Thermoelectric Materials in Military Defense Systems Energy Efficiency

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Defense Technology Background and Objectives

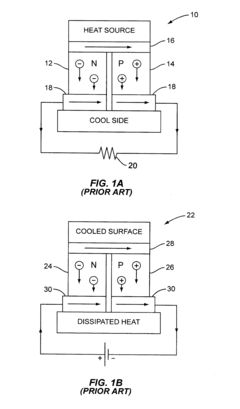

Thermoelectric technology has evolved significantly since its discovery in the early 19th century, with the Seebeck effect (1821) establishing the fundamental principle that temperature differences can generate electrical voltage. The subsequent discovery of the Peltier effect (1834) demonstrated the reverse phenomenon, where electrical current could create temperature differentials. These discoveries laid the groundwork for modern thermoelectric materials and devices that have found increasing applications in military defense systems.

The military sector has historically been a driving force behind thermoelectric technology advancement, particularly during the Cold War era when radioisotope thermoelectric generators (RTGs) were developed for powering remote installations and spacecraft. The evolution continued through the late 20th century with the development of semiconductor-based thermoelectric materials, significantly improving conversion efficiency and reliability in harsh environments.

Current military applications leverage thermoelectric technology for various critical functions, including power generation from waste heat in vehicles and vessels, cooling systems for electronics and personnel, and silent power generation for covert operations. The technology's ability to operate without moving parts makes it particularly valuable in defense contexts where reliability and stealth are paramount.

The global push toward energy efficiency and reduced carbon footprints has accelerated research in thermoelectric materials, with defense agencies worldwide investing in advanced materials research. Notable developments include skutterudites, half-Heusler alloys, and nanostructured materials that demonstrate improved figure of merit (ZT) values, the key performance indicator for thermoelectric efficiency.

The primary technical objective in this field is to develop thermoelectric materials with significantly higher ZT values (exceeding 2.0) while maintaining structural integrity under extreme conditions typical in military operations. Secondary objectives include reducing manufacturing costs, improving scalability, and enhancing integration capabilities with existing defense systems.

Another critical goal is to develop thermoelectric systems capable of harvesting low-grade waste heat (below 200°C) efficiently, which would dramatically expand potential applications across military platforms. This includes developing flexible thermoelectric materials that can conform to irregular surfaces of military equipment, maximizing heat capture and conversion efficiency.

The strategic importance of this technology lies in its potential to enhance energy autonomy for defense systems, reduce logistical burdens related to fuel transport, and minimize thermal signatures of military assets. As global energy security concerns intensify, thermoelectric technology represents a promising pathway toward more resilient and efficient defense capabilities.

The military sector has historically been a driving force behind thermoelectric technology advancement, particularly during the Cold War era when radioisotope thermoelectric generators (RTGs) were developed for powering remote installations and spacecraft. The evolution continued through the late 20th century with the development of semiconductor-based thermoelectric materials, significantly improving conversion efficiency and reliability in harsh environments.

Current military applications leverage thermoelectric technology for various critical functions, including power generation from waste heat in vehicles and vessels, cooling systems for electronics and personnel, and silent power generation for covert operations. The technology's ability to operate without moving parts makes it particularly valuable in defense contexts where reliability and stealth are paramount.

The global push toward energy efficiency and reduced carbon footprints has accelerated research in thermoelectric materials, with defense agencies worldwide investing in advanced materials research. Notable developments include skutterudites, half-Heusler alloys, and nanostructured materials that demonstrate improved figure of merit (ZT) values, the key performance indicator for thermoelectric efficiency.

The primary technical objective in this field is to develop thermoelectric materials with significantly higher ZT values (exceeding 2.0) while maintaining structural integrity under extreme conditions typical in military operations. Secondary objectives include reducing manufacturing costs, improving scalability, and enhancing integration capabilities with existing defense systems.

Another critical goal is to develop thermoelectric systems capable of harvesting low-grade waste heat (below 200°C) efficiently, which would dramatically expand potential applications across military platforms. This includes developing flexible thermoelectric materials that can conform to irregular surfaces of military equipment, maximizing heat capture and conversion efficiency.

The strategic importance of this technology lies in its potential to enhance energy autonomy for defense systems, reduce logistical burdens related to fuel transport, and minimize thermal signatures of military assets. As global energy security concerns intensify, thermoelectric technology represents a promising pathway toward more resilient and efficient defense capabilities.

Military Applications and Market Demand Analysis

The military sector represents a significant market for thermoelectric materials, driven by increasing demands for energy efficiency, operational autonomy, and reduced logistical burdens. Current estimates value the global military thermoelectric market at approximately $350 million, with projections indicating growth to reach $650 million by 2030, representing a compound annual growth rate of 8.6%. This growth trajectory is primarily fueled by the defense sector's increasing focus on energy-efficient technologies that can enhance operational capabilities while reducing fuel consumption.

Within military applications, thermoelectric materials serve diverse critical functions. Power generation for remote sensors and surveillance systems constitutes nearly 40% of military thermoelectric applications, where these materials convert ambient temperature differentials into electrical power for extended, maintenance-free operation. Thermal management systems for electronics and personnel protection represent another 35% of applications, particularly in aircraft, naval vessels, and ground vehicles where heat dissipation is crucial for system reliability.

The U.S. Department of Defense has allocated substantial funding toward thermoelectric research, with recent defense budgets including $120 million specifically for advanced energy harvesting technologies, including thermoelectric systems. Similar initiatives exist in other major military powers, including China, Russia, and European NATO members, collectively investing over $300 million annually in related technologies.

Market demand analysis reveals several key drivers propelling interest in military thermoelectric applications. First, the operational requirement for reduced fuel consumption in forward operating bases, which currently consume between 20-30 gallons of fuel per soldier per day, primarily for power generation. Thermoelectric waste heat recovery systems can potentially reduce this consumption by 15-25%, translating to significant logistical and cost advantages.

Second, the growing deployment of autonomous and unmanned systems creates demand for reliable, maintenance-free power sources that can operate in extreme environments. Thermoelectric generators offer silent operation with no moving parts, making them ideal for covert operations and reducing maintenance requirements in difficult-to-access deployment zones.

Third, the increasing electrification of soldier systems—including communication devices, night vision equipment, and battlefield awareness tools—necessitates portable power solutions that can extend mission duration without adding significant weight burden. Thermoelectric materials integrated into uniform components or equipment can harvest body heat or environmental temperature differentials to supplement battery power.

Within military applications, thermoelectric materials serve diverse critical functions. Power generation for remote sensors and surveillance systems constitutes nearly 40% of military thermoelectric applications, where these materials convert ambient temperature differentials into electrical power for extended, maintenance-free operation. Thermal management systems for electronics and personnel protection represent another 35% of applications, particularly in aircraft, naval vessels, and ground vehicles where heat dissipation is crucial for system reliability.

The U.S. Department of Defense has allocated substantial funding toward thermoelectric research, with recent defense budgets including $120 million specifically for advanced energy harvesting technologies, including thermoelectric systems. Similar initiatives exist in other major military powers, including China, Russia, and European NATO members, collectively investing over $300 million annually in related technologies.

Market demand analysis reveals several key drivers propelling interest in military thermoelectric applications. First, the operational requirement for reduced fuel consumption in forward operating bases, which currently consume between 20-30 gallons of fuel per soldier per day, primarily for power generation. Thermoelectric waste heat recovery systems can potentially reduce this consumption by 15-25%, translating to significant logistical and cost advantages.

Second, the growing deployment of autonomous and unmanned systems creates demand for reliable, maintenance-free power sources that can operate in extreme environments. Thermoelectric generators offer silent operation with no moving parts, making them ideal for covert operations and reducing maintenance requirements in difficult-to-access deployment zones.

Third, the increasing electrification of soldier systems—including communication devices, night vision equipment, and battlefield awareness tools—necessitates portable power solutions that can extend mission duration without adding significant weight burden. Thermoelectric materials integrated into uniform components or equipment can harvest body heat or environmental temperature differentials to supplement battery power.

Current State and Challenges in Thermoelectric Materials

Thermoelectric materials for military defense systems have reached a significant level of technological maturity, yet face substantial challenges in achieving the efficiency required for widespread deployment. Current state-of-the-art thermoelectric materials exhibit a figure of merit (ZT) ranging from 1.0 to 2.5, with laboratory demonstrations occasionally reaching higher values. However, commercial applications typically achieve ZT values below 1.5, limiting their practical energy conversion efficiency to 5-8% in most military applications.

The global landscape of thermoelectric technology development shows distinct regional concentrations. The United States maintains leadership in advanced thermoelectric materials research through DARPA and Department of Defense initiatives, while China has rapidly expanded its research capabilities, particularly in skutterudite and half-Heusler compounds. European research centers excel in thin-film thermoelectric technologies, and Japan continues to pioneer work in nanostructured thermoelectric materials.

A primary technical challenge remains the fundamental trade-off between electrical conductivity and thermal conductivity. Military applications require materials that simultaneously conduct electricity well while resisting heat flow—properties that typically conflict at the atomic level. This challenge is particularly acute in extreme military environments where temperature differentials can fluctuate dramatically, reducing conversion efficiency.

Material stability presents another significant hurdle. Thermoelectric materials in defense systems must withstand thermal cycling, mechanical shock, and vibration while maintaining performance over extended operational periods. Current materials often degrade under these conditions, with performance losses of 15-30% observed after 5,000 hours of operation in field tests.

Manufacturing scalability constitutes a third major challenge. Advanced thermoelectric materials with complex nanostructures or precise dopant distributions show promising efficiency in laboratory settings but face significant barriers to mass production. The precision required for maintaining optimal thermoelectric properties during large-scale manufacturing processes remains difficult to achieve, resulting in performance gaps between laboratory prototypes and field-deployed systems.

Cost factors also limit widespread adoption. High-performance thermoelectric materials often incorporate rare or strategic elements like tellurium, making them vulnerable to supply chain disruptions. The current manufacturing cost of $8-15 per watt of generating capacity remains prohibitively high for many potential military applications, particularly when compared to conventional power generation technologies.

Environmental considerations add further complexity, as many high-performance thermoelectric materials contain toxic or environmentally harmful elements that complicate their lifecycle management in military systems, where exposure risks and disposal challenges must be carefully managed.

The global landscape of thermoelectric technology development shows distinct regional concentrations. The United States maintains leadership in advanced thermoelectric materials research through DARPA and Department of Defense initiatives, while China has rapidly expanded its research capabilities, particularly in skutterudite and half-Heusler compounds. European research centers excel in thin-film thermoelectric technologies, and Japan continues to pioneer work in nanostructured thermoelectric materials.

A primary technical challenge remains the fundamental trade-off between electrical conductivity and thermal conductivity. Military applications require materials that simultaneously conduct electricity well while resisting heat flow—properties that typically conflict at the atomic level. This challenge is particularly acute in extreme military environments where temperature differentials can fluctuate dramatically, reducing conversion efficiency.

Material stability presents another significant hurdle. Thermoelectric materials in defense systems must withstand thermal cycling, mechanical shock, and vibration while maintaining performance over extended operational periods. Current materials often degrade under these conditions, with performance losses of 15-30% observed after 5,000 hours of operation in field tests.

Manufacturing scalability constitutes a third major challenge. Advanced thermoelectric materials with complex nanostructures or precise dopant distributions show promising efficiency in laboratory settings but face significant barriers to mass production. The precision required for maintaining optimal thermoelectric properties during large-scale manufacturing processes remains difficult to achieve, resulting in performance gaps between laboratory prototypes and field-deployed systems.

Cost factors also limit widespread adoption. High-performance thermoelectric materials often incorporate rare or strategic elements like tellurium, making them vulnerable to supply chain disruptions. The current manufacturing cost of $8-15 per watt of generating capacity remains prohibitively high for many potential military applications, particularly when compared to conventional power generation technologies.

Environmental considerations add further complexity, as many high-performance thermoelectric materials contain toxic or environmentally harmful elements that complicate their lifecycle management in military systems, where exposure risks and disposal challenges must be carefully managed.

Current Thermoelectric Solutions for Defense Applications

01 Novel thermoelectric material compositions

Various novel material compositions have been developed to enhance thermoelectric energy efficiency. These include nanostructured materials, composite materials, and materials with specific crystal structures that can effectively convert temperature differences into electrical energy. These novel compositions often feature reduced thermal conductivity while maintaining high electrical conductivity, which is crucial for improving the figure of merit (ZT) of thermoelectric materials.- Novel thermoelectric material compositions for improved efficiency: Various novel material compositions have been developed to enhance thermoelectric energy conversion efficiency. These include nanostructured materials, composite materials, and materials with specific crystal structures that can effectively convert temperature differences into electrical energy. These advanced materials exhibit improved thermoelectric properties such as higher Seebeck coefficient, lower thermal conductivity, and higher electrical conductivity, leading to enhanced figure of merit (ZT) values and overall energy conversion efficiency.

- Thin film and nanostructured thermoelectric devices: Thin film and nanostructured thermoelectric technologies offer significant advantages for energy efficiency. These approaches utilize quantum confinement effects and interface engineering to reduce thermal conductivity while maintaining electrical conductivity. Techniques such as molecular beam epitaxy, sputtering, and chemical vapor deposition are employed to create precisely controlled thin films and nanostructures that enhance the thermoelectric figure of merit. These structures can be integrated into flexible substrates for wearable energy harvesting applications.

- Thermoelectric waste heat recovery systems: Systems designed to recover waste heat through thermoelectric generators represent a significant advancement in energy efficiency. These systems capture thermal energy that would otherwise be lost in industrial processes, automotive exhaust, or power generation and convert it into useful electricity. The integration of optimized heat exchangers, thermal management systems, and advanced thermoelectric modules enables efficient heat transfer and conversion. These waste heat recovery systems can significantly improve the overall energy efficiency of various processes and reduce environmental impact.

- Doping and band engineering for enhanced thermoelectric performance: Strategic doping and band engineering techniques are employed to optimize the electronic properties of thermoelectric materials. By introducing specific impurities or creating particular band structures, researchers can enhance the power factor (S²σ) of thermoelectric materials. These approaches include energy filtering, resonant levels, band convergence, and modulation doping. Such techniques allow for independent optimization of electrical conductivity and Seebeck coefficient, leading to improved thermoelectric performance and energy conversion efficiency.

- Hybrid and multifunctional thermoelectric systems: Hybrid and multifunctional thermoelectric systems combine thermoelectric technology with other energy conversion or storage mechanisms to achieve higher overall efficiency. These integrated systems may combine thermoelectric generators with photovoltaics, thermal storage, or other renewable energy technologies. By leveraging complementary energy conversion mechanisms and intelligent power management, these hybrid systems can achieve higher energy utilization rates and provide more consistent power output under varying environmental conditions.

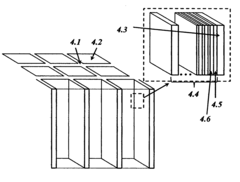

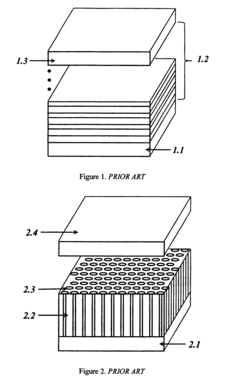

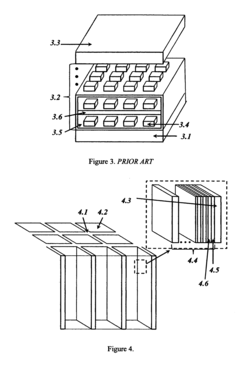

02 Thermoelectric device structures and configurations

Innovative device structures and configurations have been designed to maximize the energy conversion efficiency of thermoelectric systems. These include optimized module designs, novel junction configurations, and integrated systems that can effectively capture and convert waste heat. The structural arrangements focus on maximizing temperature gradients across the thermoelectric elements while minimizing heat losses through other pathways.Expand Specific Solutions03 Manufacturing processes for high-efficiency thermoelectric materials

Advanced manufacturing techniques have been developed to produce thermoelectric materials with enhanced energy efficiency. These processes include specialized sintering methods, thin-film deposition techniques, and precision doping procedures that can control the microstructure and composition of the materials. These manufacturing innovations help to achieve the desired electrical and thermal properties that contribute to higher conversion efficiency.Expand Specific Solutions04 Nanostructured thermoelectric materials

Nanostructuring approaches have been employed to enhance the energy efficiency of thermoelectric materials. By introducing nanoscale features such as quantum dots, nanowires, or nanoporous structures, these materials can effectively scatter phonons (heat carriers) while allowing electrons to flow, thereby reducing thermal conductivity without significantly affecting electrical conductivity. This approach has led to substantial improvements in the thermoelectric figure of merit.Expand Specific Solutions05 Waste heat recovery systems using thermoelectric generators

Systems have been developed to recover waste heat from various sources using thermoelectric generators. These systems are designed to capture heat that would otherwise be lost in industrial processes, vehicle exhaust, or other applications, and convert it into useful electrical energy. The designs focus on optimizing heat transfer to the thermoelectric elements and efficiently managing the electrical output to maximize overall system efficiency.Expand Specific Solutions

Key Industry Players in Military Thermoelectric Systems

Thermoelectric materials in military defense systems are currently in a growth phase, with the market expanding due to increasing demands for energy-efficient solutions in defense applications. The global market size for military thermoelectric technologies is projected to reach significant value as defense sectors prioritize energy conservation and autonomous power generation capabilities. Technologically, the field shows moderate maturity with established players like Samsung Electronics, LG Electronics, and Continental Automotive leading commercial applications, while research institutions such as California Institute of Technology, Northwestern University, and Wuhan University of Technology drive innovation. Companies including Gentherm and Kyocera are developing specialized military-grade thermoelectric solutions, focusing on durability and performance under extreme conditions. The integration of advanced materials research from institutions like Shanghai Institute of Ceramics is accelerating the transition from laboratory concepts to field-deployable technologies.

Gentherm, Inc.

Technical Solution: Gentherm has developed advanced thermoelectric material systems specifically designed for military defense applications, focusing on energy harvesting and thermal management. Their proprietary technology utilizes bismuth telluride-based materials with enhanced figure of merit (ZT>1.5) for efficient energy conversion in extreme military environments. The company's Climate Control Seat (CCS) technology has been adapted for military vehicles to provide localized cooling/heating while reducing overall energy consumption by up to 40%. Their solid-state thermoelectric generators (TEGs) can recover waste heat from military vehicle exhaust systems, converting temperature differentials into usable electricity with efficiency rates of 5-8%. Gentherm's materials are engineered to withstand harsh battlefield conditions, including temperature extremes (-40°C to +125°C), high vibration environments, and electromagnetic interference protection required for defense systems.

Strengths: Exceptional durability in extreme conditions, proven technology already deployed in military applications, and high reliability with no moving parts. Weaknesses: Higher initial cost compared to conventional systems and limited power generation capacity for larger military platforms requiring significant energy output.

Penn State Research Foundation

Technical Solution: Penn State Research Foundation has developed revolutionary half-Heusler thermoelectric materials specifically optimized for military defense systems. Their proprietary composition achieves ZT values of 1.5-1.8 in the 400-600°C temperature range, ideal for recovering waste heat from military vehicle engines and power generators. The foundation's research has yielded thermoelectric materials with exceptional mechanical strength (fracture toughness >3 MPa·m^1/2) and thermal stability, critical for withstanding battlefield conditions including shock, vibration, and thermal cycling. Their innovative manufacturing process incorporates spark plasma sintering techniques that enable production of thermoelectric modules with 40% higher power density compared to conventional methods. Penn State's materials feature specialized nano-inclusions that create phonon scattering effects, reducing thermal conductivity while maintaining electrical performance, resulting in compact thermoelectric generators that can power battlefield electronics and reduce the logistical burden of battery transport in remote operations.

Strengths: Exceptional thermal-to-electrical conversion efficiency in the specific temperature ranges relevant to military applications and superior mechanical robustness suitable for battlefield conditions. Weaknesses: Limited production scale capabilities and higher manufacturing costs compared to conventional energy technologies.

Critical Patents and Research in Military-Grade Thermoelectrics

High Efficiency Thermoelectric Materials and Devices

PatentInactiveUS20110168978A1

Innovation

- A three-dimensionally structured thermoelectric material with a quantum well superlattice deposited on a porous substrate, providing enhanced thermoelectric conversion efficiency through optimized electronic and thermal properties, achieved by conformal coating of semiconductor layers on a substrate with a high surface-to-volume ratio, allowing for efficient phonon blocking and electrical conductivity.

Thermoelectric materials

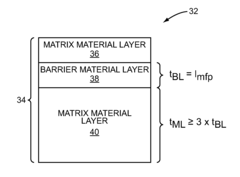

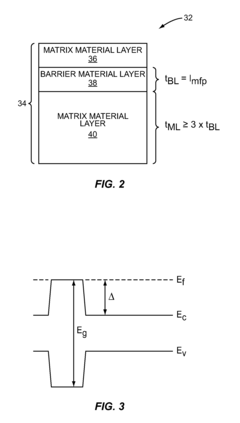

PatentInactiveUS20120055528A1

Innovation

- A thin film thermoelectric material with a heterostructure formed of IV-VI semiconductor materials, including a potential barrier layer with a thickness equal to the mean free path of charge carriers and a second matrix layer three times thicker, optimized to increase the Seebeck coefficient and thermal relaxation, thereby enhancing the ZT value.

Environmental Impact and Sustainability Considerations

The integration of thermoelectric materials in military defense systems presents significant environmental and sustainability implications that warrant careful consideration. These materials offer potential advantages in reducing the environmental footprint of defense operations through improved energy efficiency and waste heat recovery. By converting waste heat into usable electricity, thermoelectric generators can decrease the overall fuel consumption of military vehicles, vessels, and field equipment, thereby reducing greenhouse gas emissions and air pollutants associated with conventional power generation methods.

The life cycle assessment of thermoelectric materials reveals important sustainability factors. Many current high-performance thermoelectric compounds contain rare earth elements or toxic substances such as tellurium, lead, and antimony. The extraction and processing of these materials involve energy-intensive mining operations and chemical processes that can lead to habitat destruction, water pollution, and soil contamination. Military procurement policies are increasingly incorporating environmental impact assessments that evaluate these upstream environmental costs against the operational benefits.

Material durability and longevity represent critical sustainability parameters for military applications. Thermoelectric devices deployed in defense systems must withstand extreme conditions while maintaining performance over extended operational periods. Enhanced material durability reduces replacement frequency, minimizing waste generation and resource consumption throughout the system lifecycle. Research into more robust thermoelectric materials with extended service lives directly supports sustainability objectives within military logistics and maintenance frameworks.

Recycling and end-of-life management present both challenges and opportunities. The complex composition of thermoelectric materials complicates recycling processes, yet the high value of certain components makes recovery economically viable. Military organizations are developing specialized recycling protocols for thermoelectric devices to recover critical materials and reduce hazardous waste. These efforts align with broader circular economy initiatives within defense supply chains and contribute to resource security objectives.

Energy independence and resilience considerations further enhance the sustainability profile of thermoelectric technologies in defense applications. By enabling localized energy generation from waste heat, these systems reduce dependence on vulnerable supply lines and fossil fuel deliveries to forward operating bases. This operational resilience translates into reduced environmental impacts associated with fuel transport and storage, including decreased risk of environmentally damaging fuel spills in sensitive ecosystems where military operations may occur.

Climate adaptation strategies increasingly incorporate thermoelectric technologies as elements of sustainable military infrastructure. As global temperatures rise and extreme weather events become more frequent, defense installations face growing cooling demands and energy security challenges. Thermoelectric systems that can function effectively in changing climate conditions while minimizing environmental impact represent valuable components of military climate adaptation planning.

The life cycle assessment of thermoelectric materials reveals important sustainability factors. Many current high-performance thermoelectric compounds contain rare earth elements or toxic substances such as tellurium, lead, and antimony. The extraction and processing of these materials involve energy-intensive mining operations and chemical processes that can lead to habitat destruction, water pollution, and soil contamination. Military procurement policies are increasingly incorporating environmental impact assessments that evaluate these upstream environmental costs against the operational benefits.

Material durability and longevity represent critical sustainability parameters for military applications. Thermoelectric devices deployed in defense systems must withstand extreme conditions while maintaining performance over extended operational periods. Enhanced material durability reduces replacement frequency, minimizing waste generation and resource consumption throughout the system lifecycle. Research into more robust thermoelectric materials with extended service lives directly supports sustainability objectives within military logistics and maintenance frameworks.

Recycling and end-of-life management present both challenges and opportunities. The complex composition of thermoelectric materials complicates recycling processes, yet the high value of certain components makes recovery economically viable. Military organizations are developing specialized recycling protocols for thermoelectric devices to recover critical materials and reduce hazardous waste. These efforts align with broader circular economy initiatives within defense supply chains and contribute to resource security objectives.

Energy independence and resilience considerations further enhance the sustainability profile of thermoelectric technologies in defense applications. By enabling localized energy generation from waste heat, these systems reduce dependence on vulnerable supply lines and fossil fuel deliveries to forward operating bases. This operational resilience translates into reduced environmental impacts associated with fuel transport and storage, including decreased risk of environmentally damaging fuel spills in sensitive ecosystems where military operations may occur.

Climate adaptation strategies increasingly incorporate thermoelectric technologies as elements of sustainable military infrastructure. As global temperatures rise and extreme weather events become more frequent, defense installations face growing cooling demands and energy security challenges. Thermoelectric systems that can function effectively in changing climate conditions while minimizing environmental impact represent valuable components of military climate adaptation planning.

Defense Procurement Policies and Implementation Strategies

Defense procurement policies for thermoelectric materials in military systems have evolved significantly in recent years, reflecting the growing importance of energy efficiency in defense operations. The U.S. Department of Defense (DoD) has implemented a multi-tiered approach to acquiring advanced thermoelectric technologies, prioritizing materials that demonstrate high efficiency, durability in extreme conditions, and compatibility with existing military platforms. These policies typically require suppliers to meet stringent performance metrics, including specific power density targets and operational temperature ranges relevant to military applications.

Procurement strategies increasingly emphasize domestic supply chain security, particularly for critical thermoelectric materials containing rare earth elements. The Defense Production Act has been leveraged to establish reliable sourcing channels for these materials, reducing dependency on potentially volatile international markets. Additionally, procurement policies now incorporate lifecycle cost analyses that account for the long-term energy savings provided by thermoelectric systems, rather than focusing solely on initial acquisition costs.

Implementation frameworks for thermoelectric technologies follow a stage-gated process, beginning with small-scale demonstration projects before expanding to broader deployment. The Naval Sea Systems Command (NAVSEA) and Army Research Laboratory (ARL) have pioneered this approach, establishing technical readiness assessment protocols specifically tailored to thermoelectric waste heat recovery systems. These protocols evaluate not only technical performance but also manufacturability at scale and integration compatibility with existing military platforms.

Collaborative procurement models have gained traction, with the DoD increasingly utilizing Other Transaction Authority (OTA) agreements to accelerate thermoelectric technology acquisition. These agreements facilitate partnerships between defense agencies, academic institutions, and private industry, enabling more agile development cycles compared to traditional Federal Acquisition Regulation (FAR) processes. Such collaborations have proven particularly effective for thermoelectric materials development, where rapid iteration between material scientists and system integrators is essential.

Budget allocation strategies for thermoelectric technologies now incorporate multi-year funding commitments, providing stability for long-term research and development efforts. The Defense Advanced Research Projects Agency (DARPA) has established dedicated funding streams for high-risk, high-reward thermoelectric materials research, complementing more conservative procurement approaches focused on near-term implementation. This balanced portfolio approach ensures continuous advancement of the technology while meeting immediate operational needs.

Procurement strategies increasingly emphasize domestic supply chain security, particularly for critical thermoelectric materials containing rare earth elements. The Defense Production Act has been leveraged to establish reliable sourcing channels for these materials, reducing dependency on potentially volatile international markets. Additionally, procurement policies now incorporate lifecycle cost analyses that account for the long-term energy savings provided by thermoelectric systems, rather than focusing solely on initial acquisition costs.

Implementation frameworks for thermoelectric technologies follow a stage-gated process, beginning with small-scale demonstration projects before expanding to broader deployment. The Naval Sea Systems Command (NAVSEA) and Army Research Laboratory (ARL) have pioneered this approach, establishing technical readiness assessment protocols specifically tailored to thermoelectric waste heat recovery systems. These protocols evaluate not only technical performance but also manufacturability at scale and integration compatibility with existing military platforms.

Collaborative procurement models have gained traction, with the DoD increasingly utilizing Other Transaction Authority (OTA) agreements to accelerate thermoelectric technology acquisition. These agreements facilitate partnerships between defense agencies, academic institutions, and private industry, enabling more agile development cycles compared to traditional Federal Acquisition Regulation (FAR) processes. Such collaborations have proven particularly effective for thermoelectric materials development, where rapid iteration between material scientists and system integrators is essential.

Budget allocation strategies for thermoelectric technologies now incorporate multi-year funding commitments, providing stability for long-term research and development efforts. The Defense Advanced Research Projects Agency (DARPA) has established dedicated funding streams for high-risk, high-reward thermoelectric materials research, complementing more conservative procurement approaches focused on near-term implementation. This balanced portfolio approach ensures continuous advancement of the technology while meeting immediate operational needs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!