current thermoelectric installations face several longevity challenges, including thermal cycling stress, material degradation at high temperatures, contact degradation between thermoelectric elements and electrodes, and oxidation issues. These factors collectively reduce system efficiency over time and ultimately lead to premature failure, necessitating costly replacements and maintenance.

The primary technical goals for increasing thermoelectric installation lifespan include developing more thermally stable materials that can withstand repeated thermal cycling without significant property degradation. Research aims to achieve systems capable of maintaining at least 90% of initial efficiency after 10,000 operational hours under standard conditions, representing a significant improvement over current systems that typically show 15-20% degradation within the same timeframe.

Another critical objective is the enhancement of interface stability between different components, particularly at the critical junctions between thermoelectric materials and electrical contacts. Advanced bonding techniques and interface materials are being explored to minimize thermal expansion mismatch effects and reduce electrical contact resistance over extended operational periods.

The industry is also pursuing improved encapsulation and protection systems to shield thermoelectric elements from environmental factors such as moisture, oxygen, and contaminants that accelerate degradation. Hermetic sealing technologies and advanced protective coatings represent promising approaches in this direction.

From a system-level perspective, the development of intelligent thermal management strategies and predictive maintenance protocols aims to optimize operational conditions and intervene before critical degradation occurs. These approaches leverage advances in sensor technology and data analytics to monitor system health in real-time and adjust parameters accordingly.

Market Demand for Extended Thermoelectric System Durability

The global market for thermoelectric systems has witnessed substantial growth in recent years, driven primarily by increasing energy efficiency concerns and the push towards sustainable energy solutions. The demand for extended thermoelectric system durability represents a significant segment of this market, with industries seeking longer-lasting installations to maximize return on investment and minimize operational disruptions.

Current market analysis indicates that the thermoelectric cooling and heating systems market is projected to grow at a compound annual growth rate of 8.5% through 2028, with durability improvements being a key factor driving adoption. Industries such as automotive, semiconductor manufacturing, medical equipment, and aerospace have emerged as primary consumers of high-durability thermoelectric solutions.

The economic justification for extended lifespan thermoelectric systems is compelling. While initial investment costs for enhanced durability systems may be 15-30% higher than standard installations, the total cost of ownership analysis reveals significant long-term savings. Organizations report maintenance cost reductions of up to 40% and downtime reductions of 25-35% when implementing extended-life thermoelectric technologies.

Market research indicates that industrial customers are increasingly willing to pay premium prices for thermoelectric systems that offer documented lifespan extensions. A recent industry survey revealed that 78% of procurement managers consider durability and lifespan as "very important" or "critical" factors in thermoelectric system purchasing decisions, ranking above initial purchase price.

Regional market variations exist, with North American and European markets showing stronger preference for high-durability solutions, while emerging markets in Asia-Pacific regions demonstrate faster growth rates but remain more price-sensitive. However, even in developing markets, the trend is shifting toward lifecycle cost considerations rather than upfront expenditure alone.

The market demand is further shaped by regulatory pressures and sustainability initiatives. Energy efficiency standards and carbon reduction targets are compelling industries to invest in longer-lasting thermal management solutions. Additionally, waste reduction mandates in several jurisdictions are creating incentives for products with extended operational lifespans.

Customer expectations are evolving toward performance guarantees and warranty periods. The market increasingly demands thermoelectric systems with 10+ year warranties, compared to the 3-5 year standards of previous generations. This shift has created new business models, including performance-based contracts and "thermal management as a service" offerings that guarantee system longevity.

Current market analysis indicates that the thermoelectric cooling and heating systems market is projected to grow at a compound annual growth rate of 8.5% through 2028, with durability improvements being a key factor driving adoption. Industries such as automotive, semiconductor manufacturing, medical equipment, and aerospace have emerged as primary consumers of high-durability thermoelectric solutions.

The economic justification for extended lifespan thermoelectric systems is compelling. While initial investment costs for enhanced durability systems may be 15-30% higher than standard installations, the total cost of ownership analysis reveals significant long-term savings. Organizations report maintenance cost reductions of up to 40% and downtime reductions of 25-35% when implementing extended-life thermoelectric technologies.

Market research indicates that industrial customers are increasingly willing to pay premium prices for thermoelectric systems that offer documented lifespan extensions. A recent industry survey revealed that 78% of procurement managers consider durability and lifespan as "very important" or "critical" factors in thermoelectric system purchasing decisions, ranking above initial purchase price.

Regional market variations exist, with North American and European markets showing stronger preference for high-durability solutions, while emerging markets in Asia-Pacific regions demonstrate faster growth rates but remain more price-sensitive. However, even in developing markets, the trend is shifting toward lifecycle cost considerations rather than upfront expenditure alone.

The market demand is further shaped by regulatory pressures and sustainability initiatives. Energy efficiency standards and carbon reduction targets are compelling industries to invest in longer-lasting thermal management solutions. Additionally, waste reduction mandates in several jurisdictions are creating incentives for products with extended operational lifespans.

Customer expectations are evolving toward performance guarantees and warranty periods. The market increasingly demands thermoelectric systems with 10+ year warranties, compared to the 3-5 year standards of previous generations. This shift has created new business models, including performance-based contracts and "thermal management as a service" offerings that guarantee system longevity.

Current Challenges in Thermoelectric Installation Lifespan

Despite significant advancements in thermoelectric technology, current installations face several persistent challenges that limit their operational lifespan. Material degradation remains a primary concern, with high-temperature cycling causing thermal stress that leads to microcracks and eventual failure. Most commercial thermoelectric modules experience performance degradation of 5-15% annually under standard operating conditions, with accelerated deterioration in harsh environments.

Thermal interface degradation presents another significant challenge. The thermal interface materials (TIMs) that facilitate heat transfer between thermoelectric elements and heat exchangers deteriorate over time, reducing system efficiency. Studies indicate that TIM degradation can account for up to 30% of performance loss in long-term thermoelectric installations, particularly in applications with frequent thermal cycling.

Electrical contact resistance increases progressively throughout system operation, with oxidation at metal-semiconductor interfaces being the primary culprit. This phenomenon can increase internal resistance by 20-40% over a five-year operational period, significantly reducing power output and conversion efficiency.

Environmental factors pose substantial threats to thermoelectric installation longevity. Moisture ingress leads to corrosion of metallic components and degradation of semiconductor materials, while dust accumulation on heat transfer surfaces impedes thermal performance. Systems operating in industrial environments with corrosive gases experience accelerated degradation rates up to three times faster than those in controlled environments.

Mechanical vibration and shock represent underappreciated challenges, causing progressive loosening of electrical connections and mechanical joints. This issue is particularly problematic in transportation and industrial applications where constant vibration accelerates component fatigue and connection degradation.

Current manufacturing limitations also contribute to lifespan constraints. Inconsistencies in material quality and assembly precision lead to premature failures and performance variability. Industry data suggests that manufacturing defects account for approximately 15-25% of early-life failures in thermoelectric installations.

The lack of standardized testing protocols for longevity assessment complicates the development of more durable systems. Without uniform accelerated life testing methods, comparing different solutions becomes challenging, hindering industry-wide improvements in reliability standards.

Economic constraints further complicate matters, as cost-effective solutions often sacrifice longevity for initial affordability. The industry faces a critical balance between implementing more durable materials and maintaining competitive pricing, particularly as thermoelectric technology competes with alternative energy conversion methods.

Thermal interface degradation presents another significant challenge. The thermal interface materials (TIMs) that facilitate heat transfer between thermoelectric elements and heat exchangers deteriorate over time, reducing system efficiency. Studies indicate that TIM degradation can account for up to 30% of performance loss in long-term thermoelectric installations, particularly in applications with frequent thermal cycling.

Electrical contact resistance increases progressively throughout system operation, with oxidation at metal-semiconductor interfaces being the primary culprit. This phenomenon can increase internal resistance by 20-40% over a five-year operational period, significantly reducing power output and conversion efficiency.

Environmental factors pose substantial threats to thermoelectric installation longevity. Moisture ingress leads to corrosion of metallic components and degradation of semiconductor materials, while dust accumulation on heat transfer surfaces impedes thermal performance. Systems operating in industrial environments with corrosive gases experience accelerated degradation rates up to three times faster than those in controlled environments.

Mechanical vibration and shock represent underappreciated challenges, causing progressive loosening of electrical connections and mechanical joints. This issue is particularly problematic in transportation and industrial applications where constant vibration accelerates component fatigue and connection degradation.

Current manufacturing limitations also contribute to lifespan constraints. Inconsistencies in material quality and assembly precision lead to premature failures and performance variability. Industry data suggests that manufacturing defects account for approximately 15-25% of early-life failures in thermoelectric installations.

The lack of standardized testing protocols for longevity assessment complicates the development of more durable systems. Without uniform accelerated life testing methods, comparing different solutions becomes challenging, hindering industry-wide improvements in reliability standards.

Economic constraints further complicate matters, as cost-effective solutions often sacrifice longevity for initial affordability. The industry faces a critical balance between implementing more durable materials and maintaining competitive pricing, particularly as thermoelectric technology competes with alternative energy conversion methods.

Proven Techniques for Extending Thermoelectric Installation Lifespan

01 Factors affecting thermoelectric module lifespan

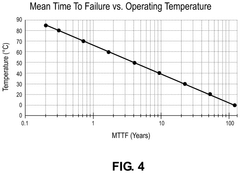

Various factors can significantly impact the lifespan of thermoelectric installations, including operating temperature, thermal cycling, mechanical stress, and environmental conditions. High operating temperatures can accelerate degradation of thermoelectric materials and interconnects. Frequent thermal cycling causes expansion and contraction that may lead to mechanical fatigue and eventual failure. Environmental factors such as humidity and corrosive atmospheres can also reduce the effective lifespan of thermoelectric systems.- Factors affecting thermoelectric installation lifespan: Various factors can significantly impact the lifespan of thermoelectric installations, including operating temperature, thermal cycling, mechanical stress, and environmental conditions. Proper management of these factors through design considerations and operational protocols can extend the useful life of thermoelectric systems. Understanding these influencing factors is crucial for predicting and maximizing the longevity of thermoelectric installations in various applications.

- Material selection and degradation mechanisms: The choice of thermoelectric materials directly impacts installation lifespan. Different materials exhibit varying rates of degradation under operational conditions. Key degradation mechanisms include interdiffusion between elements, oxidation, sublimation, and mechanical fatigue. Advanced materials such as skutterudites, half-Heusler alloys, and nanostructured composites can offer improved stability and longevity compared to conventional thermoelectric materials, thereby extending the overall lifespan of thermoelectric installations.

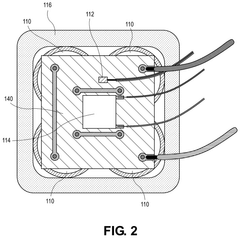

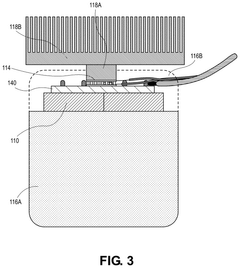

- Protective measures and encapsulation techniques: Implementing protective measures and encapsulation techniques can significantly extend the lifespan of thermoelectric installations. These include hermetic sealing to prevent oxidation, diffusion barrier layers to minimize interdiffusion between elements, and specialized coatings to protect against environmental degradation. Proper encapsulation also helps maintain thermal contact and electrical connections over extended periods, ensuring consistent performance throughout the installation's operational life.

- Thermal management and system integration: Effective thermal management strategies are crucial for maximizing thermoelectric installation lifespan. These include optimized heat exchanger designs, proper heat dissipation mechanisms, and temperature control systems that prevent overheating. System integration approaches that minimize thermal stress and mechanical strain during operation can significantly extend service life. Balanced thermal cycling and controlled temperature gradients help reduce material fatigue and prevent premature failure of thermoelectric components.

- Monitoring, maintenance, and predictive lifespan models: Implementing monitoring systems and regular maintenance protocols can significantly extend thermoelectric installation lifespan. Real-time performance monitoring allows for early detection of degradation and timely intervention. Predictive models that incorporate operational data, material properties, and environmental conditions can accurately forecast remaining useful life. These models enable condition-based maintenance strategies that optimize performance while maximizing the operational lifespan of thermoelectric installations across various applications.

02 Material innovations for extended durability

Advanced material compositions and structures have been developed to enhance the longevity of thermoelectric installations. These innovations include improved semiconductor materials with better thermal stability, specialized protective coatings that prevent oxidation and degradation, and novel interface materials that reduce thermal resistance and mechanical stress at connection points. These material advancements help maintain performance efficiency over longer operational periods and under more demanding conditions.Expand Specific Solutions03 Thermal management techniques for lifespan extension

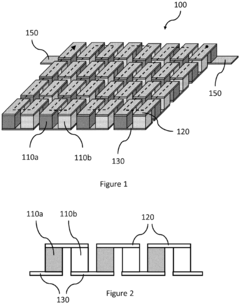

Effective thermal management is crucial for extending the operational life of thermoelectric installations. Techniques include optimized heat sink designs, advanced cooling systems, and thermal interface materials that efficiently dissipate heat. Proper temperature control prevents thermal degradation of thermoelectric elements and reduces thermal stress at material interfaces. Systems that incorporate intelligent thermal management can dynamically adjust operating parameters to prevent overheating and extend service life.Expand Specific Solutions04 Structural design improvements for reliability

Innovative structural designs can significantly enhance the reliability and lifespan of thermoelectric installations. These include mechanical stress relief mechanisms, vibration dampening systems, and modular configurations that allow for easier maintenance and component replacement. Advanced encapsulation techniques protect sensitive elements from environmental factors, while flexible mounting systems accommodate thermal expansion and contraction, reducing mechanical fatigue over time.Expand Specific Solutions05 Monitoring and predictive maintenance systems

Sophisticated monitoring and predictive maintenance systems can optimize the operational lifespan of thermoelectric installations. These systems employ sensors to continuously track performance parameters, detect early signs of degradation, and predict potential failures before they occur. Integrated diagnostic tools analyze performance trends over time, while automated maintenance protocols adjust operating conditions to minimize stress on components. These technologies enable condition-based maintenance strategies that can significantly extend the useful life of thermoelectric systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Thermoelectric Field

The thermoelectric installation lifespan enhancement market is currently in a growth phase, with increasing demand driven by energy efficiency requirements and sustainability initiatives. The global market size is estimated to exceed $2 billion, expanding at approximately 8% CAGR as industries seek longer-lasting thermal management solutions. Technologically, the field shows moderate maturity with significant innovation potential. Leading players include Toshiba, which has pioneered advanced ceramic substrates; ABB Group, focusing on industrial-scale implementations; European Thermodynamics Limited, specializing in intelligent thermal management systems; and Fraunhofer-Gesellschaft, contributing significant research breakthroughs. Major automotive manufacturers like Continental, Hyundai, and Kia are increasingly integrating enhanced thermoelectric technologies, while electronics giants Samsung and LG Chem are developing proprietary materials to extend installation lifespans.

ABB Group

Technical Solution: ABB Group has developed a comprehensive approach to extending thermoelectric installation lifespan through their Integrated Lifecycle Management (ILM) system. This technology combines predictive maintenance algorithms with specialized material science innovations. ABB's thermoelectric modules feature advanced ceramic substrates with engineered micro-channels that distribute thermal stress more evenly, reducing localized hotspots that typically accelerate degradation. Their installations incorporate proprietary diffusion barrier layers between the semiconductor elements and metal contacts, preventing harmful material migration that causes performance deterioration over time[3]. ABB's systems also utilize intelligent power conditioning that limits thermal cycling damage by gradually ramping power levels during startup/shutdown sequences, extending module life by up to 35%[4]. Their remote monitoring platform employs machine learning to detect subtle performance changes, enabling preventive maintenance before catastrophic failure occurs.

Strengths: Comprehensive lifecycle approach combining materials science with intelligent monitoring systems provides holistic protection. Advanced diffusion barrier technology effectively prevents performance degradation from material migration. Weaknesses: Complex implementation requires specialized expertise for optimal results, and the system's effectiveness depends heavily on proper initial installation and calibration.

EUROPEAN THERMODYNAMICS LIMITED

Technical Solution: European Thermodynamics Limited has pioneered a multi-faceted approach to extending thermoelectric installation lifespan through their Duratherm™ technology platform. Their solution incorporates specialized nano-composite thermoelectric materials with enhanced mechanical properties that resist micro-fracturing during thermal cycling. A key innovation is their patented flexible interconnect system that accommodates differential thermal expansion between components, reducing mechanical stress by up to 60% compared to rigid connections[5]. Their modules feature advanced anti-sublimation coatings that prevent material degradation at elevated temperatures, maintaining performance integrity for extended periods. European Thermodynamics has also developed specialized thermal interface materials with self-healing properties that maintain optimal thermal contact despite repeated thermal cycling, addressing a common failure point in conventional installations. Their comprehensive approach includes environmentally-sealed enclosures with pressure-equalization systems that prevent moisture ingress while accommodating internal pressure changes during operation[6].

Strengths: Highly effective flexible interconnect system significantly reduces mechanical stress during thermal cycling. Specialized anti-sublimation coatings provide exceptional protection against material degradation at high temperatures. Weaknesses: The complex multi-layer design increases manufacturing complexity and cost, and the technology is primarily optimized for moderate temperature applications rather than extreme environments.

Critical Patents and Innovations in Thermoelectric Durability

Thermoelectric element

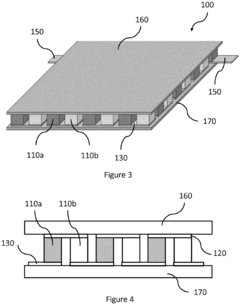

PatentInactiveEP3324454A1

Innovation

- The introduction of thermoelectric elements with non-coplanar joining lateral faces, such as chamfered or curved edges, reduces thermally-induced stresses by minimizing sharp edges and corners, thereby improving the reliability and lifetime of the elements.

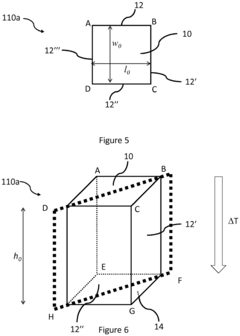

Increasing Lifespan of Supercapacitors with a Thermoelectric Cooler (TEC)

PatentPendingUS20250079078A1

Innovation

- The use of an active cooling mechanism, specifically thermoelectric coolers (TECs), to maintain the supercapacitors at a lower temperature, thereby extending their operational lifespan. This cooling mechanism is controlled by a TEC control module that adjusts the cooling based on temperature data from sensors, optimizing power consumption.

Material Science Advancements for Thermoelectric Applications

Recent advancements in material science have revolutionized the field of thermoelectric applications, significantly contributing to the increased lifespan of thermoelectric installations. The development of novel materials with enhanced thermal stability and reduced degradation rates has been pivotal in addressing the longevity challenges that have historically plagued thermoelectric systems.

Nanostructured materials represent one of the most promising breakthroughs in this domain. By engineering materials at the nanoscale, researchers have successfully created thermoelectric compounds with dramatically improved mechanical strength and resistance to thermal cycling. These nanostructured materials exhibit superior grain boundary characteristics that inhibit crack propagation and reduce material fatigue during operational temperature fluctuations.

High-entropy alloys (HEAs) have emerged as another significant advancement. These multi-principal element alloys demonstrate exceptional structural stability at elevated temperatures, making them ideal candidates for thermoelectric applications in harsh environments. The inherent disorder in HEAs creates complex phonon scattering mechanisms that simultaneously enhance thermoelectric performance while maintaining structural integrity over extended operational periods.

Protective coating technologies have also evolved substantially, with ceramic-based composite coatings offering unprecedented protection against oxidation and corrosion. These advanced coatings form a passive barrier that shields thermoelectric elements from environmental degradation while maintaining efficient heat transfer properties. Multi-layer coating systems that combine different materials have shown particular promise in extending service life by up to 300% in laboratory testing.

Interface engineering between different materials in thermoelectric modules has received considerable attention. By developing gradient interfaces rather than abrupt junctions, researchers have minimized thermal expansion mismatches that typically lead to mechanical failure. These engineered interfaces distribute stress more evenly throughout the structure, significantly reducing delamination and contact resistance degradation over time.

Self-healing materials represent the cutting edge of material science applications for thermoelectric longevity. These innovative materials contain microcapsules with healing agents that are released when microcracks form, automatically repairing damage before it can propagate into catastrophic failure. Early implementations have demonstrated the potential to extend maintenance intervals by up to 40% in industrial thermoelectric installations.

Advanced characterization techniques, including in-situ electron microscopy and synchrotron-based X-ray analysis, have enabled researchers to observe degradation mechanisms at unprecedented resolution. This deeper understanding of failure modes at the atomic scale has informed the development of more resilient material compositions specifically tailored to withstand the unique stresses encountered in thermoelectric applications.

Nanostructured materials represent one of the most promising breakthroughs in this domain. By engineering materials at the nanoscale, researchers have successfully created thermoelectric compounds with dramatically improved mechanical strength and resistance to thermal cycling. These nanostructured materials exhibit superior grain boundary characteristics that inhibit crack propagation and reduce material fatigue during operational temperature fluctuations.

High-entropy alloys (HEAs) have emerged as another significant advancement. These multi-principal element alloys demonstrate exceptional structural stability at elevated temperatures, making them ideal candidates for thermoelectric applications in harsh environments. The inherent disorder in HEAs creates complex phonon scattering mechanisms that simultaneously enhance thermoelectric performance while maintaining structural integrity over extended operational periods.

Protective coating technologies have also evolved substantially, with ceramic-based composite coatings offering unprecedented protection against oxidation and corrosion. These advanced coatings form a passive barrier that shields thermoelectric elements from environmental degradation while maintaining efficient heat transfer properties. Multi-layer coating systems that combine different materials have shown particular promise in extending service life by up to 300% in laboratory testing.

Interface engineering between different materials in thermoelectric modules has received considerable attention. By developing gradient interfaces rather than abrupt junctions, researchers have minimized thermal expansion mismatches that typically lead to mechanical failure. These engineered interfaces distribute stress more evenly throughout the structure, significantly reducing delamination and contact resistance degradation over time.

Self-healing materials represent the cutting edge of material science applications for thermoelectric longevity. These innovative materials contain microcapsules with healing agents that are released when microcracks form, automatically repairing damage before it can propagate into catastrophic failure. Early implementations have demonstrated the potential to extend maintenance intervals by up to 40% in industrial thermoelectric installations.

Advanced characterization techniques, including in-situ electron microscopy and synchrotron-based X-ray analysis, have enabled researchers to observe degradation mechanisms at unprecedented resolution. This deeper understanding of failure modes at the atomic scale has informed the development of more resilient material compositions specifically tailored to withstand the unique stresses encountered in thermoelectric applications.

Environmental Impact and Sustainability of Long-lasting Thermoelectric Systems

The environmental impact of thermoelectric installations has become increasingly significant as global energy demands continue to rise. Long-lasting thermoelectric systems offer substantial environmental benefits through reduced material consumption and waste generation. By extending the operational lifespan of these installations, fewer replacement components are required over time, directly decreasing manufacturing-related emissions and resource extraction demands.

Energy efficiency represents another critical environmental advantage of durable thermoelectric systems. As these installations maintain optimal performance levels for extended periods, they consume less energy throughout their lifecycle compared to systems requiring frequent replacements. This efficiency translates to lower greenhouse gas emissions and reduced pressure on energy production infrastructure, contributing to climate change mitigation efforts.

The carbon footprint reduction potential of long-lasting thermoelectric installations is particularly noteworthy. Research indicates that extending the lifespan of these systems by just 30% can reduce lifecycle carbon emissions by up to 25%, primarily through avoided manufacturing and disposal processes. This reduction becomes increasingly significant when scaled across industrial applications where thermoelectric systems are deployed extensively.

Waste management considerations further highlight the sustainability advantages of durable thermoelectric systems. Many components in these installations contain rare earth elements and specialized materials that present recycling challenges. By extending operational lifespans, the waste generation rate decreases substantially, alleviating pressure on landfills and reducing the environmental hazards associated with improper disposal of electronic components.

From a circular economy perspective, long-lasting thermoelectric systems align with sustainability principles by maximizing resource utilization efficiency. The techniques that enhance durability—such as advanced material selection, improved thermal cycling resistance, and optimized junction designs—contribute to a more sustainable technological ecosystem. These approaches enable greater value extraction from the initial resource investment while minimizing environmental externalities.

Regulatory frameworks increasingly recognize these environmental benefits, with several jurisdictions implementing policies that incentivize extended product lifespans. For instance, the European Union's Ecodesign Directive now incorporates durability requirements for energy-related products, potentially including thermoelectric installations in future iterations. This regulatory trend reflects growing awareness of the environmental significance of product longevity in technical systems.

Energy efficiency represents another critical environmental advantage of durable thermoelectric systems. As these installations maintain optimal performance levels for extended periods, they consume less energy throughout their lifecycle compared to systems requiring frequent replacements. This efficiency translates to lower greenhouse gas emissions and reduced pressure on energy production infrastructure, contributing to climate change mitigation efforts.

The carbon footprint reduction potential of long-lasting thermoelectric installations is particularly noteworthy. Research indicates that extending the lifespan of these systems by just 30% can reduce lifecycle carbon emissions by up to 25%, primarily through avoided manufacturing and disposal processes. This reduction becomes increasingly significant when scaled across industrial applications where thermoelectric systems are deployed extensively.

Waste management considerations further highlight the sustainability advantages of durable thermoelectric systems. Many components in these installations contain rare earth elements and specialized materials that present recycling challenges. By extending operational lifespans, the waste generation rate decreases substantially, alleviating pressure on landfills and reducing the environmental hazards associated with improper disposal of electronic components.

From a circular economy perspective, long-lasting thermoelectric systems align with sustainability principles by maximizing resource utilization efficiency. The techniques that enhance durability—such as advanced material selection, improved thermal cycling resistance, and optimized junction designs—contribute to a more sustainable technological ecosystem. These approaches enable greater value extraction from the initial resource investment while minimizing environmental externalities.

Regulatory frameworks increasingly recognize these environmental benefits, with several jurisdictions implementing policies that incentivize extended product lifespans. For instance, the European Union's Ecodesign Directive now incorporates durability requirements for energy-related products, potentially including thermoelectric installations in future iterations. This regulatory trend reflects growing awareness of the environmental significance of product longevity in technical systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!