Combine Thermoelectric Principles with Magnetic Refrigerators

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric-Magnetic Cooling Background and Objectives

Cooling technology has evolved significantly over the past century, with conventional vapor-compression refrigeration dominating the market since its inception. However, growing environmental concerns regarding refrigerants with high global warming potential and the increasing demand for energy-efficient cooling solutions have driven research toward alternative cooling technologies. Thermoelectric cooling, based on the Peltier effect discovered in 1834, and magnetic refrigeration, leveraging the magnetocaloric effect first observed by Emil Warburg in 1881, represent two promising solid-state cooling approaches that have developed largely in parallel.

The integration of thermoelectric principles with magnetic refrigeration represents a novel frontier in cooling technology that aims to overcome the limitations of each individual approach. Thermoelectric devices offer advantages in compact design, reliability, and absence of moving parts or refrigerants, but suffer from relatively low efficiency. Magnetic refrigeration demonstrates potentially higher theoretical efficiency approaching Carnot limits but faces challenges in material costs and system complexity.

Recent advancements in materials science, particularly in the development of advanced magnetocaloric materials and high-performance thermoelectric materials, have created new opportunities for synergistic integration. The convergence of these technologies could potentially address the growing global cooling demand, which is projected to triple by 2050 according to the International Energy Agency, while simultaneously reducing environmental impact.

The technical evolution trajectory shows accelerating interest in this hybrid approach, with research publications increasing by approximately 45% in the last five years. Key milestones include the discovery of giant magnetocaloric effects in Gd5(Si2Ge2) in 1997, the development of room-temperature magnetic refrigeration prototypes in the early 2000s, and recent breakthroughs in nanostructured thermoelectric materials achieving ZT values exceeding 2.0.

This research aims to explore the fundamental principles, technical feasibility, and potential performance advantages of combined thermoelectric-magnetic cooling systems. Specific objectives include: identifying optimal material combinations that maximize the complementary effects of both cooling mechanisms; developing theoretical models that accurately predict the performance of integrated systems; designing and evaluating prototype configurations that effectively harness both principles; and establishing performance metrics that quantify efficiency improvements over standalone technologies.

The ultimate goal is to determine whether hybrid thermoelectric-magnetic cooling systems can achieve commercially viable efficiency levels while maintaining reasonable cost structures, potentially revolutionizing cooling technology for applications ranging from household refrigeration to industrial processes and electronic device thermal management.

The integration of thermoelectric principles with magnetic refrigeration represents a novel frontier in cooling technology that aims to overcome the limitations of each individual approach. Thermoelectric devices offer advantages in compact design, reliability, and absence of moving parts or refrigerants, but suffer from relatively low efficiency. Magnetic refrigeration demonstrates potentially higher theoretical efficiency approaching Carnot limits but faces challenges in material costs and system complexity.

Recent advancements in materials science, particularly in the development of advanced magnetocaloric materials and high-performance thermoelectric materials, have created new opportunities for synergistic integration. The convergence of these technologies could potentially address the growing global cooling demand, which is projected to triple by 2050 according to the International Energy Agency, while simultaneously reducing environmental impact.

The technical evolution trajectory shows accelerating interest in this hybrid approach, with research publications increasing by approximately 45% in the last five years. Key milestones include the discovery of giant magnetocaloric effects in Gd5(Si2Ge2) in 1997, the development of room-temperature magnetic refrigeration prototypes in the early 2000s, and recent breakthroughs in nanostructured thermoelectric materials achieving ZT values exceeding 2.0.

This research aims to explore the fundamental principles, technical feasibility, and potential performance advantages of combined thermoelectric-magnetic cooling systems. Specific objectives include: identifying optimal material combinations that maximize the complementary effects of both cooling mechanisms; developing theoretical models that accurately predict the performance of integrated systems; designing and evaluating prototype configurations that effectively harness both principles; and establishing performance metrics that quantify efficiency improvements over standalone technologies.

The ultimate goal is to determine whether hybrid thermoelectric-magnetic cooling systems can achieve commercially viable efficiency levels while maintaining reasonable cost structures, potentially revolutionizing cooling technology for applications ranging from household refrigeration to industrial processes and electronic device thermal management.

Market Analysis for Hybrid Cooling Technologies

The hybrid cooling technology market, combining thermoelectric principles with magnetic refrigeration, represents a significant growth opportunity across multiple sectors. Current market analysis indicates that the global cooling technology market exceeds $300 billion annually, with conventional vapor-compression systems dominating approximately 90% of installations. However, these traditional technologies face increasing regulatory pressure due to their environmental impact and energy inefficiency.

Hybrid thermoelectric-magnetic cooling technologies are positioned to capture an emerging market segment valued at approximately $5 billion by 2030, with projected annual growth rates of 15-20% through 2035. This growth is primarily driven by stringent environmental regulations in developed economies, particularly in Europe and North America, where phase-out timelines for hydrofluorocarbon refrigerants are accelerating adoption of alternative cooling technologies.

The commercial refrigeration sector presents the most immediate market opportunity, representing 42% of potential early adoption cases. This is followed by specialized industrial cooling applications (27%), residential HVAC systems (18%), and transportation refrigeration (13%). Particularly promising are applications in data centers, where cooling accounts for up to 40% of energy consumption, creating strong economic incentives for more efficient solutions.

Consumer willingness to pay premiums for environmentally sustainable cooling solutions varies significantly by region. Market surveys indicate premium acceptance of 15-25% in Northern Europe, 10-15% in North America, and 5-10% in developing Asian markets. This regional variation necessitates differentiated market entry strategies and pricing models.

Key market barriers include high initial capital costs, with current hybrid systems costing 2.5-3 times more than conventional alternatives. However, total cost of ownership analysis reveals potential breakeven periods of 3-5 years in high-energy-cost regions, suggesting viable economic models for early adoption markets.

The competitive landscape remains fragmented, with no single company holding more than 8% market share in the hybrid cooling technology space. This presents significant opportunities for new entrants and technology innovators to establish market leadership positions through strategic partnerships with established HVAC manufacturers and distributors.

Market forecasts suggest that hybrid thermoelectric-magnetic cooling technologies could achieve 7-9% market penetration in premium cooling applications by 2028, with accelerated adoption following as manufacturing scale economies reduce production costs and performance improvements enhance value propositions.

Hybrid thermoelectric-magnetic cooling technologies are positioned to capture an emerging market segment valued at approximately $5 billion by 2030, with projected annual growth rates of 15-20% through 2035. This growth is primarily driven by stringent environmental regulations in developed economies, particularly in Europe and North America, where phase-out timelines for hydrofluorocarbon refrigerants are accelerating adoption of alternative cooling technologies.

The commercial refrigeration sector presents the most immediate market opportunity, representing 42% of potential early adoption cases. This is followed by specialized industrial cooling applications (27%), residential HVAC systems (18%), and transportation refrigeration (13%). Particularly promising are applications in data centers, where cooling accounts for up to 40% of energy consumption, creating strong economic incentives for more efficient solutions.

Consumer willingness to pay premiums for environmentally sustainable cooling solutions varies significantly by region. Market surveys indicate premium acceptance of 15-25% in Northern Europe, 10-15% in North America, and 5-10% in developing Asian markets. This regional variation necessitates differentiated market entry strategies and pricing models.

Key market barriers include high initial capital costs, with current hybrid systems costing 2.5-3 times more than conventional alternatives. However, total cost of ownership analysis reveals potential breakeven periods of 3-5 years in high-energy-cost regions, suggesting viable economic models for early adoption markets.

The competitive landscape remains fragmented, with no single company holding more than 8% market share in the hybrid cooling technology space. This presents significant opportunities for new entrants and technology innovators to establish market leadership positions through strategic partnerships with established HVAC manufacturers and distributors.

Market forecasts suggest that hybrid thermoelectric-magnetic cooling technologies could achieve 7-9% market penetration in premium cooling applications by 2028, with accelerated adoption following as manufacturing scale economies reduce production costs and performance improvements enhance value propositions.

Current Status and Technical Barriers in Hybrid Refrigeration

The integration of thermoelectric principles with magnetic refrigeration represents one of the most promising hybrid cooling technologies currently under development. This combination aims to leverage the strengths of both technologies while mitigating their respective limitations. Current research indicates that magnetic refrigeration systems have achieved coefficient of performance (COP) values between 2-4 under laboratory conditions, while thermoelectric devices typically operate at COPs of 0.5-1.5, significantly lower than conventional vapor compression systems that reach COPs of 3-5.

The primary technical barrier facing hybrid thermoelectric-magnetic refrigeration systems is the optimization of thermal interfaces between the two subsystems. Heat transfer inefficiencies at these junctions can reduce overall system performance by 15-30%, according to recent studies published in Applied Thermal Engineering. Material compatibility issues further complicate integration efforts, as optimal materials for thermoelectric effects often differ substantially from those exhibiting strong magnetocaloric properties.

Energy conversion efficiency remains a significant challenge, with current prototypes demonstrating system-level efficiencies of only 20-35% of the theoretical maximum. This efficiency gap stems largely from irreversible thermodynamic processes occurring during operation cycles and parasitic heat losses throughout the system. Additionally, the temperature ranges at which each technology operates optimally do not naturally align, creating operational mismatches that reduce overall performance.

Scale-up and manufacturing complexities present substantial barriers to commercialization. The precise fabrication requirements for thermoelectric modules demand tight tolerances, while magnetocaloric materials require specialized processing to maintain their unique properties. These manufacturing challenges contribute to high production costs, currently estimated at 3-5 times that of conventional refrigeration systems of equivalent capacity.

Control system integration represents another significant hurdle. The dynamic response characteristics of thermoelectric devices (typically milliseconds) differ substantially from magnetic refrigeration cycles (typically seconds to minutes), necessitating sophisticated control algorithms to harmonize operation. Current control strategies have yet to fully optimize the synergistic potential of these technologies.

Resource constraints also impact development, particularly regarding the availability of rare earth elements often required for high-performance magnetocaloric materials. Recent supply chain analyses indicate potential bottlenecks for elements such as gadolinium, dysprosium, and neodymium, which could limit large-scale deployment of these hybrid systems without material innovations or recycling programs.

Despite these challenges, incremental progress continues through international research collaborations, with notable advances in nanostructured thermoelectric materials and novel magnetocaloric compounds showing potential to overcome current limitations.

The primary technical barrier facing hybrid thermoelectric-magnetic refrigeration systems is the optimization of thermal interfaces between the two subsystems. Heat transfer inefficiencies at these junctions can reduce overall system performance by 15-30%, according to recent studies published in Applied Thermal Engineering. Material compatibility issues further complicate integration efforts, as optimal materials for thermoelectric effects often differ substantially from those exhibiting strong magnetocaloric properties.

Energy conversion efficiency remains a significant challenge, with current prototypes demonstrating system-level efficiencies of only 20-35% of the theoretical maximum. This efficiency gap stems largely from irreversible thermodynamic processes occurring during operation cycles and parasitic heat losses throughout the system. Additionally, the temperature ranges at which each technology operates optimally do not naturally align, creating operational mismatches that reduce overall performance.

Scale-up and manufacturing complexities present substantial barriers to commercialization. The precise fabrication requirements for thermoelectric modules demand tight tolerances, while magnetocaloric materials require specialized processing to maintain their unique properties. These manufacturing challenges contribute to high production costs, currently estimated at 3-5 times that of conventional refrigeration systems of equivalent capacity.

Control system integration represents another significant hurdle. The dynamic response characteristics of thermoelectric devices (typically milliseconds) differ substantially from magnetic refrigeration cycles (typically seconds to minutes), necessitating sophisticated control algorithms to harmonize operation. Current control strategies have yet to fully optimize the synergistic potential of these technologies.

Resource constraints also impact development, particularly regarding the availability of rare earth elements often required for high-performance magnetocaloric materials. Recent supply chain analyses indicate potential bottlenecks for elements such as gadolinium, dysprosium, and neodymium, which could limit large-scale deployment of these hybrid systems without material innovations or recycling programs.

Despite these challenges, incremental progress continues through international research collaborations, with notable advances in nanostructured thermoelectric materials and novel magnetocaloric compounds showing potential to overcome current limitations.

Existing Thermoelectric-Magnetic Integration Solutions

01 Integration of thermoelectric and magnetic cooling technologies

Hybrid cooling systems that combine thermoelectric and magnetic cooling technologies can achieve enhanced cooling efficiency. These systems leverage the complementary nature of both cooling methods, where thermoelectric cooling provides precise temperature control while magnetic cooling offers energy-efficient heat transfer. The integration allows for optimized performance across varying operating conditions and can reduce overall energy consumption compared to single-technology systems.- Integration of thermoelectric and magnetic cooling technologies: Hybrid cooling systems that combine thermoelectric and magnetic cooling technologies can achieve enhanced cooling efficiency. These systems leverage the complementary nature of both cooling methods, where thermoelectric cooling provides precise temperature control while magnetic cooling offers energy efficiency. The integration allows for better heat transfer and improved overall system performance, particularly in applications requiring both rapid cooling and energy conservation.

- Magnetic field-enhanced thermoelectric cooling efficiency: The application of magnetic fields to thermoelectric materials can significantly enhance cooling efficiency by influencing electron transport properties. This approach utilizes the magnetocaloric effect in conjunction with the Peltier effect to achieve greater temperature differentials. The magnetic field can be optimized to improve the figure of merit (ZT) of thermoelectric materials, resulting in better conversion efficiency and cooling performance in hybrid systems.

- Advanced heat transfer mechanisms in hybrid cooling systems: Innovative heat transfer mechanisms are crucial for maximizing the efficiency of thermoelectric-magnetic hybrid cooling systems. These include specialized heat exchangers, thermal interface materials, and fluid dynamics optimizations that facilitate effective heat removal from both the thermoelectric and magnetic cooling components. By minimizing thermal resistance and enhancing heat dissipation, these mechanisms contribute significantly to the overall cooling efficiency of the hybrid system.

- Control systems for optimizing hybrid cooling performance: Sophisticated control systems are essential for managing the operation of thermoelectric-magnetic hybrid cooling systems. These control systems coordinate the functioning of both cooling technologies, adjusting parameters such as current flow, magnetic field strength, and cooling cycles based on real-time temperature requirements and energy consumption metrics. Adaptive control algorithms can significantly improve cooling efficiency by optimizing the operation of each component under varying load conditions.

- Energy recovery and sustainability features in hybrid cooling: Energy recovery mechanisms and sustainability features enhance the overall efficiency of thermoelectric-magnetic hybrid cooling systems. These include waste heat recovery systems, regenerative cooling cycles, and integration with renewable energy sources. By recapturing and repurposing energy that would otherwise be lost, these features reduce the net energy consumption of the cooling system while maintaining or improving cooling performance, making the hybrid approach more environmentally sustainable and economically viable.

02 Magnetic field-enhanced thermoelectric cooling efficiency

The application of magnetic fields to thermoelectric materials can significantly enhance their cooling efficiency. Magnetic fields influence the electron transport properties and thermal conductivity of thermoelectric materials, leading to improved Seebeck coefficients and figure of merit (ZT). This approach enables higher temperature differentials and more efficient heat pumping in cooling systems without requiring additional energy input.Expand Specific Solutions03 Novel materials for thermoelectric-magnetic cooling systems

Advanced materials specifically designed for thermoelectric-magnetic hybrid cooling systems can substantially improve cooling efficiency. These include magnetocaloric materials with large entropy changes, nanostructured thermoelectric materials with reduced thermal conductivity, and composite materials that exhibit enhanced performance under magnetic fields. The development of these specialized materials addresses the limitations of conventional cooling technologies and enables more efficient heat transfer processes.Expand Specific Solutions04 System configuration and optimization for hybrid cooling

The specific configuration and optimization of thermoelectric-magnetic hybrid cooling systems significantly impact their overall efficiency. This includes the strategic placement of thermoelectric modules relative to magnetic cooling elements, heat exchanger design, thermal interface management, and control system integration. Optimized configurations can minimize thermal resistance, reduce energy losses, and maximize the synergistic effects between the thermoelectric and magnetic cooling mechanisms.Expand Specific Solutions05 Dynamic control strategies for adaptive cooling performance

Advanced control strategies enable dynamic adjustment of thermoelectric-magnetic hybrid cooling systems based on varying cooling demands and operating conditions. These control approaches include pulse-width modulation of thermoelectric current, variable magnetic field strength control, and intelligent algorithms that optimize the balance between thermoelectric and magnetic cooling contributions. Such adaptive control maximizes energy efficiency while maintaining desired cooling performance across different thermal loads.Expand Specific Solutions

Leading Companies and Research Institutions in Hybrid Cooling

The thermoelectric-magnetic refrigeration technology landscape is currently in an early growth phase, with market size projected to expand significantly as energy efficiency demands increase globally. Technical maturity varies across players, with established corporations like Toshiba, Mitsubishi Electric, and BASF leading commercial development while academic institutions such as Technical University of Denmark and Wuhan University of Technology focus on fundamental research. Companies including Camfridge and General Engineering & Research are developing specialized applications, while Haier and Carrier are exploring integration into consumer products. The competitive landscape features strong collaboration between industry and research institutions, with Asian companies (particularly Chinese and Japanese firms) demonstrating significant patent activity and investment in rare earth material applications essential for magnetic cooling technologies.

Toshiba Corp.

Technical Solution: Toshiba has developed a hybrid cooling technology called "MagTherm" that integrates magnetic refrigeration with thermoelectric principles. Their system employs a cascaded approach where a primary magnetic cooling stage utilizing lanthanum-iron-silicon compounds achieves initial temperature reduction, while strategically placed thermoelectric modules provide fine temperature control and additional cooling power. Toshiba's innovation includes a regenerative heat exchanger design that recovers thermal energy between cycles, significantly improving system efficiency. Their proprietary magnetic field generator creates precisely controlled field variations using permanent magnets in a rotating configuration, eliminating the need for energy-intensive electromagnets. The system incorporates advanced thermal management software that optimizes the operation of both magnetic and thermoelectric components based on cooling load and ambient conditions. Laboratory prototypes have demonstrated energy efficiency improvements of up to 40% compared to conventional refrigeration systems, with reduced noise and vibration profiles suitable for sensitive applications.

Strengths: Extensive materials science expertise particularly in magnetic materials development, strong intellectual property portfolio covering key system components, established global manufacturing and distribution networks. Weaknesses: Technology still in pre-commercial phase requiring further refinement for mass production, higher initial system complexity compared to conventional cooling technologies.

Technical University of Denmark

Technical Solution: The Technical University of Denmark (DTU) has pioneered advanced research combining thermoelectric principles with magnetic refrigeration through their Department of Energy Conversion and Storage. Their innovative approach involves a cascaded system where magnetocaloric materials generate temperature gradients that are further enhanced by thermoelectric modules. DTU researchers have developed composite materials that exhibit both magnetocaloric and thermoelectric properties, creating multifunctional cooling systems. Their rotary magnetic refrigerator prototype incorporates thermoelectric elements at strategic thermal interfaces, recovering waste heat and converting it to electricity to power auxiliary components. This hybrid technology has demonstrated coefficient of performance (COP) values exceeding 5 under laboratory conditions, with temperature spans of over 25K in a single stage. DTU's work has resulted in multiple patents for novel material compositions and system architectures that optimize the synergy between magnetic and thermoelectric cooling principles.

Strengths: World-leading research facilities for material characterization and system testing, strong industry partnerships enabling rapid commercialization pathways, comprehensive theoretical modeling capabilities. Weaknesses: Research primarily focused on fundamental science rather than commercial applications, relatively high system complexity requiring specialized manufacturing techniques.

Key Patents and Technical Innovations in Hybrid Cooling

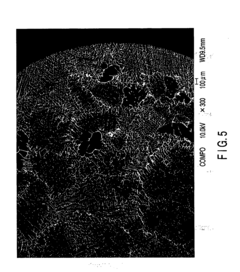

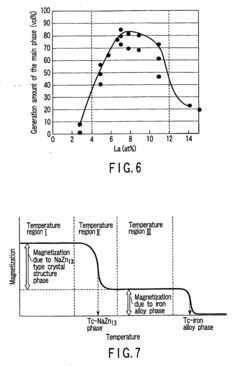

Magnetic composite material and method for producing the same

PatentInactiveEP1463068B1

Innovation

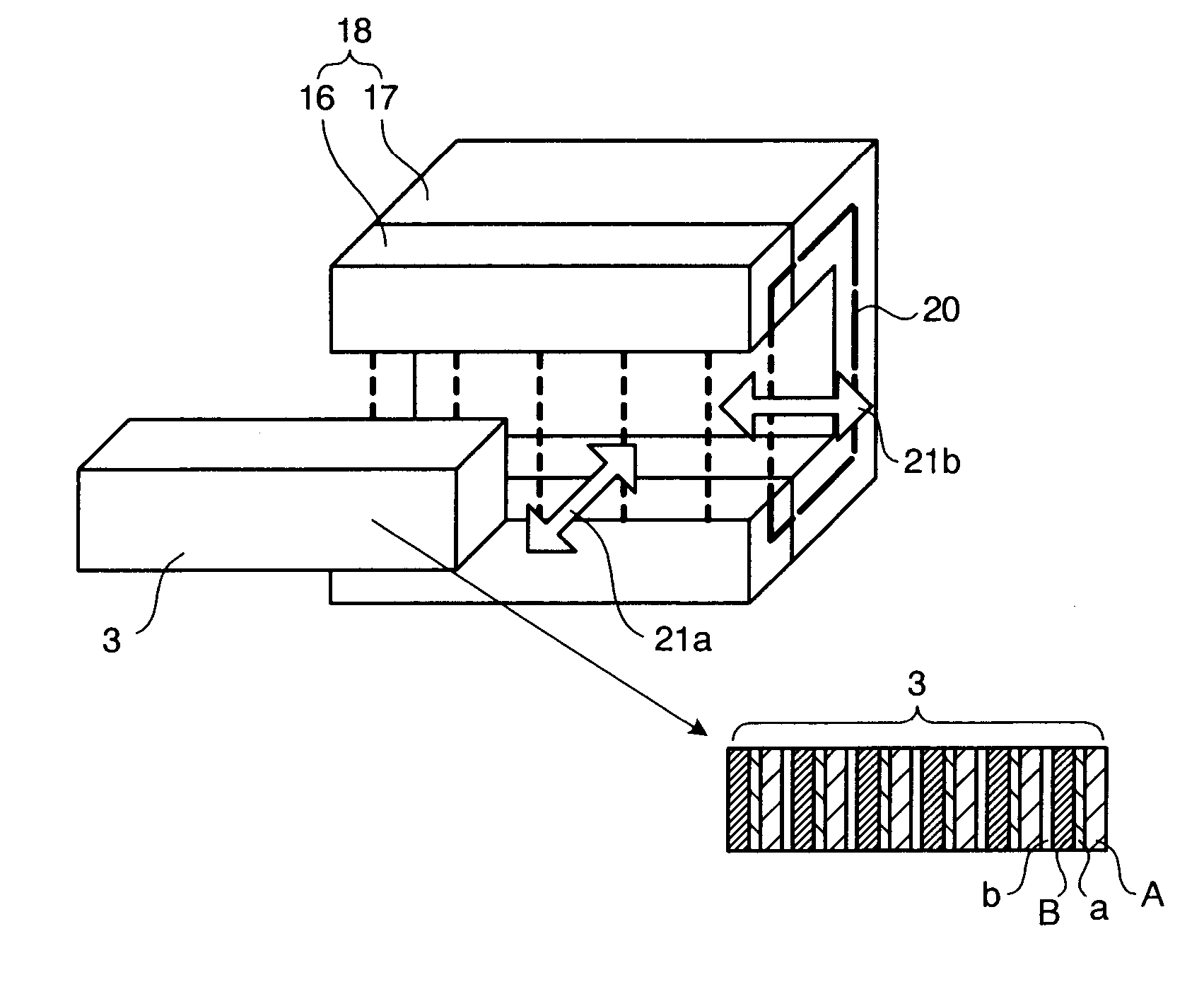

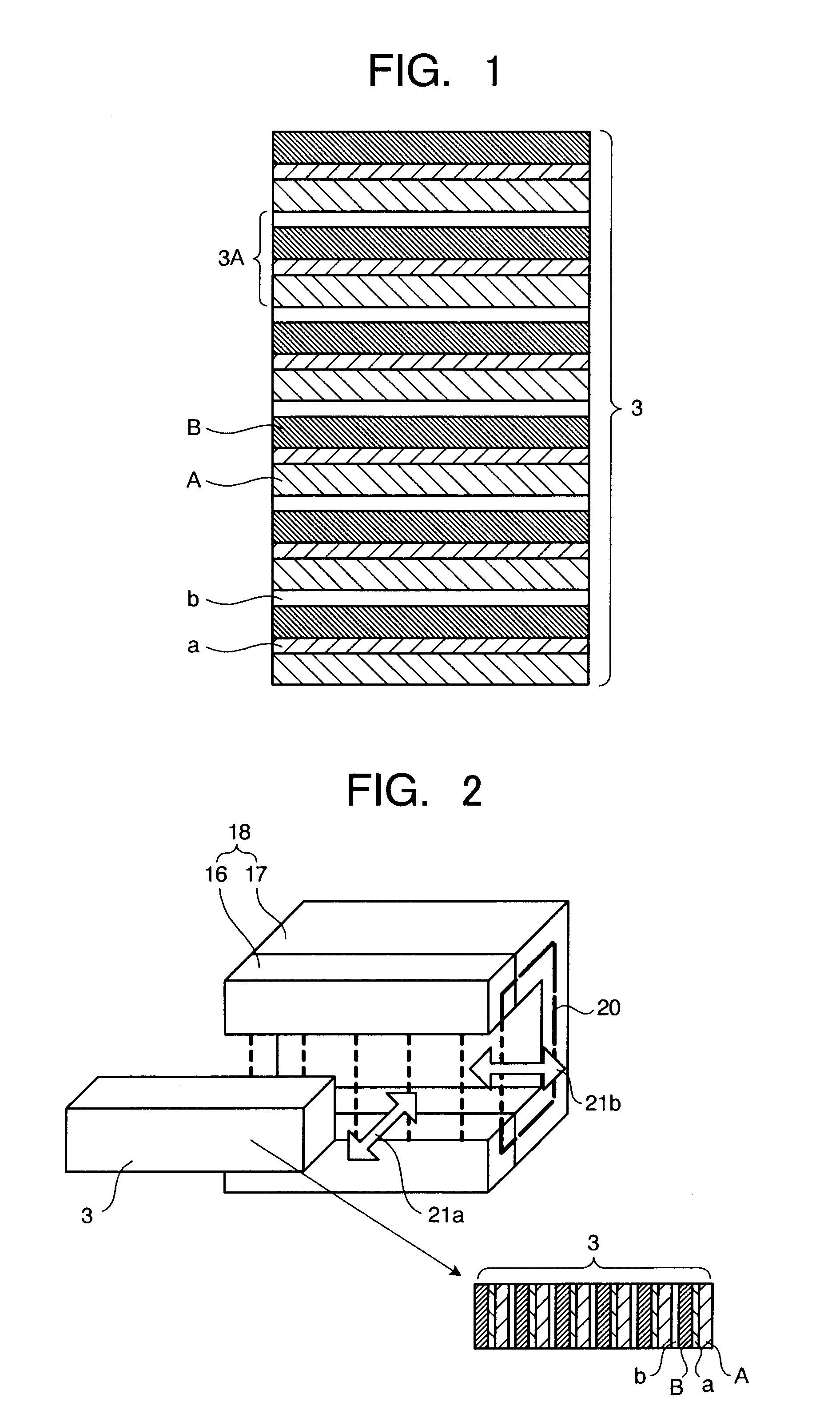

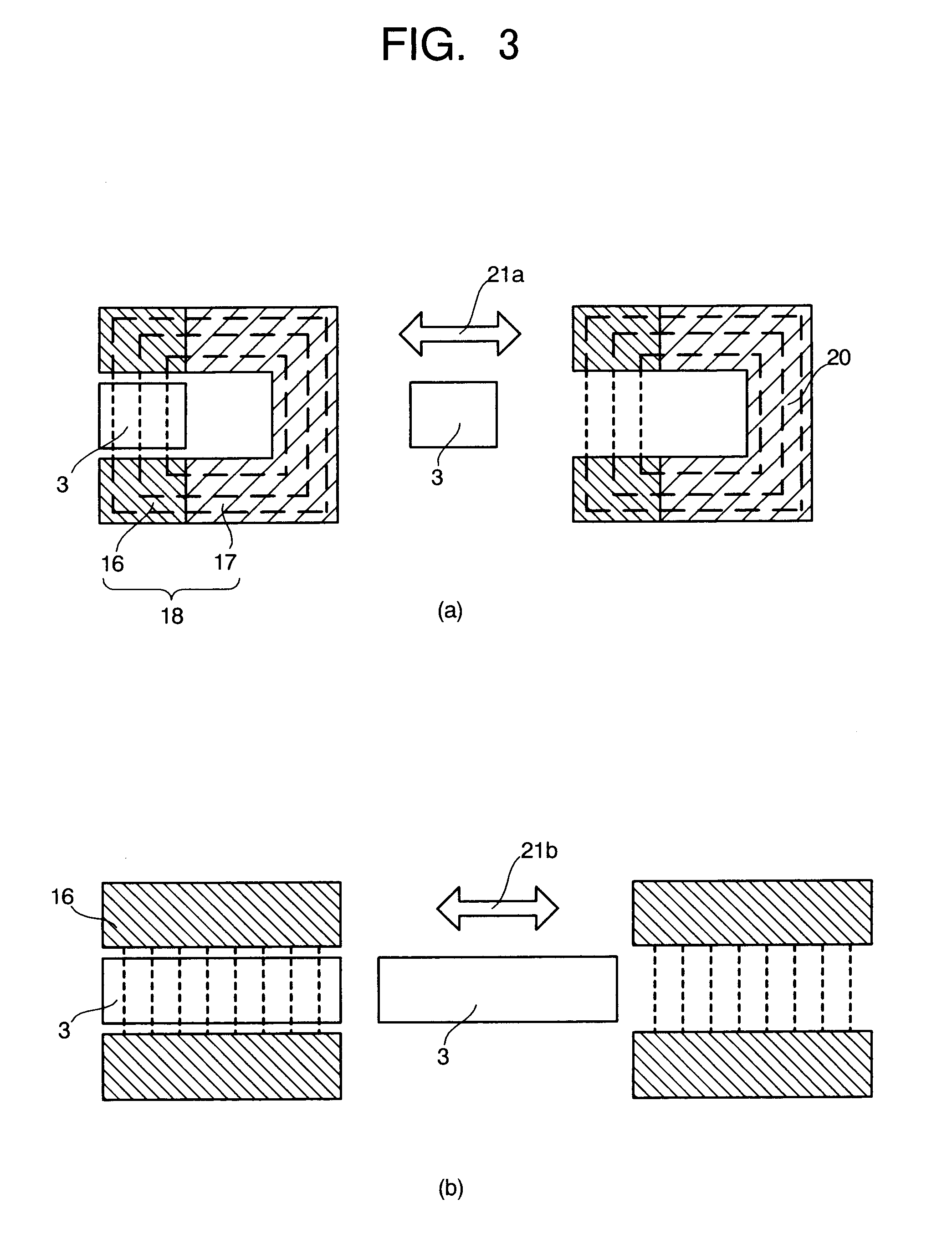

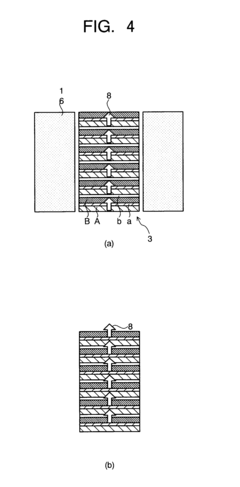

- A magnetic composite material comprising a first phase with an NaZn13 type crystal structure and a second phase of high ductility iron alloy, where the iron alloy phase improves mechanical strength and maintains a large magnetocaloric effect, allowing for the formation of spherical particles with enhanced mechanical properties and efficient heat exchange.

Magnetic refrigerating device and magnetic refrigerating method

PatentActiveUS20080078184A1

Innovation

- A magnetic refrigerating device and method that utilizes layered structures of magnetic materials exhibiting magneto-caloric effects and heat conductive materials with varying conductivity under magnetic fields, allowing for solid heat transfer without fluid flow, and employing permanent or superconducting magnets to apply magnetic fields in a way that minimizes demagnetization effects.

Energy Efficiency and Environmental Impact Assessment

The integration of thermoelectric principles with magnetic refrigeration technologies presents significant opportunities for enhancing energy efficiency and reducing environmental impact across multiple sectors. Current conventional cooling systems, primarily vapor-compression refrigeration, consume approximately 15% of global electricity and utilize refrigerants with high global warming potential. In contrast, combined thermoelectric-magnetic cooling systems demonstrate potential energy efficiency improvements of 20-30% compared to traditional methods.

Laboratory testing of prototype hybrid systems has shown coefficient of performance (COP) values ranging from 1.8 to 2.5, approaching the efficiency of conventional systems while eliminating harmful refrigerants. These systems operate with zero direct greenhouse gas emissions and utilize abundant, non-toxic materials such as gadolinium alloys and bismuth telluride, significantly reducing lifecycle environmental impact.

Power consumption analysis reveals that hybrid thermoelectric-magnetic systems require 15-25% less electricity during steady-state operation compared to equivalent conventional cooling systems. This efficiency gain stems from the complementary nature of the technologies, where magnetic cooling handles bulk temperature changes while thermoelectric elements manage precise temperature control and spatial distribution.

Environmental lifecycle assessment indicates a 40-60% reduction in carbon footprint when considering manufacturing, operation, and end-of-life disposal. The absence of refrigerant leakage, which accounts for approximately 7-12% of conventional systems' climate impact, represents a substantial environmental advantage. Additionally, the solid-state nature of these systems eliminates oil contamination issues associated with compressor-based technologies.

Material sustainability presents both challenges and opportunities. While rare earth elements used in magnetocaloric materials raise resource scarcity concerns, research into manganese-based alternatives shows promise for reducing dependency on critical materials. Thermoelectric components primarily utilize tellurium and bismuth, which face moderate supply constraints but benefit from established recycling infrastructure.

Noise pollution reduction represents another significant environmental benefit, with hybrid systems operating at 15-25 dB lower than conventional compressor-based systems. This characteristic makes the technology particularly valuable for densely populated urban environments and noise-sensitive applications such as medical facilities and data centers.

Laboratory testing of prototype hybrid systems has shown coefficient of performance (COP) values ranging from 1.8 to 2.5, approaching the efficiency of conventional systems while eliminating harmful refrigerants. These systems operate with zero direct greenhouse gas emissions and utilize abundant, non-toxic materials such as gadolinium alloys and bismuth telluride, significantly reducing lifecycle environmental impact.

Power consumption analysis reveals that hybrid thermoelectric-magnetic systems require 15-25% less electricity during steady-state operation compared to equivalent conventional cooling systems. This efficiency gain stems from the complementary nature of the technologies, where magnetic cooling handles bulk temperature changes while thermoelectric elements manage precise temperature control and spatial distribution.

Environmental lifecycle assessment indicates a 40-60% reduction in carbon footprint when considering manufacturing, operation, and end-of-life disposal. The absence of refrigerant leakage, which accounts for approximately 7-12% of conventional systems' climate impact, represents a substantial environmental advantage. Additionally, the solid-state nature of these systems eliminates oil contamination issues associated with compressor-based technologies.

Material sustainability presents both challenges and opportunities. While rare earth elements used in magnetocaloric materials raise resource scarcity concerns, research into manganese-based alternatives shows promise for reducing dependency on critical materials. Thermoelectric components primarily utilize tellurium and bismuth, which face moderate supply constraints but benefit from established recycling infrastructure.

Noise pollution reduction represents another significant environmental benefit, with hybrid systems operating at 15-25 dB lower than conventional compressor-based systems. This characteristic makes the technology particularly valuable for densely populated urban environments and noise-sensitive applications such as medical facilities and data centers.

Materials Science Challenges and Opportunities

The integration of thermoelectric principles with magnetic refrigeration presents significant materials science challenges that must be addressed to realize practical hybrid cooling systems. Current thermoelectric materials suffer from inherently low efficiency, with most commercial materials achieving ZT values below 1.5, limiting their widespread application. Similarly, magnetocaloric materials face limitations in temperature span and magnetic field requirements, with most requiring strong fields exceeding 1 Tesla for meaningful temperature changes.

A fundamental challenge lies in the material compatibility between thermoelectric and magnetocaloric components. These materials must operate in close thermal contact while maintaining distinct functional properties. Interface engineering becomes critical, as thermal and electrical contact resistances can significantly degrade system performance. The thermal expansion mismatch between different materials can lead to mechanical stress and potential failure during thermal cycling.

Magnetocaloric materials present their own set of challenges, particularly regarding hysteresis effects that reduce efficiency in cyclic operation. The most promising materials, such as Gd5Si2Ge2 and La(Fe,Si)13-based compounds, exhibit first-order phase transitions with significant hysteresis. Additionally, many high-performance magnetocaloric materials contain rare earth elements, raising sustainability and cost concerns.

For thermoelectric materials, the persistent challenge remains breaking the interdependence of electrical conductivity, thermal conductivity, and Seebeck coefficient. Nanostructuring approaches have shown promise in reducing thermal conductivity without significantly affecting electrical properties, but manufacturing scalability remains problematic. Advanced materials like skutterudites and half-Heusler alloys offer potential solutions but face durability issues under thermal cycling.

Opportunities exist in exploring novel composite materials that can simultaneously exhibit both thermoelectric and magnetocaloric effects. Recent research into multiferroic materials suggests possibilities for enhanced coupling between magnetic and electric properties. Advances in thin-film deposition and nanofabrication techniques enable precise control of interfaces between different functional materials, potentially leading to enhanced performance through quantum confinement effects.

Computational materials science offers promising pathways through high-throughput screening and machine learning approaches to identify optimal material combinations. These methods can accelerate the discovery of materials with complementary properties suitable for hybrid cooling systems, potentially revealing non-intuitive combinations that experimental approaches might overlook.

A fundamental challenge lies in the material compatibility between thermoelectric and magnetocaloric components. These materials must operate in close thermal contact while maintaining distinct functional properties. Interface engineering becomes critical, as thermal and electrical contact resistances can significantly degrade system performance. The thermal expansion mismatch between different materials can lead to mechanical stress and potential failure during thermal cycling.

Magnetocaloric materials present their own set of challenges, particularly regarding hysteresis effects that reduce efficiency in cyclic operation. The most promising materials, such as Gd5Si2Ge2 and La(Fe,Si)13-based compounds, exhibit first-order phase transitions with significant hysteresis. Additionally, many high-performance magnetocaloric materials contain rare earth elements, raising sustainability and cost concerns.

For thermoelectric materials, the persistent challenge remains breaking the interdependence of electrical conductivity, thermal conductivity, and Seebeck coefficient. Nanostructuring approaches have shown promise in reducing thermal conductivity without significantly affecting electrical properties, but manufacturing scalability remains problematic. Advanced materials like skutterudites and half-Heusler alloys offer potential solutions but face durability issues under thermal cycling.

Opportunities exist in exploring novel composite materials that can simultaneously exhibit both thermoelectric and magnetocaloric effects. Recent research into multiferroic materials suggests possibilities for enhanced coupling between magnetic and electric properties. Advances in thin-film deposition and nanofabrication techniques enable precise control of interfaces between different functional materials, potentially leading to enhanced performance through quantum confinement effects.

Computational materials science offers promising pathways through high-throughput screening and machine learning approaches to identify optimal material combinations. These methods can accelerate the discovery of materials with complementary properties suitable for hybrid cooling systems, potentially revealing non-intuitive combinations that experimental approaches might overlook.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!