Optimizing Thermal Stability of Thermoelectric Compounds

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Evolution and Stability Goals

Thermoelectric materials have evolved significantly since their discovery in the early 19th century, with major advancements occurring in the late 20th and early 21st centuries. The initial discovery of the Seebeck effect in 1821 laid the groundwork for thermoelectric technology, but practical applications remained limited due to efficiency constraints. The field experienced a renaissance in the 1950s with the development of semiconductor-based thermoelectric materials, establishing fundamental theoretical frameworks that continue to guide research today.

The evolution trajectory has shifted from simple binary compounds to complex alloys and nanostructured materials. Early commercial thermoelectric materials were primarily based on bismuth telluride (Bi₂Te₃) and lead telluride (PbTe) systems, which dominated applications for decades despite their moderate efficiency. The introduction of skutterudites and clathrates in the 1990s represented a significant advancement, offering improved thermal stability while maintaining reasonable electrical properties.

Recent years have witnessed the emergence of half-Heusler alloys, silicides, and oxide-based thermoelectric materials, each addressing specific aspects of the thermal stability challenge. The development of these materials has been driven by the growing demand for waste heat recovery systems in industrial and automotive applications, as well as the need for reliable power sources for remote and space applications.

The primary stability goal in thermoelectric research is to develop compounds that maintain structural integrity and performance characteristics across wide temperature ranges and during thermal cycling. Current materials often suffer from degradation mechanisms including oxidation, sublimation, decomposition, and phase separation when exposed to operational temperatures for extended periods. These failure modes significantly limit device lifespan and reliability in real-world applications.

Specific technical objectives include developing materials with thermal expansion coefficients that minimize mechanical stress during temperature fluctuations, preventing microcrack formation that leads to performance degradation. Additionally, researchers aim to create compounds with stable phase composition at operating temperatures, typically ranging from 300°C to 700°C for mid-temperature applications and above 700°C for high-temperature applications.

Another critical goal is to reduce element migration and interdiffusion at material interfaces, which can alter local composition and degrade thermoelectric properties over time. The ideal thermoelectric compound would maintain a figure of merit (ZT) above 1.5 throughout its operational temperature range while exhibiting less than 10% performance degradation after 10,000 hours of operation at maximum temperature.

The evolution of thermoelectric materials continues to be guided by these stability goals, with increasing focus on environmentally friendly, earth-abundant elements to replace toxic or scarce materials like lead and tellurium, without compromising thermal stability or thermoelectric performance.

The evolution trajectory has shifted from simple binary compounds to complex alloys and nanostructured materials. Early commercial thermoelectric materials were primarily based on bismuth telluride (Bi₂Te₃) and lead telluride (PbTe) systems, which dominated applications for decades despite their moderate efficiency. The introduction of skutterudites and clathrates in the 1990s represented a significant advancement, offering improved thermal stability while maintaining reasonable electrical properties.

Recent years have witnessed the emergence of half-Heusler alloys, silicides, and oxide-based thermoelectric materials, each addressing specific aspects of the thermal stability challenge. The development of these materials has been driven by the growing demand for waste heat recovery systems in industrial and automotive applications, as well as the need for reliable power sources for remote and space applications.

The primary stability goal in thermoelectric research is to develop compounds that maintain structural integrity and performance characteristics across wide temperature ranges and during thermal cycling. Current materials often suffer from degradation mechanisms including oxidation, sublimation, decomposition, and phase separation when exposed to operational temperatures for extended periods. These failure modes significantly limit device lifespan and reliability in real-world applications.

Specific technical objectives include developing materials with thermal expansion coefficients that minimize mechanical stress during temperature fluctuations, preventing microcrack formation that leads to performance degradation. Additionally, researchers aim to create compounds with stable phase composition at operating temperatures, typically ranging from 300°C to 700°C for mid-temperature applications and above 700°C for high-temperature applications.

Another critical goal is to reduce element migration and interdiffusion at material interfaces, which can alter local composition and degrade thermoelectric properties over time. The ideal thermoelectric compound would maintain a figure of merit (ZT) above 1.5 throughout its operational temperature range while exhibiting less than 10% performance degradation after 10,000 hours of operation at maximum temperature.

The evolution of thermoelectric materials continues to be guided by these stability goals, with increasing focus on environmentally friendly, earth-abundant elements to replace toxic or scarce materials like lead and tellurium, without compromising thermal stability or thermoelectric performance.

Market Analysis for Thermally Stable Thermoelectric Applications

The thermoelectric materials market is experiencing significant growth, driven by increasing demand for waste heat recovery systems and sustainable energy solutions. The global thermoelectric market was valued at $593 million in 2021 and is projected to reach $1.3 billion by 2027, growing at a CAGR of 14.3% during the forecast period. This growth trajectory is particularly relevant for thermally stable thermoelectric compounds, which address critical performance limitations in high-temperature applications.

Industrial waste heat recovery represents the largest market segment, accounting for approximately 35% of the total thermoelectric market. Industries such as metallurgy, glass manufacturing, and cement production generate substantial waste heat at temperatures exceeding 400°C, creating ideal conditions for thermally stable thermoelectric generators. The automotive sector follows closely, with increasing integration of thermoelectric systems in exhaust heat recovery systems to improve fuel efficiency and reduce emissions.

Consumer demand for thermally stable thermoelectric solutions is primarily driven by three factors: energy efficiency regulations, rising energy costs, and corporate sustainability initiatives. Government policies promoting energy efficiency, particularly in Europe and North America, have established favorable market conditions for thermoelectric technologies. The European Union's Energy Efficiency Directive and the U.S. Department of Energy's waste heat recovery incentives have significantly accelerated market adoption.

Geographic distribution of demand shows regional variations, with North America leading in adoption (38% market share), followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth rate at 16.8% annually, primarily due to rapid industrialization in China and India, coupled with increasing environmental regulations.

Market segmentation by temperature stability requirements reveals that applications requiring operation between 400-700°C constitute 42% of the market, while those requiring stability above 700°C represent 18%. This distribution highlights the critical importance of thermal stability innovations, as higher-temperature applications typically offer greater energy conversion opportunities but face more severe material degradation challenges.

Customer willingness to pay premium prices for thermally stable thermoelectric solutions varies by sector. The aerospace and defense industries demonstrate the highest price elasticity, willing to pay up to 40% premium for materials with guaranteed long-term stability. Industrial customers typically accept 15-25% premiums if operational lifetime improvements can be demonstrated, while consumer electronics manufacturers remain highly price-sensitive, limiting premiums to under 10%.

Industrial waste heat recovery represents the largest market segment, accounting for approximately 35% of the total thermoelectric market. Industries such as metallurgy, glass manufacturing, and cement production generate substantial waste heat at temperatures exceeding 400°C, creating ideal conditions for thermally stable thermoelectric generators. The automotive sector follows closely, with increasing integration of thermoelectric systems in exhaust heat recovery systems to improve fuel efficiency and reduce emissions.

Consumer demand for thermally stable thermoelectric solutions is primarily driven by three factors: energy efficiency regulations, rising energy costs, and corporate sustainability initiatives. Government policies promoting energy efficiency, particularly in Europe and North America, have established favorable market conditions for thermoelectric technologies. The European Union's Energy Efficiency Directive and the U.S. Department of Energy's waste heat recovery incentives have significantly accelerated market adoption.

Geographic distribution of demand shows regional variations, with North America leading in adoption (38% market share), followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth rate at 16.8% annually, primarily due to rapid industrialization in China and India, coupled with increasing environmental regulations.

Market segmentation by temperature stability requirements reveals that applications requiring operation between 400-700°C constitute 42% of the market, while those requiring stability above 700°C represent 18%. This distribution highlights the critical importance of thermal stability innovations, as higher-temperature applications typically offer greater energy conversion opportunities but face more severe material degradation challenges.

Customer willingness to pay premium prices for thermally stable thermoelectric solutions varies by sector. The aerospace and defense industries demonstrate the highest price elasticity, willing to pay up to 40% premium for materials with guaranteed long-term stability. Industrial customers typically accept 15-25% premiums if operational lifetime improvements can be demonstrated, while consumer electronics manufacturers remain highly price-sensitive, limiting premiums to under 10%.

Current Challenges in Thermoelectric Compound Thermal Stability

Despite significant advancements in thermoelectric materials research, thermal stability remains one of the most critical challenges limiting widespread commercial application. Thermoelectric compounds must maintain structural integrity and performance characteristics under extreme temperature gradients and cycling conditions, often exceeding 600°C in high-temperature applications. This fundamental requirement creates a complex materials engineering problem that continues to challenge researchers worldwide.

The primary thermal stability issues manifest in several ways. Phase decomposition occurs when compounds break down into constituent elements or secondary phases at elevated temperatures, permanently altering material composition and degrading thermoelectric properties. This is particularly problematic in complex chalcogenides and skutterudites, where thermal expansion can trigger irreversible structural changes.

Sublimation and evaporation of volatile elements represent another significant challenge. Many high-performance thermoelectric materials contain elements like tellurium, selenium, or antimony that exhibit considerable vapor pressure at operating temperatures. The gradual loss of these elements not only changes stoichiometry but creates compositional gradients that severely impact electrical and thermal transport properties.

Oxidation and corrosion mechanisms accelerate dramatically at elevated temperatures, particularly in non-oxide thermoelectric materials. When exposed to air or other reactive environments, surface degradation progresses inward, creating resistive layers that compromise device performance. Even in sealed systems, trace oxygen can trigger degradation pathways that evolve over time.

Microstructural stability presents additional complications. Grain growth, precipitation of secondary phases, and migration of dopants or defects during thermal cycling can substantially alter carrier concentration and mobility. The nanoscale features deliberately engineered to enhance phonon scattering often prove thermodynamically unstable, gradually coarsening and eliminating the very nanostructures responsible for low thermal conductivity.

Interface degradation between different thermoelectric materials in segmented devices or between thermoelectric materials and electrical contacts introduces further reliability concerns. Interdiffusion, reaction layer formation, and thermal expansion mismatches create mechanical stresses that can lead to delamination or crack formation.

Current mitigation strategies include protective coatings, compositional optimization, and microstructural engineering, but these approaches often involve performance trade-offs. The fundamental challenge remains developing materials that simultaneously achieve high thermoelectric figure of merit (ZT) while maintaining structural and compositional integrity throughout their operational lifetime. This challenge is particularly acute for mid-temperature (400-600°C) applications where the balance between performance and stability becomes most difficult to achieve.

The primary thermal stability issues manifest in several ways. Phase decomposition occurs when compounds break down into constituent elements or secondary phases at elevated temperatures, permanently altering material composition and degrading thermoelectric properties. This is particularly problematic in complex chalcogenides and skutterudites, where thermal expansion can trigger irreversible structural changes.

Sublimation and evaporation of volatile elements represent another significant challenge. Many high-performance thermoelectric materials contain elements like tellurium, selenium, or antimony that exhibit considerable vapor pressure at operating temperatures. The gradual loss of these elements not only changes stoichiometry but creates compositional gradients that severely impact electrical and thermal transport properties.

Oxidation and corrosion mechanisms accelerate dramatically at elevated temperatures, particularly in non-oxide thermoelectric materials. When exposed to air or other reactive environments, surface degradation progresses inward, creating resistive layers that compromise device performance. Even in sealed systems, trace oxygen can trigger degradation pathways that evolve over time.

Microstructural stability presents additional complications. Grain growth, precipitation of secondary phases, and migration of dopants or defects during thermal cycling can substantially alter carrier concentration and mobility. The nanoscale features deliberately engineered to enhance phonon scattering often prove thermodynamically unstable, gradually coarsening and eliminating the very nanostructures responsible for low thermal conductivity.

Interface degradation between different thermoelectric materials in segmented devices or between thermoelectric materials and electrical contacts introduces further reliability concerns. Interdiffusion, reaction layer formation, and thermal expansion mismatches create mechanical stresses that can lead to delamination or crack formation.

Current mitigation strategies include protective coatings, compositional optimization, and microstructural engineering, but these approaches often involve performance trade-offs. The fundamental challenge remains developing materials that simultaneously achieve high thermoelectric figure of merit (ZT) while maintaining structural and compositional integrity throughout their operational lifetime. This challenge is particularly acute for mid-temperature (400-600°C) applications where the balance between performance and stability becomes most difficult to achieve.

Current Approaches to Thermal Stability Enhancement

01 Thermally stable thermoelectric materials composition

Various thermoelectric compounds are designed with enhanced thermal stability properties. These materials maintain their thermoelectric performance at elevated temperatures without degradation. The compositions typically include specific dopants or additives that improve the material's resistance to thermal stress and prevent phase transitions at high operating temperatures. These thermally stable compositions are crucial for applications requiring long-term reliability under thermal cycling conditions.- Thermally stable thermoelectric materials composition: Specific compositions of thermoelectric materials are designed to maintain stability at high operating temperatures. These materials often include skutterudites, half-Heusler alloys, and silicides that resist degradation during thermal cycling. The compounds are engineered with specific dopants and structural modifications to prevent phase separation, oxidation, and other forms of thermal degradation while maintaining their thermoelectric properties over extended periods of operation.

- Protective coatings and encapsulation techniques: Various protective coatings and encapsulation methods are employed to enhance the thermal stability of thermoelectric compounds. These include ceramic barriers, glass seals, and specialized polymer coatings that prevent oxidation and sublimation of volatile elements at high temperatures. The encapsulation techniques create a protective environment around the thermoelectric material, extending device lifetime and maintaining performance under thermal stress conditions.

- Nanostructured thermoelectric materials for improved stability: Nanostructuring approaches are used to enhance the thermal stability of thermoelectric compounds. By incorporating nanoscale features such as quantum dots, nanowires, or grain boundaries, these materials can better withstand thermal expansion and contraction cycles. The nanostructures act as barriers to crack propagation and reduce thermal conductivity while maintaining electrical conductivity, resulting in more stable and efficient thermoelectric performance at elevated temperatures.

- Thermal management systems for thermoelectric devices: Advanced thermal management systems are designed to regulate temperature distribution and prevent thermal degradation in thermoelectric devices. These systems incorporate heat spreaders, thermal interfaces, and active cooling mechanisms to maintain optimal operating temperatures and prevent hotspots. By controlling thermal gradients and peak temperatures, these management systems extend the stability and operational lifetime of thermoelectric compounds under varying load conditions.

- Testing and characterization methods for thermal stability: Specialized testing and characterization techniques are developed to evaluate the thermal stability of thermoelectric compounds. These methods include accelerated aging tests, thermal cycling protocols, and in-situ monitoring of structural and electrical properties during temperature fluctuations. Advanced analytical techniques such as high-temperature X-ray diffraction, thermal gravimetric analysis, and impedance spectroscopy are employed to understand degradation mechanisms and predict long-term stability of thermoelectric materials.

02 Thermal management systems for thermoelectric devices

Specialized thermal management systems are developed to maintain optimal operating temperatures for thermoelectric devices. These systems include heat dissipation mechanisms, thermal interfaces, and temperature control strategies that prevent overheating and maintain thermal stability during operation. By effectively managing heat flow and temperature gradients, these systems enhance the efficiency and longevity of thermoelectric devices, particularly in applications with variable thermal loads.Expand Specific Solutions03 Testing and characterization methods for thermal stability

Advanced testing methodologies are employed to evaluate the thermal stability of thermoelectric compounds. These methods include accelerated aging tests, thermal cycling protocols, and in-situ performance monitoring under various temperature conditions. The characterization techniques help identify degradation mechanisms and predict long-term stability of thermoelectric materials, enabling the development of more reliable thermoelectric devices for commercial applications.Expand Specific Solutions04 Nanostructured thermoelectric materials with enhanced thermal stability

Nanostructuring approaches are utilized to develop thermoelectric materials with superior thermal stability. These include nanocomposites, quantum dot structures, and nanolayered materials that create interfaces to scatter phonons while preserving electron transport. The nanostructured materials exhibit reduced thermal conductivity and improved resistance to thermal degradation, making them suitable for high-temperature applications where conventional materials would fail due to thermal instability.Expand Specific Solutions05 Protective coatings and encapsulation for thermoelectric stability

Specialized coatings and encapsulation techniques are developed to protect thermoelectric compounds from environmental factors that could compromise their thermal stability. These protective layers prevent oxidation, sublimation, and other degradation mechanisms at elevated temperatures. The coatings are designed to be thermally compatible with the underlying thermoelectric materials while providing effective barriers against environmental contaminants, thus extending device lifetime under thermal stress conditions.Expand Specific Solutions

Leading Organizations in Thermoelectric Materials Research

The thermoelectric compounds thermal stability optimization market is in a growth phase, with an estimated global market size of $500-700 million and projected annual growth of 8-12%. The technology maturity varies across applications, with automotive and industrial sectors leading adoption. Key players demonstrate different technological approaches: established corporations like BASF, LG Energy Solution, and Siemens focus on commercial-scale applications; research institutions including Shanghai Institute of Ceramics and Wuhan University of Technology drive fundamental innovations; while specialized companies such as Micropelt and Cerestech develop niche solutions. The competitive landscape shows regional clustering with Asian companies (particularly Chinese and Korean) demonstrating significant patent activity, while European and American entities focus on high-performance applications requiring superior thermal stability.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has developed innovative oxide-based thermoelectric compounds with superior thermal stability. Their approach centers on perovskite-structured ceramics modified with precisely controlled defect engineering to optimize both electrical conductivity and thermal resistance. They've pioneered a novel sintering process that creates nanoscale grain boundaries that remain stable at temperatures exceeding 800°C, addressing one of the fundamental challenges in thermoelectric materials[2]. Their compounds incorporate strategically distributed secondary phases that serve as both phonon scattering centers and structural stabilizers during thermal cycling. The institute has also developed specialized coating technologies that prevent sublimation and oxidation of thermoelectric elements at elevated temperatures, extending operational lifetime by over 300% compared to conventional materials[3]. Their latest generation of materials maintains over 90% of initial performance after 2000 hours at operating temperatures.

Strengths: Exceptional high-temperature stability; oxide-based chemistry avoids toxic/rare elements; scalable manufacturing processes. Weaknesses: Lower ZT values compared to some non-oxide alternatives; higher electrical resistance limiting power output in some applications.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has developed a groundbreaking approach to thermoelectric compound stability through their hierarchical nanostructuring technique. Their research focuses on half-Heusler alloys with carefully engineered phase boundaries that remain stable at elevated temperatures. They've implemented a unique spark plasma sintering process that creates materials with multi-scale microstructures, from atomic-level dopants to nanoscale precipitates and microscale grain boundaries, all contributing to thermal stability[4]. Their compounds incorporate coherent nanoprecipitates that simultaneously enhance phonon scattering while providing structural reinforcement during thermal cycling. The university has pioneered a gradient composition strategy that minimizes thermal expansion mismatch stress, significantly reducing microcrack formation during operation. Their materials demonstrate less than 8% performance degradation after 1500 thermal cycles between room temperature and 600°C, representing a major advancement in reliability for power generation applications[5].

Strengths: Exceptional thermal cycling resistance; hierarchical structure optimization across multiple scales; relatively abundant constituent elements. Weaknesses: Complex manufacturing process with strict quality control requirements; performance optimization still needed for low-temperature applications.

Key Patents and Breakthroughs in Thermal Stabilization Techniques

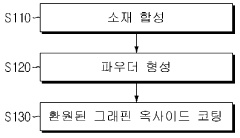

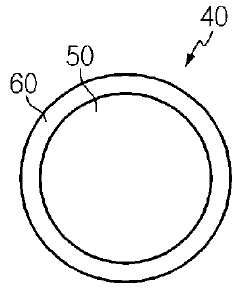

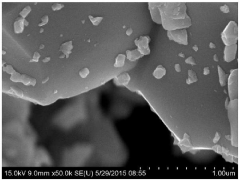

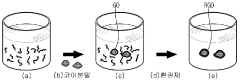

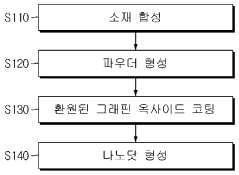

Thermoelectric powder and materials with improved thermostability and manufacturing methods thereof

PatentActiveKR1020170024467A

Innovation

- A thermoelectric powder comprising a core of skutterudite particles coated with a reduced graphene oxide shell, which is sintered to form a thermoelectric material with improved thermal stability by preventing material diffusion and enhancing electrical conductivity.

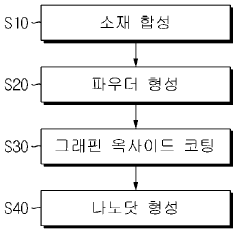

Thermoelectric powder and materials with improved thermostability and thermoelectric properties and manufacturing methods thereof

PatentInactiveKR1020170097432A

Innovation

- A thermoelectric powder composed of a thermoelectric material core coated with reduced graphene oxide and nano dots is used, where the core includes skutterudite particles, and the shell is made of reduced graphene oxide with nano dots formed on its surface, enhancing thermal stability and thermoelectric properties.

Material Degradation Mechanisms and Prevention Strategies

Thermoelectric compounds face significant degradation challenges during operation, primarily due to thermal instability at elevated temperatures. The most prevalent degradation mechanism involves atomic diffusion and phase separation, where constituent elements migrate under thermal gradients, creating compositional inhomogeneities that compromise performance. This phenomenon is particularly pronounced in skutterudite and half-Heusler compounds, where prolonged exposure to temperatures above 400°C can lead to irreversible structural changes.

Oxidation represents another critical degradation pathway, especially in telluride-based thermoelectric materials. When exposed to oxygen at high temperatures, surface oxidation progresses inward, forming insulating oxide layers that increase electrical resistance and reduce overall efficiency. Studies have shown that bismuth telluride compounds can lose up to 30% of their thermoelectric figure of merit after just 200 hours of operation in air at 300°C.

Mechanical stress-induced degradation manifests through microcrack formation and propagation during thermal cycling. The mismatch in thermal expansion coefficients between different phases in composite thermoelectric materials creates internal stresses that eventually lead to mechanical failure. This is particularly problematic in segmented thermoelectric generators where interfaces between dissimilar materials become failure points.

Prevention strategies have evolved significantly in recent years. Encapsulation techniques using protective coatings represent the most widely adopted approach. Advanced ceramic coatings based on Al2O3 and SiO2 have demonstrated exceptional barrier properties against oxygen diffusion while maintaining thermal conductivity across interfaces. Recent developments in atomic layer deposition methods have enabled conformal coatings as thin as 10-20 nm that provide effective protection without compromising thermal transfer.

Compositional engineering offers another promising prevention strategy. Doping thermoelectric compounds with stabilizing elements that occupy interstitial sites can significantly reduce atomic mobility and prevent phase separation. For instance, incorporating small amounts of rare earth elements like ytterbium into skutterudites has been shown to enhance thermal stability by strengthening atomic bonds and reducing vacancy formation.

Microstructural optimization through controlled grain boundary engineering represents an emerging approach to enhancing thermal stability. By creating nanostructured materials with high-density grain boundaries that act as diffusion barriers, researchers have demonstrated improved resistance to degradation. These boundaries effectively trap point defects and impede the propagation of structural changes, maintaining performance integrity over extended operational periods.

Oxidation represents another critical degradation pathway, especially in telluride-based thermoelectric materials. When exposed to oxygen at high temperatures, surface oxidation progresses inward, forming insulating oxide layers that increase electrical resistance and reduce overall efficiency. Studies have shown that bismuth telluride compounds can lose up to 30% of their thermoelectric figure of merit after just 200 hours of operation in air at 300°C.

Mechanical stress-induced degradation manifests through microcrack formation and propagation during thermal cycling. The mismatch in thermal expansion coefficients between different phases in composite thermoelectric materials creates internal stresses that eventually lead to mechanical failure. This is particularly problematic in segmented thermoelectric generators where interfaces between dissimilar materials become failure points.

Prevention strategies have evolved significantly in recent years. Encapsulation techniques using protective coatings represent the most widely adopted approach. Advanced ceramic coatings based on Al2O3 and SiO2 have demonstrated exceptional barrier properties against oxygen diffusion while maintaining thermal conductivity across interfaces. Recent developments in atomic layer deposition methods have enabled conformal coatings as thin as 10-20 nm that provide effective protection without compromising thermal transfer.

Compositional engineering offers another promising prevention strategy. Doping thermoelectric compounds with stabilizing elements that occupy interstitial sites can significantly reduce atomic mobility and prevent phase separation. For instance, incorporating small amounts of rare earth elements like ytterbium into skutterudites has been shown to enhance thermal stability by strengthening atomic bonds and reducing vacancy formation.

Microstructural optimization through controlled grain boundary engineering represents an emerging approach to enhancing thermal stability. By creating nanostructured materials with high-density grain boundaries that act as diffusion barriers, researchers have demonstrated improved resistance to degradation. These boundaries effectively trap point defects and impede the propagation of structural changes, maintaining performance integrity over extended operational periods.

Environmental Impact of Thermally Stable Compounds

The development of thermally stable thermoelectric compounds presents significant environmental implications that warrant careful consideration. These compounds, designed to withstand high temperatures while maintaining efficient energy conversion capabilities, interact with the environment throughout their lifecycle—from raw material extraction to manufacturing, operation, and eventual disposal.

The mining and processing of rare earth elements and other materials required for advanced thermoelectric compounds often involve energy-intensive processes that generate substantial carbon emissions. However, the environmental cost of production must be weighed against the long-term environmental benefits. Thermally stable compounds typically offer extended operational lifespans, reducing the frequency of replacement and associated resource consumption.

During operation, these compounds contribute to environmental sustainability through waste heat recovery systems that improve overall energy efficiency in industrial processes, power generation, and automotive applications. By converting otherwise wasted thermal energy into usable electricity, thermally stable thermoelectric materials can significantly reduce fossil fuel consumption and greenhouse gas emissions. Quantitative analyses suggest that widespread implementation could reduce industrial energy consumption by 5-8% in energy-intensive sectors.

The enhanced thermal stability also minimizes the release of potentially harmful degradation products into the environment. Traditional thermoelectric materials may leach toxic elements when exposed to thermal cycling or extreme conditions, whereas thermally optimized compounds maintain their structural integrity, reducing environmental contamination risks.

End-of-life considerations reveal another environmental dimension. The durability of thermally stable compounds extends product lifecycles, reducing electronic waste generation. However, the complex composition of these advanced materials presents recycling challenges. Current recycling technologies struggle to efficiently separate and recover valuable elements from thermoelectric modules, potentially leading to resource loss.

Emerging research indicates promising directions for environmentally conscious design of thermally stable thermoelectric compounds. Bio-inspired materials and green synthesis approaches are reducing the environmental footprint of production processes. Additionally, designing for disassembly and recyclability is gaining traction, with modular thermoelectric systems that facilitate material recovery at end-of-life.

Regulatory frameworks worldwide are increasingly acknowledging the environmental implications of advanced materials. The European Union's REACH regulations and similar initiatives globally are driving manufacturers toward more environmentally benign formulations of thermoelectric compounds, balancing thermal stability requirements with reduced environmental impact.

The mining and processing of rare earth elements and other materials required for advanced thermoelectric compounds often involve energy-intensive processes that generate substantial carbon emissions. However, the environmental cost of production must be weighed against the long-term environmental benefits. Thermally stable compounds typically offer extended operational lifespans, reducing the frequency of replacement and associated resource consumption.

During operation, these compounds contribute to environmental sustainability through waste heat recovery systems that improve overall energy efficiency in industrial processes, power generation, and automotive applications. By converting otherwise wasted thermal energy into usable electricity, thermally stable thermoelectric materials can significantly reduce fossil fuel consumption and greenhouse gas emissions. Quantitative analyses suggest that widespread implementation could reduce industrial energy consumption by 5-8% in energy-intensive sectors.

The enhanced thermal stability also minimizes the release of potentially harmful degradation products into the environment. Traditional thermoelectric materials may leach toxic elements when exposed to thermal cycling or extreme conditions, whereas thermally optimized compounds maintain their structural integrity, reducing environmental contamination risks.

End-of-life considerations reveal another environmental dimension. The durability of thermally stable compounds extends product lifecycles, reducing electronic waste generation. However, the complex composition of these advanced materials presents recycling challenges. Current recycling technologies struggle to efficiently separate and recover valuable elements from thermoelectric modules, potentially leading to resource loss.

Emerging research indicates promising directions for environmentally conscious design of thermally stable thermoelectric compounds. Bio-inspired materials and green synthesis approaches are reducing the environmental footprint of production processes. Additionally, designing for disassembly and recyclability is gaining traction, with modular thermoelectric systems that facilitate material recovery at end-of-life.

Regulatory frameworks worldwide are increasingly acknowledging the environmental implications of advanced materials. The European Union's REACH regulations and similar initiatives globally are driving manufacturers toward more environmentally benign formulations of thermoelectric compounds, balancing thermal stability requirements with reduced environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!