Measuring Microstructural Effects on Thermoelectric Material Performance

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Background and Research Objectives

Thermoelectric materials have emerged as a promising solution for direct conversion between thermal and electrical energy, offering significant potential for waste heat recovery and sustainable energy generation. The history of thermoelectric materials dates back to the early 19th century with the discovery of the Seebeck effect by Thomas Johann Seebeck in 1821, followed by the Peltier effect in 1834. However, the practical application of these materials remained limited for decades due to their low conversion efficiency.

The efficiency of thermoelectric materials is primarily evaluated through the dimensionless figure of merit ZT, defined as ZT = S²σT/κ, where S is the Seebeck coefficient, σ is electrical conductivity, T is absolute temperature, and κ is thermal conductivity. The interdependence of these parameters presents a fundamental challenge in thermoelectric material development, as improving one parameter often adversely affects others.

Recent technological advancements have revitalized interest in thermoelectric materials, with significant progress in enhancing ZT values through nanostructuring, band engineering, and novel material compositions. The evolution of characterization techniques has enabled researchers to better understand the correlation between microstructural features and thermoelectric performance, which is crucial for targeted material design and optimization.

The global push for energy efficiency and carbon neutrality has further accelerated research in thermoelectric materials, with applications expanding beyond traditional sectors like aerospace to automotive, industrial waste heat recovery, and consumer electronics. Market projections indicate substantial growth potential, with the thermoelectric generator market expected to reach several billion dollars by 2030.

The primary objective of this research is to develop comprehensive methodologies for measuring and quantifying the effects of microstructural characteristics on thermoelectric performance. This includes investigating how grain boundaries, defects, phase distributions, and compositional variations influence the thermal and electrical transport properties at multiple length scales.

Additionally, this research aims to establish correlations between processing parameters, resulting microstructures, and thermoelectric properties to enable predictive modeling and accelerated material development. By understanding these relationships, we can design tailored microstructures that optimize the competing transport parameters simultaneously.

Furthermore, this investigation seeks to identify novel characterization techniques that can provide real-time, non-destructive assessment of microstructural features relevant to thermoelectric performance. This would facilitate rapid screening of material candidates and process optimization, significantly reducing development cycles for new thermoelectric materials and devices.

The efficiency of thermoelectric materials is primarily evaluated through the dimensionless figure of merit ZT, defined as ZT = S²σT/κ, where S is the Seebeck coefficient, σ is electrical conductivity, T is absolute temperature, and κ is thermal conductivity. The interdependence of these parameters presents a fundamental challenge in thermoelectric material development, as improving one parameter often adversely affects others.

Recent technological advancements have revitalized interest in thermoelectric materials, with significant progress in enhancing ZT values through nanostructuring, band engineering, and novel material compositions. The evolution of characterization techniques has enabled researchers to better understand the correlation between microstructural features and thermoelectric performance, which is crucial for targeted material design and optimization.

The global push for energy efficiency and carbon neutrality has further accelerated research in thermoelectric materials, with applications expanding beyond traditional sectors like aerospace to automotive, industrial waste heat recovery, and consumer electronics. Market projections indicate substantial growth potential, with the thermoelectric generator market expected to reach several billion dollars by 2030.

The primary objective of this research is to develop comprehensive methodologies for measuring and quantifying the effects of microstructural characteristics on thermoelectric performance. This includes investigating how grain boundaries, defects, phase distributions, and compositional variations influence the thermal and electrical transport properties at multiple length scales.

Additionally, this research aims to establish correlations between processing parameters, resulting microstructures, and thermoelectric properties to enable predictive modeling and accelerated material development. By understanding these relationships, we can design tailored microstructures that optimize the competing transport parameters simultaneously.

Furthermore, this investigation seeks to identify novel characterization techniques that can provide real-time, non-destructive assessment of microstructural features relevant to thermoelectric performance. This would facilitate rapid screening of material candidates and process optimization, significantly reducing development cycles for new thermoelectric materials and devices.

Market Analysis for Thermoelectric Applications

The global thermoelectric market is experiencing significant growth, driven by increasing demand for energy efficiency solutions and waste heat recovery systems. Currently valued at approximately $460 million, the market is projected to reach $720 million by 2027, representing a compound annual growth rate of 8.3%. This growth trajectory is primarily fueled by applications in automotive, industrial manufacturing, and consumer electronics sectors where thermoelectric materials convert waste heat into usable electricity.

The automotive industry represents the largest market segment, accounting for nearly 35% of thermoelectric applications. Major automotive manufacturers are increasingly incorporating thermoelectric generators (TEGs) into vehicle exhaust systems to improve fuel efficiency and reduce emissions. This trend is particularly pronounced in regions with stringent environmental regulations such as Europe and North America.

Industrial waste heat recovery presents another substantial market opportunity. Manufacturing processes in steel, glass, and cement industries generate significant thermal energy that is typically lost. Thermoelectric systems capable of capturing this waste heat could potentially recover 5-10% of industrial energy consumption, translating to billions in energy savings globally.

Consumer electronics constitutes a rapidly growing application area, with thermoelectric cooling solutions being integrated into high-performance computing systems, portable refrigeration, and temperature-controlled wearable devices. This segment is expected to grow at 12% annually, outpacing the overall market.

Geographically, North America and Europe currently lead market adoption, collectively representing 65% of global thermoelectric applications. However, Asia-Pacific regions, particularly China, Japan, and South Korea, are demonstrating the fastest growth rates due to expanding industrial bases and government initiatives promoting energy efficiency technologies.

Market penetration remains constrained by the relatively low conversion efficiency of current thermoelectric materials, typically ranging from 5-8%. Industry analysis indicates that achieving efficiency improvements to 12-15% would trigger widespread commercial adoption across multiple sectors. This efficiency threshold represents the critical market inflection point where thermoelectric solutions become economically viable for mainstream applications without subsidies.

Customer requirements vary significantly across application domains. Automotive applications prioritize durability under thermal cycling and vibration resistance, while consumer electronics emphasize miniaturization and cost-effectiveness. Industrial applications focus on scalability and long-term reliability under harsh operating conditions. Understanding these microstructural performance relationships is therefore essential for developing market-specific thermoelectric solutions.

The automotive industry represents the largest market segment, accounting for nearly 35% of thermoelectric applications. Major automotive manufacturers are increasingly incorporating thermoelectric generators (TEGs) into vehicle exhaust systems to improve fuel efficiency and reduce emissions. This trend is particularly pronounced in regions with stringent environmental regulations such as Europe and North America.

Industrial waste heat recovery presents another substantial market opportunity. Manufacturing processes in steel, glass, and cement industries generate significant thermal energy that is typically lost. Thermoelectric systems capable of capturing this waste heat could potentially recover 5-10% of industrial energy consumption, translating to billions in energy savings globally.

Consumer electronics constitutes a rapidly growing application area, with thermoelectric cooling solutions being integrated into high-performance computing systems, portable refrigeration, and temperature-controlled wearable devices. This segment is expected to grow at 12% annually, outpacing the overall market.

Geographically, North America and Europe currently lead market adoption, collectively representing 65% of global thermoelectric applications. However, Asia-Pacific regions, particularly China, Japan, and South Korea, are demonstrating the fastest growth rates due to expanding industrial bases and government initiatives promoting energy efficiency technologies.

Market penetration remains constrained by the relatively low conversion efficiency of current thermoelectric materials, typically ranging from 5-8%. Industry analysis indicates that achieving efficiency improvements to 12-15% would trigger widespread commercial adoption across multiple sectors. This efficiency threshold represents the critical market inflection point where thermoelectric solutions become economically viable for mainstream applications without subsidies.

Customer requirements vary significantly across application domains. Automotive applications prioritize durability under thermal cycling and vibration resistance, while consumer electronics emphasize miniaturization and cost-effectiveness. Industrial applications focus on scalability and long-term reliability under harsh operating conditions. Understanding these microstructural performance relationships is therefore essential for developing market-specific thermoelectric solutions.

Current Challenges in Microstructural Characterization

Despite significant advancements in thermoelectric materials research, microstructural characterization remains one of the most challenging aspects of correlating structure with performance. Current characterization techniques often struggle to capture the multi-scale nature of microstructural features that influence thermoelectric properties, ranging from atomic-level defects to mesoscale grain boundaries.

A primary challenge lies in the non-destructive visualization of internal microstructures at high resolution while maintaining the material in its operational state. Traditional electron microscopy techniques provide excellent spatial resolution but typically require sample preparation that may alter the original microstructure. Additionally, these methods often cannot be performed under the temperature gradients that exist during actual device operation.

The quantitative correlation between observed microstructural features and measured thermoelectric properties presents another significant hurdle. While techniques such as scanning thermal microscopy and time-domain thermoreflectance can map thermal conductivity variations, they often lack the spatial resolution to capture nanoscale features critical to electron and phonon transport mechanisms. This resolution gap creates difficulties in establishing direct cause-effect relationships between specific microstructural elements and overall material performance.

In-situ characterization under operational conditions represents perhaps the most formidable challenge. Thermoelectric materials operate under temperature gradients that can significantly alter microstructural features through thermal expansion, phase transitions, or accelerated diffusion processes. Current technologies struggle to simultaneously monitor these dynamic microstructural changes while measuring electrical and thermal transport properties.

The heterogeneous nature of high-performance thermoelectric materials further complicates characterization efforts. Many advanced thermoelectric systems incorporate nanoinclusions, precipitates, or compositional gradients deliberately engineered to enhance performance. Accurately identifying and quantifying these features across different length scales requires multiple complementary techniques, creating challenges in data integration and interpretation.

Statistical representation poses another significant challenge. Microstructural features in thermoelectric materials often exhibit substantial variability, requiring large sampling volumes to obtain statistically meaningful data. However, high-resolution characterization techniques typically examine extremely small sample volumes, creating uncertainty about how representative the observed microstructures are of the bulk material behavior.

Finally, the multi-physics nature of thermoelectric phenomena necessitates simultaneous characterization of thermal, electrical, and structural properties—a capability not fully realized in any single existing analytical technique. This limitation forces researchers to piece together data from multiple instruments, often introducing uncertainties in correlating structure-property relationships.

A primary challenge lies in the non-destructive visualization of internal microstructures at high resolution while maintaining the material in its operational state. Traditional electron microscopy techniques provide excellent spatial resolution but typically require sample preparation that may alter the original microstructure. Additionally, these methods often cannot be performed under the temperature gradients that exist during actual device operation.

The quantitative correlation between observed microstructural features and measured thermoelectric properties presents another significant hurdle. While techniques such as scanning thermal microscopy and time-domain thermoreflectance can map thermal conductivity variations, they often lack the spatial resolution to capture nanoscale features critical to electron and phonon transport mechanisms. This resolution gap creates difficulties in establishing direct cause-effect relationships between specific microstructural elements and overall material performance.

In-situ characterization under operational conditions represents perhaps the most formidable challenge. Thermoelectric materials operate under temperature gradients that can significantly alter microstructural features through thermal expansion, phase transitions, or accelerated diffusion processes. Current technologies struggle to simultaneously monitor these dynamic microstructural changes while measuring electrical and thermal transport properties.

The heterogeneous nature of high-performance thermoelectric materials further complicates characterization efforts. Many advanced thermoelectric systems incorporate nanoinclusions, precipitates, or compositional gradients deliberately engineered to enhance performance. Accurately identifying and quantifying these features across different length scales requires multiple complementary techniques, creating challenges in data integration and interpretation.

Statistical representation poses another significant challenge. Microstructural features in thermoelectric materials often exhibit substantial variability, requiring large sampling volumes to obtain statistically meaningful data. However, high-resolution characterization techniques typically examine extremely small sample volumes, creating uncertainty about how representative the observed microstructures are of the bulk material behavior.

Finally, the multi-physics nature of thermoelectric phenomena necessitates simultaneous characterization of thermal, electrical, and structural properties—a capability not fully realized in any single existing analytical technique. This limitation forces researchers to piece together data from multiple instruments, often introducing uncertainties in correlating structure-property relationships.

State-of-the-Art Microstructural Analysis Methods

01 Novel thermoelectric materials composition

Various novel compositions have been developed to enhance thermoelectric performance. These include nanostructured materials, composite materials, and materials with specific dopants that can significantly improve the figure of merit (ZT). These novel compositions often feature reduced thermal conductivity while maintaining good electrical conductivity, which is crucial for high-performance thermoelectric materials.- Novel thermoelectric materials composition: Various novel compositions have been developed to enhance thermoelectric performance. These include nanostructured materials, composite materials, and materials with specific dopants that can significantly improve the figure of merit (ZT). These novel compositions often feature reduced thermal conductivity while maintaining good electrical conductivity, which is crucial for efficient thermoelectric conversion. The materials may incorporate elements such as bismuth, tellurium, lead, or various transition metals to achieve optimal thermoelectric properties.

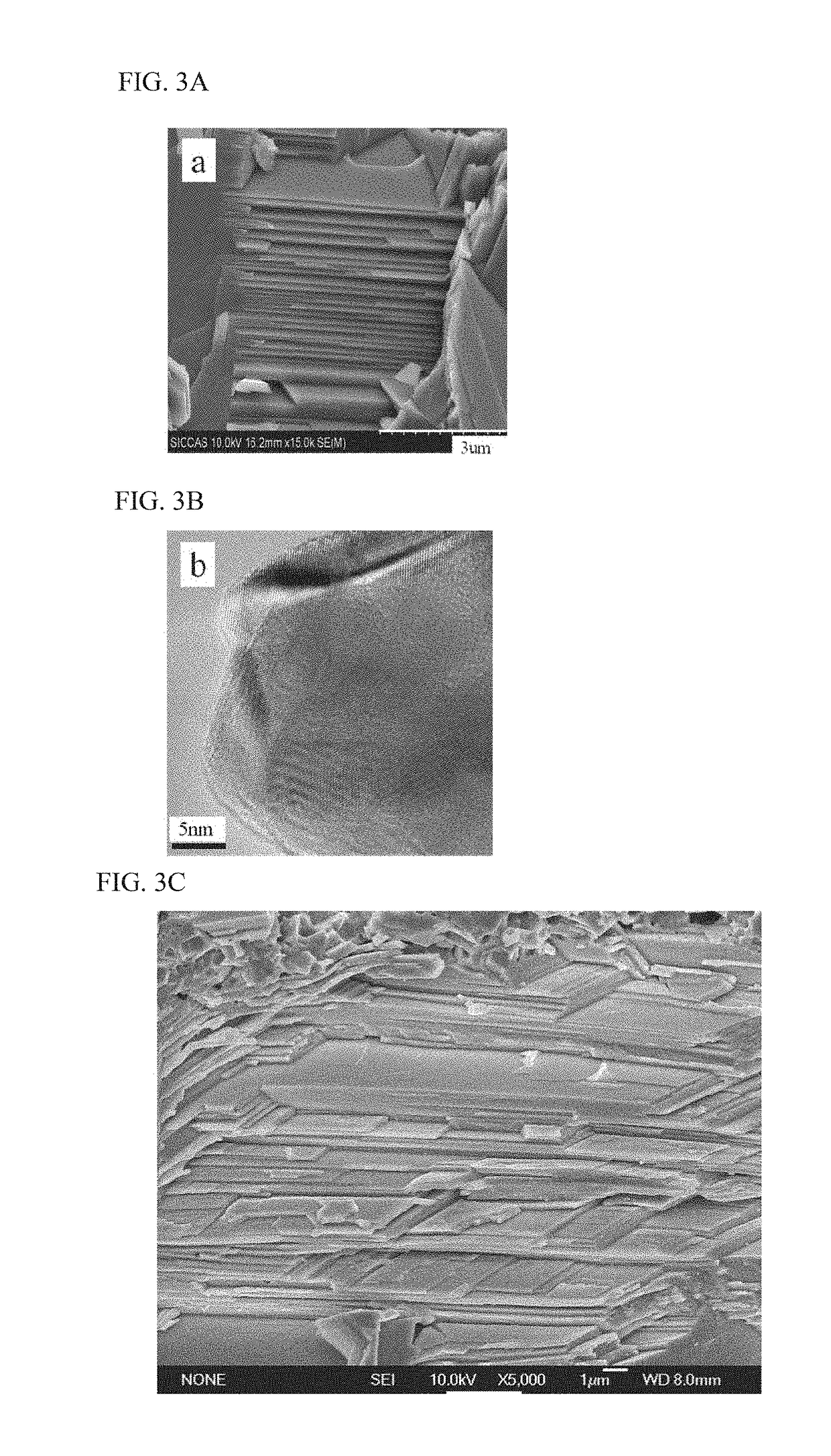

- Nanostructuring techniques for improved performance: Nanostructuring techniques are employed to enhance thermoelectric performance by creating interfaces that scatter phonons (heat carriers) while allowing electrons to flow. These techniques include creating nanowires, quantum dots, superlattices, and other nanostructured architectures. By introducing nanoscale features, the thermal conductivity can be significantly reduced without substantially affecting electrical conductivity, thereby improving the overall thermoelectric figure of merit. These approaches often involve precise control of material growth and processing conditions.

- Fabrication methods for high-performance thermoelectric devices: Advanced fabrication methods have been developed to produce high-performance thermoelectric devices. These include techniques such as spark plasma sintering, hot pressing, melt spinning, and various deposition methods. These processes are designed to control the microstructure, density, and crystallinity of thermoelectric materials, which directly impact their performance. Proper fabrication techniques can minimize defects, optimize grain boundaries, and ensure good electrical contacts, all of which are essential for maximizing device efficiency.

- Performance enhancement through doping and alloying: Doping and alloying strategies are employed to optimize the electronic properties of thermoelectric materials. By introducing specific impurities or combining different materials in precise ratios, researchers can tune the carrier concentration, band structure, and Seebeck coefficient. These modifications can lead to significant improvements in electrical conductivity while maintaining low thermal conductivity. Various dopants and alloying elements are selected based on their ability to create favorable electronic states or introduce beneficial scattering mechanisms.

- Measurement and characterization of thermoelectric properties: Accurate measurement and characterization techniques are essential for evaluating thermoelectric material performance. These include methods for determining the Seebeck coefficient, electrical conductivity, thermal conductivity, and figure of merit (ZT). Advanced characterization tools such as Hall effect measurements, laser flash analysis, and scanning thermal microscopy provide detailed insights into material properties. These measurements help researchers understand the fundamental transport mechanisms and identify strategies for further performance improvements.

02 Nanostructuring techniques for improved thermoelectric efficiency

Nanostructuring techniques are employed to enhance thermoelectric performance by creating interfaces that scatter phonons more effectively than electrons. These techniques include creating nanowires, quantum dots, superlattices, and other nanostructured architectures that reduce thermal conductivity while preserving electrical properties. The resulting materials show significantly improved ZT values compared to their bulk counterparts.Expand Specific Solutions03 Skutterudite and half-Heusler compounds for thermoelectric applications

Skutterudite and half-Heusler compounds represent important classes of thermoelectric materials with promising performance characteristics. These materials feature complex crystal structures that inherently reduce thermal conductivity. They can be further enhanced through filling the voids in their structures with rattling atoms or through strategic doping to optimize carrier concentration, resulting in improved thermoelectric efficiency.Expand Specific Solutions04 Thin film and flexible thermoelectric materials

Thin film and flexible thermoelectric materials are being developed for applications where traditional rigid thermoelectric modules are unsuitable. These materials can be deposited on various substrates, including flexible ones, enabling conformal thermoelectric generators that can harvest waste heat from irregularly shaped surfaces. Advanced deposition techniques and material engineering approaches are used to maintain high thermoelectric performance despite the dimensional constraints.Expand Specific Solutions05 Performance enhancement through interface engineering and doping

Interface engineering and strategic doping are critical approaches to enhancing thermoelectric performance. By carefully controlling interfaces between different materials or phases, phonon scattering can be increased while electron transport remains relatively unaffected. Similarly, precise doping strategies can optimize carrier concentration and mobility, leading to improved power factors. These techniques have enabled significant advancements in the figure of merit for various thermoelectric material systems.Expand Specific Solutions

Leading Research Institutions and Industry Players

The thermoelectric materials performance measurement field is currently in a growth phase, with increasing market interest driven by energy efficiency demands. The competitive landscape features a mix of academic institutions (Tsinghua University, California Institute of Technology, Southeast University) and industrial players (Toyota, Samsung, Siemens) collaborating on microstructural research. Government laboratories like Naval Research Laboratory and Electronics & Telecommunications Research Institute provide foundational research support. Technical maturity varies significantly across applications, with automotive and industrial sectors leading commercialization efforts while novel microstructural measurement techniques remain predominantly in research phases. Asian institutions, particularly from China and South Korea, demonstrate strong representation in patent activities, indicating regional technology leadership in this emerging field.

California Institute of Technology

Technical Solution: Caltech has pioneered advanced scanning probe microscopy techniques to directly correlate thermoelectric performance with microstructural features at nanoscale resolution. Their approach combines Scanning Thermal Microscopy (SThM) with Transmission Electron Microscopy (TEM) to simultaneously map thermal conductivity variations and crystallographic defects in thermoelectric materials. This multi-modal characterization allows researchers to identify how grain boundaries, dislocations, and nanoprecipitates affect local Seebeck coefficient and electrical conductivity. Caltech has developed proprietary algorithms that quantitatively link microstructural parameters to the power factor and ZT value, enabling predictive modeling of how specific defect engineering strategies will impact overall thermoelectric efficiency. Their recent work has demonstrated that controlled introduction of coherent nanoprecipitates can reduce thermal conductivity by up to 45% while maintaining electrical transport properties.

Strengths: Exceptional spatial resolution (sub-10nm) for thermal property mapping; sophisticated data analysis capabilities linking microstructure to performance metrics; world-class electron microscopy facilities. Weaknesses: Techniques require expensive instrumentation; characterization limited to small sample areas; challenges in extending findings to bulk material performance.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive measurement platform specifically designed to evaluate microstructural effects on thermoelectric materials for automotive waste heat recovery applications. Their approach integrates high-throughput screening methods with advanced microstructural characterization to optimize material composition and processing. Toyota's proprietary system combines laser flash thermal diffusivity measurements with automated Hall effect and Seebeck coefficient mapping to generate spatially-resolved performance data across material samples with engineered microstructural gradients. This allows researchers to rapidly assess how variations in grain size, texture, and secondary phase distribution affect the thermoelectric figure of merit. Toyota has particularly focused on developing in-situ measurement capabilities that monitor how microstructure evolves during thermal cycling, providing crucial insights into material stability under automotive operating conditions. Their research has demonstrated that controlling interface density through hierarchical structuring can enhance ZT values by up to 30% compared to conventional processing methods.

Strengths: Industry-leading capabilities for evaluating thermoelectric performance under realistic operating conditions; extensive materials processing expertise; ability to rapidly scale promising materials to production. Weaknesses: Research primarily focused on materials suitable for automotive applications; less emphasis on fundamental physics of electron-phonon interactions; proprietary nature limits academic collaboration.

Key Scientific Breakthroughs in Structure-Property Relationships

Resistance-temperature and hotplate sensors

PatentWO2020009915A1

Innovation

- A compact resistance-temperature sensor design where a conducting sample is directly deposited on a substrate with a thick capping layer, allowing self-heating and temperature determination through power input, and a hotplate sensor with a separate heating element for improved temperature control and uniformity.

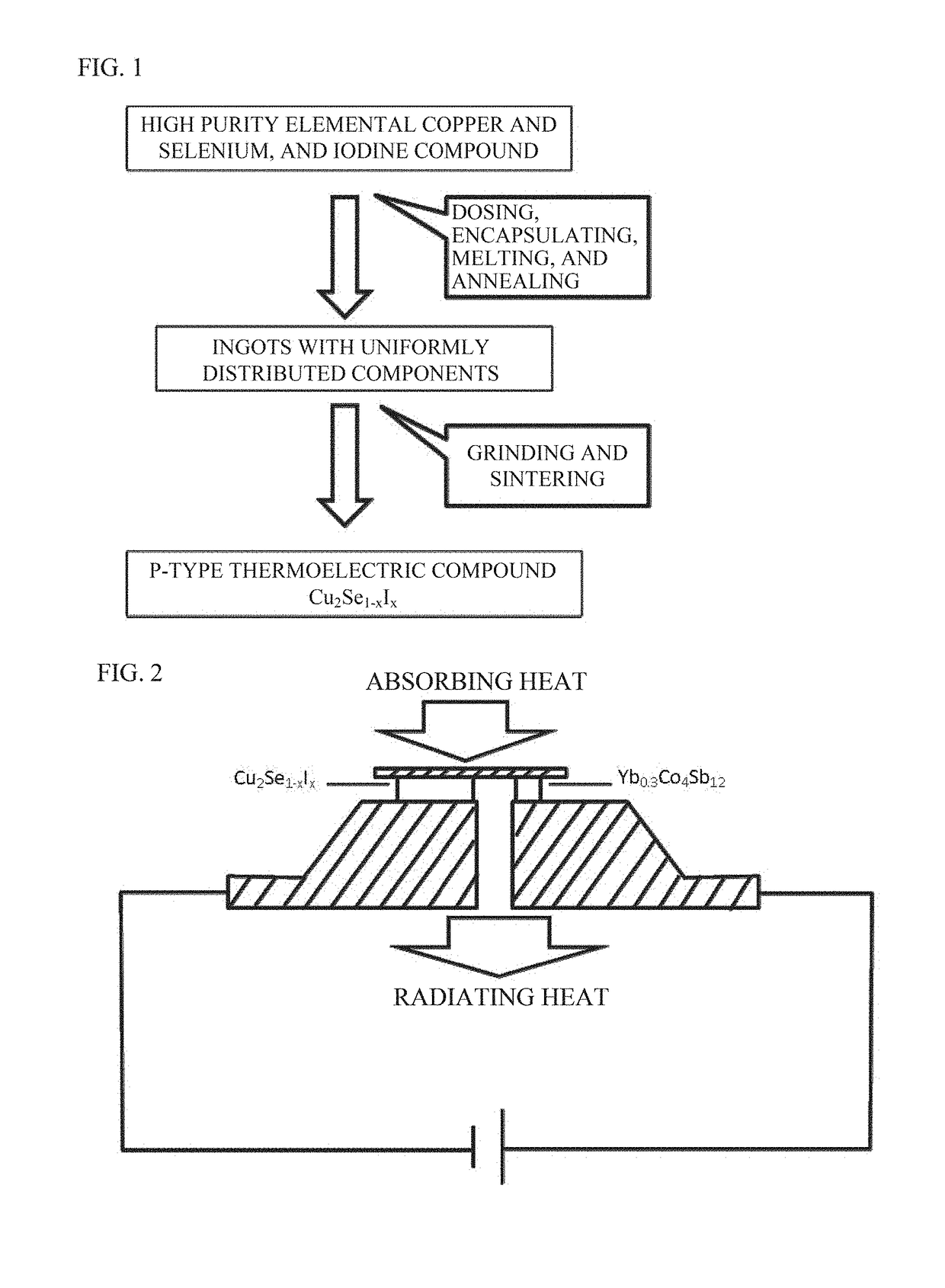

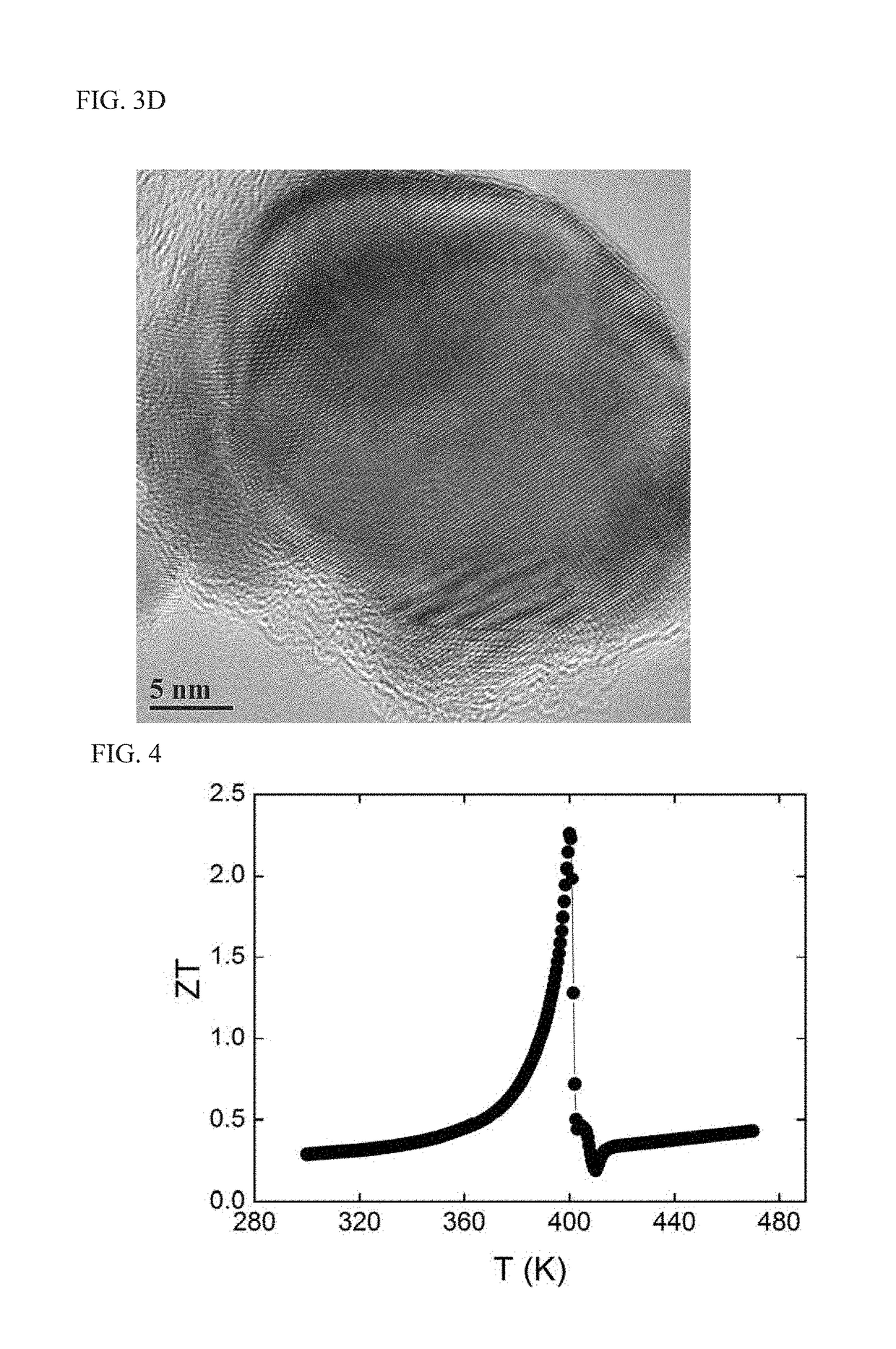

P-type high-performance thermoelectric material with reversible phase change, and preparation method therefor

PatentActiveUS10177295B2

Innovation

- A P-type copper-selenide-based thermoelectric material with a reversible phase transition, characterized by the chemical composition Cu2Se1-xIx, where 0<x≤0.08, exhibiting a high Seebeck coefficient and low thermal conductivity, and a method involving vacuum encapsulation, gradient heating, annealing, and pressure sintering to achieve a layered structure with improved thermoelectric performance.

Materials Sustainability and Environmental Impact

The sustainability aspects of thermoelectric materials represent a critical dimension in evaluating their long-term viability and environmental impact. Current thermoelectric materials often contain rare, toxic, or environmentally problematic elements such as tellurium, lead, and antimony. Microstructural engineering approaches must therefore consider not only performance metrics but also environmental footprints across the entire lifecycle.

Material scarcity presents a significant challenge, as high-performance thermoelectric compounds frequently rely on elements with limited natural abundance. For instance, tellurium, essential in bismuth telluride (Bi₂Te₃), faces supply constraints with global reserves estimated at only 31,000 metric tons. Microstructural modifications that enable reduced reliance on such critical elements while maintaining performance characteristics represent a promising research direction.

Toxicity concerns further complicate the widespread adoption of thermoelectric technologies. Lead-based materials, despite their excellent thermoelectric properties, pose serious environmental and health risks. Microstructural engineering approaches that enable substitution with benign alternatives or encapsulation strategies to prevent leaching are increasingly important. Recent research demonstrates that nanostructuring can enhance the performance of less toxic alternatives, potentially enabling their commercial viability.

Energy payback time—the period required for a thermoelectric device to generate the energy consumed during its production—is directly influenced by microstructural characteristics. Manufacturing processes for precisely engineered microstructures often demand additional energy inputs. Life cycle assessments indicate that nanostructured thermoelectric materials may require 20-30% more energy during fabrication compared to bulk counterparts, necessitating performance improvements that offset this initial energy investment.

Recyclability presents another dimension where microstructure plays a determining role. Complex, multi-phase microstructures that enhance thermoelectric performance can simultaneously complicate end-of-life material recovery. Developing microstructural designs that facilitate separation and reclamation of valuable components represents an emerging research priority, with preliminary studies suggesting that hierarchical structures may offer advantages for selective dissolution recovery methods.

Water usage in manufacturing processes for microstructurally engineered thermoelectric materials also warrants consideration. Certain nanofabrication techniques require substantial quantities of ultra-pure water, with production of highly engineered thermoelectric materials consuming up to 5,000 liters per kilogram of finished material. Developing water-efficient microstructural engineering approaches thus represents an important sustainability objective.

Material scarcity presents a significant challenge, as high-performance thermoelectric compounds frequently rely on elements with limited natural abundance. For instance, tellurium, essential in bismuth telluride (Bi₂Te₃), faces supply constraints with global reserves estimated at only 31,000 metric tons. Microstructural modifications that enable reduced reliance on such critical elements while maintaining performance characteristics represent a promising research direction.

Toxicity concerns further complicate the widespread adoption of thermoelectric technologies. Lead-based materials, despite their excellent thermoelectric properties, pose serious environmental and health risks. Microstructural engineering approaches that enable substitution with benign alternatives or encapsulation strategies to prevent leaching are increasingly important. Recent research demonstrates that nanostructuring can enhance the performance of less toxic alternatives, potentially enabling their commercial viability.

Energy payback time—the period required for a thermoelectric device to generate the energy consumed during its production—is directly influenced by microstructural characteristics. Manufacturing processes for precisely engineered microstructures often demand additional energy inputs. Life cycle assessments indicate that nanostructured thermoelectric materials may require 20-30% more energy during fabrication compared to bulk counterparts, necessitating performance improvements that offset this initial energy investment.

Recyclability presents another dimension where microstructure plays a determining role. Complex, multi-phase microstructures that enhance thermoelectric performance can simultaneously complicate end-of-life material recovery. Developing microstructural designs that facilitate separation and reclamation of valuable components represents an emerging research priority, with preliminary studies suggesting that hierarchical structures may offer advantages for selective dissolution recovery methods.

Water usage in manufacturing processes for microstructurally engineered thermoelectric materials also warrants consideration. Certain nanofabrication techniques require substantial quantities of ultra-pure water, with production of highly engineered thermoelectric materials consuming up to 5,000 liters per kilogram of finished material. Developing water-efficient microstructural engineering approaches thus represents an important sustainability objective.

Standardization and Quality Control Protocols

The development of standardized protocols for measuring microstructural effects on thermoelectric performance represents a critical challenge in advancing thermoelectric materials research. Current methodologies exhibit significant variations across research institutions, leading to inconsistent results and hindering meaningful comparisons between studies. Establishing comprehensive quality control protocols would enable more reliable data collection and facilitate accelerated material optimization.

A fundamental requirement for standardization involves sample preparation techniques. Precise control of grain size, orientation, boundary characteristics, and defect concentrations must be rigorously documented and maintained across experiments. This includes standardized procedures for powder processing, sintering parameters, and post-processing treatments that directly influence microstructural features.

Measurement methodologies require particular attention to standardization. Temperature-dependent electrical conductivity, Seebeck coefficient, and thermal conductivity measurements should follow established protocols regarding sample dimensions, contact preparations, and environmental conditions. The development of reference materials with well-characterized microstructures would provide crucial calibration standards for comparing measurement systems across different laboratories.

Statistical analysis frameworks represent another essential component of quality control. Protocols should specify minimum sample sizes, appropriate statistical methods for data analysis, and confidence interval reporting requirements. This statistical rigor would help distinguish genuine microstructural effects from measurement artifacts or random variations, particularly when dealing with nanoscale features that exhibit inherent variability.

Imaging and characterization techniques demand standardized approaches for quantifying microstructural parameters. Electron microscopy protocols should specify sample preparation methods, imaging conditions, and analytical procedures for extracting quantitative data on grain size distributions, boundary characteristics, and phase compositions. Advanced techniques such as electron backscatter diffraction (EBSD) require particular attention to standardization due to their complexity.

Data reporting formats constitute the final critical element of quality control. Establishing minimum reporting requirements for microstructural parameters, measurement conditions, and uncertainty analysis would facilitate more effective knowledge sharing and meta-analysis across the research community. Digital data repositories with standardized formats would further enhance reproducibility and enable machine learning approaches to identify complex structure-property relationships.

Implementation of these protocols through international collaborations and standards organizations would significantly accelerate progress in understanding microstructural effects on thermoelectric performance, ultimately leading to more efficient materials development pathways.

A fundamental requirement for standardization involves sample preparation techniques. Precise control of grain size, orientation, boundary characteristics, and defect concentrations must be rigorously documented and maintained across experiments. This includes standardized procedures for powder processing, sintering parameters, and post-processing treatments that directly influence microstructural features.

Measurement methodologies require particular attention to standardization. Temperature-dependent electrical conductivity, Seebeck coefficient, and thermal conductivity measurements should follow established protocols regarding sample dimensions, contact preparations, and environmental conditions. The development of reference materials with well-characterized microstructures would provide crucial calibration standards for comparing measurement systems across different laboratories.

Statistical analysis frameworks represent another essential component of quality control. Protocols should specify minimum sample sizes, appropriate statistical methods for data analysis, and confidence interval reporting requirements. This statistical rigor would help distinguish genuine microstructural effects from measurement artifacts or random variations, particularly when dealing with nanoscale features that exhibit inherent variability.

Imaging and characterization techniques demand standardized approaches for quantifying microstructural parameters. Electron microscopy protocols should specify sample preparation methods, imaging conditions, and analytical procedures for extracting quantitative data on grain size distributions, boundary characteristics, and phase compositions. Advanced techniques such as electron backscatter diffraction (EBSD) require particular attention to standardization due to their complexity.

Data reporting formats constitute the final critical element of quality control. Establishing minimum reporting requirements for microstructural parameters, measurement conditions, and uncertainty analysis would facilitate more effective knowledge sharing and meta-analysis across the research community. Digital data repositories with standardized formats would further enhance reproducibility and enable machine learning approaches to identify complex structure-property relationships.

Implementation of these protocols through international collaborations and standards organizations would significantly accelerate progress in understanding microstructural effects on thermoelectric performance, ultimately leading to more efficient materials development pathways.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!