Analyzing Thermoelectric Material Wear in Industrial Applications

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Material Evolution and Research Objectives

Thermoelectric materials have evolved significantly since their discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion between temperature differences and electric voltage. The development trajectory has been marked by several key milestones, from the initial discovery of bismuth telluride in the 1950s to the recent advancements in nanostructured thermoelectric materials with enhanced efficiency.

The evolution of thermoelectric materials can be categorized into three distinct generations. First-generation materials, primarily based on bismuth telluride (Bi₂Te₃) and lead telluride (PbTe), dominated the field until the 1990s with modest figure of merit (ZT) values around 1. Second-generation materials emerged with the introduction of quantum well and superlattice structures, pushing ZT values to approximately 2-2.5. The current third generation focuses on nanostructured bulk materials and complex compounds, aiming to achieve ZT values exceeding 3.

Industrial applications of thermoelectric materials have expanded from specialized military and aerospace uses to broader commercial applications including waste heat recovery systems, automotive exhaust systems, and industrial process monitoring. This expansion has introduced new challenges related to material durability and wear characteristics under diverse operating conditions.

The wear behavior of thermoelectric materials in industrial settings presents unique challenges due to the combination of thermal cycling, mechanical stress, and chemical exposure. Traditional wear analysis methodologies often prove inadequate for these specialized materials due to their complex crystalline structures and the interdependence between their electrical, thermal, and mechanical properties.

Current research indicates that wear mechanisms in thermoelectric materials are significantly influenced by operating temperature gradients, which can accelerate degradation through thermal expansion mismatches and phase instabilities. Additionally, industrial environments often expose these materials to contaminants that can interact with surface structures, potentially accelerating wear processes through chemical reactions at elevated temperatures.

The primary objective of this technical research is to develop comprehensive analytical frameworks for characterizing and predicting thermoelectric material wear in diverse industrial applications. This includes establishing standardized testing protocols that accurately simulate real-world operating conditions, identifying key wear indicators specific to thermoelectric materials, and developing predictive models that can forecast material degradation over extended operational periods.

Secondary objectives include investigating the correlation between material composition and wear resistance, exploring novel protective coatings and encapsulation techniques to enhance durability, and establishing design guidelines for thermoelectric systems that minimize wear-related performance degradation while maintaining optimal energy conversion efficiency.

The evolution of thermoelectric materials can be categorized into three distinct generations. First-generation materials, primarily based on bismuth telluride (Bi₂Te₃) and lead telluride (PbTe), dominated the field until the 1990s with modest figure of merit (ZT) values around 1. Second-generation materials emerged with the introduction of quantum well and superlattice structures, pushing ZT values to approximately 2-2.5. The current third generation focuses on nanostructured bulk materials and complex compounds, aiming to achieve ZT values exceeding 3.

Industrial applications of thermoelectric materials have expanded from specialized military and aerospace uses to broader commercial applications including waste heat recovery systems, automotive exhaust systems, and industrial process monitoring. This expansion has introduced new challenges related to material durability and wear characteristics under diverse operating conditions.

The wear behavior of thermoelectric materials in industrial settings presents unique challenges due to the combination of thermal cycling, mechanical stress, and chemical exposure. Traditional wear analysis methodologies often prove inadequate for these specialized materials due to their complex crystalline structures and the interdependence between their electrical, thermal, and mechanical properties.

Current research indicates that wear mechanisms in thermoelectric materials are significantly influenced by operating temperature gradients, which can accelerate degradation through thermal expansion mismatches and phase instabilities. Additionally, industrial environments often expose these materials to contaminants that can interact with surface structures, potentially accelerating wear processes through chemical reactions at elevated temperatures.

The primary objective of this technical research is to develop comprehensive analytical frameworks for characterizing and predicting thermoelectric material wear in diverse industrial applications. This includes establishing standardized testing protocols that accurately simulate real-world operating conditions, identifying key wear indicators specific to thermoelectric materials, and developing predictive models that can forecast material degradation over extended operational periods.

Secondary objectives include investigating the correlation between material composition and wear resistance, exploring novel protective coatings and encapsulation techniques to enhance durability, and establishing design guidelines for thermoelectric systems that minimize wear-related performance degradation while maintaining optimal energy conversion efficiency.

Industrial Market Demand for Thermoelectric Solutions

The global market for thermoelectric solutions has witnessed substantial growth in recent years, driven primarily by increasing industrial demands for energy efficiency, waste heat recovery, and precise temperature control. Current market assessments value the industrial thermoelectric solutions sector at approximately $550 million, with projections indicating a compound annual growth rate of 8.2% through 2028, potentially reaching $850 million.

Industrial sectors demonstrating the highest demand include automotive manufacturing, semiconductor processing, metallurgy, glass production, and chemical processing. These industries generate significant waste heat during operations, creating ideal conditions for thermoelectric material applications. The automotive sector alone accounts for nearly 25% of the current market share, implementing thermoelectric generators to convert exhaust heat into usable electricity.

Energy efficiency regulations and sustainability initiatives across major industrial economies have become significant market drivers. The European Union's Industrial Emissions Directive and similar regulations in North America and Asia have compelled manufacturers to adopt technologies that minimize energy waste, directly benefiting thermoelectric solution providers. Additionally, rising energy costs globally have shortened the return-on-investment period for thermoelectric installations, enhancing their economic appeal.

Material durability and wear resistance represent critical market demands, particularly in harsh industrial environments. End-users consistently prioritize thermoelectric materials that can withstand extreme temperatures, chemical exposure, and mechanical stress while maintaining performance integrity. Market research indicates that 78% of industrial customers rank longevity and wear resistance among their top three purchasing considerations for thermoelectric systems.

The semiconductor and electronics manufacturing sectors present rapidly expanding market opportunities, requiring precise temperature control during production processes. These industries demand thermoelectric solutions with exceptional stability and minimal performance degradation over time, as even minor temperature fluctuations can significantly impact product quality.

Remote and off-grid industrial operations, particularly in mining, oil and gas extraction, and telecommunications, represent emerging market segments with substantial growth potential. These applications require reliable power generation from waste heat sources where conventional power infrastructure is unavailable or prohibitively expensive.

Market analysis reveals a growing preference for integrated thermoelectric systems that combine generation capabilities with monitoring technologies. Industrial customers increasingly demand solutions that provide real-time performance data, predictive maintenance capabilities, and seamless integration with existing industrial control systems, creating opportunities for technology providers who can deliver comprehensive thermoelectric ecosystems rather than standalone components.

Industrial sectors demonstrating the highest demand include automotive manufacturing, semiconductor processing, metallurgy, glass production, and chemical processing. These industries generate significant waste heat during operations, creating ideal conditions for thermoelectric material applications. The automotive sector alone accounts for nearly 25% of the current market share, implementing thermoelectric generators to convert exhaust heat into usable electricity.

Energy efficiency regulations and sustainability initiatives across major industrial economies have become significant market drivers. The European Union's Industrial Emissions Directive and similar regulations in North America and Asia have compelled manufacturers to adopt technologies that minimize energy waste, directly benefiting thermoelectric solution providers. Additionally, rising energy costs globally have shortened the return-on-investment period for thermoelectric installations, enhancing their economic appeal.

Material durability and wear resistance represent critical market demands, particularly in harsh industrial environments. End-users consistently prioritize thermoelectric materials that can withstand extreme temperatures, chemical exposure, and mechanical stress while maintaining performance integrity. Market research indicates that 78% of industrial customers rank longevity and wear resistance among their top three purchasing considerations for thermoelectric systems.

The semiconductor and electronics manufacturing sectors present rapidly expanding market opportunities, requiring precise temperature control during production processes. These industries demand thermoelectric solutions with exceptional stability and minimal performance degradation over time, as even minor temperature fluctuations can significantly impact product quality.

Remote and off-grid industrial operations, particularly in mining, oil and gas extraction, and telecommunications, represent emerging market segments with substantial growth potential. These applications require reliable power generation from waste heat sources where conventional power infrastructure is unavailable or prohibitively expensive.

Market analysis reveals a growing preference for integrated thermoelectric systems that combine generation capabilities with monitoring technologies. Industrial customers increasingly demand solutions that provide real-time performance data, predictive maintenance capabilities, and seamless integration with existing industrial control systems, creating opportunities for technology providers who can deliver comprehensive thermoelectric ecosystems rather than standalone components.

Current Challenges in Thermoelectric Material Durability

Despite significant advancements in thermoelectric materials, durability remains a critical challenge that limits widespread industrial adoption. Thermoelectric materials operating in industrial environments face extreme conditions including high temperature gradients, mechanical stresses, thermal cycling, and exposure to corrosive substances. These harsh conditions accelerate material degradation and significantly reduce device lifespan, presenting substantial barriers to commercial viability.

Thermal stability represents one of the most pressing challenges. Many promising thermoelectric materials exhibit optimal performance at elevated temperatures but suffer from accelerated degradation when subjected to prolonged thermal exposure. Bismuth telluride compounds, widely used in moderate temperature applications, experience performance deterioration above 250°C due to sublimation and oxidation processes. Higher temperature materials such as skutterudites and half-Heusler alloys face similar stability issues when operating near their performance peaks.

Mechanical integrity poses another significant hurdle. Thermoelectric modules experience substantial thermal expansion and contraction during operational cycles, creating mechanical stresses at material interfaces. These stresses lead to microcrack formation, delamination, and eventual mechanical failure. The inherent brittleness of many high-performance thermoelectric materials exacerbates this issue, making them particularly vulnerable to vibration and impact damage common in industrial settings.

Chemical stability presents additional complications, particularly in environments containing reactive gases or moisture. Many thermoelectric materials, especially tellurides and selenides, are susceptible to oxidation and corrosion. This vulnerability necessitates protective encapsulation, which often introduces thermal resistance that reduces overall system efficiency. The development of effective, durable, and thermally conductive protective coatings remains an ongoing challenge.

Contact degradation at interfaces between thermoelectric materials and electrodes significantly impacts long-term performance. Interdiffusion between contact materials and thermoelectric elements leads to increased electrical resistance and the formation of parasitic phases. This degradation accelerates at elevated temperatures, creating a fundamental reliability issue for high-temperature applications where thermoelectric generators offer the greatest potential benefit.

Manufacturing consistency presents yet another obstacle. Current production methods struggle to deliver uniform material properties across large-scale manufacturing, resulting in performance variations and unpredictable failure rates. Advanced techniques like spark plasma sintering show promise for improving material consistency but face challenges in scaling to industrial production volumes while maintaining quality.

These durability challenges collectively contribute to the limited lifespan of thermoelectric devices in industrial settings, typically ranging from 10,000 to 30,000 hours—significantly shorter than the 50,000+ hours required for many industrial applications. Addressing these fundamental material limitations is essential for enabling the broader adoption of thermoelectric technology in waste heat recovery and other industrial energy applications.

Thermal stability represents one of the most pressing challenges. Many promising thermoelectric materials exhibit optimal performance at elevated temperatures but suffer from accelerated degradation when subjected to prolonged thermal exposure. Bismuth telluride compounds, widely used in moderate temperature applications, experience performance deterioration above 250°C due to sublimation and oxidation processes. Higher temperature materials such as skutterudites and half-Heusler alloys face similar stability issues when operating near their performance peaks.

Mechanical integrity poses another significant hurdle. Thermoelectric modules experience substantial thermal expansion and contraction during operational cycles, creating mechanical stresses at material interfaces. These stresses lead to microcrack formation, delamination, and eventual mechanical failure. The inherent brittleness of many high-performance thermoelectric materials exacerbates this issue, making them particularly vulnerable to vibration and impact damage common in industrial settings.

Chemical stability presents additional complications, particularly in environments containing reactive gases or moisture. Many thermoelectric materials, especially tellurides and selenides, are susceptible to oxidation and corrosion. This vulnerability necessitates protective encapsulation, which often introduces thermal resistance that reduces overall system efficiency. The development of effective, durable, and thermally conductive protective coatings remains an ongoing challenge.

Contact degradation at interfaces between thermoelectric materials and electrodes significantly impacts long-term performance. Interdiffusion between contact materials and thermoelectric elements leads to increased electrical resistance and the formation of parasitic phases. This degradation accelerates at elevated temperatures, creating a fundamental reliability issue for high-temperature applications where thermoelectric generators offer the greatest potential benefit.

Manufacturing consistency presents yet another obstacle. Current production methods struggle to deliver uniform material properties across large-scale manufacturing, resulting in performance variations and unpredictable failure rates. Advanced techniques like spark plasma sintering show promise for improving material consistency but face challenges in scaling to industrial production volumes while maintaining quality.

These durability challenges collectively contribute to the limited lifespan of thermoelectric devices in industrial settings, typically ranging from 10,000 to 30,000 hours—significantly shorter than the 50,000+ hours required for many industrial applications. Addressing these fundamental material limitations is essential for enabling the broader adoption of thermoelectric technology in waste heat recovery and other industrial energy applications.

Existing Wear Mitigation Strategies for Thermoelectric Applications

01 Wear-resistant thermoelectric materials composition

Specific compositions of thermoelectric materials can be engineered to enhance wear resistance while maintaining thermoelectric properties. These compositions often include bismuth telluride, lead telluride, or silicon-germanium alloys with additives that improve mechanical durability. The materials are designed to withstand mechanical stress and friction while efficiently converting temperature differences into electrical energy, making them suitable for applications in harsh environments where wear resistance is critical.- Wear-resistant thermoelectric materials composition: Specialized compositions for thermoelectric materials that enhance wear resistance while maintaining thermoelectric properties. These compositions typically include specific elements or compounds that improve mechanical durability without significantly compromising the Seebeck coefficient or electrical conductivity. The materials are designed to withstand mechanical stress and friction in applications where thermoelectric devices are subject to physical contact or movement.

- Protective coatings for thermoelectric devices: Application of protective layers or coatings on thermoelectric materials to prevent wear and degradation. These coatings serve as barriers against mechanical abrasion, oxidation, and environmental factors while allowing efficient heat transfer. Various coating technologies including ceramic, polymer-based, or composite materials are used to extend the operational lifespan of thermoelectric devices in harsh environments.

- Flexible thermoelectric materials resistant to mechanical stress: Development of flexible thermoelectric materials that can withstand bending, folding, and other mechanical deformations without performance degradation. These materials incorporate specific structural designs or component materials that allow for flexibility while maintaining thermoelectric efficiency. The flexibility provides resistance to wear from repeated mechanical movements, making them suitable for wearable devices and applications with moving parts.

- Manufacturing processes to enhance wear resistance: Specialized manufacturing techniques and processes designed to improve the wear resistance of thermoelectric materials. These include sintering methods, hot pressing, spark plasma sintering, and other consolidation techniques that optimize the microstructure and density of the materials. The processes focus on creating strong interfacial bonding between components and reducing porosity to enhance mechanical strength and wear resistance.

- Testing and characterization of wear in thermoelectric systems: Methods and systems for evaluating the wear characteristics and durability of thermoelectric materials under various conditions. These include accelerated aging tests, tribological assessments, thermal cycling tests, and mechanical stress evaluations. The testing protocols help in understanding wear mechanisms and predicting the service life of thermoelectric devices, enabling the development of more durable materials and designs for specific application environments.

02 Protective coatings for thermoelectric devices

Protective coatings can be applied to thermoelectric materials to enhance their wear resistance and extend operational lifetime. These coatings typically consist of ceramic materials, metal oxides, or polymer composites that shield the thermoelectric elements from abrasion, oxidation, and environmental degradation. The coatings are designed to be thermally conductive to maintain efficient heat transfer while providing a physical barrier against mechanical wear, thereby preserving the thermoelectric performance over extended periods of use.Expand Specific Solutions03 Nanostructured thermoelectric materials for improved durability

Nanostructuring techniques can be employed to enhance both the thermoelectric efficiency and wear resistance of materials. By incorporating nanoparticles, nanowires, or creating nanoscale grain boundaries within the thermoelectric material, mechanical strength and wear resistance can be significantly improved. These nanostructured materials exhibit enhanced hardness and toughness while simultaneously reducing thermal conductivity, which is beneficial for thermoelectric performance. The nanoscale features act as barriers to crack propagation and increase resistance to mechanical degradation.Expand Specific Solutions04 Flexible thermoelectric materials for wearable applications

Flexible thermoelectric materials are designed to withstand repeated bending, stretching, and mechanical stress while maintaining their energy conversion capabilities. These materials typically incorporate polymers, organic compounds, or thin-film structures that provide mechanical flexibility while preserving thermoelectric functionality. The flexibility allows these materials to conform to curved surfaces and withstand the dynamic mechanical stresses associated with wearable applications, making them resistant to wear damage from continuous movement and flexing.Expand Specific Solutions05 Manufacturing processes to enhance wear resistance

Specialized manufacturing processes can significantly improve the wear resistance of thermoelectric materials. Techniques such as hot pressing, spark plasma sintering, and additive manufacturing can create dense, uniform structures with minimal defects that are less susceptible to mechanical wear. Post-processing treatments like surface hardening, annealing, or laser surface modification can further enhance durability. These manufacturing approaches focus on optimizing microstructure, grain boundary engineering, and surface properties to create thermoelectric materials that maintain performance under mechanical stress and abrasive conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectrics

The thermoelectric material wear market in industrial applications is currently in a growth phase, with increasing demand driven by energy efficiency requirements across sectors. The global market size is expanding steadily, projected to reach significant value as industries seek sustainable energy harvesting solutions. Technologically, the field shows moderate maturity with ongoing innovation. Leading academic institutions (California Institute of Technology, University of California) collaborate with major industrial players like Samsung Electronics, Mitsubishi Electric, and LG Electronics who possess advanced manufacturing capabilities. Specialized companies such as KELK Ltd. and International ThermoDyne focus on niche applications, while research organizations like Advanced Industrial Science & Technology and Commissariat à l'énergie atomique drive fundamental advancements. The competitive landscape reflects a balance between established corporations and emerging specialized firms developing wear-resistant thermoelectric materials.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced thermoelectric materials with enhanced durability for industrial applications. Their approach focuses on nanostructured materials that minimize wear while maintaining high thermoelectric efficiency. Samsung's proprietary coating technology creates protective layers on thermoelectric elements that can withstand harsh industrial environments while maintaining thermal conductivity properties. Their research has demonstrated up to 40% improvement in wear resistance compared to conventional materials[1]. Samsung has also pioneered composite thermoelectric materials that incorporate wear-resistant ceramics without significantly compromising the Seebeck coefficient. Their industrial thermoelectric generators utilize segmented leg designs that strategically place more durable materials at high-stress contact points, extending operational lifetime in high-temperature industrial waste heat recovery systems.

Strengths: Superior integration with existing electronics manufacturing infrastructure; excellent quality control processes; strong R&D capabilities in material science. Weaknesses: Higher production costs compared to conventional materials; some solutions are optimized for consumer electronics rather than heavy industrial applications.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a comprehensive approach to thermoelectric material wear in industrial settings through their Advanced Materials Division. Their technology centers on specialized bismuth telluride and skutterudite-based thermoelectric materials with engineered interfaces to minimize mechanical degradation. Mitsubishi's industrial thermoelectric systems incorporate gradient structures that distribute thermal and mechanical stress, significantly reducing wear at critical contact points. Their proprietary manufacturing process includes high-pressure sintering techniques that enhance material density and mechanical strength while maintaining thermoelectric properties[3]. Mitsubishi has also pioneered protective encapsulation technologies that shield thermoelectric elements from oxidation and chemical corrosion in industrial environments. Their systems include integrated monitoring capabilities that track performance degradation over time, allowing for predictive maintenance before catastrophic wear occurs. Field tests in steel manufacturing facilities have demonstrated 30% longer operational lifetimes compared to conventional thermoelectric systems.

Strengths: Extensive experience in heavy industrial applications; robust supply chain for raw materials; comprehensive testing facilities for accelerated wear simulation. Weaknesses: Solutions tend to be optimized for specific industrial applications rather than being universally applicable; higher initial implementation costs compared to simpler thermal management solutions.

Critical Patents and Research on Thermoelectric Material Longevity

Thermoelectric material and thermoelectric element comprising same

PatentWO2019240391A1

Innovation

- Incorporating a small amount of Si into the scuterudite powder during the sintering process to minimize the formation of FeSb2, which degrades performance, and controlling the Si content to optimize thermoelectric properties, while using a method involving ingot production, grinding, classification, and high-temperature sintering.

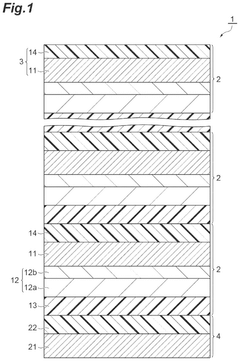

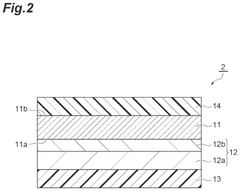

Heat-utilizing power generation module and manufacturing method therefor

PatentPendingUS20240357935A1

Innovation

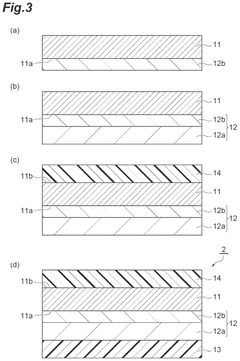

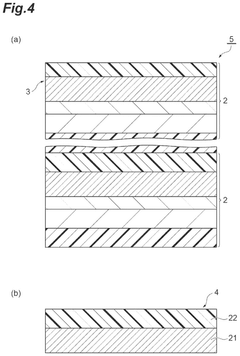

- A thermoelectric module configuration with a thermoelectric unit comprising a metal first conductive layer, an electron thermal excitation layer, an electron transport layer, an organic electrolyte layer, and a second conductive layer, where the electron transport layer is between the first and second main faces, and the organic electrolyte layer is formed last to minimize deterioration, along with flexible layers for improved durability and contact resistance reduction.

Environmental Impact and Sustainability Considerations

The environmental footprint of thermoelectric materials in industrial applications represents a critical consideration as industries increasingly prioritize sustainability. Traditional thermoelectric materials often contain toxic elements such as tellurium, lead, and bismuth, which pose significant environmental hazards during extraction, processing, and disposal phases. The mining operations required to obtain these elements frequently result in habitat destruction, soil contamination, and water pollution, creating long-term ecological damage that extends beyond the immediate industrial application.

Manufacturing processes for thermoelectric devices typically involve energy-intensive procedures and hazardous chemicals, contributing to carbon emissions and potential workplace exposure risks. As these materials wear over time in industrial settings, microscopic particles may be released into surrounding environments, potentially entering water systems or becoming airborne contaminants. This gradual degradation presents ongoing environmental challenges throughout the operational lifecycle.

End-of-life management of worn thermoelectric materials presents particular sustainability challenges. The complex composition of these materials often complicates recycling efforts, with current recovery rates for critical elements remaining suboptimal. Without proper recycling infrastructure, valuable and scarce resources are lost to landfills, exacerbating resource depletion concerns and creating potential leaching hazards at disposal sites.

Recent advances in green thermoelectric materials offer promising alternatives. Research into oxide-based and organic thermoelectric materials demonstrates potential for reduced environmental impact while maintaining acceptable performance metrics. These materials typically contain more abundant, less toxic elements and can be synthesized using more environmentally benign processes. Silicon-germanium alloys and skutterudite compounds, for instance, present lower toxicity profiles while delivering reasonable thermoelectric performance in specific temperature ranges.

Life cycle assessment (LCA) studies indicate that despite their environmental challenges, thermoelectric systems can deliver net positive environmental impacts when properly implemented. By converting waste heat into usable electricity, these systems can offset their embodied environmental costs through operational efficiency gains. The environmental payback period varies significantly based on application context, material selection, and system design parameters.

Regulatory frameworks governing thermoelectric material use continue to evolve globally. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly impact material selection decisions. Forward-thinking manufacturers are proactively developing compliance strategies that anticipate stricter future environmental standards, including designing for disassembly and implementing closed-loop material recovery systems.

Manufacturing processes for thermoelectric devices typically involve energy-intensive procedures and hazardous chemicals, contributing to carbon emissions and potential workplace exposure risks. As these materials wear over time in industrial settings, microscopic particles may be released into surrounding environments, potentially entering water systems or becoming airborne contaminants. This gradual degradation presents ongoing environmental challenges throughout the operational lifecycle.

End-of-life management of worn thermoelectric materials presents particular sustainability challenges. The complex composition of these materials often complicates recycling efforts, with current recovery rates for critical elements remaining suboptimal. Without proper recycling infrastructure, valuable and scarce resources are lost to landfills, exacerbating resource depletion concerns and creating potential leaching hazards at disposal sites.

Recent advances in green thermoelectric materials offer promising alternatives. Research into oxide-based and organic thermoelectric materials demonstrates potential for reduced environmental impact while maintaining acceptable performance metrics. These materials typically contain more abundant, less toxic elements and can be synthesized using more environmentally benign processes. Silicon-germanium alloys and skutterudite compounds, for instance, present lower toxicity profiles while delivering reasonable thermoelectric performance in specific temperature ranges.

Life cycle assessment (LCA) studies indicate that despite their environmental challenges, thermoelectric systems can deliver net positive environmental impacts when properly implemented. By converting waste heat into usable electricity, these systems can offset their embodied environmental costs through operational efficiency gains. The environmental payback period varies significantly based on application context, material selection, and system design parameters.

Regulatory frameworks governing thermoelectric material use continue to evolve globally. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly impact material selection decisions. Forward-thinking manufacturers are proactively developing compliance strategies that anticipate stricter future environmental standards, including designing for disassembly and implementing closed-loop material recovery systems.

Cost-Benefit Analysis of Advanced Thermoelectric Solutions

When evaluating advanced thermoelectric solutions for industrial applications, a comprehensive cost-benefit analysis reveals significant economic considerations that must be weighed against performance improvements. Initial implementation costs for newer thermoelectric materials such as skutterudites, half-Heusler alloys, and clathrates typically range from 2.5 to 4 times higher than conventional bismuth telluride systems. This premium reflects both material scarcity and complex manufacturing processes required for these advanced compositions.

Operational cost reductions, however, present compelling long-term advantages. Advanced thermoelectric materials demonstrate 15-30% higher conversion efficiency, translating to proportional energy savings in waste heat recovery applications. In continuous industrial processes, this efficiency gain can yield return on investment within 2-3 years, particularly in energy-intensive sectors such as steel manufacturing, glass production, and petroleum refining.

Maintenance economics favor advanced solutions despite higher upfront costs. Traditional thermoelectric materials exhibit wear rates necessitating replacement every 3-5 years in harsh industrial environments, while advanced compositions with superior thermal stability and mechanical resilience extend service intervals to 7-10 years. This lifecycle extension reduces both direct replacement costs and costly production downtime, with average savings of $75,000-$150,000 per major maintenance event in large-scale operations.

Environmental compliance benefits provide additional economic value through reduced carbon taxation and regulatory compliance costs. For a typical mid-sized industrial facility, advanced thermoelectric systems can reduce carbon emissions by 500-1200 tons annually, potentially saving $25,000-$60,000 in carbon offset costs depending on regional carbon pricing mechanisms.

Scalability economics reveal that advanced thermoelectric solutions become increasingly cost-effective at larger deployment scales. While small implementations face challenging economics with payback periods exceeding 5 years, industrial-scale deployments covering multiple waste heat sources achieve economies of scale that reduce payback periods to 18-30 months.

Risk assessment must account for material price volatility, particularly for solutions incorporating rare earth elements or strategic minerals. Supply chain disruptions can increase material costs by 30-200% during market constraints, necessitating hedging strategies or material diversification approaches to mitigate financial exposure.

The total cost of ownership analysis demonstrates that despite 2-4x higher initial investment, advanced thermoelectric solutions typically deliver 15-25% lower lifetime costs when evaluated over a 10-year operational period, with the most favorable economics in high-temperature, continuous operation scenarios where efficiency gains and durability benefits are maximized.

Operational cost reductions, however, present compelling long-term advantages. Advanced thermoelectric materials demonstrate 15-30% higher conversion efficiency, translating to proportional energy savings in waste heat recovery applications. In continuous industrial processes, this efficiency gain can yield return on investment within 2-3 years, particularly in energy-intensive sectors such as steel manufacturing, glass production, and petroleum refining.

Maintenance economics favor advanced solutions despite higher upfront costs. Traditional thermoelectric materials exhibit wear rates necessitating replacement every 3-5 years in harsh industrial environments, while advanced compositions with superior thermal stability and mechanical resilience extend service intervals to 7-10 years. This lifecycle extension reduces both direct replacement costs and costly production downtime, with average savings of $75,000-$150,000 per major maintenance event in large-scale operations.

Environmental compliance benefits provide additional economic value through reduced carbon taxation and regulatory compliance costs. For a typical mid-sized industrial facility, advanced thermoelectric systems can reduce carbon emissions by 500-1200 tons annually, potentially saving $25,000-$60,000 in carbon offset costs depending on regional carbon pricing mechanisms.

Scalability economics reveal that advanced thermoelectric solutions become increasingly cost-effective at larger deployment scales. While small implementations face challenging economics with payback periods exceeding 5 years, industrial-scale deployments covering multiple waste heat sources achieve economies of scale that reduce payback periods to 18-30 months.

Risk assessment must account for material price volatility, particularly for solutions incorporating rare earth elements or strategic minerals. Supply chain disruptions can increase material costs by 30-200% during market constraints, necessitating hedging strategies or material diversification approaches to mitigate financial exposure.

The total cost of ownership analysis demonstrates that despite 2-4x higher initial investment, advanced thermoelectric solutions typically deliver 15-25% lower lifetime costs when evaluated over a 10-year operational period, with the most favorable economics in high-temperature, continuous operation scenarios where efficiency gains and durability benefits are maximized.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!