How to Implement Zirconia in Optical Sensor Technology?

Zirconia in Optical Sensors: Background and Objectives

Zirconia, a versatile ceramic material, has emerged as a promising candidate for optical sensor technology due to its unique properties and potential applications. The evolution of zirconia in this field can be traced back to the early 2000s when researchers began exploring its optical characteristics. As the demand for more sensitive and reliable sensors grew, zirconia's exceptional thermal stability, mechanical strength, and optical transparency caught the attention of scientists and engineers.

The primary objective of implementing zirconia in optical sensor technology is to enhance the performance, durability, and versatility of sensing devices across various industries. Researchers aim to leverage zirconia's high refractive index, wide bandgap, and excellent chemical resistance to develop sensors capable of operating in harsh environments and detecting a wide range of analytes with improved accuracy and sensitivity.

One of the key trends driving the development of zirconia-based optical sensors is the increasing need for miniaturization and integration in modern sensing systems. As industries move towards more compact and efficient devices, zirconia's ability to be fabricated into thin films and nanostructures makes it an ideal candidate for next-generation sensor designs.

The potential applications of zirconia in optical sensor technology span across multiple sectors, including environmental monitoring, biomedical diagnostics, industrial process control, and aerospace. In environmental sensing, zirconia-based sensors show promise for detecting pollutants and monitoring air and water quality with high precision. In the biomedical field, these sensors could revolutionize point-of-care diagnostics by enabling rapid and accurate detection of various biomarkers.

As research in this area progresses, scientists are exploring novel ways to modify and functionalize zirconia surfaces to enhance their sensing capabilities. This includes doping with rare earth elements, creating nanocomposites, and developing hybrid structures that combine zirconia with other materials to achieve synergistic effects.

The implementation of zirconia in optical sensor technology faces several challenges, including optimizing fabrication processes, improving long-term stability, and reducing production costs. Overcoming these hurdles is crucial for the widespread adoption of zirconia-based sensors in commercial applications.

Looking ahead, the future of zirconia in optical sensor technology appears promising, with ongoing research focused on expanding its functionality and addressing current limitations. As new fabrication techniques and material combinations emerge, zirconia is poised to play a significant role in shaping the next generation of optical sensing devices, offering improved performance, reliability, and versatility across a wide range of applications.

Market Demand Analysis for Zirconia-based Optical Sensors

The market demand for zirconia-based optical sensors has been experiencing significant growth in recent years, driven by advancements in various industries and the unique properties of zirconia. This market segment is poised for continued expansion due to the increasing need for high-performance sensing technologies in critical applications.

One of the primary drivers of market demand is the automotive industry. As vehicles become more sophisticated and autonomous, the need for reliable and durable sensors has intensified. Zirconia-based optical sensors offer excellent resistance to harsh environments, making them ideal for use in engine management systems, exhaust gas monitoring, and fuel cell applications. The global push towards electric and hybrid vehicles further amplifies this demand, as these sensors play a crucial role in optimizing energy efficiency and reducing emissions.

The aerospace sector represents another significant market for zirconia-based optical sensors. These sensors are essential for monitoring engine performance, fuel efficiency, and structural health in aircraft. With the aerospace industry's continuous focus on improving safety and reducing operational costs, the demand for high-precision, reliable sensors is expected to grow steadily.

In the healthcare and medical devices sector, zirconia-based optical sensors are gaining traction due to their biocompatibility and stability. These sensors are used in various medical applications, including blood gas analysis, glucose monitoring, and drug delivery systems. The aging global population and the increasing prevalence of chronic diseases are driving the demand for advanced medical diagnostics and monitoring devices, further boosting the market for zirconia-based sensors.

The industrial sector, particularly in process control and environmental monitoring applications, is another key driver of market demand. Zirconia-based sensors are widely used in industrial furnaces, boilers, and waste incineration plants for oxygen sensing and combustion control. The growing emphasis on energy efficiency and environmental regulations is expected to fuel the demand for these sensors in industrial applications.

Market analysis indicates that the Asia-Pacific region is likely to witness the highest growth rate in the zirconia-based optical sensor market. This is attributed to rapid industrialization, increasing automotive production, and significant investments in healthcare infrastructure in countries like China and India. North America and Europe are also expected to maintain strong market positions due to their advanced manufacturing capabilities and stringent environmental regulations.

While the market outlook is generally positive, there are challenges that could impact demand. These include the high initial cost of zirconia-based sensors compared to traditional alternatives and the need for specialized expertise in their implementation and maintenance. However, as technology advances and production scales up, these barriers are expected to diminish, further driving market growth.

In conclusion, the market demand for zirconia-based optical sensors is robust and diverse, spanning multiple industries and applications. The unique properties of zirconia, combined with the increasing need for high-performance sensing technologies, position this market segment for sustained growth in the coming years.

Current State and Challenges in Zirconia Optical Sensor Technology

The current state of zirconia implementation in optical sensor technology is characterized by significant advancements and persistent challenges. Zirconia, known for its exceptional optical and mechanical properties, has gained traction in various sensing applications. Its high refractive index, wide bandgap, and excellent thermal stability make it an attractive material for optical sensors.

In recent years, researchers have successfully developed zirconia-based optical sensors for a range of applications, including temperature sensing, gas detection, and biomolecular recognition. These sensors leverage zirconia's unique properties to achieve high sensitivity and stability in harsh environments. For instance, zirconia nanoparticles have been incorporated into fiber optic sensors to enhance their performance in extreme temperature conditions.

Despite these advancements, several challenges persist in the widespread implementation of zirconia in optical sensor technology. One major hurdle is the complexity of fabrication processes. The synthesis of high-quality zirconia nanostructures with controlled size, shape, and crystalline phase remains challenging. This complexity often leads to inconsistencies in sensor performance and limits large-scale production.

Another significant challenge lies in the integration of zirconia with existing optical sensing platforms. While zirconia offers superior properties, its compatibility with conventional optical components and readout systems can be problematic. Researchers are actively working on developing novel integration techniques to overcome these limitations and fully harness zirconia's potential.

The long-term stability of zirconia-based optical sensors is also an area of ongoing research. Although zirconia exhibits excellent thermal and chemical stability, prolonged exposure to harsh environments can lead to degradation of sensor performance. Addressing this issue requires the development of protective coatings and innovative sensor designs that maintain sensitivity while enhancing durability.

Furthermore, the cost-effectiveness of zirconia-based optical sensors remains a concern for widespread commercial adoption. The high-purity zirconia precursors and specialized fabrication techniques often result in elevated production costs. Efforts are underway to optimize manufacturing processes and explore alternative synthesis routes to reduce costs without compromising sensor quality.

In terms of geographical distribution, research and development in zirconia optical sensor technology are concentrated in several key regions. North America and Europe lead in fundamental research and advanced applications, while Asia, particularly China and Japan, is rapidly advancing in both research and commercialization efforts. This global distribution of expertise presents opportunities for international collaboration but also intensifies competition in the field.

Existing Zirconia Implementation Methods in Optical Sensors

01 Zirconia synthesis and processing methods

Various techniques for synthesizing and processing zirconia materials, including sol-gel methods, hydrothermal synthesis, and sintering processes. These methods aim to control the crystal structure, particle size, and properties of zirconia for different applications.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, crystalline structure, and purity. These methods aim to produce zirconia with specific properties suitable for different applications in industries such as ceramics, electronics, and catalysis.

- Zirconia-based dental materials: Zirconia is widely used in dental applications due to its biocompatibility, strength, and aesthetic properties. Innovations in this field include improved formulations for dental prosthetics, coatings, and composite materials that enhance durability and mimic natural tooth appearance.

- Zirconia in advanced ceramics and coatings: Zirconia plays a crucial role in the development of advanced ceramics and coatings. Research focuses on enhancing the material's thermal, mechanical, and chemical properties for applications in extreme environments, such as high-temperature industrial processes and aerospace components.

- Zirconia-based catalysts and sensors: Zirconia is utilized in the creation of catalysts and sensors for various industrial and environmental applications. Innovations in this area include the development of zirconia-supported catalysts for chemical processes and gas sensors for detecting pollutants and toxic substances.

- Zirconia in energy and electronic applications: Zirconia finds applications in energy-related technologies and electronic devices. Research in this field focuses on using zirconia in solid oxide fuel cells, battery components, and as a dielectric material in electronic circuits, aiming to improve energy efficiency and device performance.

02 Zirconia-based dental materials

Development of zirconia-based materials for dental applications, such as crowns, bridges, and implants. These materials offer high strength, biocompatibility, and aesthetic properties suitable for dental restorations.Expand Specific Solutions03 Zirconia in catalysis and fuel cells

Utilization of zirconia as a catalyst support or component in various catalytic processes and as an electrolyte material in solid oxide fuel cells. Zirconia's stability and ionic conductivity make it valuable for these applications.Expand Specific Solutions04 Zirconia coatings and thin films

Methods for depositing zirconia coatings and thin films on various substrates for applications such as thermal barrier coatings, optical coatings, and protective layers. These coatings enhance the durability and performance of materials in harsh environments.Expand Specific Solutions05 Zirconia composites and nanostructures

Development of zirconia-based composites and nanostructured materials with enhanced mechanical, thermal, and electrical properties. These materials combine zirconia with other components to create advanced materials for various industrial and technological applications.Expand Specific Solutions

Key Players in Zirconia Optical Sensor Industry

The implementation of zirconia in optical sensor technology is in a growth phase, with increasing market size and technological advancements. The global market for zirconia-based optical sensors is expanding due to their superior properties and diverse applications. Companies like 3M Innovative Properties Co., Tosoh Corp., and Sumitomo Chemical Co., Ltd. are at the forefront of this technology, developing advanced zirconia materials for optical sensing. The technological maturity varies, with established players like EssilorLuxottica SA and emerging innovators such as Shanghai University contributing to the field. Research institutions like the University of Science & Technology of China and Harvard College are pushing boundaries in zirconia-based optical sensor development, indicating a dynamic and competitive landscape with potential for further growth and innovation.

Tosoh Corp.

Sumitomo Chemical Co., Ltd.

Core Innovations in Zirconia-based Optical Sensing

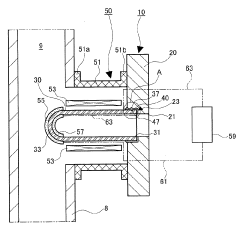

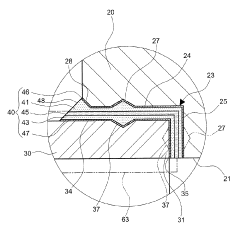

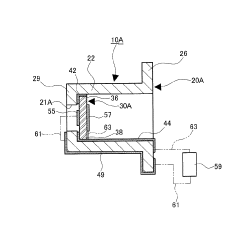

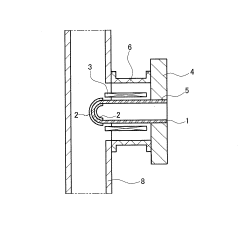

- A zirconia oxygen sensor component using a ceramic member with a vent hole, joined to a zirconia member via a sintered conductive platinum paste bonding layer, which includes a gold-platinum alloy to enhance airtightness and thermal stability, allowing attachment to high-temperature environments.

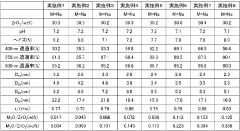

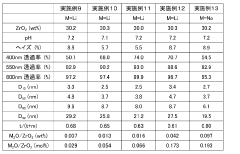

- A highly transparent zirconia sol with a zirconia particle content of 20 wt% or more, containing alkali metal oxides with a specific molar ratio, and optimized hydrolysis conditions, which includes heating an alkali metal solution, adding zirconium salt, aging, and peptizing to produce zirconium hydroxide, resulting in a sol with high transmittance and refractive index without the need for special equipment or high-temperature processing.

Material Properties and Characterization of Zirconia for Optical Sensors

Zirconia, a versatile ceramic material, exhibits exceptional properties that make it highly suitable for optical sensor applications. Its high refractive index, ranging from 2.15 to 2.18, enables efficient light manipulation and enhances sensor sensitivity. The material's excellent optical transparency in the visible and near-infrared regions allows for minimal signal loss, crucial for accurate sensor readings.

One of the key advantages of zirconia in optical sensors is its remarkable mechanical strength and durability. With a hardness of 8.5 on the Mohs scale, zirconia resists scratching and wear, ensuring long-term reliability in harsh environments. Its high fracture toughness, typically between 5-10 MPa·m^(1/2), provides resistance to crack propagation, enhancing the overall robustness of optical sensor components.

Zirconia's thermal properties further contribute to its suitability for optical sensor technology. Its low thermal conductivity, approximately 2 W/(m·K), minimizes heat transfer and thermal interference in sensor systems. Additionally, zirconia maintains its structural integrity at high temperatures, with a melting point of about 2700°C, making it ideal for sensors operating in extreme thermal conditions.

The material's chemical stability is another critical characteristic for optical sensor applications. Zirconia exhibits excellent resistance to corrosion and chemical attack, ensuring sensor longevity in diverse environments. This property is particularly valuable in industrial and biomedical sensing applications where exposure to aggressive chemicals is common.

Characterization techniques for zirconia in optical sensors include X-ray diffraction (XRD) for crystal structure analysis, scanning electron microscopy (SEM) for surface morphology examination, and spectrophotometry for optical transmittance measurements. These methods provide crucial insights into the material's properties and performance in sensor designs.

The ability to tailor zirconia's properties through doping and nanostructuring offers opportunities for enhancing its functionality in optical sensors. For instance, yttria-stabilized zirconia (YSZ) demonstrates improved ionic conductivity and oxygen sensing capabilities, expanding its potential applications in gas sensors and fuel cells.

In conclusion, zirconia's unique combination of optical, mechanical, thermal, and chemical properties, coupled with advanced characterization techniques, positions it as a promising material for next-generation optical sensor technologies. Its versatility and adaptability make it suitable for a wide range of sensing applications, from environmental monitoring to biomedical diagnostics.

Environmental Impact and Sustainability of Zirconia Optical Sensors

The implementation of zirconia in optical sensor technology brings forth significant considerations regarding environmental impact and sustainability. Zirconia-based optical sensors offer several advantages in terms of durability and performance, which can contribute to their overall sustainability profile.

Zirconia's exceptional chemical stability and resistance to harsh environments make it an ideal material for long-lasting optical sensors. This durability translates to extended product lifecycles, reducing the frequency of sensor replacement and, consequently, minimizing electronic waste generation. The longevity of zirconia optical sensors also means fewer resources are required for manufacturing and distribution over time, leading to a reduced carbon footprint compared to less durable alternatives.

From a raw material perspective, zirconium is relatively abundant in the Earth's crust, which suggests a more sustainable supply chain compared to rare earth elements often used in other optical technologies. However, the extraction and processing of zirconium ores can have environmental implications, including habitat disruption and energy-intensive refining processes. It is crucial for manufacturers to adopt responsible sourcing practices and optimize production methods to mitigate these impacts.

The energy efficiency of zirconia optical sensors during operation is another key factor in their environmental profile. These sensors typically require minimal power to function, which can lead to reduced energy consumption in the devices and systems they are integrated into. This energy efficiency not only contributes to lower operational costs but also aligns with global efforts to reduce energy-related carbon emissions.

End-of-life considerations for zirconia optical sensors present both challenges and opportunities. While zirconia itself is not biodegradable, it is recyclable. Developing efficient recycling processes for these sensors can help recover valuable materials and reduce waste. However, the complex nature of optical sensors, which often contain multiple materials, may complicate recycling efforts. Industry collaboration to establish standardized recycling protocols and infrastructure will be essential to maximize the circularity of these components.

The potential for zirconia optical sensors to enable more efficient and precise monitoring in various applications, such as environmental sensing and industrial process control, should also be considered. By providing accurate and reliable data, these sensors can contribute to optimized resource use, reduced waste, and improved energy efficiency across multiple sectors. This indirect environmental benefit could potentially outweigh the impacts associated with their production and disposal.

As the adoption of zirconia optical sensors increases, it will be crucial for manufacturers and researchers to continually assess and improve their environmental performance. This may involve exploring bio-based or recycled alternatives for sensor components, developing more energy-efficient production techniques, and designing sensors with easier disassembly and recycling in mind. By addressing these aspects, the industry can ensure that the implementation of zirconia in optical sensor technology aligns with broader sustainability goals and contributes positively to environmental stewardship.