How to Improve ICP-MS Signal-to-Noise Ratio

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ICP-MS Technology Background and Objectives

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has evolved significantly since its commercial introduction in the early 1980s. This analytical technique combines the high-temperature ICP source with a mass spectrometer to detect and quantify elements at ultra-trace concentrations, often at parts per trillion (ppt) levels. The technology emerged from earlier atomic emission spectroscopy methods but offered superior detection limits and multi-element analysis capabilities.

The evolution of ICP-MS has been marked by several key advancements, including the development of collision/reaction cells to reduce polyatomic interferences, the introduction of high-resolution mass analyzers, and improvements in sample introduction systems. These developments have progressively enhanced the technique's sensitivity, precision, and applicability across diverse scientific fields.

Current technological trends in ICP-MS focus on improving signal-to-noise ratios (SNR), which directly impacts detection limits and analytical precision. This improvement is crucial as modern applications increasingly demand the ability to detect ever-lower concentrations of elements in complex matrices. Enhanced SNR enables more reliable analysis in environmental monitoring, clinical diagnostics, food safety, and semiconductor manufacturing, where contaminants at ultra-trace levels can have significant impacts.

The primary technical objectives for improving ICP-MS signal-to-noise ratios include optimizing ion transmission efficiency from the plasma to the detector, reducing background noise from various sources, enhancing plasma stability, and developing more sophisticated signal processing algorithms. These objectives align with broader industry goals of achieving lower detection limits while maintaining or improving analytical throughput.

Another significant trend is the miniaturization and automation of ICP-MS systems, making the technology more accessible to non-specialist laboratories and enabling field-deployable applications. This direction presents unique challenges for maintaining high SNR in smaller, potentially less stable systems.

The pursuit of improved SNR in ICP-MS also intersects with advancements in complementary technologies, such as sample preparation techniques, chromatographic separations, and data processing methods. These integrated approaches recognize that optimal analytical performance requires consideration of the entire workflow, not just the core instrumentation.

As environmental regulations become more stringent and biomedical research pushes into new frontiers of trace element analysis, the technical goals for ICP-MS continue to evolve. Future developments will likely focus on intelligent noise reduction strategies, novel plasma configurations, and advanced detector technologies to further enhance the signal-to-noise performance of these sophisticated analytical instruments.

The evolution of ICP-MS has been marked by several key advancements, including the development of collision/reaction cells to reduce polyatomic interferences, the introduction of high-resolution mass analyzers, and improvements in sample introduction systems. These developments have progressively enhanced the technique's sensitivity, precision, and applicability across diverse scientific fields.

Current technological trends in ICP-MS focus on improving signal-to-noise ratios (SNR), which directly impacts detection limits and analytical precision. This improvement is crucial as modern applications increasingly demand the ability to detect ever-lower concentrations of elements in complex matrices. Enhanced SNR enables more reliable analysis in environmental monitoring, clinical diagnostics, food safety, and semiconductor manufacturing, where contaminants at ultra-trace levels can have significant impacts.

The primary technical objectives for improving ICP-MS signal-to-noise ratios include optimizing ion transmission efficiency from the plasma to the detector, reducing background noise from various sources, enhancing plasma stability, and developing more sophisticated signal processing algorithms. These objectives align with broader industry goals of achieving lower detection limits while maintaining or improving analytical throughput.

Another significant trend is the miniaturization and automation of ICP-MS systems, making the technology more accessible to non-specialist laboratories and enabling field-deployable applications. This direction presents unique challenges for maintaining high SNR in smaller, potentially less stable systems.

The pursuit of improved SNR in ICP-MS also intersects with advancements in complementary technologies, such as sample preparation techniques, chromatographic separations, and data processing methods. These integrated approaches recognize that optimal analytical performance requires consideration of the entire workflow, not just the core instrumentation.

As environmental regulations become more stringent and biomedical research pushes into new frontiers of trace element analysis, the technical goals for ICP-MS continue to evolve. Future developments will likely focus on intelligent noise reduction strategies, novel plasma configurations, and advanced detector technologies to further enhance the signal-to-noise performance of these sophisticated analytical instruments.

Market Demand Analysis for High-Sensitivity ICP-MS

The global market for high-sensitivity ICP-MS (Inductively Coupled Plasma Mass Spectrometry) systems has been experiencing robust growth, driven primarily by increasing demands in environmental monitoring, pharmaceutical research, food safety testing, and clinical diagnostics. Current market estimates value the analytical instrumentation sector at approximately $5.2 billion, with ICP-MS technology representing a significant and growing segment.

Environmental monitoring applications constitute the largest market share for high-sensitivity ICP-MS systems, accounting for nearly 35% of total demand. This is largely attributed to stricter global regulations regarding water quality, soil contamination, and air pollution monitoring, particularly in developed regions such as North America and Europe.

The pharmaceutical and biotechnology sectors follow closely, representing about 30% of market demand. These industries require ultra-sensitive trace element analysis for drug development, quality control, and biomarker research. The ability to detect contaminants at sub-parts-per-trillion levels has become essential for compliance with increasingly stringent regulatory standards.

Clinical diagnostics represents the fastest-growing application segment, with a compound annual growth rate projected at 8.7% through 2028. The rising importance of trace element analysis in disease diagnosis, particularly for metal-related disorders and toxicity assessments, is fueling this growth. Healthcare providers are increasingly recognizing the value of high-sensitivity elemental analysis in personalized medicine approaches.

Geographically, North America dominates the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by expanding industrial activities, increasing environmental concerns, and growing healthcare infrastructure in countries like China, India, and South Korea.

End-user surveys indicate that signal-to-noise ratio improvement ranks among the top three priorities for ICP-MS users, with 78% of respondents citing it as "very important" or "critical" for their applications. This demand is particularly pronounced in applications requiring detection of ultra-trace elements in complex matrices, such as rare earth elements in environmental samples or toxic metals in biological tissues.

Market analysis reveals a clear price premium for systems offering superior signal-to-noise performance, with customers willing to pay 15-20% more for instruments that can demonstrate significant improvements in detection limits and analytical precision. This trend underscores the strong commercial incentive for manufacturers to invest in signal-to-noise enhancement technologies.

Environmental monitoring applications constitute the largest market share for high-sensitivity ICP-MS systems, accounting for nearly 35% of total demand. This is largely attributed to stricter global regulations regarding water quality, soil contamination, and air pollution monitoring, particularly in developed regions such as North America and Europe.

The pharmaceutical and biotechnology sectors follow closely, representing about 30% of market demand. These industries require ultra-sensitive trace element analysis for drug development, quality control, and biomarker research. The ability to detect contaminants at sub-parts-per-trillion levels has become essential for compliance with increasingly stringent regulatory standards.

Clinical diagnostics represents the fastest-growing application segment, with a compound annual growth rate projected at 8.7% through 2028. The rising importance of trace element analysis in disease diagnosis, particularly for metal-related disorders and toxicity assessments, is fueling this growth. Healthcare providers are increasingly recognizing the value of high-sensitivity elemental analysis in personalized medicine approaches.

Geographically, North America dominates the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by expanding industrial activities, increasing environmental concerns, and growing healthcare infrastructure in countries like China, India, and South Korea.

End-user surveys indicate that signal-to-noise ratio improvement ranks among the top three priorities for ICP-MS users, with 78% of respondents citing it as "very important" or "critical" for their applications. This demand is particularly pronounced in applications requiring detection of ultra-trace elements in complex matrices, such as rare earth elements in environmental samples or toxic metals in biological tissues.

Market analysis reveals a clear price premium for systems offering superior signal-to-noise performance, with customers willing to pay 15-20% more for instruments that can demonstrate significant improvements in detection limits and analytical precision. This trend underscores the strong commercial incentive for manufacturers to invest in signal-to-noise enhancement technologies.

Current Challenges in ICP-MS Signal Quality

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) faces several significant challenges that impact signal quality and analytical performance. One of the primary issues is spectral interference, where polyatomic ions formed in the plasma or interface regions overlap with analyte signals. These interferences can significantly degrade measurement accuracy, particularly for elements with masses susceptible to oxide, hydroxide, or argide formations.

Matrix effects represent another substantial challenge, as complex sample compositions can suppress or enhance analyte signals unpredictably. High concentrations of dissolved solids often lead to signal drift and instability over analytical runs, requiring frequent recalibration and reducing throughput efficiency. The variability in ionization efficiency across different elements further complicates quantitative analysis, especially in multi-element determinations.

Instrument stability presents ongoing difficulties, with plasma fluctuations, sample introduction variations, and detector response drift all contributing to signal variability. Modern ICP-MS systems still struggle with maintaining consistent performance during extended analytical sessions, particularly when analyzing challenging matrices like seawater, biological fluids, or industrial waste.

The interface region between the plasma and the mass analyzer remains a critical bottleneck. Space-charge effects in this region can cause ion defocusing and transmission losses, disproportionately affecting lighter elements and reducing overall sensitivity. Additionally, the formation of secondary discharges at the interface can introduce signal noise and instability.

Detection limits continue to challenge analysts working with ultra-trace elements. While ICP-MS offers impressive sensitivity, achieving reliable measurements at sub-ppt levels remains difficult due to background noise from reagents, sample preparation environments, and instrument components. The signal-to-noise ratio deteriorates significantly at these extreme detection limits.

Sample introduction inefficiency represents another persistent challenge. Conventional nebulizer systems typically deliver only 1-3% of the sample to the plasma, wasting valuable sample volume and limiting sensitivity. Specialized introduction systems improve efficiency but often introduce new complications like memory effects or signal instability.

Data processing and signal integration approaches have not kept pace with hardware advancements. Many laboratories still rely on relatively simple peak integration methods that fail to fully address spectral overlaps, baseline drift, and signal spikes. More sophisticated mathematical approaches exist but remain underutilized due to implementation complexity and software limitations.

Matrix effects represent another substantial challenge, as complex sample compositions can suppress or enhance analyte signals unpredictably. High concentrations of dissolved solids often lead to signal drift and instability over analytical runs, requiring frequent recalibration and reducing throughput efficiency. The variability in ionization efficiency across different elements further complicates quantitative analysis, especially in multi-element determinations.

Instrument stability presents ongoing difficulties, with plasma fluctuations, sample introduction variations, and detector response drift all contributing to signal variability. Modern ICP-MS systems still struggle with maintaining consistent performance during extended analytical sessions, particularly when analyzing challenging matrices like seawater, biological fluids, or industrial waste.

The interface region between the plasma and the mass analyzer remains a critical bottleneck. Space-charge effects in this region can cause ion defocusing and transmission losses, disproportionately affecting lighter elements and reducing overall sensitivity. Additionally, the formation of secondary discharges at the interface can introduce signal noise and instability.

Detection limits continue to challenge analysts working with ultra-trace elements. While ICP-MS offers impressive sensitivity, achieving reliable measurements at sub-ppt levels remains difficult due to background noise from reagents, sample preparation environments, and instrument components. The signal-to-noise ratio deteriorates significantly at these extreme detection limits.

Sample introduction inefficiency represents another persistent challenge. Conventional nebulizer systems typically deliver only 1-3% of the sample to the plasma, wasting valuable sample volume and limiting sensitivity. Specialized introduction systems improve efficiency but often introduce new complications like memory effects or signal instability.

Data processing and signal integration approaches have not kept pace with hardware advancements. Many laboratories still rely on relatively simple peak integration methods that fail to fully address spectral overlaps, baseline drift, and signal spikes. More sophisticated mathematical approaches exist but remain underutilized due to implementation complexity and software limitations.

Current Signal-to-Noise Ratio Improvement Methods

01 Hardware optimization for improved signal-to-noise ratio in ICP-MS

Various hardware modifications and optimizations can significantly improve the signal-to-noise ratio in ICP-MS systems. These include specialized ion optics designs, improved plasma torch configurations, enhanced detector systems, and optimized sample introduction systems. Such hardware improvements can reduce background noise while enhancing analyte signal intensity, leading to better detection limits and analytical performance.- Hardware optimization for improved signal-to-noise ratio in ICP-MS: Various hardware components can be optimized to enhance the signal-to-noise ratio in ICP-MS systems. These include improved ion optics designs, specialized detectors, optimized plasma torch configurations, and interface modifications. Hardware innovations focus on reducing background noise while maximizing ion transmission efficiency, resulting in better detection limits and analytical performance.

- Signal processing techniques for enhancing ICP-MS sensitivity: Advanced signal processing algorithms and techniques can significantly improve the signal-to-noise ratio in ICP-MS analysis. These include digital filtering, noise reduction algorithms, signal averaging, baseline correction methods, and mathematical transformations. By implementing sophisticated data processing approaches, analysts can extract meaningful signals from noisy backgrounds, leading to enhanced detection capabilities and more reliable quantification.

- Sample introduction and preparation methods for noise reduction: Optimized sample introduction systems and preparation protocols can minimize matrix effects and interferences that contribute to noise in ICP-MS measurements. Techniques such as desolvation, aerosol filtering, flow optimization, and chemical separation methods help deliver a more consistent sample to the plasma, reducing signal fluctuations and enhancing stability. Proper sample dilution and matrix matching also contribute to improved signal-to-noise ratios.

- Plasma condition optimization for enhanced stability: Careful control and optimization of plasma conditions significantly impact the signal-to-noise ratio in ICP-MS. Parameters such as RF power, gas flow rates, plasma temperature, and torch position can be tuned to achieve optimal ionization efficiency while minimizing background interference. Stable plasma conditions lead to more consistent ion generation and improved signal quality, particularly for challenging analytes.

- Collision/reaction cell technology for interference reduction: Collision and reaction cell technologies are effective approaches for improving signal-to-noise ratios in ICP-MS by selectively removing or transforming interfering species. These cells, positioned between the ion source and mass analyzer, use collision gases or reactive gases to eliminate polyatomic interferences through kinetic energy discrimination or chemical reactions. By reducing spectral interferences, these technologies enable cleaner spectra and lower detection limits for challenging elements.

02 Signal processing techniques for enhancing ICP-MS signal-to-noise ratio

Advanced signal processing algorithms and techniques can be employed to enhance the signal-to-noise ratio in ICP-MS analysis. These include digital filtering, signal averaging, baseline correction methods, and mathematical transformations. By applying these computational approaches to raw ICP-MS data, analysts can effectively separate analyte signals from background noise, improving detection capabilities for trace elements.Expand Specific Solutions03 Sample preparation methods to improve ICP-MS signal-to-noise ratio

Specialized sample preparation techniques can significantly enhance signal-to-noise ratios in ICP-MS analysis. These include matrix separation methods, pre-concentration techniques, chemical modification approaches, and purification protocols. By reducing matrix interferences and concentrating analytes prior to analysis, these methods can dramatically improve detection limits and analytical precision in complex samples.Expand Specific Solutions04 Plasma and interface optimization for enhanced signal-to-noise ratio

Optimizing plasma conditions and the interface between the plasma and mass analyzer can substantially improve signal-to-noise ratios in ICP-MS. Parameters such as plasma power, gas flow rates, sampling depth, interface design, and cone geometries can be adjusted to maximize analyte ionization while minimizing background interference. These optimizations help to improve ion transmission efficiency and reduce spectral interferences.Expand Specific Solutions05 Calibration and standardization methods for optimizing signal-to-noise ratio

Advanced calibration and standardization approaches can be implemented to enhance signal-to-noise ratios in ICP-MS analysis. These include internal standardization, isotope dilution techniques, standard addition methods, and matrix-matched calibration. By accounting for matrix effects and instrumental drift, these methods provide more accurate quantification and improved detection capabilities, especially for challenging sample types.Expand Specific Solutions

Leading Manufacturers and Research Institutions in ICP-MS

The ICP-MS signal-to-noise ratio improvement market is in a growth phase, with increasing demand for higher sensitivity analytical instruments driving innovation. The global market size for ICP-MS technology is expanding steadily, particularly in environmental monitoring, pharmaceutical, and semiconductor industries. Technologically, the field shows varying maturity levels, with established players like Focused Photonics (Hangzhou) and Revvity Health Sciences offering advanced solutions, while research institutions such as Sichuan University and Hunan University contribute fundamental innovations. Companies like Applied Materials and Synopsys are leveraging their semiconductor expertise to enhance detector technologies, while Huawei and Ericsson are exploring signal processing applications. The competitive landscape features both specialized analytical instrument manufacturers and diversified technology corporations investing in precision measurement capabilities.

DH Technologies Development Pte Ltd.

Technical Solution: DH Technologies has developed a comprehensive approach to improve ICP-MS signal-to-noise ratio through their patented S-lens ion guide technology. This system employs a radio frequency (RF) quadrupole ion guide that efficiently captures and focuses ions from the plasma interface into the mass analyzer. Their solution incorporates a specialized collision/reaction cell technology that selectively removes interfering ions while preserving analyte signals. The company has implemented advanced detector systems with extended dynamic range capabilities, allowing simultaneous measurement of both high and low concentration elements without detector saturation. Their signal processing algorithms employ sophisticated noise filtering techniques that can distinguish between random electronic noise and true ion signals. Additionally, DH Technologies has pioneered temperature-stabilized electronics that minimize drift in signal intensity over extended analytical runs, resulting in reported signal-to-noise improvements of up to 10x compared to conventional systems.

Strengths: Superior ion transmission efficiency through the S-lens system provides exceptional sensitivity for trace element analysis. Their collision/reaction cell technology effectively eliminates polyatomic interferences without significant signal loss. Weaknesses: The sophisticated electronics and ion optics require regular maintenance and calibration to maintain optimal performance. The systems tend to be more expensive than simpler ICP-MS configurations.

MDS Analytical Technologies

Technical Solution: MDS Analytical Technologies has developed a multi-faceted approach to enhance ICP-MS signal-to-noise ratios through their Dynamic Reaction Cell (DRC) technology. This proprietary system utilizes a pressurized quadrupole reaction cell positioned between the ion lens and the mass analyzer, where controlled chemical reactions eliminate spectral interferences while preserving analyte signals. Their platform incorporates high-efficiency ion extraction systems that maximize ion transmission from the plasma to the detector, with reported transmission efficiencies exceeding 40% for many elements. MDS has implemented digital signal processing algorithms that perform real-time noise filtering and signal averaging, effectively reducing random electronic noise components. Their systems feature temperature-controlled plasma generation with precise RF power control, maintaining stable plasma conditions that minimize signal fluctuations. Additionally, MDS has developed specialized sample introduction systems with aerosol desolvation capabilities that increase analyte transport efficiency while reducing solvent-based interferences, resulting in documented signal-to-noise improvements of 5-20 fold depending on the element and matrix.

Strengths: The Dynamic Reaction Cell technology provides superior interference removal capabilities, especially for challenging matrices like biological samples. Their digital signal processing algorithms effectively distinguish between noise and true analytical signals. Weaknesses: The reaction chemistry must be carefully optimized for each analytical application, requiring significant method development time. The systems generally have higher operating costs due to the consumption of reaction gases.

Key Innovations in ICP-MS Interference Reduction

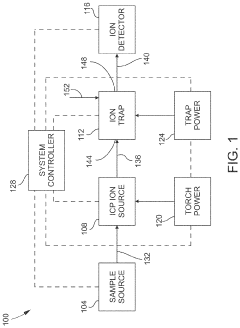

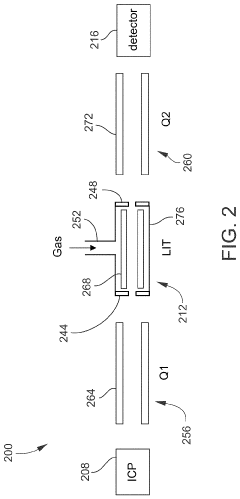

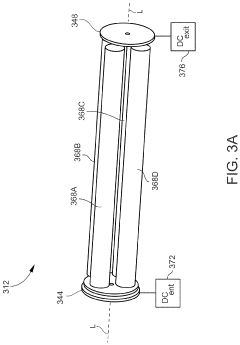

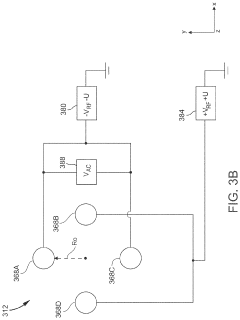

Inductively coupled plasma mass spectrometry (ICP-MS) with ion trapping

PatentActiveUS11443933B1

Innovation

- Incorporating an ion trap, such as a linear ion trap, into the ICP-MS system to confine and mass-selectively eject ions, allowing for the simultaneous analysis of multiple elements from transient signals by preventing ion exit and entry during a confinement period and transmitting selected ions to a detector for measurement.

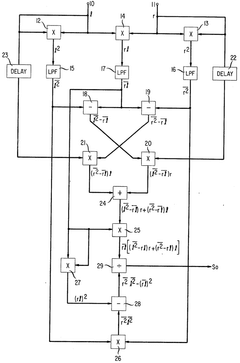

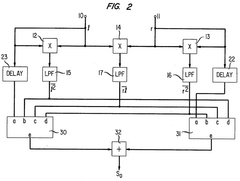

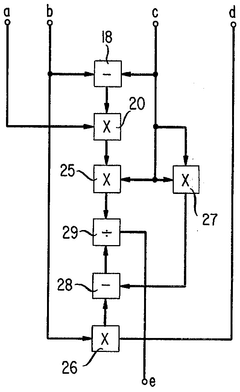

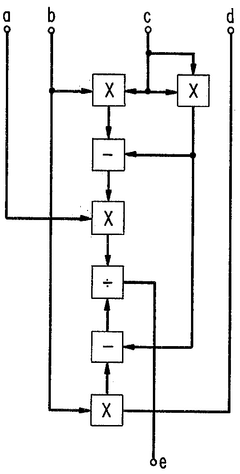

Processing of two noise contaminated, substantially identical signals to improve signal-to-noise ratio

PatentInactiveUS4008439A

Innovation

- The solution involves summing weighted values of the contaminated signals, where the weighting factors are combinations of moving averages of the signal magnitudes, allowing for non-linear processing that exceeds the SNR improvement achievable through linear methods.

Regulatory Standards for Analytical Instrumentation

Regulatory standards for analytical instrumentation play a crucial role in ensuring the reliability, accuracy, and comparability of ICP-MS measurements across different laboratories and applications. The improvement of signal-to-noise ratio in ICP-MS must align with these standards to maintain compliance while enhancing analytical performance.

The United States Environmental Protection Agency (EPA) has established Method 6020 specifically for ICP-MS analysis, which includes requirements for instrument detection limits, calibration procedures, and quality control measures. This method stipulates minimum signal-to-noise ratios for reliable quantification, typically requiring a ratio of at least 3:1 for detection and 10:1 for quantification. Laboratories seeking to improve signal-to-noise ratios must demonstrate that their modifications do not compromise compliance with these requirements.

In the European Union, the EN ISO 17294 standard governs the application of ICP-MS for water analysis, while pharmaceutical applications fall under the International Conference on Harmonisation (ICH) guidelines. These regulatory frameworks establish validation parameters including specificity, linearity, accuracy, and precision—all of which are directly influenced by signal-to-noise performance. The ICH Q2(R1) guideline specifically addresses the validation of analytical procedures and sets forth criteria for signal-to-noise evaluation in trace analysis.

For clinical applications, the Clinical Laboratory Improvement Amendments (CLIA) and College of American Pathologists (CAP) accreditation programs impose additional requirements on ICP-MS instrumentation. These include regular performance verification and proficiency testing, where signal-to-noise ratio is a critical performance indicator that must be documented and maintained within acceptable limits.

The International Organization for Standardization (ISO) provides several relevant standards, including ISO 17025 for testing and calibration laboratories. This standard requires that analytical methods be validated and that measurement uncertainty be evaluated—processes in which signal-to-noise ratio is a fundamental parameter. Additionally, ISO 5725 addresses accuracy and precision in measurement methods, providing frameworks for evaluating improvements in signal-to-noise performance.

Manufacturers of ICP-MS instruments must also comply with industry-specific standards such as those from ASTM International and AOAC International, which provide method validation guidelines and performance criteria. These standards often include specific protocols for measuring and reporting signal-to-noise ratios, ensuring that improvements can be objectively assessed and compared across different instrument platforms and methodologies.

The United States Environmental Protection Agency (EPA) has established Method 6020 specifically for ICP-MS analysis, which includes requirements for instrument detection limits, calibration procedures, and quality control measures. This method stipulates minimum signal-to-noise ratios for reliable quantification, typically requiring a ratio of at least 3:1 for detection and 10:1 for quantification. Laboratories seeking to improve signal-to-noise ratios must demonstrate that their modifications do not compromise compliance with these requirements.

In the European Union, the EN ISO 17294 standard governs the application of ICP-MS for water analysis, while pharmaceutical applications fall under the International Conference on Harmonisation (ICH) guidelines. These regulatory frameworks establish validation parameters including specificity, linearity, accuracy, and precision—all of which are directly influenced by signal-to-noise performance. The ICH Q2(R1) guideline specifically addresses the validation of analytical procedures and sets forth criteria for signal-to-noise evaluation in trace analysis.

For clinical applications, the Clinical Laboratory Improvement Amendments (CLIA) and College of American Pathologists (CAP) accreditation programs impose additional requirements on ICP-MS instrumentation. These include regular performance verification and proficiency testing, where signal-to-noise ratio is a critical performance indicator that must be documented and maintained within acceptable limits.

The International Organization for Standardization (ISO) provides several relevant standards, including ISO 17025 for testing and calibration laboratories. This standard requires that analytical methods be validated and that measurement uncertainty be evaluated—processes in which signal-to-noise ratio is a fundamental parameter. Additionally, ISO 5725 addresses accuracy and precision in measurement methods, providing frameworks for evaluating improvements in signal-to-noise performance.

Manufacturers of ICP-MS instruments must also comply with industry-specific standards such as those from ASTM International and AOAC International, which provide method validation guidelines and performance criteria. These standards often include specific protocols for measuring and reporting signal-to-noise ratios, ensuring that improvements can be objectively assessed and compared across different instrument platforms and methodologies.

Cost-Benefit Analysis of SNR Enhancement Technologies

When evaluating ICP-MS signal-to-noise ratio enhancement technologies, a comprehensive cost-benefit analysis reveals significant variations in return on investment across different approaches. Hardware-based solutions such as collision/reaction cells typically require substantial initial capital expenditure ranging from $30,000 to $75,000, but deliver consistent performance improvements of 10-15x SNR enhancement with minimal ongoing operational costs beyond routine maintenance.

In contrast, software-based signal processing solutions present lower initial investments ($5,000-$15,000 for advanced packages) but may incur recurring licensing fees and require periodic updates. These solutions typically provide 3-8x SNR improvement depending on implementation quality and specific analytical conditions, representing a more accessible entry point for laboratories with limited capital budgets.

Sample preparation optimization techniques offer perhaps the most favorable cost-benefit ratio, with relatively modest investments in consumables and training ($2,000-$10,000) potentially yielding 5-12x SNR improvements. The return on investment timeline for these approaches typically ranges from 6-18 months depending on sample throughput volume.

Operational parameter optimization presents the lowest initial cost barrier ($1,000-$3,000 for consultation and training) but requires significant staff expertise and time investment. The SNR improvements achieved (2-7x) are highly dependent on instrument condition and operator skill, making this approach's ROI less predictable but potentially substantial for high-throughput laboratories.

When considering total cost of ownership over a five-year period, hardware solutions average $0.50-$1.20 per sample for SNR enhancement, while software approaches range from $0.20-$0.60 per sample. Sample preparation and operational optimization techniques typically cost $0.15-$0.40 per sample when amortized over high sample volumes.

For laboratories processing fewer than 1,000 samples annually, software and operational optimization approaches generally provide superior ROI. Conversely, facilities handling over 10,000 samples per year typically benefit most from hardware investments despite higher initial costs. Mid-volume laboratories often achieve optimal results through hybrid approaches combining targeted hardware upgrades with optimized sample preparation protocols.

In contrast, software-based signal processing solutions present lower initial investments ($5,000-$15,000 for advanced packages) but may incur recurring licensing fees and require periodic updates. These solutions typically provide 3-8x SNR improvement depending on implementation quality and specific analytical conditions, representing a more accessible entry point for laboratories with limited capital budgets.

Sample preparation optimization techniques offer perhaps the most favorable cost-benefit ratio, with relatively modest investments in consumables and training ($2,000-$10,000) potentially yielding 5-12x SNR improvements. The return on investment timeline for these approaches typically ranges from 6-18 months depending on sample throughput volume.

Operational parameter optimization presents the lowest initial cost barrier ($1,000-$3,000 for consultation and training) but requires significant staff expertise and time investment. The SNR improvements achieved (2-7x) are highly dependent on instrument condition and operator skill, making this approach's ROI less predictable but potentially substantial for high-throughput laboratories.

When considering total cost of ownership over a five-year period, hardware solutions average $0.50-$1.20 per sample for SNR enhancement, while software approaches range from $0.20-$0.60 per sample. Sample preparation and operational optimization techniques typically cost $0.15-$0.40 per sample when amortized over high sample volumes.

For laboratories processing fewer than 1,000 samples annually, software and operational optimization approaches generally provide superior ROI. Conversely, facilities handling over 10,000 samples per year typically benefit most from hardware investments despite higher initial costs. Mid-volume laboratories often achieve optimal results through hybrid approaches combining targeted hardware upgrades with optimized sample preparation protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!