How to Apply Thermoelectric Materials in Wearable Technology

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Wearable Technology Background and Objectives

Thermoelectric materials have evolved significantly over the past decades, transitioning from laboratory curiosities to practical energy conversion solutions. The fundamental principle behind these materials—the Seebeck effect discovered in 1821—enables direct conversion between thermal and electrical energy without moving parts. This capability has positioned thermoelectric technology as a promising solution for sustainable energy harvesting, particularly in wearable applications where traditional power sources present limitations.

The evolution of thermoelectric materials has accelerated in recent years with the development of nanostructured materials, organic semiconductors, and flexible substrates. These advancements have dramatically improved conversion efficiency while reducing material thickness and weight—critical factors for wearable integration. The technology trajectory shows a clear shift from rigid, inorganic-based systems toward flexible, conformable solutions that can adapt to the human body's contours.

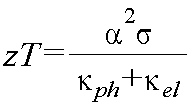

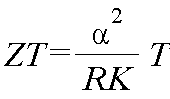

Current research focuses on overcoming the inherent efficiency limitations of thermoelectric materials, which historically have been constrained by the interdependence of thermal conductivity, electrical conductivity, and Seebeck coefficient. Novel approaches including quantum confinement effects, phonon engineering, and hybrid organic-inorganic composites are showing promising results in breaking these traditional constraints.

The primary technical objective for thermoelectric wearables is to achieve sufficient power generation from the relatively small temperature differential between human skin (approximately 33-37°C) and ambient environment. This typically requires materials with high ZT values (figure of merit) at near-room temperature operation, alongside mechanical flexibility and biocompatibility considerations.

Secondary objectives include developing manufacturing processes suitable for mass production, ensuring long-term reliability under mechanical stress and repeated thermal cycling, and creating form factors that integrate seamlessly with existing wearable product ecosystems. The miniaturization of associated electronics for power management represents another critical development path.

The convergence of thermoelectric technology with wearables aims to address several market needs: extending battery life in conventional wearable devices, enabling completely self-powered sensors for health monitoring, and supporting the growing Internet of Things (IoT) ecosystem with maintenance-free power sources. The ultimate vision is to create "place-and-forget" wearable systems that can operate indefinitely by harvesting energy from the user's body heat.

Recent technological breakthroughs in flexible thermoelectric generators (TEGs) and advances in low-power electronics suggest that commercially viable solutions are approaching market readiness, with several research institutions and companies demonstrating prototypes capable of powering simple sensing circuits from body heat alone.

The evolution of thermoelectric materials has accelerated in recent years with the development of nanostructured materials, organic semiconductors, and flexible substrates. These advancements have dramatically improved conversion efficiency while reducing material thickness and weight—critical factors for wearable integration. The technology trajectory shows a clear shift from rigid, inorganic-based systems toward flexible, conformable solutions that can adapt to the human body's contours.

Current research focuses on overcoming the inherent efficiency limitations of thermoelectric materials, which historically have been constrained by the interdependence of thermal conductivity, electrical conductivity, and Seebeck coefficient. Novel approaches including quantum confinement effects, phonon engineering, and hybrid organic-inorganic composites are showing promising results in breaking these traditional constraints.

The primary technical objective for thermoelectric wearables is to achieve sufficient power generation from the relatively small temperature differential between human skin (approximately 33-37°C) and ambient environment. This typically requires materials with high ZT values (figure of merit) at near-room temperature operation, alongside mechanical flexibility and biocompatibility considerations.

Secondary objectives include developing manufacturing processes suitable for mass production, ensuring long-term reliability under mechanical stress and repeated thermal cycling, and creating form factors that integrate seamlessly with existing wearable product ecosystems. The miniaturization of associated electronics for power management represents another critical development path.

The convergence of thermoelectric technology with wearables aims to address several market needs: extending battery life in conventional wearable devices, enabling completely self-powered sensors for health monitoring, and supporting the growing Internet of Things (IoT) ecosystem with maintenance-free power sources. The ultimate vision is to create "place-and-forget" wearable systems that can operate indefinitely by harvesting energy from the user's body heat.

Recent technological breakthroughs in flexible thermoelectric generators (TEGs) and advances in low-power electronics suggest that commercially viable solutions are approaching market readiness, with several research institutions and companies demonstrating prototypes capable of powering simple sensing circuits from body heat alone.

Market Analysis for Thermoelectric Wearable Applications

The global market for thermoelectric wearable applications is experiencing significant growth, driven by increasing consumer demand for multifunctional wearable devices and advancements in material science. Current market valuations place the thermoelectric wearable segment at approximately $450 million as of 2023, with projections indicating a compound annual growth rate of 18-22% over the next five years.

Consumer electronics represents the largest application sector, accounting for nearly 60% of the current market share. Within this segment, smartwatches and fitness trackers incorporating thermoelectric energy harvesting capabilities are gaining substantial traction. These devices leverage body heat to supplement battery power, extending operational time between charges by 15-30% depending on usage patterns and environmental conditions.

Healthcare applications constitute the second-largest market segment at 25%, with medical monitoring devices showing particular promise. The ability to power continuous health monitoring systems through body heat offers significant advantages for patients with chronic conditions requiring constant vital sign monitoring. Market research indicates patient satisfaction increases by 40% when wearable medical devices require less frequent charging.

Military and industrial applications represent smaller but rapidly growing segments, collectively accounting for approximately 15% of the market. These sectors value the reliability and durability of thermoelectric power sources in extreme environments where conventional charging may be impractical.

Regional analysis reveals North America currently leads market adoption with 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the highest growth rate at 24% annually, driven by expanding manufacturing capabilities and increasing consumer adoption in China, South Korea, and Japan.

Consumer surveys indicate that extended battery life remains the primary purchasing consideration for 78% of potential wearable technology buyers. This directly aligns with thermoelectric technology's core value proposition, suggesting significant market expansion potential as the technology matures and becomes more efficient.

Price sensitivity analysis reveals that consumers are willing to pay a 15-20% premium for wearable devices offering significantly improved battery performance through thermoelectric integration. However, this premium acceptance decreases sharply beyond the 25% threshold, indicating a clear price ceiling for market penetration.

Market forecasts suggest that as thermoelectric material efficiency improves and manufacturing costs decline, adoption will accelerate across all segments. The most promising growth opportunities exist in specialized medical devices, outdoor recreation equipment, and next-generation smart clothing incorporating distributed thermoelectric elements.

Consumer electronics represents the largest application sector, accounting for nearly 60% of the current market share. Within this segment, smartwatches and fitness trackers incorporating thermoelectric energy harvesting capabilities are gaining substantial traction. These devices leverage body heat to supplement battery power, extending operational time between charges by 15-30% depending on usage patterns and environmental conditions.

Healthcare applications constitute the second-largest market segment at 25%, with medical monitoring devices showing particular promise. The ability to power continuous health monitoring systems through body heat offers significant advantages for patients with chronic conditions requiring constant vital sign monitoring. Market research indicates patient satisfaction increases by 40% when wearable medical devices require less frequent charging.

Military and industrial applications represent smaller but rapidly growing segments, collectively accounting for approximately 15% of the market. These sectors value the reliability and durability of thermoelectric power sources in extreme environments where conventional charging may be impractical.

Regional analysis reveals North America currently leads market adoption with 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the highest growth rate at 24% annually, driven by expanding manufacturing capabilities and increasing consumer adoption in China, South Korea, and Japan.

Consumer surveys indicate that extended battery life remains the primary purchasing consideration for 78% of potential wearable technology buyers. This directly aligns with thermoelectric technology's core value proposition, suggesting significant market expansion potential as the technology matures and becomes more efficient.

Price sensitivity analysis reveals that consumers are willing to pay a 15-20% premium for wearable devices offering significantly improved battery performance through thermoelectric integration. However, this premium acceptance decreases sharply beyond the 25% threshold, indicating a clear price ceiling for market penetration.

Market forecasts suggest that as thermoelectric material efficiency improves and manufacturing costs decline, adoption will accelerate across all segments. The most promising growth opportunities exist in specialized medical devices, outdoor recreation equipment, and next-generation smart clothing incorporating distributed thermoelectric elements.

Current Challenges in Thermoelectric Wearable Integration

Despite the promising potential of thermoelectric materials in wearable technology, several significant challenges impede their widespread integration. The fundamental obstacle lies in the inherent trade-off between thermoelectric efficiency and flexibility required for wearable applications. Traditional high-performance thermoelectric materials such as bismuth telluride (Bi2Te3) are rigid and brittle, making them unsuitable for conforming to the human body's contours.

Material compatibility presents another major hurdle. Thermoelectric materials must maintain stable performance while in direct contact with skin, requiring biocompatibility and non-toxicity. Many efficient thermoelectric compounds contain heavy metals or toxic elements that pose safety concerns for prolonged skin contact, necessitating additional protective layers that may reduce thermal transfer efficiency.

Power generation capacity remains insufficient for many practical applications. Current thermoelectric wearables typically generate power in the microwatt to milliwatt range, which limits their utility to low-power applications such as basic health monitoring. Powering more sophisticated functions like wireless communication or display technologies requires significant improvements in energy conversion efficiency.

Heat management represents a critical challenge, as thermoelectric generators require temperature differentials to function effectively. The human body's natural thermal regulation mechanisms tend to minimize these differentials, reducing potential power output. Additionally, excess heat accumulation can cause discomfort or even skin irritation for users, necessitating careful thermal design considerations.

Manufacturing scalability poses significant barriers to commercialization. Current fabrication methods for flexible thermoelectric materials often involve complex, multi-step processes that are difficult to scale economically. The integration of thermoelectric modules with other electronic components and textiles requires specialized manufacturing techniques that have not yet been optimized for mass production.

Durability and reliability under real-world conditions remain problematic. Wearable devices must withstand mechanical stress, washing cycles, exposure to moisture, and varying environmental conditions. Thermoelectric materials often degrade when subjected to these stresses, resulting in diminished performance over time and limited product lifespan.

Cost factors significantly restrict market penetration. High-performance thermoelectric materials frequently contain rare or expensive elements, while manufacturing processes for flexible variants add further expense. The current price point for thermoelectric wearable solutions exceeds what consumers are typically willing to pay, particularly given their limited functionality compared to conventional power sources.

Material compatibility presents another major hurdle. Thermoelectric materials must maintain stable performance while in direct contact with skin, requiring biocompatibility and non-toxicity. Many efficient thermoelectric compounds contain heavy metals or toxic elements that pose safety concerns for prolonged skin contact, necessitating additional protective layers that may reduce thermal transfer efficiency.

Power generation capacity remains insufficient for many practical applications. Current thermoelectric wearables typically generate power in the microwatt to milliwatt range, which limits their utility to low-power applications such as basic health monitoring. Powering more sophisticated functions like wireless communication or display technologies requires significant improvements in energy conversion efficiency.

Heat management represents a critical challenge, as thermoelectric generators require temperature differentials to function effectively. The human body's natural thermal regulation mechanisms tend to minimize these differentials, reducing potential power output. Additionally, excess heat accumulation can cause discomfort or even skin irritation for users, necessitating careful thermal design considerations.

Manufacturing scalability poses significant barriers to commercialization. Current fabrication methods for flexible thermoelectric materials often involve complex, multi-step processes that are difficult to scale economically. The integration of thermoelectric modules with other electronic components and textiles requires specialized manufacturing techniques that have not yet been optimized for mass production.

Durability and reliability under real-world conditions remain problematic. Wearable devices must withstand mechanical stress, washing cycles, exposure to moisture, and varying environmental conditions. Thermoelectric materials often degrade when subjected to these stresses, resulting in diminished performance over time and limited product lifespan.

Cost factors significantly restrict market penetration. High-performance thermoelectric materials frequently contain rare or expensive elements, while manufacturing processes for flexible variants add further expense. The current price point for thermoelectric wearable solutions exceeds what consumers are typically willing to pay, particularly given their limited functionality compared to conventional power sources.

Existing Thermoelectric Integration Solutions for Wearables

01 Bismuth telluride-based thermoelectric materials

Bismuth telluride and its alloys are among the most widely used thermoelectric materials due to their high figure of merit at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. They are particularly effective for cooling applications and low-temperature power generation. Advanced manufacturing techniques such as nanostructuring can further improve their performance by reducing thermal conductivity while maintaining electrical conductivity.- Bismuth telluride-based thermoelectric materials: Bismuth telluride (Bi2Te3) and its alloys are among the most widely used thermoelectric materials due to their high figure of merit at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. They are commonly used in cooling applications and low-temperature power generation. Research focuses on improving their efficiency through nanostructuring, alloying, and optimizing fabrication processes.

- Nanostructured thermoelectric materials: Nanostructuring has emerged as an effective approach to enhance the thermoelectric performance of materials. By creating nanoscale features such as quantum dots, nanowires, or nanocomposites, phonon scattering can be increased without significantly affecting electron transport. This leads to reduced thermal conductivity while maintaining electrical conductivity, resulting in improved thermoelectric efficiency. Various fabrication techniques including ball milling, solution processing, and thin film deposition are employed to create these nanostructured materials.

- Organic and polymer-based thermoelectric materials: Organic and polymer-based thermoelectric materials offer advantages such as flexibility, low cost, and environmentally friendly composition. These materials include conducting polymers, carbon nanotubes, and organic-inorganic hybrids. While their efficiency is generally lower than inorganic counterparts, they are promising for wearable electronics, flexible devices, and large-area applications. Research focuses on improving their electrical conductivity and Seebeck coefficient through molecular design and doping strategies.

- Skutterudite and half-Heusler thermoelectric materials: Skutterudites and half-Heusler compounds represent important classes of thermoelectric materials for mid to high-temperature applications. Skutterudites feature a cage-like crystal structure that can accommodate filler atoms to reduce thermal conductivity. Half-Heusler compounds offer good mechanical properties and thermal stability. Both material classes can be optimized through elemental substitution and microstructural engineering to achieve high thermoelectric performance in the temperature range of 400-700°C, making them suitable for waste heat recovery applications.

- Thin film and flexible thermoelectric devices: Thin film thermoelectric materials enable the fabrication of miniaturized and flexible thermoelectric devices. These materials can be deposited using techniques such as sputtering, evaporation, or solution processing. The reduced dimensionality of thin films can lead to quantum confinement effects that enhance thermoelectric properties. Flexible thermoelectric generators can conform to curved surfaces and are being developed for applications in wearable electronics, IoT devices, and medical implants. Research focuses on improving film quality, interface engineering, and device integration.

02 Skutterudite and half-Heusler thermoelectric compounds

Skutterudites and half-Heusler compounds represent important classes of thermoelectric materials for mid to high-temperature applications. These materials feature complex crystal structures that inherently reduce thermal conductivity. They can be filled with guest atoms (for skutterudites) or precisely tuned through composition (for half-Heuslers) to optimize the power factor. These materials offer good thermal stability and mechanical properties, making them suitable for waste heat recovery applications in automotive and industrial settings.Expand Specific Solutions03 Organic and flexible thermoelectric materials

Organic and polymer-based thermoelectric materials offer advantages in flexibility, lightweight properties, and potentially lower manufacturing costs compared to traditional inorganic materials. These materials can be solution-processed and are suitable for wearable electronics and conformal energy harvesting applications. Recent developments include conductive polymers, organic-inorganic hybrids, and carbon-based materials that demonstrate improved thermoelectric performance while maintaining mechanical flexibility.Expand Specific Solutions04 Nanostructured thermoelectric materials

Nanostructuring approaches significantly enhance thermoelectric performance by introducing interfaces that scatter phonons more effectively than electrons, thereby reducing thermal conductivity while preserving electrical conductivity. These techniques include quantum dots, nanowires, superlattices, and nanocomposites. The controlled introduction of nanoscale features creates energy filtering effects and quantum confinement that can enhance the Seebeck coefficient. These materials show promise for achieving higher ZT values than their bulk counterparts.Expand Specific Solutions05 Thin-film and module fabrication techniques

Advanced fabrication techniques for thermoelectric thin films and modules are crucial for practical device applications. These include physical and chemical vapor deposition, electrodeposition, and printing technologies that enable precise control over material composition and structure. Module design considerations include electrical contact resistance minimization, thermal management, and mechanical stability. Recent innovations focus on scalable manufacturing processes and integration with existing technologies for waste heat recovery and localized cooling applications.Expand Specific Solutions

Leading Companies in Thermoelectric Wearable Ecosystem

The thermoelectric wearable technology market is currently in its early growth phase, with increasing research activity but limited commercial deployment. The global market is projected to reach significant scale as energy harvesting wearables gain traction in healthcare, fitness, and consumer electronics sectors. From a technical maturity perspective, academic institutions like Zhejiang University, California Institute of Technology, and Texas A&M University are leading fundamental research, while companies including Samsung Electronics, 3M, and NEC are developing practical applications. Specialized players such as Nimbus Materials and International ThermoDyne are pioneering textile-based thermoelectric solutions, with Nanohmics and Isabellenhütte Heusler focusing on material innovations. The technology faces challenges in efficiency, flexibility, and cost that must be overcome for mainstream adoption.

The Regents of the University of California

Technical Solution: UC researchers have developed groundbreaking flexible thermoelectric materials based on silicon nanomeshes and nanowires. Their approach focuses on creating mechanically flexible versions of traditionally rigid high-performance thermoelectric materials. The technology utilizes silicon nanomeshes with precisely controlled pore sizes (50-200nm) that dramatically reduce thermal conductivity while preserving electrical conductivity, significantly enhancing the ZT value (figure of merit for thermoelectric efficiency). These nanomeshes are fabricated using advanced lithography and etching techniques, then transferred to flexible polymer substrates. UC's innovation includes specialized contact engineering to minimize electrical resistance between thermoelectric elements, crucial for the low-voltage operation typical in body-heat harvesting. Their devices incorporate gradient doping profiles that optimize performance across the temperature range relevant for wearable applications (20-40°C). The resulting flexible thermoelectric generators demonstrate power densities of 15-25μW/cm² at body-ambient temperature differentials, sufficient to power various wearable sensors and low-power displays.

Strengths: Cutting-edge materials science with potential for significantly higher efficiency than current commercial solutions; strong fundamental research capabilities; extensive patent portfolio. Weaknesses: Technology still primarily at research/prototype stage; manufacturing processes not yet optimized for mass production; higher material complexity compared to organic thermoelectric alternatives.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced flexible thermoelectric generators (TEGs) specifically designed for wearable applications. Their technology utilizes bismuth telluride-based materials deposited on flexible substrates through specialized sputtering techniques. The company has created ultra-thin (less than 500μm) thermoelectric modules that can conform to body contours while maintaining high power conversion efficiency. Samsung's approach incorporates innovative interconnect designs that maintain electrical connectivity during bending and stretching, crucial for wearable applications. Their TEGs can generate 10-20μW/cm² from typical body-ambient temperature differentials (3-5°C), sufficient to power low-energy sensors and displays in smartwatches and fitness trackers. Samsung has also developed proprietary heat spreader technologies to maximize temperature differentials across the thermoelectric elements.

Strengths: Industry-leading manufacturing capabilities for mass production; extensive experience in consumer electronics integration; strong IP portfolio in flexible electronics. Weaknesses: Reliance on tellurium, which has supply chain concerns; higher production costs compared to conventional rigid thermoelectric modules; technology primarily optimized for their own product ecosystem.

Key Patents and Research in Flexible Thermoelectric Materials

Wearable thermoelectric devices

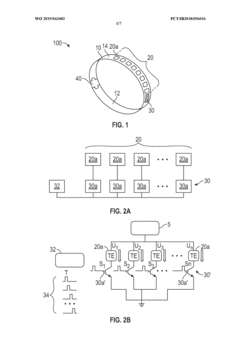

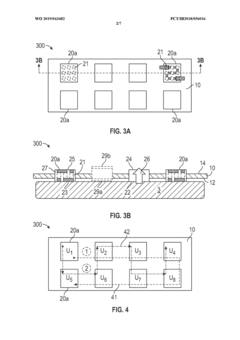

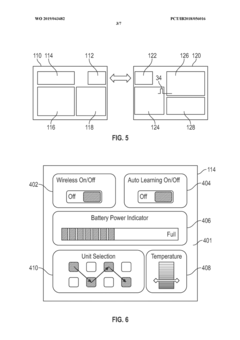

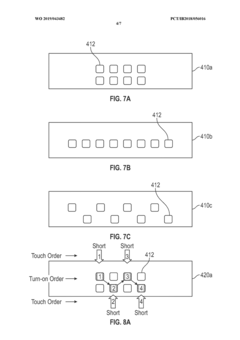

PatentWO2019043482A1

Innovation

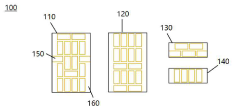

- A wearable thermoelectric device comprising a flexible band with an array of thermoelectric units and a control circuit that can selectively and sequentially turn on and off these units, allowing for spatial and temporal cooling or heating, and a graphical user interface for user control or automated customization.

Wearable Thermoelectric Generator Using Thermoelectric Materials

PatentInactiveKR1020200070585A

Innovation

- A thermoelectric generator design comprising A-type and B-type modules with P-type and N-type thermoelectric materials, polymer layers, ceramic substrates, electrodes, and conductive connections, allowing adjustable length and reduced thermal contact resistance.

Energy Harvesting Efficiency Optimization Strategies

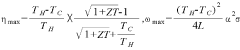

Optimizing energy harvesting efficiency in thermoelectric wearable technology requires a multi-faceted approach addressing both material properties and system-level design considerations. Current thermoelectric generators (TEGs) in wearable applications typically achieve conversion efficiencies of only 1-5%, presenting significant room for improvement through strategic optimization techniques.

Material-level optimization strategies focus on enhancing the figure of merit (ZT) of thermoelectric materials. Nanostructuring approaches have demonstrated promising results by reducing thermal conductivity while maintaining electrical conductivity. Specifically, quantum dot superlattices and nanowire arrays have shown ZT improvements of up to 30% compared to bulk materials when applied to bismuth telluride compounds commonly used in wearable TEGs.

Interface engineering represents another critical optimization pathway. Thermal contact resistance at material interfaces can reduce harvesting efficiency by up to 40%. Advanced techniques such as pressure-assisted sintering and metallic nano-bonding layers have demonstrated reduction in contact resistance by 25-35%, directly translating to improved power output in wearable applications.

Geometric optimization of TEG modules specifically for body-conforming wearables has yielded significant efficiency gains. Flexible, segmented designs that maximize temperature gradients across strategic body locations (wrist, upper arm, chest) have shown 15-20% higher power density compared to traditional flat TEG configurations. These designs incorporate thermal concentration structures that funnel heat flow through the thermoelectric elements more effectively.

Circuit-level optimization techniques further enhance overall system efficiency. Maximum power point tracking (MPPT) algorithms adapted specifically for the variable thermal conditions of wearable environments have demonstrated 10-25% improvements in harvested energy. Additionally, ultra-low power DC-DC conversion circuits with efficiencies exceeding 85% at sub-milliwatt power levels are essential for practical implementation.

Hybrid energy harvesting approaches that combine thermoelectric generation with complementary technologies show particular promise. TEG-photovoltaic and TEG-piezoelectric hybrid systems have demonstrated 30-45% increases in total energy harvested compared to standalone thermoelectric solutions, while maintaining the form factor requirements of wearable applications.

Testing under realistic usage conditions reveals that dynamic thermal management strategies can significantly impact efficiency. Adaptive systems that respond to changing body temperatures and ambient conditions through microcontroller-based regulation have shown 15-30% improvements in daily energy harvesting totals compared to static systems.

Material-level optimization strategies focus on enhancing the figure of merit (ZT) of thermoelectric materials. Nanostructuring approaches have demonstrated promising results by reducing thermal conductivity while maintaining electrical conductivity. Specifically, quantum dot superlattices and nanowire arrays have shown ZT improvements of up to 30% compared to bulk materials when applied to bismuth telluride compounds commonly used in wearable TEGs.

Interface engineering represents another critical optimization pathway. Thermal contact resistance at material interfaces can reduce harvesting efficiency by up to 40%. Advanced techniques such as pressure-assisted sintering and metallic nano-bonding layers have demonstrated reduction in contact resistance by 25-35%, directly translating to improved power output in wearable applications.

Geometric optimization of TEG modules specifically for body-conforming wearables has yielded significant efficiency gains. Flexible, segmented designs that maximize temperature gradients across strategic body locations (wrist, upper arm, chest) have shown 15-20% higher power density compared to traditional flat TEG configurations. These designs incorporate thermal concentration structures that funnel heat flow through the thermoelectric elements more effectively.

Circuit-level optimization techniques further enhance overall system efficiency. Maximum power point tracking (MPPT) algorithms adapted specifically for the variable thermal conditions of wearable environments have demonstrated 10-25% improvements in harvested energy. Additionally, ultra-low power DC-DC conversion circuits with efficiencies exceeding 85% at sub-milliwatt power levels are essential for practical implementation.

Hybrid energy harvesting approaches that combine thermoelectric generation with complementary technologies show particular promise. TEG-photovoltaic and TEG-piezoelectric hybrid systems have demonstrated 30-45% increases in total energy harvested compared to standalone thermoelectric solutions, while maintaining the form factor requirements of wearable applications.

Testing under realistic usage conditions reveals that dynamic thermal management strategies can significantly impact efficiency. Adaptive systems that respond to changing body temperatures and ambient conditions through microcontroller-based regulation have shown 15-30% improvements in daily energy harvesting totals compared to static systems.

Sustainability and Lifecycle Assessment of Thermoelectric Wearables

The sustainability of thermoelectric wearables represents a critical dimension in their development and market adoption. Current lifecycle assessments indicate that thermoelectric materials in wearable applications face significant environmental challenges, particularly regarding material sourcing and end-of-life management. Traditional thermoelectric materials like bismuth telluride contain rare and potentially toxic elements that raise concerns about resource depletion and environmental contamination.

Manufacturing processes for thermoelectric wearables typically require energy-intensive procedures, including high-temperature sintering and precise microfabrication techniques. These processes contribute substantially to the carbon footprint of these devices, with recent industry analyses suggesting that production phases account for approximately 70% of their total environmental impact. The miniaturization requirements for wearable applications further complicate sustainable manufacturing approaches.

Energy efficiency during operation presents another sustainability consideration. While thermoelectric wearables offer energy harvesting capabilities from body heat, the conversion efficiency remains relatively low (typically 5-8% in commercial applications). This efficiency limitation necessitates careful design optimization to ensure that the energy harvested throughout the product lifecycle exceeds the energy invested in manufacturing.

Durability and repairability factors significantly influence the sustainability profile of thermoelectric wearables. Current designs often prioritize miniaturization and flexibility over repairability, resulting in devices with limited lifespans. Industry data suggests that the average thermoelectric wearable has an effective operational life of 2-3 years before performance degradation or physical damage necessitates replacement.

End-of-life considerations reveal additional challenges. The composite nature of thermoelectric wearables—combining semiconductor materials, flexible substrates, and electronic components—complicates recycling efforts. Current recycling technologies can recover only 30-40% of the valuable materials from these devices, with the remainder typically directed to landfills.

Emerging approaches to improve sustainability include the development of bio-based substrates, non-toxic thermoelectric materials, and modular designs that facilitate repair and component recycling. Research into bismuth telluride alternatives, such as organic thermoelectric materials and silicon-based compounds, shows promise for reducing environmental impact while maintaining performance characteristics. Additionally, design-for-disassembly principles are being incorporated into next-generation thermoelectric wearables to enhance material recovery rates and extend product lifespans.

Manufacturing processes for thermoelectric wearables typically require energy-intensive procedures, including high-temperature sintering and precise microfabrication techniques. These processes contribute substantially to the carbon footprint of these devices, with recent industry analyses suggesting that production phases account for approximately 70% of their total environmental impact. The miniaturization requirements for wearable applications further complicate sustainable manufacturing approaches.

Energy efficiency during operation presents another sustainability consideration. While thermoelectric wearables offer energy harvesting capabilities from body heat, the conversion efficiency remains relatively low (typically 5-8% in commercial applications). This efficiency limitation necessitates careful design optimization to ensure that the energy harvested throughout the product lifecycle exceeds the energy invested in manufacturing.

Durability and repairability factors significantly influence the sustainability profile of thermoelectric wearables. Current designs often prioritize miniaturization and flexibility over repairability, resulting in devices with limited lifespans. Industry data suggests that the average thermoelectric wearable has an effective operational life of 2-3 years before performance degradation or physical damage necessitates replacement.

End-of-life considerations reveal additional challenges. The composite nature of thermoelectric wearables—combining semiconductor materials, flexible substrates, and electronic components—complicates recycling efforts. Current recycling technologies can recover only 30-40% of the valuable materials from these devices, with the remainder typically directed to landfills.

Emerging approaches to improve sustainability include the development of bio-based substrates, non-toxic thermoelectric materials, and modular designs that facilitate repair and component recycling. Research into bismuth telluride alternatives, such as organic thermoelectric materials and silicon-based compounds, shows promise for reducing environmental impact while maintaining performance characteristics. Additionally, design-for-disassembly principles are being incorporated into next-generation thermoelectric wearables to enhance material recovery rates and extend product lifespans.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!