Thermoelectric Materials in Low-Power Remote Sensor Networks

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Evolution and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century when Thomas Johann Seebeck first observed the conversion of temperature differences into electrical voltage. The subsequent discovery of the Peltier effect in 1834 further expanded the understanding of thermoelectric phenomena, establishing the foundation for modern thermoelectric materials and devices. Throughout the 20th century, thermoelectric technology remained primarily in niche applications due to efficiency limitations.

The late 1990s marked a turning point with the introduction of nanostructured thermoelectric materials, which demonstrated substantially improved figure of merit (ZT) values compared to bulk materials. This breakthrough catalyzed renewed interest in thermoelectric research for energy harvesting applications. The early 2000s witnessed the development of bismuth telluride (Bi2Te3) based materials, which became the commercial standard for near-room-temperature applications, particularly relevant for sensor networks operating in ambient conditions.

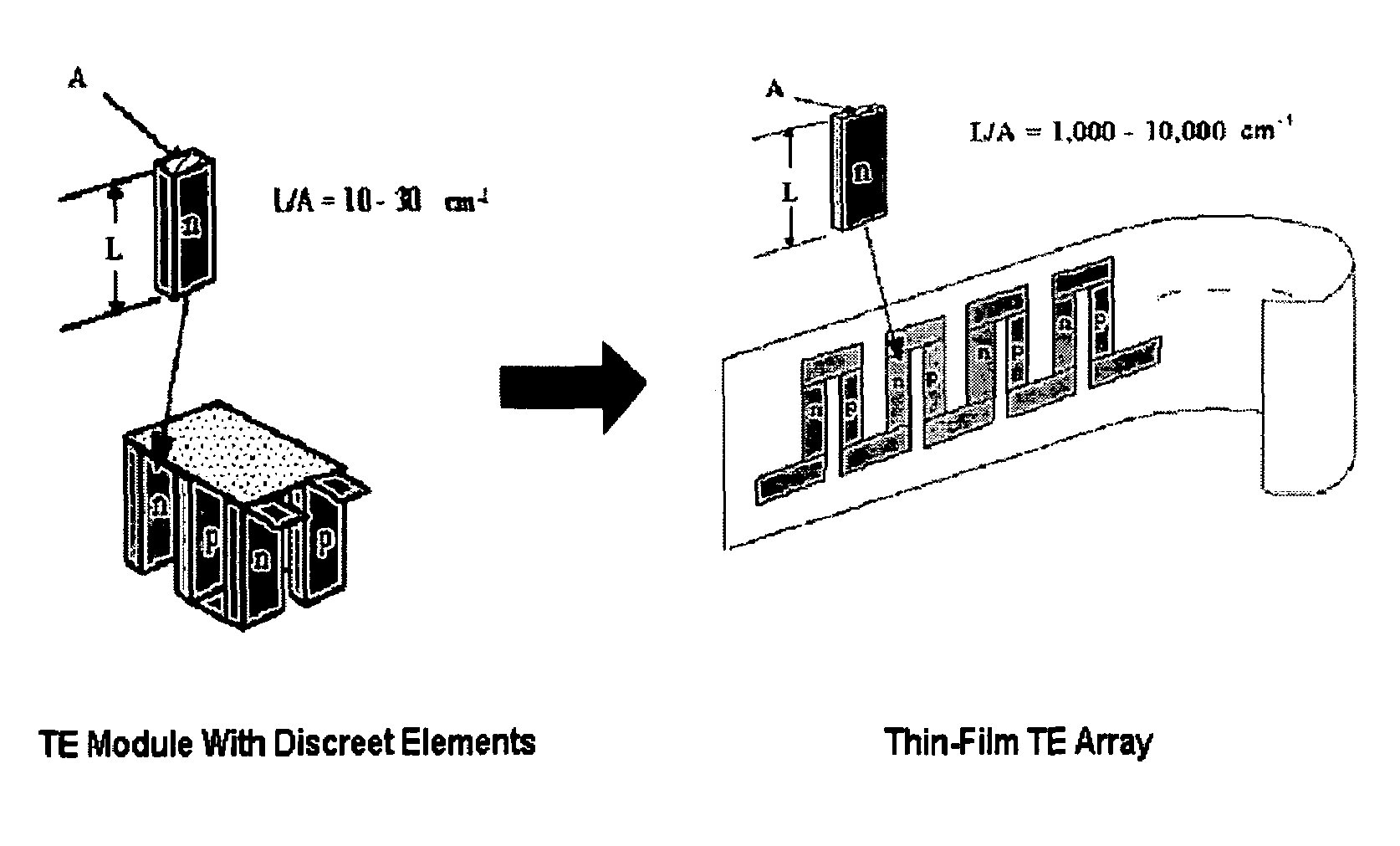

Recent technological advancements have focused on enhancing the ZT value through various approaches including quantum confinement effects, phonon engineering, and band structure engineering. These innovations have pushed thermoelectric efficiency closer to practical viability for low-power applications. Particularly noteworthy is the development of flexible thermoelectric generators (TEGs) and thin-film technologies that align perfectly with the form factor requirements of modern remote sensing networks.

In the context of low-power remote sensor networks, thermoelectric technology aims to harvest ambient thermal energy to power autonomous sensing nodes without requiring battery replacement or external power sources. This objective addresses the critical challenge of energy sustainability in Internet of Things (IoT) deployments, especially in hard-to-reach locations where maintenance is difficult or costly.

The primary technical objectives for thermoelectric materials in this application include achieving higher conversion efficiency at low temperature differentials (typically <10°C), reducing material costs while maintaining performance, enhancing mechanical flexibility for diverse deployment scenarios, and ensuring long-term reliability under varying environmental conditions. Additionally, miniaturization of thermoelectric modules to match the scale of modern microsensors represents a key goal for seamless integration.

Looking forward, the technology roadmap focuses on developing materials with ZT values exceeding 3.0 at room temperature, compared to current commercial materials with ZT values around 1.0-1.5. Research is also directed toward environmentally friendly alternatives to replace toxic or rare elements like tellurium and bismuth, with particular interest in organic thermoelectric materials and silicon-based nanostructures that offer compatibility with existing semiconductor manufacturing processes.

The late 1990s marked a turning point with the introduction of nanostructured thermoelectric materials, which demonstrated substantially improved figure of merit (ZT) values compared to bulk materials. This breakthrough catalyzed renewed interest in thermoelectric research for energy harvesting applications. The early 2000s witnessed the development of bismuth telluride (Bi2Te3) based materials, which became the commercial standard for near-room-temperature applications, particularly relevant for sensor networks operating in ambient conditions.

Recent technological advancements have focused on enhancing the ZT value through various approaches including quantum confinement effects, phonon engineering, and band structure engineering. These innovations have pushed thermoelectric efficiency closer to practical viability for low-power applications. Particularly noteworthy is the development of flexible thermoelectric generators (TEGs) and thin-film technologies that align perfectly with the form factor requirements of modern remote sensing networks.

In the context of low-power remote sensor networks, thermoelectric technology aims to harvest ambient thermal energy to power autonomous sensing nodes without requiring battery replacement or external power sources. This objective addresses the critical challenge of energy sustainability in Internet of Things (IoT) deployments, especially in hard-to-reach locations where maintenance is difficult or costly.

The primary technical objectives for thermoelectric materials in this application include achieving higher conversion efficiency at low temperature differentials (typically <10°C), reducing material costs while maintaining performance, enhancing mechanical flexibility for diverse deployment scenarios, and ensuring long-term reliability under varying environmental conditions. Additionally, miniaturization of thermoelectric modules to match the scale of modern microsensors represents a key goal for seamless integration.

Looking forward, the technology roadmap focuses on developing materials with ZT values exceeding 3.0 at room temperature, compared to current commercial materials with ZT values around 1.0-1.5. Research is also directed toward environmentally friendly alternatives to replace toxic or rare elements like tellurium and bismuth, with particular interest in organic thermoelectric materials and silicon-based nanostructures that offer compatibility with existing semiconductor manufacturing processes.

Market Analysis for Energy Harvesting in IoT Sensors

The energy harvesting market for IoT sensors is experiencing robust growth, driven by the increasing deployment of wireless sensor networks across various industries. Current market valuations place this sector at approximately $450 million in 2023, with projections indicating a compound annual growth rate (CAGR) of 13.2% through 2028, potentially reaching $840 million by that time. This growth trajectory is particularly evident in industrial monitoring, smart agriculture, and infrastructure applications where remote deployment necessitates self-powered solutions.

Demand analysis reveals that thermoelectric materials are gaining significant traction within this market, particularly for applications where temperature differentials are readily available. Industries such as manufacturing, automotive, and process control represent the largest current market segments, collectively accounting for nearly 40% of thermoelectric energy harvesting implementations. The healthcare sector is emerging as a rapidly growing vertical, with wearable medical devices increasingly incorporating thermoelectric generators to extend battery life or enable continuous operation.

Geographic market distribution shows North America leading with approximately 35% market share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region demonstrates the highest growth rate at 15.7% annually, driven by rapid industrial automation in China, Japan, and South Korea. Notably, these regions are investing heavily in smart city infrastructure, creating substantial opportunities for thermoelectric-powered sensor networks.

Customer requirements analysis indicates a clear preference for energy harvesting solutions that can deliver 1-10 mW of continuous power, with particular emphasis on reliability in variable environmental conditions. End-users consistently prioritize three key factors: energy conversion efficiency, long-term durability (minimum 5-year operational lifespan), and cost-effectiveness compared to traditional battery replacement cycles.

Market barriers include the relatively high initial cost of thermoelectric materials, with premium bismuth telluride solutions commanding significant price premiums over conventional power sources. Additionally, awareness gaps among potential industrial adopters and technical integration challenges with existing sensor platforms represent significant market friction points that must be addressed to accelerate adoption.

Competitive landscape analysis reveals a market dominated by established players like Laird Thermal Systems, Ferrotec, and Gentherm, who collectively hold approximately 45% market share. However, emerging startups focusing on novel material science approaches are rapidly gaining traction, particularly those developing flexible thermoelectric materials suitable for irregular surfaces and wearable applications.

Demand analysis reveals that thermoelectric materials are gaining significant traction within this market, particularly for applications where temperature differentials are readily available. Industries such as manufacturing, automotive, and process control represent the largest current market segments, collectively accounting for nearly 40% of thermoelectric energy harvesting implementations. The healthcare sector is emerging as a rapidly growing vertical, with wearable medical devices increasingly incorporating thermoelectric generators to extend battery life or enable continuous operation.

Geographic market distribution shows North America leading with approximately 35% market share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region demonstrates the highest growth rate at 15.7% annually, driven by rapid industrial automation in China, Japan, and South Korea. Notably, these regions are investing heavily in smart city infrastructure, creating substantial opportunities for thermoelectric-powered sensor networks.

Customer requirements analysis indicates a clear preference for energy harvesting solutions that can deliver 1-10 mW of continuous power, with particular emphasis on reliability in variable environmental conditions. End-users consistently prioritize three key factors: energy conversion efficiency, long-term durability (minimum 5-year operational lifespan), and cost-effectiveness compared to traditional battery replacement cycles.

Market barriers include the relatively high initial cost of thermoelectric materials, with premium bismuth telluride solutions commanding significant price premiums over conventional power sources. Additionally, awareness gaps among potential industrial adopters and technical integration challenges with existing sensor platforms represent significant market friction points that must be addressed to accelerate adoption.

Competitive landscape analysis reveals a market dominated by established players like Laird Thermal Systems, Ferrotec, and Gentherm, who collectively hold approximately 45% market share. However, emerging startups focusing on novel material science approaches are rapidly gaining traction, particularly those developing flexible thermoelectric materials suitable for irregular surfaces and wearable applications.

Current Challenges in Thermoelectric Material Development

Despite significant advancements in thermoelectric materials over the past decade, several critical challenges continue to impede their widespread adoption in low-power remote sensor networks. The fundamental limitation remains the relatively low conversion efficiency, with most commercially available thermoelectric materials exhibiting a figure of merit (ZT) below 2, whereas practical applications in energy-constrained environments ideally require ZT values exceeding 3. This efficiency gap significantly constrains the power generation capabilities in small temperature gradient scenarios typical of environmental monitoring applications.

Material cost and scalability present another substantial hurdle. High-performance thermoelectric materials often rely on rare or toxic elements such as tellurium, bismuth, and lead, raising concerns about supply chain sustainability and environmental impact. The manufacturing processes for these materials frequently involve complex synthesis routes requiring precise control of stoichiometry and microstructure, which translates to higher production costs and challenges in scaling to industrial volumes needed for widespread sensor network deployment.

Mechanical robustness and long-term stability remain problematic, particularly in harsh environmental conditions where remote sensors typically operate. Thermal cycling, moisture exposure, and mechanical stress can lead to performance degradation through microcrack formation, oxidation, and compositional changes. Current materials exhibit significant performance deterioration after extended field deployment, with efficiency losses of 15-30% observed over operational lifetimes of 3-5 years.

Integration challenges at the system level further complicate implementation. The rigid nature of many high-performance thermoelectric materials creates compatibility issues with flexible or conformal sensor platforms. Additionally, thermal management at the microscale presents unique difficulties, as conventional heat sink approaches become ineffective at the dimensions required for compact sensor nodes, resulting in suboptimal temperature gradients across the thermoelectric elements.

Emerging applications in wearable and implantable sensing introduce additional constraints related to biocompatibility and form factor. Current thermoelectric materials that perform well in industrial settings often contain elements unsuitable for prolonged human contact, limiting their application in health monitoring systems that could benefit from thermal energy harvesting.

The interdisciplinary nature of these challenges necessitates collaborative research spanning materials science, electrical engineering, and thermal management. Recent research directions have focused on nanostructured materials, organic thermoelectrics, and hybrid systems, though each approach introduces its own set of technical hurdles that must be overcome before practical implementation in energy-autonomous sensor networks becomes feasible.

Material cost and scalability present another substantial hurdle. High-performance thermoelectric materials often rely on rare or toxic elements such as tellurium, bismuth, and lead, raising concerns about supply chain sustainability and environmental impact. The manufacturing processes for these materials frequently involve complex synthesis routes requiring precise control of stoichiometry and microstructure, which translates to higher production costs and challenges in scaling to industrial volumes needed for widespread sensor network deployment.

Mechanical robustness and long-term stability remain problematic, particularly in harsh environmental conditions where remote sensors typically operate. Thermal cycling, moisture exposure, and mechanical stress can lead to performance degradation through microcrack formation, oxidation, and compositional changes. Current materials exhibit significant performance deterioration after extended field deployment, with efficiency losses of 15-30% observed over operational lifetimes of 3-5 years.

Integration challenges at the system level further complicate implementation. The rigid nature of many high-performance thermoelectric materials creates compatibility issues with flexible or conformal sensor platforms. Additionally, thermal management at the microscale presents unique difficulties, as conventional heat sink approaches become ineffective at the dimensions required for compact sensor nodes, resulting in suboptimal temperature gradients across the thermoelectric elements.

Emerging applications in wearable and implantable sensing introduce additional constraints related to biocompatibility and form factor. Current thermoelectric materials that perform well in industrial settings often contain elements unsuitable for prolonged human contact, limiting their application in health monitoring systems that could benefit from thermal energy harvesting.

The interdisciplinary nature of these challenges necessitates collaborative research spanning materials science, electrical engineering, and thermal management. Recent research directions have focused on nanostructured materials, organic thermoelectrics, and hybrid systems, though each approach introduces its own set of technical hurdles that must be overcome before practical implementation in energy-autonomous sensor networks becomes feasible.

State-of-the-Art Thermoelectric Solutions for Sensor Networks

01 Bismuth telluride-based thermoelectric materials

Bismuth telluride (Bi2Te3) and its alloys are among the most widely used thermoelectric materials due to their high efficiency at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. They are commonly used in cooling applications and low-temperature power generation. Research focuses on improving their figure of merit (ZT) through nanostructuring and compositional optimization.- Bismuth telluride-based thermoelectric materials: Bismuth telluride (Bi2Te3) and its alloys are among the most widely used thermoelectric materials due to their high efficiency at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. They are commonly used in cooling applications and low-temperature power generation. Research focuses on improving their figure of merit (ZT) through nanostructuring and compositional optimization.

- Skutterudite and half-Heusler thermoelectric compounds: Skutterudites and half-Heusler compounds represent important classes of mid to high-temperature thermoelectric materials. These materials feature complex crystal structures that provide naturally low thermal conductivity while maintaining good electrical properties. They can be filled with guest atoms (for skutterudites) or precisely tuned through elemental substitution (for half-Heuslers) to optimize their thermoelectric performance for power generation applications.

- Organic and flexible thermoelectric materials: Organic thermoelectric materials offer advantages of flexibility, low cost, and environmental friendliness compared to traditional inorganic materials. These include conducting polymers and organic-inorganic composites that can be processed using solution-based techniques. Recent developments focus on improving their inherently low thermal conductivity while enhancing electrical conductivity through doping and nanostructuring, making them suitable for wearable thermoelectric generators and flexible electronic applications.

- Nanostructured thermoelectric materials: Nanostructuring has emerged as a powerful approach to enhance thermoelectric performance by reducing thermal conductivity while preserving electrical properties. This includes quantum dots, nanowires, thin films, and superlattice structures that create phonon scattering interfaces. These materials exploit quantum confinement effects and boundary scattering to achieve higher ZT values than their bulk counterparts, enabling more efficient energy conversion for both cooling and power generation applications.

- Thermoelectric device structures and fabrication methods: Advanced fabrication techniques and device architectures are crucial for translating thermoelectric material properties into practical devices. This includes methods for creating efficient p-n junctions, minimizing contact resistance, and optimizing leg geometries. Novel approaches include printing technologies for flexible devices, segmented legs using different materials optimized for specific temperature ranges, and integrated circuit compatible fabrication processes that enable miniaturization and mass production of thermoelectric modules.

02 Skutterudite and half-Heusler thermoelectric compounds

Skutterudites and half-Heusler compounds represent important classes of mid to high-temperature thermoelectric materials. These materials feature complex crystal structures that provide naturally low thermal conductivity while maintaining good electrical properties. They can be filled with guest atoms (for skutterudites) or precisely tuned through elemental substitution (for half-Heuslers) to optimize their thermoelectric performance for power generation applications.Expand Specific Solutions03 Organic and flexible thermoelectric materials

Organic and polymer-based thermoelectric materials offer advantages of flexibility, low cost, and environmental friendliness. These materials can be processed using solution-based techniques and are suitable for wearable or conformal energy harvesting applications. Recent developments focus on improving the inherently low thermal conductivity of these materials while enhancing their electrical conductivity through various doping strategies and composite formations.Expand Specific Solutions04 Nanostructured thermoelectric materials

Nanostructuring approaches significantly enhance thermoelectric performance by reducing thermal conductivity while preserving electrical properties. These techniques include creating quantum dots, nanowires, thin films, and superlattice structures. The introduction of nanoscale interfaces increases phonon scattering, leading to reduced thermal conductivity. Various fabrication methods such as ball milling, hot pressing, and epitaxial growth are employed to create these nanostructured thermoelectric materials.Expand Specific Solutions05 Thermoelectric device structures and modules

Innovations in thermoelectric device structures focus on optimizing the arrangement and connection of thermoelectric materials to maximize power output or cooling efficiency. These include segmented legs, cascaded structures, and thin-film configurations. Advanced manufacturing techniques allow for miniaturization and integration with other electronic components. Module designs address thermal management, electrical contact resistance, and mechanical stability to enhance overall system performance and durability.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectrics

Thermoelectric materials for low-power remote sensor networks are gaining traction in an emerging market characterized by rapid technological advancement. The industry is in its growth phase, with market size projected to expand significantly due to increasing IoT applications and demand for self-powered sensors. Technologically, companies like Phononic, Alphabet Energy, and Laird Thermal Systems are leading commercial development, while research institutions such as California Institute of Technology, Max Planck Society, and Samsung Electronics are advancing fundamental materials science. Academic-industrial collaborations between universities (Columbia, Zhejiang) and corporations (DENSO, Corning) are accelerating innovation in material efficiency and manufacturing scalability. The competitive landscape features both established electronics manufacturers and specialized thermoelectric startups, with increasing patent activity indicating growing market maturity.

Phononic, Inc.

Technical Solution: Phononic has developed proprietary thermoelectric materials and system designs specifically optimized for low-power remote sensor networks. Their SilverCore™ technology utilizes bismuth telluride-based semiconductor materials with nano-structured interfaces that significantly enhance the Seebeck coefficient while reducing thermal conductivity. This approach achieves ZT values exceeding 1.5 at room temperature, approximately 50% higher than conventional materials. Phononic's solid-state energy harvesting modules incorporate advanced thermal management techniques including vacuum insulation and specialized heat exchangers to maximize temperature differentials across the thermoelectric elements. Their integrated power management circuits optimize energy extraction across varying temperature conditions, enabling continuous operation of wireless sensors with as little as 2°C temperature differential between ambient environments.

Strengths: Industry-leading ZT values in commercial products; highly integrated solutions with power management; scalable manufacturing process. Weaknesses: Higher cost compared to conventional solutions; performance degradation in extreme temperature environments; requires careful thermal interface management for optimal performance.

Alphabet Energy, Inc.

Technical Solution: Alphabet Energy has pioneered the development of silicon nanowire-based thermoelectric materials specifically designed for low-power remote sensor networks. Their proprietary PowerBlocks™ technology leverages CMOS-compatible manufacturing processes to create highly efficient thermoelectric generators that can operate with temperature differentials as low as 5°C. The company's approach involves precisely controlled doping of silicon nanowires to optimize carrier concentration and mobility, resulting in significantly improved power factors compared to bulk silicon. Alphabet's modular design allows for customization based on specific application requirements, with their latest generation achieving power densities of up to 1mW/cm² at a 10°C temperature differential. Their integrated energy harvesting systems incorporate advanced thermal management and power conditioning circuits that enable direct integration with wireless sensor nodes, eliminating the need for battery replacement in remote deployments.

Strengths: Silicon-based technology leverages existing semiconductor manufacturing infrastructure; highly scalable production; compatible with IoT sensor form factors. Weaknesses: Lower ZT values compared to some exotic materials; performance limitations in very low temperature differential environments; higher initial implementation costs compared to battery-powered solutions.

Key Patents and Research Breakthroughs in Thermoelectric Materials

Thermoelectric power source utilizing ambient energy harvesting for remote sensing and transmitting

PatentActiveUS7834263B2

Innovation

- A method and apparatus that harness and convert ambient temperature differences in the environment into electrical energy using thermoelectric devices, amplifying temperature gradients through means like heat pipes to generate power for extended periods.

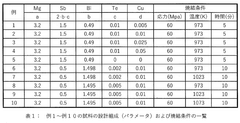

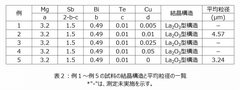

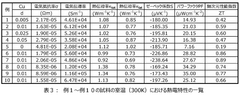

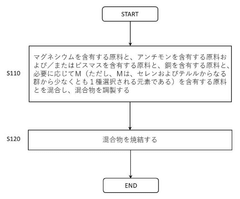

Thermoelectric material, method for proudcing same, and thermoelectric power generation element

PatentWO2022054577A1

Innovation

- A thermoelectric material composition of magnesium (Mg), antimony (Sb), bismuth (Bi), and copper (Cu), optionally with selenium (Se) or tellurium (Te), optimized with specific parameters to enhance electrical conductivity and reduce thermal conductivity, forming an n-type material with improved figure of merit, suitable for thermoelectric power generation elements.

Environmental Impact and Sustainability of Thermoelectric Materials

The environmental impact of thermoelectric materials in low-power remote sensor networks represents a critical consideration as these technologies gain wider adoption. Traditional thermoelectric materials often contain toxic or rare elements such as tellurium, bismuth, and lead, raising significant environmental concerns regarding their extraction, processing, and eventual disposal. Mining operations for these elements frequently result in habitat destruction, water pollution, and substantial carbon emissions, contradicting the sustainability goals that remote sensing networks often aim to support.

Recent advancements have focused on developing more environmentally friendly alternatives using abundant, non-toxic elements. Silicon-germanium alloys, magnesium silicide, and organic thermoelectric materials offer promising alternatives with reduced environmental footprints. These materials can be synthesized through less energy-intensive processes and contain fewer hazardous substances, thereby minimizing environmental impact throughout their lifecycle.

Life cycle assessment (LCA) studies indicate that thermoelectric generators in remote sensor networks can achieve carbon payback periods of 1-3 years depending on deployment conditions and material composition. This represents a significant improvement over earlier generations of materials which often required 5-7 years to offset their production emissions. The extended operational lifetime of modern thermoelectric materials—often exceeding 10 years without maintenance—further enhances their sustainability profile.

Recyclability presents both challenges and opportunities in thermoelectric material sustainability. While complex alloys and compounds can be difficult to separate and reclaim, emerging design approaches incorporate modular construction and material selection specifically optimized for end-of-life recovery. Research indicates that up to 85% of certain thermoelectric materials can be recovered and repurposed, substantially reducing waste and resource consumption.

The energy autonomy provided by thermoelectric generators in remote sensor networks delivers additional environmental benefits by eliminating the need for battery replacement and associated transportation emissions. In wilderness monitoring applications, this reduces human intrusion into sensitive ecosystems while maintaining continuous environmental data collection. Studies estimate that a network of 1,000 thermoelectric-powered sensors can prevent approximately 2-3 tons of battery waste over a decade of operation.

Manufacturing innovations, including additive manufacturing techniques and green chemistry approaches, are progressively reducing the environmental impact of thermoelectric material production. These advances have decreased processing energy requirements by approximately 30% over the past five years while simultaneously reducing hazardous waste generation by similar margins.

Recent advancements have focused on developing more environmentally friendly alternatives using abundant, non-toxic elements. Silicon-germanium alloys, magnesium silicide, and organic thermoelectric materials offer promising alternatives with reduced environmental footprints. These materials can be synthesized through less energy-intensive processes and contain fewer hazardous substances, thereby minimizing environmental impact throughout their lifecycle.

Life cycle assessment (LCA) studies indicate that thermoelectric generators in remote sensor networks can achieve carbon payback periods of 1-3 years depending on deployment conditions and material composition. This represents a significant improvement over earlier generations of materials which often required 5-7 years to offset their production emissions. The extended operational lifetime of modern thermoelectric materials—often exceeding 10 years without maintenance—further enhances their sustainability profile.

Recyclability presents both challenges and opportunities in thermoelectric material sustainability. While complex alloys and compounds can be difficult to separate and reclaim, emerging design approaches incorporate modular construction and material selection specifically optimized for end-of-life recovery. Research indicates that up to 85% of certain thermoelectric materials can be recovered and repurposed, substantially reducing waste and resource consumption.

The energy autonomy provided by thermoelectric generators in remote sensor networks delivers additional environmental benefits by eliminating the need for battery replacement and associated transportation emissions. In wilderness monitoring applications, this reduces human intrusion into sensitive ecosystems while maintaining continuous environmental data collection. Studies estimate that a network of 1,000 thermoelectric-powered sensors can prevent approximately 2-3 tons of battery waste over a decade of operation.

Manufacturing innovations, including additive manufacturing techniques and green chemistry approaches, are progressively reducing the environmental impact of thermoelectric material production. These advances have decreased processing energy requirements by approximately 30% over the past five years while simultaneously reducing hazardous waste generation by similar margins.

Integration Strategies for Thermoelectric Powering in Sensor Networks

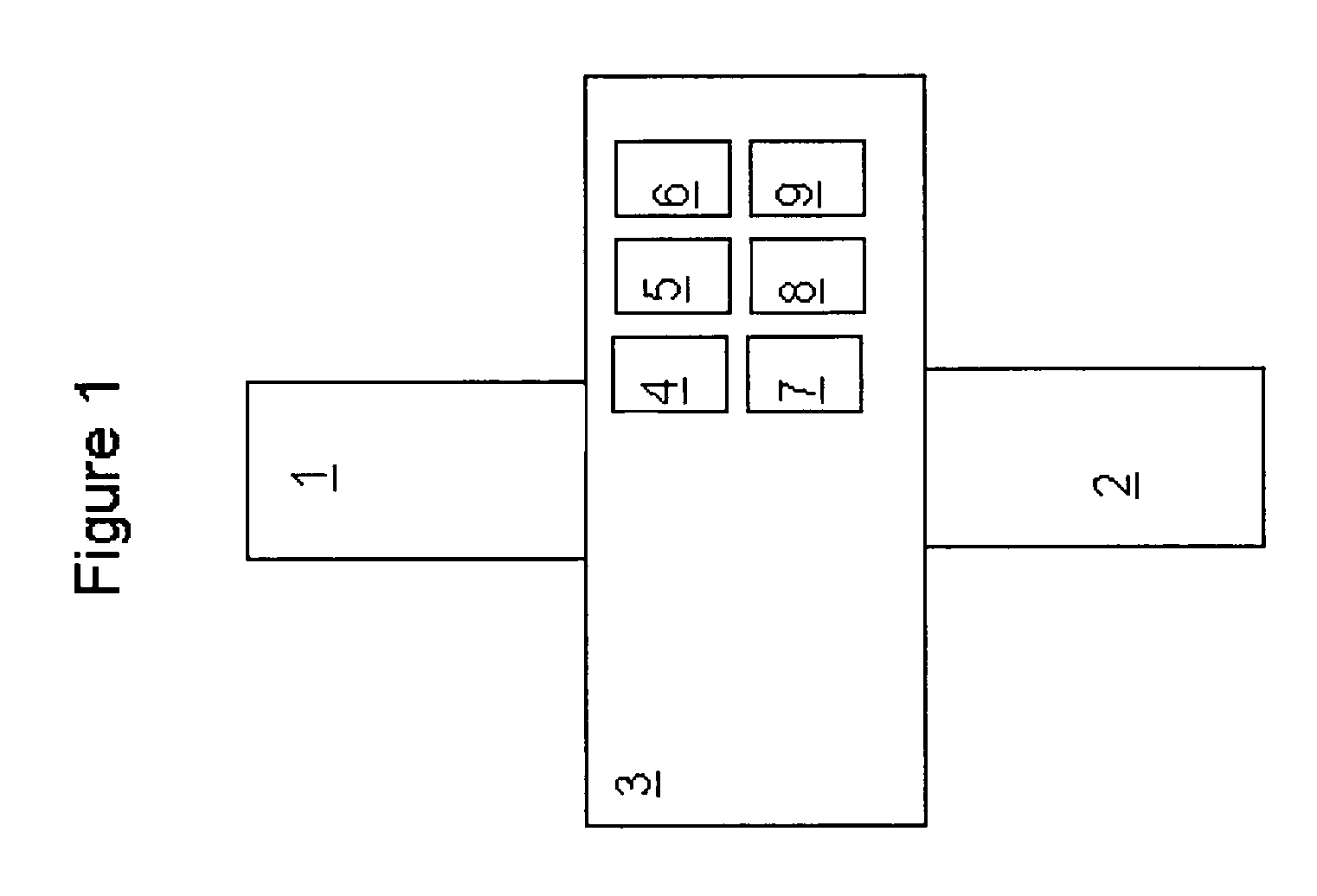

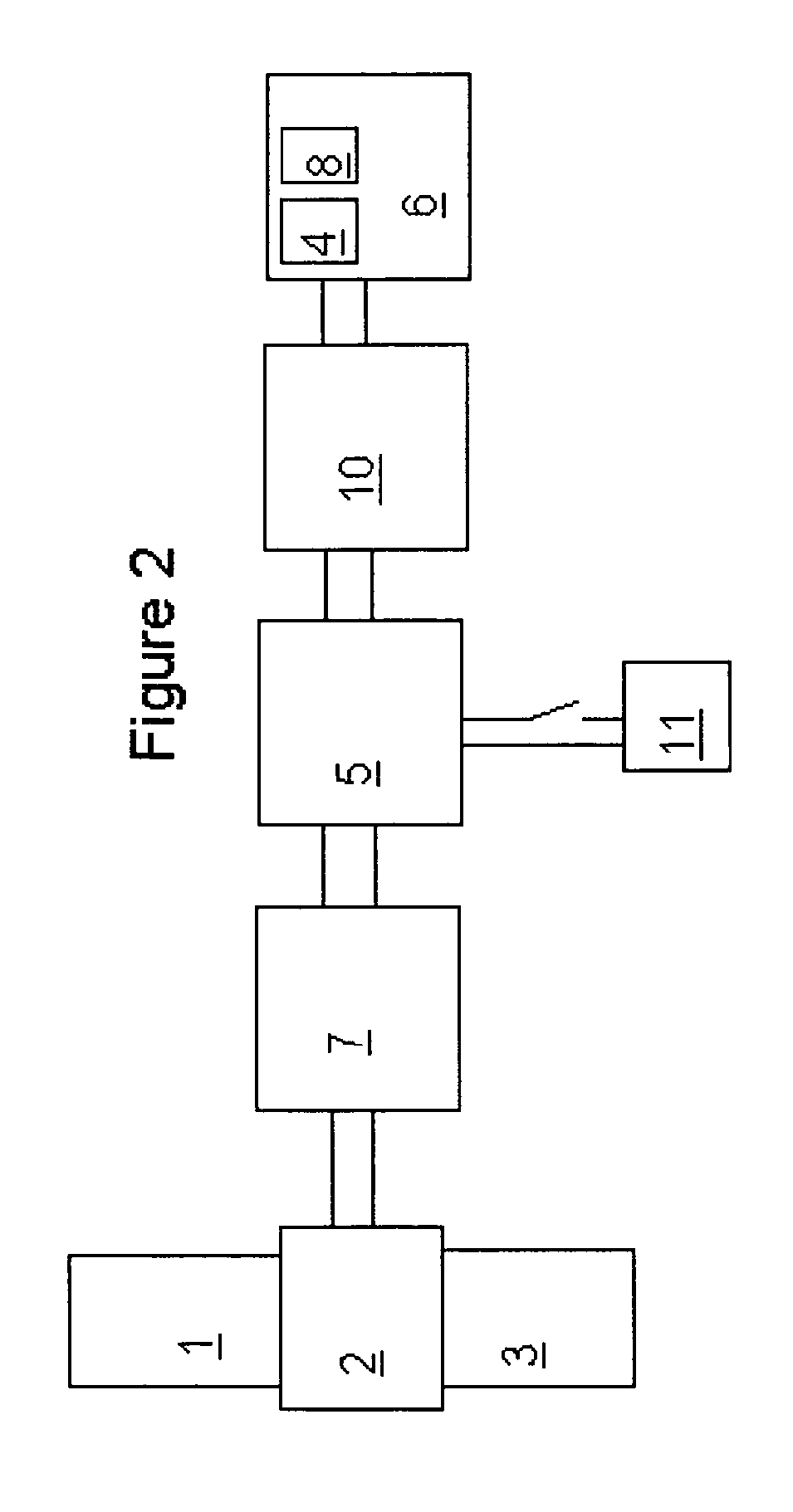

The integration of thermoelectric generators (TEGs) into low-power remote sensor networks requires careful consideration of multiple design factors to ensure optimal performance. Direct attachment methods, where TEGs are physically connected to heat sources, represent the most common integration approach. This technique maximizes thermal contact and efficiency but necessitates careful mechanical design to maintain consistent thermal interfaces over time, particularly in environments with temperature cycling or vibration.

Substrate-level integration offers an alternative approach where TEGs are embedded directly into circuit boards or sensor housings. This method reduces overall system size and eliminates connection points that could fail, but introduces manufacturing complexity and potential thermal management challenges. Recent advances in flexible thermoelectric materials have enabled new form factors, allowing TEGs to conform to curved surfaces or be integrated into wearable devices.

Thermal management represents a critical aspect of TEG integration. Effective heat sinking is essential to maintain temperature differentials, with passive solutions preferred for remote applications due to their reliability and zero power consumption. Innovative approaches include phase-change materials that can temporarily store excess heat and specialized heat spreaders that distribute thermal energy across larger surface areas to improve efficiency.

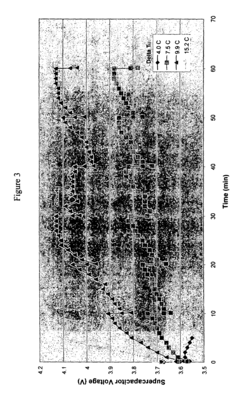

Electrical integration considerations include voltage conditioning circuits to handle the variable output of TEGs under fluctuating temperature conditions. Maximum power point tracking (MPPT) circuits have been adapted from solar energy systems to optimize power extraction from thermoelectric generators, with specialized low-power versions developed specifically for sensor network applications. Energy storage elements such as supercapacitors or thin-film batteries are typically incorporated to buffer energy harvesting variations.

Modular integration frameworks have emerged as a promising approach, where standardized TEG modules can be easily incorporated into various sensor platforms. These frameworks often include pre-engineered thermal and electrical interfaces that simplify integration while maintaining performance. Companies like Laird Thermal Systems and Analog Devices have developed reference designs specifically for sensor network applications that incorporate both the thermal and electrical aspects of TEG integration.

Hybrid energy harvesting systems represent an advanced integration strategy, combining thermoelectric generation with other harvesting technologies such as photovoltaic or piezoelectric systems. These complementary approaches can overcome the limitations of individual harvesting methods and provide more consistent power availability. The control circuitry for such systems must intelligently manage multiple energy inputs while maintaining overall system efficiency.

Substrate-level integration offers an alternative approach where TEGs are embedded directly into circuit boards or sensor housings. This method reduces overall system size and eliminates connection points that could fail, but introduces manufacturing complexity and potential thermal management challenges. Recent advances in flexible thermoelectric materials have enabled new form factors, allowing TEGs to conform to curved surfaces or be integrated into wearable devices.

Thermal management represents a critical aspect of TEG integration. Effective heat sinking is essential to maintain temperature differentials, with passive solutions preferred for remote applications due to their reliability and zero power consumption. Innovative approaches include phase-change materials that can temporarily store excess heat and specialized heat spreaders that distribute thermal energy across larger surface areas to improve efficiency.

Electrical integration considerations include voltage conditioning circuits to handle the variable output of TEGs under fluctuating temperature conditions. Maximum power point tracking (MPPT) circuits have been adapted from solar energy systems to optimize power extraction from thermoelectric generators, with specialized low-power versions developed specifically for sensor network applications. Energy storage elements such as supercapacitors or thin-film batteries are typically incorporated to buffer energy harvesting variations.

Modular integration frameworks have emerged as a promising approach, where standardized TEG modules can be easily incorporated into various sensor platforms. These frameworks often include pre-engineered thermal and electrical interfaces that simplify integration while maintaining performance. Companies like Laird Thermal Systems and Analog Devices have developed reference designs specifically for sensor network applications that incorporate both the thermal and electrical aspects of TEG integration.

Hybrid energy harvesting systems represent an advanced integration strategy, combining thermoelectric generation with other harvesting technologies such as photovoltaic or piezoelectric systems. These complementary approaches can overcome the limitations of individual harvesting methods and provide more consistent power availability. The control circuitry for such systems must intelligently manage multiple energy inputs while maintaining overall system efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!