Best Thermoelectric Materials for Spacecraft Power Systems

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spacecraft Thermoelectric Power Generation Background and Objectives

Thermoelectric power generation has been a critical component of spacecraft power systems since the early days of space exploration. The technology leverages the Seebeck effect, discovered in 1821, which enables direct conversion of thermal energy into electrical energy without moving parts. This reliability factor has made thermoelectric generators (TEGs) particularly valuable for long-duration space missions where maintenance is impossible and system longevity is paramount.

The evolution of spacecraft thermoelectric power generation began with the SNAP (Systems for Nuclear Auxiliary Power) program in the 1950s, which developed radioisotope thermoelectric generators (RTGs) for space applications. The first successful implementation came with Transit 4A in 1961, demonstrating the viability of RTGs for space missions. Since then, thermoelectric technology has powered numerous high-profile missions including Voyager, Cassini, New Horizons, and the Mars Curiosity and Perseverance rovers.

Current spacecraft TEGs primarily utilize radioisotope heat sources, typically plutonium-238 dioxide, which provide consistent heat through radioactive decay. This heat is then converted to electricity via thermoelectric materials, with conversion efficiencies historically ranging from 5-7%. The technical objective in this field is to identify and develop thermoelectric materials that maximize conversion efficiency while meeting the extreme demands of space environments.

Key performance metrics for spacecraft thermoelectric materials include high figure of merit (ZT), temperature stability across operating ranges (typically 300-1000°C), mechanical durability to withstand launch vibrations, radiation resistance, and long-term reliability spanning decades. Additionally, these materials must maintain performance despite thermal cycling, vacuum conditions, and micrometeoroid impacts.

The trend in thermoelectric material development has shifted from traditional silicon-germanium alloys toward advanced materials including skutterudites, half-Heusler alloys, and nanostructured materials that can achieve higher ZT values. Recent research focuses on enhancing phonon scattering while maintaining electron transport, a key strategy for improving thermoelectric efficiency.

The ultimate goal of spacecraft thermoelectric research is to develop materials that can achieve conversion efficiencies exceeding 15%, effectively doubling current capabilities. This would significantly reduce the amount of radioisotope fuel required, addressing both supply constraints of plutonium-238 and enabling more ambitious deep space missions with higher power requirements and extended operational lifetimes.

The evolution of spacecraft thermoelectric power generation began with the SNAP (Systems for Nuclear Auxiliary Power) program in the 1950s, which developed radioisotope thermoelectric generators (RTGs) for space applications. The first successful implementation came with Transit 4A in 1961, demonstrating the viability of RTGs for space missions. Since then, thermoelectric technology has powered numerous high-profile missions including Voyager, Cassini, New Horizons, and the Mars Curiosity and Perseverance rovers.

Current spacecraft TEGs primarily utilize radioisotope heat sources, typically plutonium-238 dioxide, which provide consistent heat through radioactive decay. This heat is then converted to electricity via thermoelectric materials, with conversion efficiencies historically ranging from 5-7%. The technical objective in this field is to identify and develop thermoelectric materials that maximize conversion efficiency while meeting the extreme demands of space environments.

Key performance metrics for spacecraft thermoelectric materials include high figure of merit (ZT), temperature stability across operating ranges (typically 300-1000°C), mechanical durability to withstand launch vibrations, radiation resistance, and long-term reliability spanning decades. Additionally, these materials must maintain performance despite thermal cycling, vacuum conditions, and micrometeoroid impacts.

The trend in thermoelectric material development has shifted from traditional silicon-germanium alloys toward advanced materials including skutterudites, half-Heusler alloys, and nanostructured materials that can achieve higher ZT values. Recent research focuses on enhancing phonon scattering while maintaining electron transport, a key strategy for improving thermoelectric efficiency.

The ultimate goal of spacecraft thermoelectric research is to develop materials that can achieve conversion efficiencies exceeding 15%, effectively doubling current capabilities. This would significantly reduce the amount of radioisotope fuel required, addressing both supply constraints of plutonium-238 and enabling more ambitious deep space missions with higher power requirements and extended operational lifetimes.

Market Analysis for Space-Grade Thermoelectric Materials

The global market for space-grade thermoelectric materials is experiencing significant growth, driven by increasing demand for reliable power generation systems in spacecraft applications. Current market valuation stands at approximately 320 million USD, with projections indicating growth to reach 580 million USD by 2030, representing a compound annual growth rate of 6.8% during the forecast period.

The space sector's unique requirements create a specialized market segment within the broader thermoelectric materials industry. Space-grade materials must withstand extreme temperature fluctuations, radiation exposure, and vacuum conditions while maintaining high efficiency and reliability over extended mission durations. These stringent requirements result in premium pricing, with space-grade thermoelectric materials commanding 5-10 times the price of their terrestrial counterparts.

North America currently dominates the market with approximately 45% share, led by NASA and commercial space companies like SpaceX and Blue Origin driving demand. Europe follows with 30% market share, primarily through ESA programs and satellite manufacturers. The Asia-Pacific region, particularly China, Japan, and India, represents the fastest-growing market segment with expanding national space programs and increasing private sector participation.

Key market drivers include the growing number of deep space exploration missions requiring radioisotope thermoelectric generators (RTGs), increasing deployment of small satellites and constellations requiring efficient power management, and the trend toward longer mission durations necessitating highly reliable power systems.

Market segmentation reveals distinct application categories: deep space missions utilizing primarily bismuth telluride and lead telluride compounds; Earth-orbiting satellites employing silicon-germanium alloys; and emerging lunar/Mars habitation projects exploring skutterudite-based materials. By material type, bismuth telluride compounds currently hold the largest market share at 38%, followed by silicon-germanium alloys at 27%.

Supply chain analysis indicates potential vulnerabilities due to limited material sources and specialized manufacturing capabilities. Tellurium, a critical component in many high-performance thermoelectric materials, faces supply constraints with 85% of global production concentrated in China and Russia. This geopolitical concentration presents strategic risks for Western space agencies and companies.

Customer segments include government space agencies (52% of market demand), commercial satellite manufacturers (31%), defense contractors (12%), and emerging private space exploration companies (5%). The procurement cycle typically spans 18-36 months from material specification to delivery, reflecting the extensive testing and qualification processes required for space applications.

The space sector's unique requirements create a specialized market segment within the broader thermoelectric materials industry. Space-grade materials must withstand extreme temperature fluctuations, radiation exposure, and vacuum conditions while maintaining high efficiency and reliability over extended mission durations. These stringent requirements result in premium pricing, with space-grade thermoelectric materials commanding 5-10 times the price of their terrestrial counterparts.

North America currently dominates the market with approximately 45% share, led by NASA and commercial space companies like SpaceX and Blue Origin driving demand. Europe follows with 30% market share, primarily through ESA programs and satellite manufacturers. The Asia-Pacific region, particularly China, Japan, and India, represents the fastest-growing market segment with expanding national space programs and increasing private sector participation.

Key market drivers include the growing number of deep space exploration missions requiring radioisotope thermoelectric generators (RTGs), increasing deployment of small satellites and constellations requiring efficient power management, and the trend toward longer mission durations necessitating highly reliable power systems.

Market segmentation reveals distinct application categories: deep space missions utilizing primarily bismuth telluride and lead telluride compounds; Earth-orbiting satellites employing silicon-germanium alloys; and emerging lunar/Mars habitation projects exploring skutterudite-based materials. By material type, bismuth telluride compounds currently hold the largest market share at 38%, followed by silicon-germanium alloys at 27%.

Supply chain analysis indicates potential vulnerabilities due to limited material sources and specialized manufacturing capabilities. Tellurium, a critical component in many high-performance thermoelectric materials, faces supply constraints with 85% of global production concentrated in China and Russia. This geopolitical concentration presents strategic risks for Western space agencies and companies.

Customer segments include government space agencies (52% of market demand), commercial satellite manufacturers (31%), defense contractors (12%), and emerging private space exploration companies (5%). The procurement cycle typically spans 18-36 months from material specification to delivery, reflecting the extensive testing and qualification processes required for space applications.

Current Thermoelectric Materials: Capabilities and Limitations

Thermoelectric materials currently employed in spacecraft power systems primarily consist of traditional semiconductors that convert thermal energy directly into electrical power through the Seebeck effect. The most widely used materials in space applications are silicon-germanium (SiGe) alloys, which have demonstrated reliable performance in radioisotope thermoelectric generators (RTGs) for deep space missions like Voyager, Cassini, and New Horizons. These materials operate effectively at high temperatures (800-1000°C) and have proven durability over decades of operation in harsh space environments.

Lead telluride (PbTe) and its alloys represent another significant class of thermoelectric materials utilized in space power systems, particularly for intermediate temperature ranges (400-700°C). These materials offer good thermoelectric performance with ZT values (figure of merit) typically ranging from 0.8 to 1.4, depending on doping and operating temperature. However, they face limitations regarding thermal stability during extended missions and contain environmentally problematic lead.

Bismuth telluride (Bi₂Te₃) compounds dominate low-temperature applications (below 250°C) with relatively high ZT values around 1.0 at room temperature. While these materials demonstrate excellent performance in terrestrial applications, their utility in spacecraft is limited to specific thermal management scenarios rather than primary power generation due to their low temperature capabilities.

Despite decades of implementation, current thermoelectric materials face significant limitations for space applications. Conversion efficiency remains a primary challenge, with most systems operating at only 5-8% efficiency, substantially lower than other power generation technologies. This inefficiency necessitates larger radioisotope fuel loads, increasing mission weight and cost while presenting radiation safety concerns.

Mechanical durability presents another critical limitation, as thermoelectric materials must withstand intense vibration during launch and thermal cycling in space. Current materials often develop microcracks over time, degrading performance and reliability during extended missions. Additionally, the thermal stability of many thermoelectric materials deteriorates at elevated temperatures, causing compositional changes and performance degradation.

Resource constraints also impact material selection, as many high-performance thermoelectric compounds contain tellurium, germanium, and other elements with limited terrestrial abundance. This scarcity affects manufacturing scalability and increases production costs, particularly problematic for larger spacecraft power requirements.

Radiation resistance represents a particular concern for space applications, as cosmic radiation can induce defects in semiconductor materials, altering their electrical properties and degrading thermoelectric performance over time. Current materials provide adequate but not optimal radiation hardness, requiring additional shielding that increases system mass.

AI and ML: Artificial intelligence and machine learning are revolutionizing thermoelectric material discovery by enabling rapid screening of thousands of potential compounds and predicting their properties without extensive physical testing.

Lead telluride (PbTe) and its alloys represent another significant class of thermoelectric materials utilized in space power systems, particularly for intermediate temperature ranges (400-700°C). These materials offer good thermoelectric performance with ZT values (figure of merit) typically ranging from 0.8 to 1.4, depending on doping and operating temperature. However, they face limitations regarding thermal stability during extended missions and contain environmentally problematic lead.

Bismuth telluride (Bi₂Te₃) compounds dominate low-temperature applications (below 250°C) with relatively high ZT values around 1.0 at room temperature. While these materials demonstrate excellent performance in terrestrial applications, their utility in spacecraft is limited to specific thermal management scenarios rather than primary power generation due to their low temperature capabilities.

Despite decades of implementation, current thermoelectric materials face significant limitations for space applications. Conversion efficiency remains a primary challenge, with most systems operating at only 5-8% efficiency, substantially lower than other power generation technologies. This inefficiency necessitates larger radioisotope fuel loads, increasing mission weight and cost while presenting radiation safety concerns.

Mechanical durability presents another critical limitation, as thermoelectric materials must withstand intense vibration during launch and thermal cycling in space. Current materials often develop microcracks over time, degrading performance and reliability during extended missions. Additionally, the thermal stability of many thermoelectric materials deteriorates at elevated temperatures, causing compositional changes and performance degradation.

Resource constraints also impact material selection, as many high-performance thermoelectric compounds contain tellurium, germanium, and other elements with limited terrestrial abundance. This scarcity affects manufacturing scalability and increases production costs, particularly problematic for larger spacecraft power requirements.

Radiation resistance represents a particular concern for space applications, as cosmic radiation can induce defects in semiconductor materials, altering their electrical properties and degrading thermoelectric performance over time. Current materials provide adequate but not optimal radiation hardness, requiring additional shielding that increases system mass.

AI and ML: Artificial intelligence and machine learning are revolutionizing thermoelectric material discovery by enabling rapid screening of thousands of potential compounds and predicting their properties without extensive physical testing.

State-of-the-Art Thermoelectric Materials for Space Applications

01 Bismuth telluride-based thermoelectric materials

Bismuth telluride (Bi2Te3) and its alloys are among the most widely used thermoelectric materials due to their high efficiency at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. They are commonly used in cooling applications and low-temperature power generation. Research focuses on improving their figure of merit (ZT) through nanostructuring and compositional optimization.- Bismuth telluride-based thermoelectric materials: Bismuth telluride (Bi2Te3) and its alloys are among the most widely used thermoelectric materials due to their high efficiency at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. They are commonly used in cooling applications and low-temperature power generation. Recent advancements include nanostructuring techniques to improve the figure of merit (ZT) by reducing thermal conductivity while maintaining electrical conductivity.

- Skutterudite and half-Heusler thermoelectric compounds: Skutterudites and half-Heusler compounds represent important classes of thermoelectric materials for mid to high-temperature applications. These materials feature complex crystal structures that inherently reduce thermal conductivity. They can be filled with rattler atoms or modified with various dopants to further enhance their thermoelectric performance. Recent research has focused on optimizing their composition and microstructure to achieve higher conversion efficiency for waste heat recovery applications.

- Organic and polymer-based thermoelectric materials: Organic and polymer-based thermoelectric materials offer advantages such as flexibility, low cost, and environmental friendliness compared to traditional inorganic materials. These materials can be solution-processed, making them suitable for large-area applications and wearable devices. Recent developments have focused on improving their inherently low electrical conductivity through various strategies including molecular doping, composite formation with carbon nanomaterials, and optimizing polymer chain alignment to enhance charge transport properties.

- Nanostructured thermoelectric materials: Nanostructuring has emerged as a powerful approach to enhance the performance of thermoelectric materials. By introducing nanoscale features such as quantum dots, nanowires, or grain boundaries, phonon scattering can be increased without significantly affecting electron transport. This leads to reduced thermal conductivity while maintaining electrical conductivity, resulting in improved thermoelectric efficiency. Various fabrication techniques including ball milling, hot pressing, and solution-based methods are employed to create these nanostructured materials.

- Thin film and flexible thermoelectric devices: Thin film thermoelectric materials enable the development of miniaturized and flexible energy harvesting devices. These materials can be deposited using various techniques such as sputtering, evaporation, or solution processing onto different substrates including flexible polymers. The reduced dimensionality of thin films can lead to quantum confinement effects that enhance thermoelectric properties. Recent innovations include superlattice structures and flexible thermoelectric generators that can conform to curved surfaces for wearable applications or irregular heat sources.

02 Skutterudite and half-Heusler thermoelectric compounds

Skutterudites and half-Heusler compounds represent important classes of thermoelectric materials for mid to high-temperature applications. These materials feature complex crystal structures that inherently reduce thermal conductivity while maintaining good electrical properties. They can be filled with guest atoms (for skutterudites) or precisely tuned through elemental substitution (for half-Heuslers) to optimize their thermoelectric performance, making them suitable for waste heat recovery applications.Expand Specific Solutions03 Organic and polymer-based thermoelectric materials

Organic and polymer-based thermoelectric materials offer advantages of flexibility, low cost, and environmental friendliness compared to traditional inorganic materials. These materials can be solution-processed and are suitable for large-area applications. Recent developments focus on enhancing the electrical conductivity while maintaining low thermal conductivity through molecular design and doping strategies. They show promise for wearable thermoelectric generators and low-temperature applications.Expand Specific Solutions04 Nanostructured thermoelectric materials

Nanostructuring approaches significantly enhance thermoelectric performance by introducing interfaces that scatter phonons more effectively than electrons, thereby reducing thermal conductivity while preserving electrical conductivity. These techniques include creating quantum dots, nanowires, superlattices, and nanocomposites. The increased phonon scattering at grain boundaries and interfaces leads to improved figure of merit (ZT) values across various material systems, enabling more efficient thermoelectric devices.Expand Specific Solutions05 Thermoelectric device structures and fabrication methods

Advanced fabrication methods and device architectures are crucial for translating thermoelectric material properties into efficient devices. These include techniques for creating reliable electrical contacts, reducing thermal and electrical contact resistances, and optimizing leg geometries. Novel approaches such as flexible substrates, printed thermoelectric materials, and segmented legs allow for customized devices that can operate across wider temperature ranges and in various form factors, enhancing overall system efficiency.Expand Specific Solutions

Leading Organizations in Space Thermoelectric Material Development

The thermoelectric materials market for spacecraft power systems is in a growth phase, with increasing demand driven by space exploration initiatives. The competitive landscape features collaboration between research institutions and aerospace companies, with key players including Caltech, Max Planck Society, and University of California leading fundamental research, while companies like Safran, Gentherm, and Atomos Nuclear & Space focus on commercial applications. The market is characterized by a technology maturity spectrum where traditional bismuth telluride systems are established, but advanced materials research is actively pursued by aerospace entities like China Academy of Launch Vehicle Technology and specialized manufacturers such as MicroXact. The integration of thermoelectric technology with spacecraft systems represents a strategic focus for both government space agencies and private aerospace companies seeking improved power efficiency in extreme environments.

California Institute of Technology

Technical Solution: Caltech's Jet Propulsion Laboratory (JPL) has pioneered advanced thermoelectric materials for spacecraft power systems through their Multi-Mission Radioisotope Thermoelectric Generator (MMRTG) technology. Their latest generation employs skutterudite-based thermoelectric couples that achieve ZT values of 1.4-1.7 at operating temperatures, representing a significant improvement over previous PbTe/TAGS materials. JPL's innovative manufacturing techniques include spark plasma sintering to create nanostructured materials with optimized grain boundaries that scatter phonons while allowing electron transport, effectively decoupling thermal and electrical conductivity. Their systems incorporate segmented thermoelectric legs that optimize performance across the temperature gradient experienced in space applications (from ~1000°C at the hot junction to ~200°C at the cold junction). JPL has also developed specialized sublimation suppression coatings that extend thermoelectric material lifespan in vacuum environments by preventing material degradation during long-duration missions.

Strengths: Extensive flight heritage with proven reliability on multiple NASA missions including Mars rovers and deep space probes; advanced materials science capabilities; comprehensive testing facilities for space environment simulation. Weaknesses: Higher production costs compared to commercial alternatives; long development cycles; primarily focused on government/NASA applications rather than commercial space sector.

Atomos Nuclear & Space Corp.

Technical Solution: Atomos Nuclear & Space has developed advanced radioisotope thermoelectric generators (RTGs) specifically designed for deep space missions. Their technology utilizes skutterudite-based thermoelectric materials that demonstrate significantly improved conversion efficiency (12-14%) compared to traditional PbTe-based systems (7-8%). The company's proprietary manufacturing process creates nanostructured thermoelectric materials with reduced thermal conductivity while maintaining electrical conductivity, achieving ZT values exceeding 1.5 at operating temperatures. Their modular RTG design allows for scalable power generation from 50W to 500W, with integrated radiation shielding and thermal management systems optimized for the space environment. Atomos has also pioneered the use of advanced aerogel insulation materials that minimize parasitic heat losses, further improving system efficiency in the vacuum of space.

Strengths: Superior conversion efficiency compared to legacy systems; modular scalable design; radiation-hardened components; long operational lifespan (15+ years). Weaknesses: Higher initial production costs; limited flight heritage compared to traditional systems; requires specialized handling of nuclear materials; regulatory challenges for launch approval.

Critical Patents and Research in High-Performance Space Thermoelectrics

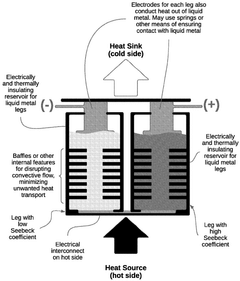

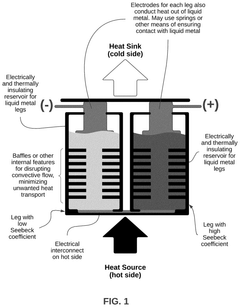

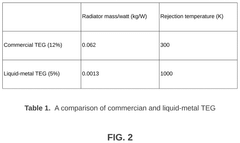

System and methods for high temperature liquid-metal thermoelectric power conversion

PatentWO2025095999A1

Innovation

- A thermoelectric generator system using liquid metal TEG junctions with legs made from metals, alloys, or composites that can operate at high temperatures, allowing for partial or full melting during operation, thereby achieving higher conversion efficiencies and tolerance to ionizing radiation.

System and methods for high temperature liquid-metal thermoelectric power conversion

PatentPendingUS20250081850A1

Innovation

- A thermoelectric generator system using a liquid metal TEG junction with legs made of materials like bismuth and antimony, which can operate at high temperatures above 1200 K, and are contained in thermally and electrically insulating reservoirs to prevent convective heat transport.

Radiation Resistance and Long-Term Reliability Assessment

Spacecraft operating in the harsh environment of space face significant challenges from radiation exposure, which can severely impact the performance and longevity of thermoelectric materials. The radiation environment in space consists primarily of high-energy particles including galactic cosmic rays, solar particles, and trapped radiation in planetary magnetospheres. These radiation sources can cause displacement damage, ionization effects, and transmutation in thermoelectric materials, leading to degradation of their electrical and thermal properties.

Traditional thermoelectric materials such as Bi2Te3 and PbTe exhibit significant performance degradation when exposed to radiation doses typical in space missions. Studies have shown that radiation can increase carrier concentration in some materials while decreasing it in others, fundamentally altering their thermoelectric efficiency. Material displacement damage can also increase phonon scattering, affecting thermal conductivity and overall figure of merit (ZT).

SiGe alloys have demonstrated superior radiation resistance compared to many alternatives, maintaining stable performance after exposure to neutron fluences exceeding 10^19 n/cm². This exceptional stability has made SiGe the preferred choice for radioisotope thermoelectric generators (RTGs) in deep space missions like Voyager, which continue to function decades after launch. The radiation hardness of SiGe is attributed to its strong covalent bonding and high melting point, which minimize atomic displacement and subsequent property changes.

Emerging materials such as skutterudites and half-Heusler alloys show promising radiation resistance characteristics in laboratory testing. Skutterudites with filled cages demonstrate enhanced stability under radiation due to the "rattling" atoms absorbing displacement energy. Similarly, half-Heusler compounds benefit from their ordered crystal structure that can better accommodate radiation-induced defects without catastrophic property changes.

Long-term reliability assessment methodologies have evolved to better predict thermoelectric material performance in space. Accelerated testing protocols now combine high-dose radiation exposure with thermal cycling to simulate decades of operation. Advanced characterization techniques including in-situ electrical measurements during irradiation provide more accurate degradation models. Computational approaches using density functional theory can now predict radiation damage effects on electronic structure and transport properties, enabling more targeted material development.

For mission-critical applications, redundancy strategies and protective shielding designs have been developed to extend thermoelectric system lifetimes. Thin-film protective coatings using radiation-resistant materials like Al2O3 have shown promise in laboratory tests, reducing performance degradation by up to 40% under equivalent radiation conditions. These protective measures, combined with inherently radiation-resistant materials, form the foundation of reliable long-duration power systems for spacecraft operating in extreme radiation environments.

Traditional thermoelectric materials such as Bi2Te3 and PbTe exhibit significant performance degradation when exposed to radiation doses typical in space missions. Studies have shown that radiation can increase carrier concentration in some materials while decreasing it in others, fundamentally altering their thermoelectric efficiency. Material displacement damage can also increase phonon scattering, affecting thermal conductivity and overall figure of merit (ZT).

SiGe alloys have demonstrated superior radiation resistance compared to many alternatives, maintaining stable performance after exposure to neutron fluences exceeding 10^19 n/cm². This exceptional stability has made SiGe the preferred choice for radioisotope thermoelectric generators (RTGs) in deep space missions like Voyager, which continue to function decades after launch. The radiation hardness of SiGe is attributed to its strong covalent bonding and high melting point, which minimize atomic displacement and subsequent property changes.

Emerging materials such as skutterudites and half-Heusler alloys show promising radiation resistance characteristics in laboratory testing. Skutterudites with filled cages demonstrate enhanced stability under radiation due to the "rattling" atoms absorbing displacement energy. Similarly, half-Heusler compounds benefit from their ordered crystal structure that can better accommodate radiation-induced defects without catastrophic property changes.

Long-term reliability assessment methodologies have evolved to better predict thermoelectric material performance in space. Accelerated testing protocols now combine high-dose radiation exposure with thermal cycling to simulate decades of operation. Advanced characterization techniques including in-situ electrical measurements during irradiation provide more accurate degradation models. Computational approaches using density functional theory can now predict radiation damage effects on electronic structure and transport properties, enabling more targeted material development.

For mission-critical applications, redundancy strategies and protective shielding designs have been developed to extend thermoelectric system lifetimes. Thin-film protective coatings using radiation-resistant materials like Al2O3 have shown promise in laboratory tests, reducing performance degradation by up to 40% under equivalent radiation conditions. These protective measures, combined with inherently radiation-resistant materials, form the foundation of reliable long-duration power systems for spacecraft operating in extreme radiation environments.

Environmental Impact and Resource Sustainability Considerations

The development and deployment of thermoelectric materials for spacecraft power systems necessitate careful consideration of environmental impacts and resource sustainability throughout their lifecycle. The extraction of rare earth elements and specialized metals commonly used in high-performance thermoelectric materials—such as tellurium, bismuth, lead, and antimony—often involves energy-intensive mining operations that generate significant carbon emissions and can lead to habitat destruction and water pollution. These environmental concerns are particularly pronounced for materials like lead telluride and bismuth telluride, which contain elements with limited global reserves.

Manufacturing processes for thermoelectric modules typically require high temperatures and specialized equipment, resulting in substantial energy consumption and associated carbon footprints. The semiconductor industry's standard fabrication techniques used for these materials often involve toxic chemicals and generate hazardous waste streams that require careful management and disposal protocols to prevent environmental contamination.

Space agencies and manufacturers are increasingly adopting life cycle assessment (LCA) methodologies to evaluate the environmental impact of thermoelectric materials from raw material extraction through manufacturing, use, and end-of-life disposal. This holistic approach has revealed that while thermoelectric systems offer emissions-free operation in space, their production phase carries significant environmental burdens that must be addressed through improved manufacturing techniques and material selection.

Recent research has focused on developing more sustainable alternatives to traditional thermoelectric materials. Skutterudites and half-Heusler alloys, for instance, utilize more abundant elements while maintaining acceptable performance characteristics. Silicon-germanium alloys, though containing the relatively scarce germanium, offer excellent high-temperature stability and can be manufactured using established semiconductor industry processes with improving efficiency and reduced waste generation.

Resource scarcity presents a significant challenge for scaling thermoelectric technology in spacecraft applications. Tellurium, a critical component in many high-performance thermoelectric materials, is among the rarest elements in the Earth's crust, with production primarily dependent on copper refining byproducts. This supply constraint has prompted research into material systems with reduced dependence on critical raw materials, including organic thermoelectric materials and nanostructured composites that enhance performance while minimizing the use of scarce elements.

Recycling and recovery strategies for end-of-life thermoelectric modules are becoming increasingly important as space agencies implement sustainability initiatives. Advanced separation techniques and hydrometallurgical processes are being developed to recover valuable elements from decommissioned spacecraft components, though the complex nature of thermoelectric materials presents significant technical challenges for achieving high recovery rates.

Manufacturing processes for thermoelectric modules typically require high temperatures and specialized equipment, resulting in substantial energy consumption and associated carbon footprints. The semiconductor industry's standard fabrication techniques used for these materials often involve toxic chemicals and generate hazardous waste streams that require careful management and disposal protocols to prevent environmental contamination.

Space agencies and manufacturers are increasingly adopting life cycle assessment (LCA) methodologies to evaluate the environmental impact of thermoelectric materials from raw material extraction through manufacturing, use, and end-of-life disposal. This holistic approach has revealed that while thermoelectric systems offer emissions-free operation in space, their production phase carries significant environmental burdens that must be addressed through improved manufacturing techniques and material selection.

Recent research has focused on developing more sustainable alternatives to traditional thermoelectric materials. Skutterudites and half-Heusler alloys, for instance, utilize more abundant elements while maintaining acceptable performance characteristics. Silicon-germanium alloys, though containing the relatively scarce germanium, offer excellent high-temperature stability and can be manufactured using established semiconductor industry processes with improving efficiency and reduced waste generation.

Resource scarcity presents a significant challenge for scaling thermoelectric technology in spacecraft applications. Tellurium, a critical component in many high-performance thermoelectric materials, is among the rarest elements in the Earth's crust, with production primarily dependent on copper refining byproducts. This supply constraint has prompted research into material systems with reduced dependence on critical raw materials, including organic thermoelectric materials and nanostructured composites that enhance performance while minimizing the use of scarce elements.

Recycling and recovery strategies for end-of-life thermoelectric modules are becoming increasingly important as space agencies implement sustainability initiatives. Advanced separation techniques and hydrometallurgical processes are being developed to recover valuable elements from decommissioned spacecraft components, though the complex nature of thermoelectric materials presents significant technical challenges for achieving high recovery rates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!