How to Integrate Thermoelectric Materials in Sustainable Designs

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Background and Integration Goals

Thermoelectric materials have evolved significantly since their discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion between temperature differences and electric voltage. This fundamental principle has driven the development of thermoelectric technology through several distinct phases, from basic scientific understanding to increasingly sophisticated applications in energy harvesting and thermal management systems.

The evolution of thermoelectric materials has been marked by continuous improvements in their figure of merit (ZT), which determines conversion efficiency. First-generation materials based on bismuth telluride (Bi₂Te₃) achieved ZT values around 1, while second-generation materials incorporated nanostructuring techniques to reduce thermal conductivity. Current third-generation materials utilize complex crystal structures and advanced manufacturing processes to achieve ZT values exceeding 2 in laboratory settings.

Recent advancements have focused on developing sustainable thermoelectric materials that reduce or eliminate toxic and rare elements while maintaining performance. This shift aligns with global sustainability goals and addresses supply chain vulnerabilities associated with critical materials. Researchers are exploring abundant, earth-friendly alternatives such as silicides, oxides, and organic thermoelectric compounds that offer promising performance with reduced environmental impact.

The integration of thermoelectric materials into sustainable designs presents unique technical challenges and opportunities. These materials can capture waste heat from industrial processes, vehicle exhaust systems, and even body heat, converting otherwise wasted thermal energy into useful electricity. This capability positions thermoelectric technology as a valuable contributor to circular economy principles and energy efficiency initiatives.

The primary technical goal for thermoelectric integration is to develop modular, scalable systems that can be seamlessly incorporated into existing infrastructure and new sustainable designs. This requires addressing challenges in thermal interface management, electrical connection optimization, and mechanical durability under thermal cycling conditions. Additionally, integration must consider the full lifecycle environmental impact of thermoelectric systems, from material sourcing to end-of-life recycling.

Looking forward, the field aims to achieve breakthrough improvements in conversion efficiency while reducing costs and environmental footprint. Research is increasingly focused on multifunctional thermoelectric materials that can serve dual purposes in sustainable designs, such as structural elements with energy harvesting capabilities or building materials that provide both insulation and power generation. These developments point toward a future where thermoelectric technology becomes an integral component of sustainable energy systems rather than a specialized add-on solution.

The evolution of thermoelectric materials has been marked by continuous improvements in their figure of merit (ZT), which determines conversion efficiency. First-generation materials based on bismuth telluride (Bi₂Te₃) achieved ZT values around 1, while second-generation materials incorporated nanostructuring techniques to reduce thermal conductivity. Current third-generation materials utilize complex crystal structures and advanced manufacturing processes to achieve ZT values exceeding 2 in laboratory settings.

Recent advancements have focused on developing sustainable thermoelectric materials that reduce or eliminate toxic and rare elements while maintaining performance. This shift aligns with global sustainability goals and addresses supply chain vulnerabilities associated with critical materials. Researchers are exploring abundant, earth-friendly alternatives such as silicides, oxides, and organic thermoelectric compounds that offer promising performance with reduced environmental impact.

The integration of thermoelectric materials into sustainable designs presents unique technical challenges and opportunities. These materials can capture waste heat from industrial processes, vehicle exhaust systems, and even body heat, converting otherwise wasted thermal energy into useful electricity. This capability positions thermoelectric technology as a valuable contributor to circular economy principles and energy efficiency initiatives.

The primary technical goal for thermoelectric integration is to develop modular, scalable systems that can be seamlessly incorporated into existing infrastructure and new sustainable designs. This requires addressing challenges in thermal interface management, electrical connection optimization, and mechanical durability under thermal cycling conditions. Additionally, integration must consider the full lifecycle environmental impact of thermoelectric systems, from material sourcing to end-of-life recycling.

Looking forward, the field aims to achieve breakthrough improvements in conversion efficiency while reducing costs and environmental footprint. Research is increasingly focused on multifunctional thermoelectric materials that can serve dual purposes in sustainable designs, such as structural elements with energy harvesting capabilities or building materials that provide both insulation and power generation. These developments point toward a future where thermoelectric technology becomes an integral component of sustainable energy systems rather than a specialized add-on solution.

Market Analysis for Sustainable Thermoelectric Applications

The global market for thermoelectric materials in sustainable applications is experiencing significant growth, driven by increasing environmental concerns and the push for energy efficiency across industries. Current market valuations place the sustainable thermoelectric sector at approximately $600 million, with projections indicating growth to reach $1.2 billion by 2028, representing a compound annual growth rate of 12.3% during the forecast period.

Consumer electronics represents the largest application segment, accounting for nearly 40% of the market share. This dominance stems from the integration of thermoelectric cooling solutions in portable devices, wearables, and smart home systems. The automotive sector follows closely, with thermoelectric generators (TEGs) being increasingly adopted for waste heat recovery in vehicles, contributing to improved fuel efficiency and reduced emissions.

Demand patterns show regional variations, with North America and Europe leading in adoption due to stringent environmental regulations and sustainability initiatives. However, the Asia-Pacific region, particularly China and South Korea, is witnessing the fastest growth rate at 15.7% annually, driven by rapid industrialization and government support for green technologies.

Market research indicates that consumer willingness to pay a premium for sustainable products extends to thermoelectric applications, with surveys showing that 68% of consumers are willing to pay up to 20% more for products with demonstrable energy-saving capabilities. This trend is particularly pronounced in the residential and commercial building sectors, where energy efficiency certifications carry significant market value.

The competitive landscape is characterized by a mix of established players and innovative startups. Traditional thermoelectric material manufacturers are expanding their product portfolios to include sustainable designs, while new entrants are focusing on novel material compositions and manufacturing techniques to improve efficiency and reduce costs.

Supply chain analysis reveals potential vulnerabilities in the sourcing of rare earth elements and other critical materials used in high-performance thermoelectric devices. This has prompted increased investment in research for alternative materials and recycling technologies, creating additional market opportunities in the circular economy space.

End-user segmentation shows diverse applications across residential, commercial, industrial, and transportation sectors. The industrial waste heat recovery segment is projected to grow at the highest rate of 14.2% annually, as manufacturers seek to improve energy efficiency and meet carbon reduction targets.

Market barriers include relatively high initial costs, with payback periods ranging from 3-7 years depending on the application. However, as manufacturing scales up and material science advances, these costs are expected to decrease by approximately 30% over the next five years, significantly expanding market penetration potential.

Consumer electronics represents the largest application segment, accounting for nearly 40% of the market share. This dominance stems from the integration of thermoelectric cooling solutions in portable devices, wearables, and smart home systems. The automotive sector follows closely, with thermoelectric generators (TEGs) being increasingly adopted for waste heat recovery in vehicles, contributing to improved fuel efficiency and reduced emissions.

Demand patterns show regional variations, with North America and Europe leading in adoption due to stringent environmental regulations and sustainability initiatives. However, the Asia-Pacific region, particularly China and South Korea, is witnessing the fastest growth rate at 15.7% annually, driven by rapid industrialization and government support for green technologies.

Market research indicates that consumer willingness to pay a premium for sustainable products extends to thermoelectric applications, with surveys showing that 68% of consumers are willing to pay up to 20% more for products with demonstrable energy-saving capabilities. This trend is particularly pronounced in the residential and commercial building sectors, where energy efficiency certifications carry significant market value.

The competitive landscape is characterized by a mix of established players and innovative startups. Traditional thermoelectric material manufacturers are expanding their product portfolios to include sustainable designs, while new entrants are focusing on novel material compositions and manufacturing techniques to improve efficiency and reduce costs.

Supply chain analysis reveals potential vulnerabilities in the sourcing of rare earth elements and other critical materials used in high-performance thermoelectric devices. This has prompted increased investment in research for alternative materials and recycling technologies, creating additional market opportunities in the circular economy space.

End-user segmentation shows diverse applications across residential, commercial, industrial, and transportation sectors. The industrial waste heat recovery segment is projected to grow at the highest rate of 14.2% annually, as manufacturers seek to improve energy efficiency and meet carbon reduction targets.

Market barriers include relatively high initial costs, with payback periods ranging from 3-7 years depending on the application. However, as manufacturing scales up and material science advances, these costs are expected to decrease by approximately 30% over the next five years, significantly expanding market penetration potential.

Current Challenges in Thermoelectric Material Integration

Despite significant advancements in thermoelectric material development, their integration into sustainable designs faces several critical challenges. The efficiency of thermoelectric materials, measured by the figure of merit ZT, remains a primary limitation. Current commercial materials typically achieve ZT values between 1-2, whereas practical applications for widespread adoption require ZT values exceeding 3. This efficiency gap significantly impacts the cost-effectiveness of thermoelectric solutions in sustainable design contexts.

Material compatibility presents another substantial hurdle. Thermoelectric materials often contain rare, toxic, or expensive elements such as tellurium, bismuth, and lead. These materials must interface with conventional building materials and electronic components while maintaining performance integrity. The thermal expansion coefficient mismatch between thermoelectric modules and host materials frequently leads to mechanical stress, reduced lifespan, and potential system failures in real-world applications.

Manufacturing scalability constitutes a significant barrier to widespread implementation. Current production methods for high-quality thermoelectric materials typically involve complex processes such as hot pressing, spark plasma sintering, or molecular beam epitaxy. These techniques are difficult to scale economically for mass production, creating a bottleneck between laboratory innovation and commercial viability in sustainable design applications.

Thermal management challenges further complicate integration efforts. Effective thermoelectric generation requires maintaining substantial temperature differentials across materials. In sustainable building designs, this necessitates sophisticated heat sink systems and thermal interfaces that add complexity, weight, and cost to the overall solution. Poor thermal management leads to diminished performance and accelerated degradation of thermoelectric components.

Durability and lifespan concerns also impede adoption. Thermoelectric materials must withstand thermal cycling, humidity variations, and mechanical stresses while maintaining performance over extended periods. Current materials often experience performance degradation after repeated thermal cycling, presenting reliability issues for long-term sustainable applications where maintenance access may be limited.

Cost factors remain perhaps the most prohibitive challenge. The price-to-performance ratio of thermoelectric solutions currently exceeds that of alternative technologies in many sustainable design applications. With material costs ranging from $200-1000 per kilogram for high-performance thermoelectrics, and additional expenses for integration components, the economic viability for widespread implementation remains questionable despite the environmental benefits.

Standardization gaps further complicate integration efforts. Unlike established technologies such as photovoltaics, thermoelectric integration lacks comprehensive industry standards for testing, performance metrics, and design guidelines. This absence creates uncertainty for designers and engineers attempting to incorporate these materials into sustainable systems, slowing adoption and innovation cycles.

Material compatibility presents another substantial hurdle. Thermoelectric materials often contain rare, toxic, or expensive elements such as tellurium, bismuth, and lead. These materials must interface with conventional building materials and electronic components while maintaining performance integrity. The thermal expansion coefficient mismatch between thermoelectric modules and host materials frequently leads to mechanical stress, reduced lifespan, and potential system failures in real-world applications.

Manufacturing scalability constitutes a significant barrier to widespread implementation. Current production methods for high-quality thermoelectric materials typically involve complex processes such as hot pressing, spark plasma sintering, or molecular beam epitaxy. These techniques are difficult to scale economically for mass production, creating a bottleneck between laboratory innovation and commercial viability in sustainable design applications.

Thermal management challenges further complicate integration efforts. Effective thermoelectric generation requires maintaining substantial temperature differentials across materials. In sustainable building designs, this necessitates sophisticated heat sink systems and thermal interfaces that add complexity, weight, and cost to the overall solution. Poor thermal management leads to diminished performance and accelerated degradation of thermoelectric components.

Durability and lifespan concerns also impede adoption. Thermoelectric materials must withstand thermal cycling, humidity variations, and mechanical stresses while maintaining performance over extended periods. Current materials often experience performance degradation after repeated thermal cycling, presenting reliability issues for long-term sustainable applications where maintenance access may be limited.

Cost factors remain perhaps the most prohibitive challenge. The price-to-performance ratio of thermoelectric solutions currently exceeds that of alternative technologies in many sustainable design applications. With material costs ranging from $200-1000 per kilogram for high-performance thermoelectrics, and additional expenses for integration components, the economic viability for widespread implementation remains questionable despite the environmental benefits.

Standardization gaps further complicate integration efforts. Unlike established technologies such as photovoltaics, thermoelectric integration lacks comprehensive industry standards for testing, performance metrics, and design guidelines. This absence creates uncertainty for designers and engineers attempting to incorporate these materials into sustainable systems, slowing adoption and innovation cycles.

Existing Integration Methods for Thermoelectric Materials

01 Bismuth telluride-based thermoelectric materials

Bismuth telluride and its alloys are among the most widely used thermoelectric materials due to their high figure of merit at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. They are commonly used in cooling applications and low-temperature power generation. Innovations in nanostructuring and composition optimization have led to improved efficiency in these materials.- Novel thermoelectric material compositions: Various novel compositions have been developed for thermoelectric materials to improve energy conversion efficiency. These include specialized alloys, nanostructured materials, and composite materials that exhibit enhanced Seebeck coefficients and reduced thermal conductivity. These novel compositions are designed to maximize the figure of merit (ZT) of thermoelectric materials, making them more efficient for power generation and cooling applications.

- Thin film thermoelectric devices: Thin film technology has been applied to thermoelectric materials to create miniaturized and flexible devices. These thin film structures can be fabricated using various deposition techniques and offer advantages such as reduced material usage, flexibility, and integration capabilities with other electronic components. Thin film thermoelectric devices are particularly useful for small-scale energy harvesting and localized cooling applications.

- Nanostructured thermoelectric materials: Nanostructuring techniques have been employed to enhance the performance of thermoelectric materials by introducing nanoscale features that scatter phonons while allowing electrons to flow. These approaches include quantum dots, nanowires, nanocomposites, and superlattice structures that effectively reduce thermal conductivity without significantly affecting electrical conductivity, thereby improving the overall thermoelectric efficiency.

- Thermoelectric module designs and configurations: Various designs and configurations have been developed for thermoelectric modules to optimize performance and address specific application requirements. These include segmented legs, cascaded structures, and novel interconnection methods that improve thermal management, mechanical stability, and overall conversion efficiency. Advanced module designs also focus on reducing contact resistance and improving heat transfer at interfaces.

- Environmentally friendly thermoelectric materials: Research has focused on developing thermoelectric materials that are environmentally friendly, avoiding toxic or rare elements. These materials include oxide-based thermoelectrics, silicides, and other abundant element compositions that offer sustainable alternatives to traditional thermoelectric materials containing lead, tellurium, or other scarce elements. These eco-friendly materials aim to provide comparable performance while reducing environmental impact and material costs.

02 Skutterudite and half-Heusler thermoelectric compounds

Skutterudites and half-Heusler compounds represent important classes of thermoelectric materials for mid to high-temperature applications. These materials feature complex crystal structures that inherently reduce thermal conductivity while maintaining good electrical properties. They can be filled with guest atoms (for skutterudites) or precisely tuned in composition (for half-Heuslers) to optimize their thermoelectric performance, making them suitable for waste heat recovery applications.Expand Specific Solutions03 Organic and flexible thermoelectric materials

Organic and flexible thermoelectric materials represent an emerging class of materials that can be used in wearable or conformable energy harvesting devices. These materials typically include conducting polymers, organic-inorganic hybrids, or carbon-based composites. Their advantages include mechanical flexibility, solution processability, and potential for low-cost manufacturing, though they generally have lower efficiency compared to inorganic counterparts.Expand Specific Solutions04 Nanostructured thermoelectric materials

Nanostructuring has emerged as a powerful approach to enhance thermoelectric performance by reducing thermal conductivity while preserving electrical conductivity. These materials incorporate features such as quantum dots, nanowires, nanoparticles, or superlattices to create phonon scattering interfaces. The controlled introduction of nanoscale features allows for independent optimization of electrical and thermal transport properties, leading to significant improvements in conversion efficiency.Expand Specific Solutions05 Thermoelectric device structures and modules

Innovations in thermoelectric device structures focus on optimizing the arrangement and connection of thermoelectric materials to maximize power output or cooling efficiency. These include advanced module designs with improved thermal management, reduced contact resistance, and better mechanical stability. Novel architectures such as segmented legs, cascaded structures, or thin-film configurations are developed to address specific application requirements and operating conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectrics

The thermoelectric materials integration market is currently in a growth phase, with increasing demand driven by sustainable design applications across multiple industries. The market size is expanding as energy harvesting technologies gain traction, projected to reach significant value in the coming years. Technologically, the field shows varying maturity levels across applications. Leading players include established corporations like LG Innotek, Continental Automotive, and Toshiba Materials, who are developing commercial applications, while specialized companies like O-Flexx Technologies and Laird Thermal Systems focus exclusively on thermoelectric solutions. Research institutions such as MIT, Shanghai Institute of Ceramics, and Harbin Institute of Technology are advancing fundamental technologies, creating a competitive landscape balanced between industrial implementation and academic innovation.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive thermoelectric integration framework for automotive and industrial applications focused on sustainability. Their system combines waste heat recovery from exhaust systems with intelligent thermal management to improve overall energy efficiency. Bosch's proprietary thermoelectric generators utilize segmented materials optimized for different temperature ranges, achieving conversion efficiencies of up to 10% in high-temperature automotive applications. Their design incorporates nano-structured materials with reduced rare earth content while maintaining performance metrics. A key innovation is their "thermal bridge" technology that creates efficient heat transfer pathways between hot and cold sides while minimizing thermal short-circuiting. Bosch has implemented a closed-loop manufacturing process that recovers over 85% of the semiconductor materials used in their thermoelectric devices, significantly reducing environmental impact. Their automotive thermoelectric systems have demonstrated fuel efficiency improvements of 2-5% in real-world testing conditions by converting waste heat from exhaust systems into usable electricity for vehicle systems[2][5].

Strengths: Extensive automotive integration expertise; proven fuel efficiency improvements in commercial vehicles; advanced manufacturing processes with high material recovery rates. Weaknesses: Systems primarily optimized for high-temperature applications; relatively high implementation costs; complex integration requirements that may limit retrofit applications.

Siemens AG

Technical Solution: Siemens has pioneered an integrated approach to thermoelectric material implementation in industrial energy systems and smart building technologies. Their "Thermal Energy Harvesting Platform" incorporates advanced bismuth-telluride and skutterudite-based thermoelectric materials into modular units that can be deployed across various industrial processes. Siemens' proprietary manufacturing technique creates nano-structured interfaces that reduce thermal conductivity while maintaining electrical conductivity, achieving ZT values (figure of merit) exceeding 1.5 at operating temperatures. Their building integration system combines thermoelectric generation with smart building management systems, creating a closed-loop energy recovery network that captures waste heat from HVAC systems, server rooms, and industrial processes. Siemens has developed specialized ceramic substrates that improve thermal cycling durability by 300% compared to conventional designs, enabling longer service life in fluctuating temperature environments. Their industrial implementations have demonstrated energy recovery of 15-20 kWh per day from medium-sized industrial processes, with ROI periods averaging 3-5 years depending on installation scale and energy costs[4][7].

Strengths: Comprehensive system integration with existing building management systems; proven industrial-scale implementations; advanced material science with proprietary manufacturing techniques. Weaknesses: Higher initial capital investment compared to conventional systems; complex installation requirements; performance degradation in environments with highly variable heat sources.

Key Innovations in Sustainable Thermoelectric Systems

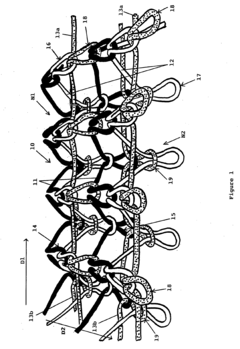

Thermoelectric structure and use of the thermoelectric structure to form a textile structure

PatentActiveEP1845565A1

Innovation

- A thermoelectric structure comprising high and low dielectric wires intertwined with conductive wires to maintain separation and position, eliminating the need for a substrate and allowing for direct integration into textile structures, facilitating manufacturing and enhancing performance by aligning temperature gradients with external environments.

Thermoelectric element

PatentActiveEP2805360A1

Innovation

- A thermoelectric element design featuring a substrate with layered contacts and a thermoelectrically active layer arranged in a trench structure, allowing for adjustable thermal resistance and reduced material usage, with the thermoelectrically active material applied as thin layers on a substrate, and alternating adhesive and thermoelectric material layers for enhanced stability and conductivity.

Life Cycle Assessment of Thermoelectric Materials

Life Cycle Assessment (LCA) of thermoelectric materials represents a critical component in evaluating their true sustainability when integrated into designs. The assessment typically begins with raw material extraction, where the environmental impacts of mining elements like bismuth, tellurium, lead, and antimony are quantified. These materials often involve energy-intensive extraction processes and may originate from regions with varying environmental regulations, creating significant ecological footprints.

The manufacturing phase of thermoelectric materials involves multiple energy-intensive processes including purification, alloying, and module assembly. Research indicates that the production of high-performance thermoelectric materials can generate substantial carbon emissions, with estimates ranging from 30-45 kg CO2 equivalent per kilogram of material, depending on the specific composition and manufacturing techniques employed.

Transportation impacts must also be considered, particularly as rare elements often travel globally before reaching manufacturing facilities. This creates additional carbon emissions that can account for 5-15% of the total life cycle impact, depending on transportation methods and distances involved.

During the use phase, thermoelectric materials demonstrate their greatest sustainability advantage. When properly integrated into waste heat recovery systems, they can generate electricity without emissions for 15-20 years, potentially offsetting their manufacturing impacts within 3-7 years depending on application efficiency and usage patterns.

End-of-life considerations present significant challenges, as many thermoelectric materials contain toxic elements that require specialized recycling processes. Current recovery rates for critical elements in thermoelectric devices remain below 35%, though emerging technologies show promise for improving this figure to 60-70% in optimized facilities.

Recent comparative LCA studies reveal that newer skutterudite and half-Heusler thermoelectric materials demonstrate 20-30% lower lifetime environmental impacts compared to traditional bismuth telluride, primarily due to reduced toxicity and improved recyclability. However, these materials still present higher embodied energy than conventional technologies in many applications.

To maximize sustainability, designers must consider the complete environmental profile rather than focusing solely on operational efficiency. Strategies such as designing for disassembly, utilizing recycled content where possible, and selecting materials with lower toxicity profiles can significantly improve the overall sustainability performance of thermoelectric implementations across their complete life cycle.

The manufacturing phase of thermoelectric materials involves multiple energy-intensive processes including purification, alloying, and module assembly. Research indicates that the production of high-performance thermoelectric materials can generate substantial carbon emissions, with estimates ranging from 30-45 kg CO2 equivalent per kilogram of material, depending on the specific composition and manufacturing techniques employed.

Transportation impacts must also be considered, particularly as rare elements often travel globally before reaching manufacturing facilities. This creates additional carbon emissions that can account for 5-15% of the total life cycle impact, depending on transportation methods and distances involved.

During the use phase, thermoelectric materials demonstrate their greatest sustainability advantage. When properly integrated into waste heat recovery systems, they can generate electricity without emissions for 15-20 years, potentially offsetting their manufacturing impacts within 3-7 years depending on application efficiency and usage patterns.

End-of-life considerations present significant challenges, as many thermoelectric materials contain toxic elements that require specialized recycling processes. Current recovery rates for critical elements in thermoelectric devices remain below 35%, though emerging technologies show promise for improving this figure to 60-70% in optimized facilities.

Recent comparative LCA studies reveal that newer skutterudite and half-Heusler thermoelectric materials demonstrate 20-30% lower lifetime environmental impacts compared to traditional bismuth telluride, primarily due to reduced toxicity and improved recyclability. However, these materials still present higher embodied energy than conventional technologies in many applications.

To maximize sustainability, designers must consider the complete environmental profile rather than focusing solely on operational efficiency. Strategies such as designing for disassembly, utilizing recycled content where possible, and selecting materials with lower toxicity profiles can significantly improve the overall sustainability performance of thermoelectric implementations across their complete life cycle.

Energy Efficiency Standards and Certifications

The integration of thermoelectric materials in sustainable designs necessitates adherence to established energy efficiency standards and certifications, which serve as crucial benchmarks for performance evaluation and market acceptance. These standards provide a framework for measuring the effectiveness of thermoelectric implementations and ensuring they meet sustainability goals.

ENERGY STAR, administered by the U.S. Environmental Protection Agency, represents one of the most recognized certification programs applicable to thermoelectric applications. Products incorporating thermoelectric materials must demonstrate energy consumption reductions of 20-30% compared to conventional alternatives to qualify for this certification. This standard has become increasingly important for consumer-facing thermoelectric solutions, particularly in HVAC systems and appliances.

The Leadership in Energy and Environmental Design (LEED) certification system offers points for innovative energy recovery systems, including those utilizing thermoelectric materials. Buildings incorporating waste heat recovery through thermoelectric generators can earn credits toward certification, making these materials attractive for green building designs. The LEED v4.1 specifically acknowledges on-site energy generation technologies, creating opportunities for thermoelectric integration.

In Europe, the Energy Performance of Buildings Directive (EPBD) establishes requirements that can be partially addressed through thermoelectric solutions. The directive's focus on nearly zero-energy buildings (nZEB) has spurred interest in thermoelectric materials for both power generation and thermal management applications. Compliance with these standards often requires detailed documentation of energy conversion efficiencies and lifecycle assessments.

ISO 50001 for Energy Management Systems provides another relevant framework for organizations implementing thermoelectric technologies. This standard requires continuous monitoring and improvement of energy performance, creating a structured approach for evaluating thermoelectric implementations over time. Organizations must demonstrate measurable energy benefits to maintain certification.

The International Electrotechnical Commission (IEC) has developed specific standards for thermoelectric devices, including IEC 62108 for concentrator photovoltaic modules and assemblies. These technical standards ensure safety, reliability, and performance consistency across different implementations, facilitating market adoption and regulatory approval.

Emerging certification programs specifically targeting waste heat recovery technologies are beginning to appear in various markets. These specialized standards focus on conversion efficiency, durability, and environmental impact throughout the product lifecycle. The Waste Heat Recovery Organization (WHRO) certification, though relatively new, is gaining recognition for thermoelectric applications in industrial settings.

ENERGY STAR, administered by the U.S. Environmental Protection Agency, represents one of the most recognized certification programs applicable to thermoelectric applications. Products incorporating thermoelectric materials must demonstrate energy consumption reductions of 20-30% compared to conventional alternatives to qualify for this certification. This standard has become increasingly important for consumer-facing thermoelectric solutions, particularly in HVAC systems and appliances.

The Leadership in Energy and Environmental Design (LEED) certification system offers points for innovative energy recovery systems, including those utilizing thermoelectric materials. Buildings incorporating waste heat recovery through thermoelectric generators can earn credits toward certification, making these materials attractive for green building designs. The LEED v4.1 specifically acknowledges on-site energy generation technologies, creating opportunities for thermoelectric integration.

In Europe, the Energy Performance of Buildings Directive (EPBD) establishes requirements that can be partially addressed through thermoelectric solutions. The directive's focus on nearly zero-energy buildings (nZEB) has spurred interest in thermoelectric materials for both power generation and thermal management applications. Compliance with these standards often requires detailed documentation of energy conversion efficiencies and lifecycle assessments.

ISO 50001 for Energy Management Systems provides another relevant framework for organizations implementing thermoelectric technologies. This standard requires continuous monitoring and improvement of energy performance, creating a structured approach for evaluating thermoelectric implementations over time. Organizations must demonstrate measurable energy benefits to maintain certification.

The International Electrotechnical Commission (IEC) has developed specific standards for thermoelectric devices, including IEC 62108 for concentrator photovoltaic modules and assemblies. These technical standards ensure safety, reliability, and performance consistency across different implementations, facilitating market adoption and regulatory approval.

Emerging certification programs specifically targeting waste heat recovery technologies are beginning to appear in various markets. These specialized standards focus on conversion efficiency, durability, and environmental impact throughout the product lifecycle. The Waste Heat Recovery Organization (WHRO) certification, though relatively new, is gaining recognition for thermoelectric applications in industrial settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!