Maximizing Thermoelectric Generation in Offshore Wind Turbines

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Generation in Wind Turbines: Background and Objectives

Thermoelectric generation in wind turbines represents a promising frontier in renewable energy technology, combining the established wind power generation with innovative thermoelectric principles to enhance overall energy efficiency. The concept has evolved significantly over the past decade, transitioning from theoretical research to practical applications in various wind turbine designs. Initially, thermoelectric generation was primarily explored in conventional land-based turbines, but recent advancements have expanded its potential implementation in offshore environments where temperature differentials can be more pronounced.

The historical development of this technology traces back to the early 2000s when researchers began investigating ways to harness waste heat from mechanical components in wind turbines. By 2010, preliminary studies demonstrated the feasibility of integrating thermoelectric generators (TEGs) into specific turbine sections, particularly in the nacelle where heat generation is most concentrated. The subsequent years witnessed incremental improvements in thermoelectric materials, with significant breakthroughs in semiconductor-based TEGs offering higher conversion efficiencies.

Current technological trends indicate a shift toward specialized thermoelectric solutions designed specifically for the unique operating conditions of offshore wind turbines. These environments present both challenges and opportunities, with greater temperature gradients between air and sea water potentially enhancing thermoelectric performance. The marine setting also introduces considerations regarding saltwater corrosion, humidity effects on thermoelectric materials, and integration with existing offshore turbine designs.

The primary technical objective in maximizing thermoelectric generation in offshore wind turbines centers on optimizing the capture and conversion of thermal energy that would otherwise be dissipated as waste heat. This encompasses improving the efficiency of thermoelectric materials, developing more effective heat exchange systems, and creating robust integration frameworks that can withstand harsh marine conditions while maintaining reliable operation over extended periods.

Secondary objectives include reducing the weight impact of thermoelectric systems on turbine structures, minimizing maintenance requirements through passive operation, and ensuring cost-effectiveness to maintain the competitive advantage of wind energy. The ultimate goal is to develop a supplementary power generation system that can increase the overall energy output of offshore wind installations by 3-8% without significantly impacting operational costs or reliability.

Looking forward, the technology trajectory suggests potential convergence with other emerging technologies such as advanced materials science, AI-driven thermal management systems, and next-generation power electronics. These intersections may unlock new possibilities for thermoelectric applications in wind energy, potentially transforming what is currently viewed as a supplementary technology into a core component of future offshore wind turbine designs.

The historical development of this technology traces back to the early 2000s when researchers began investigating ways to harness waste heat from mechanical components in wind turbines. By 2010, preliminary studies demonstrated the feasibility of integrating thermoelectric generators (TEGs) into specific turbine sections, particularly in the nacelle where heat generation is most concentrated. The subsequent years witnessed incremental improvements in thermoelectric materials, with significant breakthroughs in semiconductor-based TEGs offering higher conversion efficiencies.

Current technological trends indicate a shift toward specialized thermoelectric solutions designed specifically for the unique operating conditions of offshore wind turbines. These environments present both challenges and opportunities, with greater temperature gradients between air and sea water potentially enhancing thermoelectric performance. The marine setting also introduces considerations regarding saltwater corrosion, humidity effects on thermoelectric materials, and integration with existing offshore turbine designs.

The primary technical objective in maximizing thermoelectric generation in offshore wind turbines centers on optimizing the capture and conversion of thermal energy that would otherwise be dissipated as waste heat. This encompasses improving the efficiency of thermoelectric materials, developing more effective heat exchange systems, and creating robust integration frameworks that can withstand harsh marine conditions while maintaining reliable operation over extended periods.

Secondary objectives include reducing the weight impact of thermoelectric systems on turbine structures, minimizing maintenance requirements through passive operation, and ensuring cost-effectiveness to maintain the competitive advantage of wind energy. The ultimate goal is to develop a supplementary power generation system that can increase the overall energy output of offshore wind installations by 3-8% without significantly impacting operational costs or reliability.

Looking forward, the technology trajectory suggests potential convergence with other emerging technologies such as advanced materials science, AI-driven thermal management systems, and next-generation power electronics. These intersections may unlock new possibilities for thermoelectric applications in wind energy, potentially transforming what is currently viewed as a supplementary technology into a core component of future offshore wind turbine designs.

Market Analysis for Offshore Wind Thermoelectric Solutions

The offshore wind thermoelectric generation market is experiencing significant growth, driven by the increasing global demand for renewable energy solutions. Current market assessments indicate that offshore wind capacity has surpassed 35 gigawatts globally, with annual growth rates exceeding 30% in key markets such as Europe and Asia-Pacific. The integration of thermoelectric generation technology into this established sector represents an emerging market opportunity with substantial potential for value creation.

Market demand for offshore wind thermoelectric solutions is primarily driven by three factors: increasing efficiency requirements for renewable energy systems, growing focus on waste heat recovery across industrial applications, and supportive government policies promoting innovative clean energy technologies. The European market currently leads adoption, with the North Sea region demonstrating particular interest due to its established offshore wind infrastructure and favorable temperature differentials.

Analysis of market segments reveals that utility-scale energy providers constitute the largest potential customer base, followed by specialized renewable energy developers and maritime industrial operations. These segments collectively represent an addressable market estimated to grow at a compound annual rate of 25% through 2030, outpacing the broader renewable energy sector.

Geographic distribution of market demand shows concentration in regions with both substantial offshore wind development and significant temperature gradients between air and water. The North Sea, Baltic Sea, and select areas off the coasts of Japan, China, and the northeastern United States demonstrate the highest commercial potential. Emerging markets in Southeast Asia and South America are expected to develop as offshore wind infrastructure expands in these regions.

Pricing sensitivity analysis indicates that thermoelectric generation solutions must achieve a levelized cost of energy below 0.08 USD per kilowatt-hour to be competitive with traditional offshore wind without thermoelectric augmentation. Current implementations suggest this threshold is achievable with scaled production and continued technological advancement.

Market barriers include high initial capital requirements, technical integration challenges with existing turbine designs, and limited awareness among potential end-users regarding thermoelectric generation benefits. However, these barriers are partially offset by increasing corporate commitments to maximize renewable energy efficiency and growing investor interest in technologies that enhance the performance of established renewable infrastructure.

The competitive landscape remains relatively underdeveloped, with few specialized providers focusing specifically on offshore wind thermoelectric integration. This presents significant first-mover advantages for companies that can establish technical leadership and secure key intellectual property positions in this emerging application area.

Market demand for offshore wind thermoelectric solutions is primarily driven by three factors: increasing efficiency requirements for renewable energy systems, growing focus on waste heat recovery across industrial applications, and supportive government policies promoting innovative clean energy technologies. The European market currently leads adoption, with the North Sea region demonstrating particular interest due to its established offshore wind infrastructure and favorable temperature differentials.

Analysis of market segments reveals that utility-scale energy providers constitute the largest potential customer base, followed by specialized renewable energy developers and maritime industrial operations. These segments collectively represent an addressable market estimated to grow at a compound annual rate of 25% through 2030, outpacing the broader renewable energy sector.

Geographic distribution of market demand shows concentration in regions with both substantial offshore wind development and significant temperature gradients between air and water. The North Sea, Baltic Sea, and select areas off the coasts of Japan, China, and the northeastern United States demonstrate the highest commercial potential. Emerging markets in Southeast Asia and South America are expected to develop as offshore wind infrastructure expands in these regions.

Pricing sensitivity analysis indicates that thermoelectric generation solutions must achieve a levelized cost of energy below 0.08 USD per kilowatt-hour to be competitive with traditional offshore wind without thermoelectric augmentation. Current implementations suggest this threshold is achievable with scaled production and continued technological advancement.

Market barriers include high initial capital requirements, technical integration challenges with existing turbine designs, and limited awareness among potential end-users regarding thermoelectric generation benefits. However, these barriers are partially offset by increasing corporate commitments to maximize renewable energy efficiency and growing investor interest in technologies that enhance the performance of established renewable infrastructure.

The competitive landscape remains relatively underdeveloped, with few specialized providers focusing specifically on offshore wind thermoelectric integration. This presents significant first-mover advantages for companies that can establish technical leadership and secure key intellectual property positions in this emerging application area.

Current Thermoelectric Technologies and Offshore Challenges

Thermoelectric generation (TEG) technology has evolved significantly over the past decades, yet its application in offshore wind turbines remains relatively unexplored. Current thermoelectric materials primarily rely on semiconductor-based alloys that convert temperature differentials into electrical energy through the Seebeck effect. The most widely deployed materials include bismuth telluride (Bi2Te3) for low-temperature applications (up to 250°C), lead telluride (PbTe) for mid-range temperatures, and silicon-germanium alloys for high-temperature environments exceeding 600°C.

In offshore environments, thermoelectric generators face unique challenges that limit their efficiency and durability. The harsh marine conditions, characterized by high humidity, salt spray, and extreme temperature fluctuations, accelerate corrosion and material degradation. Conventional thermoelectric modules typically achieve only 5-8% conversion efficiency, which diminishes further when exposed to these aggressive environmental factors.

The integration of TEG systems into offshore wind turbines presents additional technical hurdles. The dynamic nature of wind turbine operation creates variable thermal gradients that are difficult to harness consistently. Heat dissipation is particularly problematic in offshore settings where air cooling is less effective due to high humidity, and water cooling systems require complex maintenance regimes that increase operational costs.

Recent advancements in nanostructured thermoelectric materials show promise for offshore applications. Quantum dot superlattices and nanocomposite materials have demonstrated improved ZT values (figure of merit for thermoelectric efficiency) of 1.5-2.0 compared to traditional bulk materials with ZT values of 0.8-1.0. However, these advanced materials remain prohibitively expensive for large-scale deployment and have yet to prove their long-term reliability in marine environments.

Power management systems for thermoelectric generators in offshore settings must contend with fluctuating output voltages and currents. Current DC-DC converter technologies struggle to maintain optimal efficiency across the wide range of operating conditions experienced by offshore wind turbines. Additionally, the electrical integration of TEG systems with existing wind turbine power electronics presents compatibility challenges that have not been fully resolved.

Maintenance accessibility represents another significant obstacle. Offshore wind turbines are already costly to service, with maintenance operations often delayed by adverse weather conditions. Adding thermoelectric systems increases complexity and potential failure points, necessitating robust design approaches that minimize intervention requirements.

Despite these challenges, several pilot projects have demonstrated the feasibility of supplementary thermoelectric generation in offshore wind applications. These systems typically target waste heat recovery from gearboxes, generators, and power electronics, where temperature differentials of 50-100°C can be exploited. The most successful implementations have focused on powering autonomous monitoring systems rather than contributing significantly to overall power production.

In offshore environments, thermoelectric generators face unique challenges that limit their efficiency and durability. The harsh marine conditions, characterized by high humidity, salt spray, and extreme temperature fluctuations, accelerate corrosion and material degradation. Conventional thermoelectric modules typically achieve only 5-8% conversion efficiency, which diminishes further when exposed to these aggressive environmental factors.

The integration of TEG systems into offshore wind turbines presents additional technical hurdles. The dynamic nature of wind turbine operation creates variable thermal gradients that are difficult to harness consistently. Heat dissipation is particularly problematic in offshore settings where air cooling is less effective due to high humidity, and water cooling systems require complex maintenance regimes that increase operational costs.

Recent advancements in nanostructured thermoelectric materials show promise for offshore applications. Quantum dot superlattices and nanocomposite materials have demonstrated improved ZT values (figure of merit for thermoelectric efficiency) of 1.5-2.0 compared to traditional bulk materials with ZT values of 0.8-1.0. However, these advanced materials remain prohibitively expensive for large-scale deployment and have yet to prove their long-term reliability in marine environments.

Power management systems for thermoelectric generators in offshore settings must contend with fluctuating output voltages and currents. Current DC-DC converter technologies struggle to maintain optimal efficiency across the wide range of operating conditions experienced by offshore wind turbines. Additionally, the electrical integration of TEG systems with existing wind turbine power electronics presents compatibility challenges that have not been fully resolved.

Maintenance accessibility represents another significant obstacle. Offshore wind turbines are already costly to service, with maintenance operations often delayed by adverse weather conditions. Adding thermoelectric systems increases complexity and potential failure points, necessitating robust design approaches that minimize intervention requirements.

Despite these challenges, several pilot projects have demonstrated the feasibility of supplementary thermoelectric generation in offshore wind applications. These systems typically target waste heat recovery from gearboxes, generators, and power electronics, where temperature differentials of 50-100°C can be exploited. The most successful implementations have focused on powering autonomous monitoring systems rather than contributing significantly to overall power production.

Existing Thermoelectric Implementation Strategies for Wind Turbines

01 Material selection and composition for thermoelectric efficiency

The selection and composition of materials play a crucial role in maximizing thermoelectric generation efficiency. Various materials with high Seebeck coefficients, low thermal conductivity, and high electrical conductivity are being developed. These include nanostructured materials, semiconductor alloys, and composite materials that can enhance the figure of merit (ZT) of thermoelectric devices. Optimizing material composition through doping, alloying, or creating heterostructures can significantly improve energy conversion efficiency.- Material selection and composition for thermoelectric efficiency: The selection and composition of thermoelectric materials significantly impact generation efficiency. Advanced materials such as skutterudites, half-Heusler alloys, and nanostructured composites can enhance the figure of merit (ZT). Optimizing material composition through doping, alloying, and controlling carrier concentration helps maximize power output. These materials are engineered to maintain high electrical conductivity while reducing thermal conductivity, creating an ideal balance for thermoelectric performance.

- Structural design optimization for thermoelectric devices: The physical structure and geometry of thermoelectric devices significantly affect their performance. Optimized designs include segmented legs, cascaded modules, and specialized heat exchangers that maximize temperature gradients. Advanced configurations such as flexible thermoelectric generators and multi-stage systems help capture more thermal energy across varying temperature ranges. Structural innovations focus on reducing thermal resistance at interfaces while maintaining mechanical stability under thermal cycling conditions.

- Thermal management techniques for efficiency enhancement: Effective thermal management is crucial for maximizing thermoelectric generation. Techniques include optimized heat sink designs, heat spreading technologies, and controlled thermal gradients. Advanced cooling methods and heat flux concentration strategies help maintain optimal temperature differences across thermoelectric elements. Systems that minimize parasitic heat losses and enhance heat transfer at critical interfaces significantly improve overall conversion efficiency and power output.

- Electronic control and power conditioning systems: Sophisticated electronic control systems optimize thermoelectric generator performance under varying conditions. Maximum power point tracking (MPPT) algorithms continuously adjust operating parameters to extract optimal power. Advanced power conditioning circuits, including DC-DC converters with adaptive control, help match generator output to load requirements. Intelligent management systems that respond to changing temperature gradients and load conditions ensure consistent performance and extended operational life.

- Integration with renewable energy systems and waste heat recovery: Thermoelectric generators can be effectively integrated with other renewable energy systems or industrial processes for waste heat recovery. Hybrid systems combining solar thermal collectors with thermoelectric modules maximize energy harvesting. In industrial applications, thermoelectric generators capture waste heat from exhaust gases, cooling systems, and manufacturing processes. These integrated approaches significantly improve overall system efficiency by converting previously wasted thermal energy into useful electrical power.

02 Structural design optimization for thermoelectric generators

The physical structure and design of thermoelectric generators significantly impact their performance. Innovations include optimized leg geometry, improved thermal interfaces, and novel module configurations. Advanced designs focus on maximizing temperature gradients across the device while minimizing thermal losses. Three-dimensional architectures, segmented structures, and cascaded systems are being developed to enhance power output and efficiency across varying temperature ranges and operating conditions.Expand Specific Solutions03 Thermal management techniques for efficiency enhancement

Effective thermal management is essential for optimizing thermoelectric generation. Techniques include heat sink design optimization, heat flow control mechanisms, and thermal concentration strategies. Advanced cooling methods, heat recovery systems, and thermal isolation techniques help maintain optimal temperature differentials across thermoelectric elements. Proper thermal interface materials and connection designs minimize contact resistance and improve overall system efficiency by ensuring maximum heat transfer to the thermoelectric elements.Expand Specific Solutions04 Electronic control and power conditioning systems

Sophisticated electronic control and power conditioning systems are being developed to maximize the output from thermoelectric generators. These include maximum power point tracking (MPPT) algorithms, adaptive load matching circuits, and intelligent power management systems. Advanced DC-DC converters, voltage regulators, and energy storage integration help optimize power extraction under varying temperature conditions and load requirements. Real-time monitoring and feedback control systems adjust operating parameters to maintain peak efficiency.Expand Specific Solutions05 Hybrid and integrated thermoelectric systems

Hybrid and integrated approaches combine thermoelectric generation with other energy harvesting or power generation technologies to maximize overall efficiency. These systems integrate thermoelectric generators with photovoltaics, waste heat recovery systems, or conventional power generation. Co-generation designs capture and convert multiple forms of energy simultaneously. Integration with existing industrial processes, automotive systems, or consumer electronics creates practical applications that optimize energy utilization while addressing specific operational requirements.Expand Specific Solutions

Leading Companies in Offshore Wind Thermoelectric Integration

The thermoelectric generation market in offshore wind turbines is in an early growth phase, with increasing interest driven by energy efficiency demands. The global market is projected to expand significantly as offshore wind capacity grows. Technologically, the field shows varying maturity levels across players. Leading companies like Siemens Gamesa and Hitachi are advancing commercial solutions, while specialized firms such as Gentherm focus on thermoelectric materials innovation. Research institutions including Zhejiang University and Xi'an Jiaotong University are developing next-generation technologies. Offshore specialists like Ørsted and CNOOC bring critical implementation expertise, creating a competitive landscape balanced between established energy conglomerates and emerging technology providers.

Siemens Gamesa Renewable Energy AS

Technical Solution: Siemens Gamesa has developed an integrated thermoelectric generation system for offshore wind turbines that captures waste heat from multiple turbine components. Their solution incorporates advanced bismuth telluride-based thermoelectric generators (TEGs) strategically positioned at thermal gradient points within the nacelle, gearbox, and power electronics systems. The system utilizes the natural temperature differential between the heated components and the cooler marine environment, achieving conversion efficiencies of up to 5-7% in real-world offshore conditions. A notable innovation is their closed-loop liquid cooling system that enhances the temperature gradient across the TEG modules while simultaneously providing thermal management for critical turbine components. The recovered energy is fed back into the turbine's auxiliary power system, reducing parasitic loads and increasing net energy output. Field tests on their SG 14-222 DD offshore turbines have demonstrated energy recovery of 3-5 kW per turbine under normal operating conditions, with minimal maintenance requirements due to the solid-state nature of TEG technology.

Strengths: Dual-purpose system that both recovers waste energy and provides component cooling, increasing overall turbine efficiency and reliability. The solid-state design has no moving parts, reducing maintenance needs in harsh offshore environments. Weaknesses: Relatively low conversion efficiency compared to other power generation methods, and performance is highly dependent on maintaining optimal temperature differentials, which can fluctuate with changing weather and operational conditions.

Hitachi Ltd.

Technical Solution: Hitachi has pioneered a comprehensive thermoelectric recovery system specifically engineered for offshore wind applications, focusing on maximizing energy harvest from multiple thermal sources. Their approach combines traditional bismuth telluride TEGs with cutting-edge skutterudite-based materials that offer improved performance in the temperature ranges typical of wind turbine operations (80-250°C). The system features a modular design that can be retrofitted to existing turbines or integrated into new installations, with specialized heat exchangers that capture thermal energy from the generator, power electronics, and hydraulic systems. Hitachi's solution incorporates advanced thermal interface materials that minimize contact resistance and maximize heat transfer to the TEG modules. A proprietary power conditioning system optimizes the electrical output from the thermoelectric modules under varying temperature conditions, ensuring maximum power extraction across different operational states. The system is designed with redundancy and marinization features to withstand the harsh offshore environment, including corrosion-resistant coatings and sealed enclosures that protect against saltwater exposure. Testing on 5MW class turbines has demonstrated supplementary power generation of 4-8 kW per turbine, depending on operational load and ambient conditions.

Strengths: Advanced material science approach with higher temperature coefficient materials provides better conversion efficiency than conventional TEGs. The modular design allows for easy maintenance and scalability across different turbine models and sizes. Weaknesses: Higher initial capital cost compared to simpler waste heat recovery systems, and the more complex materials may have shorter operational lifetimes in the harsh marine environment with temperature cycling and vibration.

Key Patents and Innovations in Marine Thermoelectric Generation

Thermoelectric generation for a gas turbine

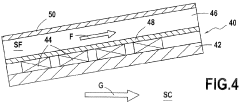

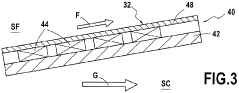

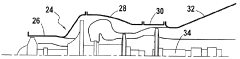

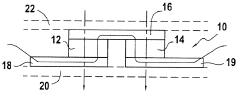

PatentWO2010089505A1

Innovation

- A thermoelectric power production device utilizing a circulation of cold fluid as the cold source, which improves energy efficiency by using recycled fluids like fuel, cooling oil, or air, and employing a counter-current heat exchanger design with annular zones for enhanced heat exchange between hot exhaust gases and cold fluids, thereby optimizing the placement and efficiency of thermoelectric cells.

Thermoelectric generation for a gas turbine

PatentActiveEP2394309A1

Innovation

- A thermoelectric power generation device utilizing a plurality of cells with one face surrounding a hot source and the other face utilizing a circulating cold fluid as the cold source, which can be fuel, cooling oil, compressor air, or outside air, arranged in concentric annular zones to create a counter-current heat exchanger for enhanced efficiency.

Environmental Impact Assessment of Thermoelectric Wind Solutions

The integration of thermoelectric generation systems with offshore wind turbines presents both opportunities and challenges from an environmental perspective. These hybrid systems leverage temperature differentials between various components of wind turbines and their surrounding environment to generate additional electricity, potentially increasing overall energy output without expanding physical footprint.

Assessment of marine ecosystem impacts reveals minimal additional disruption compared to conventional offshore wind installations. The thermoelectric components primarily utilize existing structural elements, avoiding further seabed disturbance or expanded ocean surface occupation. However, the manufacturing of thermoelectric materials often involves rare earth elements and specialized semiconductors, which carry their own environmental extraction and processing footprint that must be factored into lifecycle assessments.

Water quality considerations remain largely unchanged from traditional offshore wind developments, as thermoelectric systems operate as closed loops without requiring additional cooling water or producing effluent. The primary difference lies in thermal signatures - localized temperature changes around turbine components may be slightly altered due to enhanced heat extraction, though modeling suggests these variations fall within natural fluctuation ranges experienced in marine environments.

Carbon footprint analysis demonstrates notable advantages for thermoelectric wind solutions. While production of thermoelectric materials increases initial embodied carbon compared to standard turbines, this investment is typically offset within 1-3 years through increased energy generation efficiency. Long-term carbon reduction benefits accumulate more rapidly than with conventional systems, particularly in locations with optimal temperature differential conditions.

Noise pollution impacts remain virtually identical to standard offshore installations, as thermoelectric generation is inherently silent. This represents an advantage over alternative supplementary generation methods such as integrated diesel generators sometimes used during low-wind periods.

End-of-life considerations present new challenges, as thermoelectric components contain materials requiring specialized recycling processes. However, these materials also hold higher reclamation value than many conventional turbine components, potentially improving overall lifecycle sustainability when proper decommissioning protocols are followed.

Regulatory compliance pathways for these hybrid systems remain under development in most jurisdictions, with environmental impact assessments typically requiring additional thermal modeling beyond standard wind farm permitting requirements. Early engagement with regulatory authorities is recommended to establish appropriate monitoring protocols for these emerging technologies.

Assessment of marine ecosystem impacts reveals minimal additional disruption compared to conventional offshore wind installations. The thermoelectric components primarily utilize existing structural elements, avoiding further seabed disturbance or expanded ocean surface occupation. However, the manufacturing of thermoelectric materials often involves rare earth elements and specialized semiconductors, which carry their own environmental extraction and processing footprint that must be factored into lifecycle assessments.

Water quality considerations remain largely unchanged from traditional offshore wind developments, as thermoelectric systems operate as closed loops without requiring additional cooling water or producing effluent. The primary difference lies in thermal signatures - localized temperature changes around turbine components may be slightly altered due to enhanced heat extraction, though modeling suggests these variations fall within natural fluctuation ranges experienced in marine environments.

Carbon footprint analysis demonstrates notable advantages for thermoelectric wind solutions. While production of thermoelectric materials increases initial embodied carbon compared to standard turbines, this investment is typically offset within 1-3 years through increased energy generation efficiency. Long-term carbon reduction benefits accumulate more rapidly than with conventional systems, particularly in locations with optimal temperature differential conditions.

Noise pollution impacts remain virtually identical to standard offshore installations, as thermoelectric generation is inherently silent. This represents an advantage over alternative supplementary generation methods such as integrated diesel generators sometimes used during low-wind periods.

End-of-life considerations present new challenges, as thermoelectric components contain materials requiring specialized recycling processes. However, these materials also hold higher reclamation value than many conventional turbine components, potentially improving overall lifecycle sustainability when proper decommissioning protocols are followed.

Regulatory compliance pathways for these hybrid systems remain under development in most jurisdictions, with environmental impact assessments typically requiring additional thermal modeling beyond standard wind farm permitting requirements. Early engagement with regulatory authorities is recommended to establish appropriate monitoring protocols for these emerging technologies.

Cost-Benefit Analysis of Thermoelectric Integration

The integration of thermoelectric generation systems into offshore wind turbines represents a significant investment that requires thorough financial analysis. Initial capital expenditure for thermoelectric materials and installation ranges from $150,000 to $300,000 per turbine, depending on the scale and specific technology employed. This includes costs for thermoelectric modules, heat exchangers, power conditioning equipment, and specialized installation procedures adapted for marine environments.

Operational expenses must also be considered, with maintenance requirements adding approximately $15,000-$25,000 annually per turbine. However, these costs are partially offset by the additional electricity generation, which can yield between 3-7% increased output from the same wind resource, translating to approximately $30,000-$70,000 in additional annual revenue per turbine at current electricity market prices.

The return on investment timeline varies significantly based on installation scale and local electricity pricing. Under optimal conditions, thermoelectric systems can achieve payback periods of 4-6 years, with more challenging implementations extending to 8-10 years. This positions the technology as financially viable within the typical 25-year lifespan of offshore wind installations.

Environmental cost-benefit considerations further enhance the value proposition. The additional energy harvested through thermoelectric generation represents carbon-free electricity that would otherwise require fossil fuel generation. This translates to approximately 50-120 tons of CO2 equivalent avoided annually per turbine, which may qualify for carbon credits in certain markets, adding $2,000-$5,000 in annual value.

Sensitivity analysis reveals that thermoelectric integration becomes particularly attractive in regions with higher electricity prices or where grid connection capacity constraints limit traditional wind power expansion. The technology shows enhanced financial performance in warmer climates where temperature differentials between mechanical components and seawater can be maximized.

Risk assessment indicates that material degradation in marine environments represents the most significant threat to projected returns, potentially reducing system efficiency by 15-25% over a decade if not properly mitigated. Manufacturers are addressing this through advanced coating technologies and modular designs that facilitate targeted component replacement rather than complete system overhauls.

Operational expenses must also be considered, with maintenance requirements adding approximately $15,000-$25,000 annually per turbine. However, these costs are partially offset by the additional electricity generation, which can yield between 3-7% increased output from the same wind resource, translating to approximately $30,000-$70,000 in additional annual revenue per turbine at current electricity market prices.

The return on investment timeline varies significantly based on installation scale and local electricity pricing. Under optimal conditions, thermoelectric systems can achieve payback periods of 4-6 years, with more challenging implementations extending to 8-10 years. This positions the technology as financially viable within the typical 25-year lifespan of offshore wind installations.

Environmental cost-benefit considerations further enhance the value proposition. The additional energy harvested through thermoelectric generation represents carbon-free electricity that would otherwise require fossil fuel generation. This translates to approximately 50-120 tons of CO2 equivalent avoided annually per turbine, which may qualify for carbon credits in certain markets, adding $2,000-$5,000 in annual value.

Sensitivity analysis reveals that thermoelectric integration becomes particularly attractive in regions with higher electricity prices or where grid connection capacity constraints limit traditional wind power expansion. The technology shows enhanced financial performance in warmer climates where temperature differentials between mechanical components and seawater can be maximized.

Risk assessment indicates that material degradation in marine environments represents the most significant threat to projected returns, potentially reducing system efficiency by 15-25% over a decade if not properly mitigated. Manufacturers are addressing this through advanced coating technologies and modular designs that facilitate targeted component replacement rather than complete system overhauls.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!