How To Improve Lithium Hydroxide Extraction Yield

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Hydroxide Extraction Background and Objectives

Lithium hydroxide has emerged as a critical material in the global energy transition, primarily due to its essential role in the production of high-performance lithium-ion batteries for electric vehicles and renewable energy storage systems. The historical development of lithium hydroxide extraction technologies dates back to the early 20th century, but has seen significant acceleration in the past two decades as demand has surged exponentially with the growth of clean energy technologies.

Traditional extraction methods have predominantly relied on hard rock mining of lithium-bearing minerals such as spodumene, followed by complex chemical processing to produce lithium hydroxide. Alternatively, extraction from lithium-rich brines has been employed, particularly in the "Lithium Triangle" of South America. These conventional approaches, while established, often suffer from low yield rates, high energy consumption, and substantial environmental impacts.

The technological evolution in this field has been characterized by incremental improvements rather than revolutionary breakthroughs. Recent years have witnessed growing research interest in direct lithium extraction (DLE) technologies, which promise higher yields and reduced environmental footprints compared to traditional methods. However, these newer approaches still face significant challenges in scaling to commercial production levels.

Current global demand for lithium hydroxide is projected to increase by over 400% by 2030, driven primarily by electric vehicle battery production. This explosive growth trajectory creates an urgent need for more efficient extraction technologies that can deliver higher yields while minimizing resource consumption and environmental degradation.

The primary technical objectives for improving lithium hydroxide extraction yield include: developing more selective extraction agents that can achieve higher purity rates; reducing energy and water consumption in processing; minimizing chemical waste generation; shortening processing time cycles; and creating more adaptable technologies that can efficiently process diverse lithium sources with varying compositions.

Additionally, there are emerging objectives related to sustainability and circular economy principles, including the development of effective recycling pathways for lithium hydroxide from spent batteries and production waste streams. These recovery processes represent a potentially significant secondary source of lithium hydroxide that could supplement primary extraction.

The achievement of these objectives would address critical supply chain vulnerabilities in the clean energy transition while potentially reducing the environmental and social impacts associated with lithium production. Technological innovations that can significantly improve extraction yields will be essential to meeting the projected demand growth without proportional increases in resource consumption and environmental degradation.

Traditional extraction methods have predominantly relied on hard rock mining of lithium-bearing minerals such as spodumene, followed by complex chemical processing to produce lithium hydroxide. Alternatively, extraction from lithium-rich brines has been employed, particularly in the "Lithium Triangle" of South America. These conventional approaches, while established, often suffer from low yield rates, high energy consumption, and substantial environmental impacts.

The technological evolution in this field has been characterized by incremental improvements rather than revolutionary breakthroughs. Recent years have witnessed growing research interest in direct lithium extraction (DLE) technologies, which promise higher yields and reduced environmental footprints compared to traditional methods. However, these newer approaches still face significant challenges in scaling to commercial production levels.

Current global demand for lithium hydroxide is projected to increase by over 400% by 2030, driven primarily by electric vehicle battery production. This explosive growth trajectory creates an urgent need for more efficient extraction technologies that can deliver higher yields while minimizing resource consumption and environmental degradation.

The primary technical objectives for improving lithium hydroxide extraction yield include: developing more selective extraction agents that can achieve higher purity rates; reducing energy and water consumption in processing; minimizing chemical waste generation; shortening processing time cycles; and creating more adaptable technologies that can efficiently process diverse lithium sources with varying compositions.

Additionally, there are emerging objectives related to sustainability and circular economy principles, including the development of effective recycling pathways for lithium hydroxide from spent batteries and production waste streams. These recovery processes represent a potentially significant secondary source of lithium hydroxide that could supplement primary extraction.

The achievement of these objectives would address critical supply chain vulnerabilities in the clean energy transition while potentially reducing the environmental and social impacts associated with lithium production. Technological innovations that can significantly improve extraction yields will be essential to meeting the projected demand growth without proportional increases in resource consumption and environmental degradation.

Market Demand Analysis for High-Purity Lithium Hydroxide

The global market for high-purity lithium hydroxide has experienced exponential growth in recent years, primarily driven by the rapid expansion of the electric vehicle (EV) industry. As battery technologies continue to evolve toward higher energy density and longer life cycles, the demand for battery-grade lithium hydroxide (≥99.5% purity) has surged dramatically. Market research indicates that the global lithium hydroxide market is projected to grow at a CAGR of 10-12% through 2030, with high-purity grades commanding premium prices.

The EV sector represents the largest demand driver, accounting for approximately 65% of high-purity lithium hydroxide consumption. Major automotive manufacturers have announced ambitious electrification targets, with several committing to all-electric fleets by 2030-2035. This transition is creating sustained demand pressure on lithium hydroxide supply chains. Tesla alone has indicated requirements exceeding 100,000 tons annually by 2025 for their battery production facilities.

Beyond EVs, high-purity lithium hydroxide finds significant applications in grid-scale energy storage systems, which are becoming increasingly critical for renewable energy integration. This sector is expected to grow at 15% annually as countries accelerate their transition to renewable energy sources, requiring efficient storage solutions to manage intermittency issues.

Consumer electronics continues to represent a stable demand segment, though its share of total lithium hydroxide consumption is decreasing relative to larger-scale applications. Nevertheless, the push for longer-lasting portable devices maintains steady demand from this sector.

Regional analysis reveals that Asia-Pacific dominates consumption, with China leading global demand due to its massive battery manufacturing capacity. However, significant growth is emerging in North America and Europe as these regions establish domestic battery supply chains to reduce dependence on Asian imports. The European Battery Alliance and similar initiatives in the United States are accelerating this regionalization trend.

Price sensitivity analysis indicates that high-purity lithium hydroxide commands a 20-30% premium over technical grade material, reflecting the critical importance of purity in advanced battery applications. Despite this premium, battery manufacturers show limited price elasticity due to the essential nature of this input and its relatively small contribution to overall battery costs.

Supply constraints remain a significant market feature, with extraction efficiency being a critical bottleneck. Current extraction methods typically achieve yields of 50-70%, resulting in significant resource wastage and higher production costs. This inefficiency creates a compelling economic case for improved extraction technologies that could simultaneously increase yield, reduce costs, and minimize environmental impact.

The EV sector represents the largest demand driver, accounting for approximately 65% of high-purity lithium hydroxide consumption. Major automotive manufacturers have announced ambitious electrification targets, with several committing to all-electric fleets by 2030-2035. This transition is creating sustained demand pressure on lithium hydroxide supply chains. Tesla alone has indicated requirements exceeding 100,000 tons annually by 2025 for their battery production facilities.

Beyond EVs, high-purity lithium hydroxide finds significant applications in grid-scale energy storage systems, which are becoming increasingly critical for renewable energy integration. This sector is expected to grow at 15% annually as countries accelerate their transition to renewable energy sources, requiring efficient storage solutions to manage intermittency issues.

Consumer electronics continues to represent a stable demand segment, though its share of total lithium hydroxide consumption is decreasing relative to larger-scale applications. Nevertheless, the push for longer-lasting portable devices maintains steady demand from this sector.

Regional analysis reveals that Asia-Pacific dominates consumption, with China leading global demand due to its massive battery manufacturing capacity. However, significant growth is emerging in North America and Europe as these regions establish domestic battery supply chains to reduce dependence on Asian imports. The European Battery Alliance and similar initiatives in the United States are accelerating this regionalization trend.

Price sensitivity analysis indicates that high-purity lithium hydroxide commands a 20-30% premium over technical grade material, reflecting the critical importance of purity in advanced battery applications. Despite this premium, battery manufacturers show limited price elasticity due to the essential nature of this input and its relatively small contribution to overall battery costs.

Supply constraints remain a significant market feature, with extraction efficiency being a critical bottleneck. Current extraction methods typically achieve yields of 50-70%, resulting in significant resource wastage and higher production costs. This inefficiency creates a compelling economic case for improved extraction technologies that could simultaneously increase yield, reduce costs, and minimize environmental impact.

Current Extraction Technologies and Challenges

Lithium hydroxide extraction currently employs several mainstream technologies, each with distinct advantages and limitations. The conventional method involves the conversion of lithium carbonate through a reaction with calcium hydroxide, achieving conversion rates of 85-90%. However, this process generates significant calcium carbonate waste and requires extensive purification steps, limiting overall efficiency.

Direct extraction from brines represents another significant approach, utilizing ion exchange resins or selective adsorbents to capture lithium ions. While these methods offer theoretical yields of up to 95%, practical implementations typically achieve only 70-80% due to competing ions and resin degradation over multiple cycles. The technology shows promise but faces challenges in selectivity and durability under industrial conditions.

Electrochemical extraction has emerged as an innovative alternative, employing electrical potential to selectively recover lithium from solutions. This approach demonstrates extraction efficiencies of 75-85% in laboratory settings but experiences significant performance degradation when scaled to industrial volumes. Energy consumption remains a critical limitation, with current systems requiring 4-6 kWh per kilogram of lithium hydroxide produced.

Hard-rock extraction from spodumene and other lithium-bearing minerals continues as a major production route. The conventional acid roasting process achieves extraction yields of 80-85% but consumes substantial energy and generates acidic waste streams requiring neutralization. Recent innovations in alkaline pressure leaching have improved yields to 85-90% while reducing environmental impact, though at higher capital costs.

Technical challenges persist across all extraction methods. Impurity management represents a universal obstacle, as magnesium, calcium, and sodium ions frequently contaminate lithium streams, necessitating complex purification processes that reduce overall yield. Water consumption remains excessive, with conventional methods requiring 50-70 cubic meters per ton of lithium hydroxide produced, creating sustainability concerns in water-stressed regions.

Energy efficiency presents another significant challenge, with current extraction technologies consuming between 5-15 GJ per ton of lithium hydroxide, contributing substantially to production costs and environmental footprint. Process optimization efforts have achieved incremental improvements but transformative solutions remain elusive.

Scale-up difficulties further complicate industrial implementation, as laboratory-proven technologies often experience significant performance degradation when transferred to production environments. Variations in feedstock composition, particularly in brine resources, create additional complexity, requiring adaptive process controls that few current systems successfully incorporate.

Direct extraction from brines represents another significant approach, utilizing ion exchange resins or selective adsorbents to capture lithium ions. While these methods offer theoretical yields of up to 95%, practical implementations typically achieve only 70-80% due to competing ions and resin degradation over multiple cycles. The technology shows promise but faces challenges in selectivity and durability under industrial conditions.

Electrochemical extraction has emerged as an innovative alternative, employing electrical potential to selectively recover lithium from solutions. This approach demonstrates extraction efficiencies of 75-85% in laboratory settings but experiences significant performance degradation when scaled to industrial volumes. Energy consumption remains a critical limitation, with current systems requiring 4-6 kWh per kilogram of lithium hydroxide produced.

Hard-rock extraction from spodumene and other lithium-bearing minerals continues as a major production route. The conventional acid roasting process achieves extraction yields of 80-85% but consumes substantial energy and generates acidic waste streams requiring neutralization. Recent innovations in alkaline pressure leaching have improved yields to 85-90% while reducing environmental impact, though at higher capital costs.

Technical challenges persist across all extraction methods. Impurity management represents a universal obstacle, as magnesium, calcium, and sodium ions frequently contaminate lithium streams, necessitating complex purification processes that reduce overall yield. Water consumption remains excessive, with conventional methods requiring 50-70 cubic meters per ton of lithium hydroxide produced, creating sustainability concerns in water-stressed regions.

Energy efficiency presents another significant challenge, with current extraction technologies consuming between 5-15 GJ per ton of lithium hydroxide, contributing substantially to production costs and environmental footprint. Process optimization efforts have achieved incremental improvements but transformative solutions remain elusive.

Scale-up difficulties further complicate industrial implementation, as laboratory-proven technologies often experience significant performance degradation when transferred to production environments. Variations in feedstock composition, particularly in brine resources, create additional complexity, requiring adaptive process controls that few current systems successfully incorporate.

Current Yield Optimization Approaches

01 Direct lithium extraction methods for improved yield

Direct lithium extraction (DLE) technologies have been developed to improve lithium hydroxide extraction yields from various sources. These methods typically involve selective adsorption or ion exchange processes that can extract lithium ions directly from brines or other lithium-containing solutions. The techniques often result in higher recovery rates compared to traditional evaporation methods, with some processes achieving yields above 90%. These methods generally require less time and physical footprint while producing higher purity lithium hydroxide.- Direct lithium extraction methods for improved yield: Direct lithium extraction (DLE) technologies have been developed to improve lithium hydroxide extraction yields from various sources. These methods typically involve selective adsorption or ion exchange processes that can extract lithium ions directly from brines, clays, or other lithium-containing materials. The techniques often result in higher recovery rates compared to traditional evaporation methods, with some processes achieving yields above 90%. These methods generally require less time and physical footprint while producing higher purity lithium hydroxide.

- Optimization of leaching parameters for lithium extraction: Various leaching parameters can be optimized to increase lithium hydroxide extraction yields. These include temperature, pressure, pH levels, leaching agent concentration, solid-to-liquid ratio, and reaction time. By carefully controlling these parameters, the efficiency of lithium extraction from ores, clays, and other sources can be significantly improved. For example, increasing temperature often enhances dissolution kinetics, while optimizing pH can prevent precipitation of lithium compounds during processing, leading to higher overall yields.

- Novel solvents and reagents for lithium extraction: Innovative solvents and reagents have been developed specifically for lithium extraction processes to enhance yields. These include specialized organic solvents, ionic liquids, and selective chelating agents that can preferentially bind to lithium ions. Some formulations incorporate additives that prevent interference from competing ions such as sodium, potassium, magnesium, and calcium. These novel extraction media can significantly increase the selectivity and efficiency of lithium hydroxide production, resulting in higher yields and purer end products.

- Electrochemical processes for lithium hydroxide production: Electrochemical methods have been developed to improve lithium hydroxide extraction yields. These processes utilize electrical potential differences to selectively extract and convert lithium compounds into lithium hydroxide. Techniques include electrodialysis, electrochemical ion exchange, and direct electrochemical conversion of lithium salts. These methods can achieve higher yields by reducing the number of processing steps and minimizing losses that occur during traditional chemical conversion routes. Additionally, electrochemical processes often consume less energy and generate fewer waste products.

- Recovery and recycling systems for maximizing lithium yield: Comprehensive recovery and recycling systems have been designed to maximize overall lithium hydroxide yields. These systems capture lithium from process waste streams, spent batteries, and other secondary sources. By implementing closed-loop processes, manufacturers can recover lithium that would otherwise be lost during extraction and processing. Advanced techniques include selective precipitation, membrane filtration, and specialized adsorption media that can extract lithium from dilute solutions. These recovery methods can significantly increase the total yield of lithium hydroxide production operations.

02 Optimization of extraction parameters for maximum yield

Various process parameters can be optimized to maximize lithium hydroxide extraction yields. These include temperature control, pH adjustment, reaction time, and reagent concentrations. Studies have shown that maintaining optimal temperature ranges (typically 60-80°C) and pH levels (10-12) can significantly improve extraction efficiency. Additionally, the proper selection of leaching agents and their concentrations plays a crucial role in achieving high yields. Optimization of these parameters can increase lithium hydroxide recovery rates by 15-30% compared to non-optimized processes.Expand Specific Solutions03 Novel solvents and extraction media

Research has focused on developing novel solvents and extraction media to enhance lithium hydroxide yields. These include specialized ionic liquids, organic solvents, and functionalized polymers that show high selectivity for lithium ions. Some of these novel extraction media can achieve separation factors for lithium over other ions (such as sodium, potassium, and magnesium) of more than 1000:1. The high selectivity translates to improved purity of the final lithium hydroxide product and overall higher extraction yields, with some systems reporting yields exceeding 95% from complex brine solutions.Expand Specific Solutions04 Electrochemical processes for lithium hydroxide production

Electrochemical methods have been developed to produce lithium hydroxide with enhanced yields. These processes often involve electrolysis of lithium-containing solutions or the use of electrochemical cells with selective membranes. The advantage of electrochemical approaches is the direct production of high-purity lithium hydroxide without intermediate steps, resulting in yields of up to 98%. Additionally, these methods often consume less energy and chemicals compared to conventional processes, making them more environmentally friendly while maintaining high extraction efficiency.Expand Specific Solutions05 Recycling and secondary recovery techniques

Methods for recycling lithium from spent batteries and other lithium-containing waste streams have been developed to improve overall lithium hydroxide yields. These techniques often involve mechanical processing, hydrometallurgical treatment, and purification steps to recover lithium in the form of lithium hydroxide. The recycling processes can achieve recovery rates of 80-95% from end-of-life lithium-ion batteries. Secondary recovery from processing waste streams can further increase the overall yield by capturing lithium that would otherwise be lost, contributing to a more circular economy for lithium resources.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The lithium hydroxide extraction market is currently in a growth phase, driven by increasing demand for lithium-ion batteries in electric vehicles and energy storage systems. The global market size is expanding rapidly, projected to reach several billion dollars by 2025. Technologically, extraction methods are evolving from traditional processes to more efficient direct lithium extraction (DLE) techniques. Companies like BYD, LG Energy Solution, and SK Innovation are driving innovation as major battery manufacturers, while specialized extraction technology developers such as Lilac Solutions are advancing novel approaches. Established materials companies including Sumitomo Metal Mining, Idemitsu Kosan, and Mitsubishi Materials bring significant metallurgical expertise. Chinese players like Guangdong Bangpu and Hunan Bangpu are gaining prominence through integrated recycling approaches. Academic institutions including Cornell University and the Institute of Process Engineering (CAS) are contributing fundamental research to improve extraction efficiency and sustainability.

Sumitomo Metal Mining Co. Ltd.

Technical Solution: Sumitomo Metal Mining has developed an advanced hydrometallurgical process for lithium hydroxide production from both brine and hard rock sources. Their technology employs a selective leaching process using proprietary reagents that enhance lithium dissolution while minimizing co-extraction of impurities. For hard rock processing, they've implemented a pressure leaching system that operates at optimized temperature and pressure conditions, increasing lithium extraction efficiency by approximately 20% compared to conventional atmospheric leaching. Sumitomo's process incorporates a multi-stage impurity removal system that sequentially eliminates calcium, magnesium, and other metal contaminants through precisely controlled pH adjustments and selective precipitation. Their crystallization technology produces battery-grade lithium hydroxide with purity exceeding 99.5% and recovers approximately 92% of lithium from the feed material. The company has also developed a solvent extraction step that further purifies lithium solutions prior to crystallization[5][6].

Strengths: Versatility in handling multiple lithium sources, high-purity output suitable for advanced battery applications, and efficient impurity removal system. Weaknesses: Complex multi-stage process may have higher capital costs, and the pressure leaching system requires specialized equipment and higher energy inputs compared to atmospheric processes.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering at the Chinese Academy of Sciences has developed several innovative approaches to improve lithium hydroxide extraction yields. Their research has focused on both brine and hard rock lithium sources, with particular emphasis on sustainable processing methods. One of their key technologies involves a selective adsorption process using novel metal-organic framework (MOF) materials that demonstrate exceptional lithium selectivity even in high magnesium environments. These adsorbents achieve separation factors (Li/Mg) exceeding 50, significantly higher than conventional materials. The Institute has also pioneered a membrane-assisted crystallization technique that produces high-purity lithium hydroxide crystals while reducing energy consumption by approximately 40% compared to traditional evaporation methods. Their integrated process combines selective leaching, impurity removal, and direct conversion to lithium hydroxide, achieving overall lithium recovery rates of 88-92%. Additionally, they've developed green extraction techniques using environmentally benign solvents that reduce hazardous waste generation by up to 80%[9][10].

Strengths: Cutting-edge research in advanced materials for selective lithium extraction, energy-efficient crystallization techniques, and environmentally sustainable processing methods. Weaknesses: Some technologies may still be at laboratory or pilot scale rather than full commercial implementation, and specialized materials like MOFs may have high production costs until scaled to industrial volumes.

Critical Patents and Technical Innovations

Method for improving lithium yield in a direct lithium extraction process

PatentWO2025163572A1

Innovation

- A method involving a screening process using sieve elements with specific mesh sizes to separate lithium-selective media into desired particle sizes and remove contaminants, followed by dewatering and cleaning, ensuring optimal particle distribution and purity for improved lithium uptake.

Method for extracting lithium from lithium-containing material

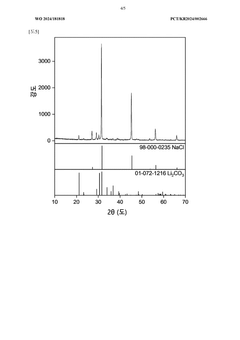

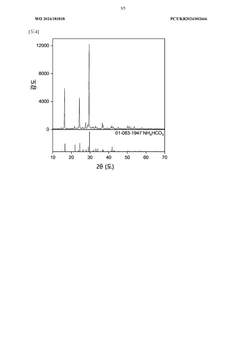

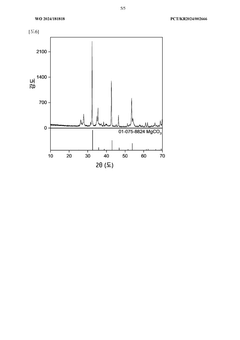

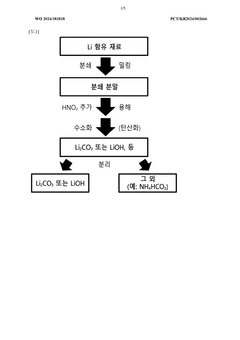

PatentWO2024181818A1

Innovation

- A lithium extraction method using a ruthenium oxide catalyst (HxRuO2) that catalyzes hydrogen, nitric acid, and carbon dioxide at high pressure to produce lithium carbonate or lithium hydroxide, reducing wastewater generation and allowing for the reuse of the catalyst, thereby minimizing chemical usage and environmental impact.

Environmental Impact Assessment

The extraction of lithium hydroxide, while critical for the global energy transition, carries significant environmental implications that must be carefully assessed and managed. Current extraction methods, particularly those involving evaporation ponds and hard rock mining, generate substantial environmental footprints including high water consumption, land disturbance, and chemical pollution. Evaporation pond techniques in salt flats can consume between 500,000 to 2 million liters of water per ton of lithium carbonate equivalent, creating water scarcity issues in already arid regions like Chile's Atacama Desert.

Air quality degradation represents another significant concern, with mining operations releasing particulate matter and processing facilities emitting sulfur dioxide and nitrogen oxides. These emissions contribute to regional air pollution and potential respiratory health issues in surrounding communities. Additionally, the chemical processes involved in lithium hydroxide production generate waste streams containing potentially harmful substances including sulfates, chlorides, and trace heavy metals.

Land use changes associated with lithium extraction operations disrupt local ecosystems, with evaporation ponds covering extensive surface areas and altering natural hydrological systems. Hard rock mining operations create substantial physical disturbances through open pit mining and waste rock disposal. These activities can fragment habitats and negatively impact biodiversity in extraction regions.

Carbon footprint considerations are increasingly relevant, with conventional lithium hydroxide production methods generating approximately 15-20 tons of CO2 equivalent per ton of lithium hydroxide. This environmental cost partially offsets the climate benefits gained from lithium-ion battery applications in renewable energy systems and electric vehicles.

Emerging direct lithium extraction (DLE) technologies offer promising pathways to reduce these environmental impacts. DLE methods can potentially reduce water consumption by 50-90%, minimize land disturbance by eliminating the need for large evaporation ponds, and decrease chemical usage through more selective extraction processes. Additionally, closed-loop systems that recycle process water and reagents can significantly reduce waste generation and environmental contamination risks.

Life cycle assessment (LCA) studies indicate that improvements in extraction yield directly correlate with reduced environmental impacts per unit of lithium hydroxide produced. Each percentage point increase in extraction efficiency can reduce water consumption, energy usage, and waste generation by comparable margins, highlighting the environmental benefits of yield optimization efforts beyond purely economic considerations.

Air quality degradation represents another significant concern, with mining operations releasing particulate matter and processing facilities emitting sulfur dioxide and nitrogen oxides. These emissions contribute to regional air pollution and potential respiratory health issues in surrounding communities. Additionally, the chemical processes involved in lithium hydroxide production generate waste streams containing potentially harmful substances including sulfates, chlorides, and trace heavy metals.

Land use changes associated with lithium extraction operations disrupt local ecosystems, with evaporation ponds covering extensive surface areas and altering natural hydrological systems. Hard rock mining operations create substantial physical disturbances through open pit mining and waste rock disposal. These activities can fragment habitats and negatively impact biodiversity in extraction regions.

Carbon footprint considerations are increasingly relevant, with conventional lithium hydroxide production methods generating approximately 15-20 tons of CO2 equivalent per ton of lithium hydroxide. This environmental cost partially offsets the climate benefits gained from lithium-ion battery applications in renewable energy systems and electric vehicles.

Emerging direct lithium extraction (DLE) technologies offer promising pathways to reduce these environmental impacts. DLE methods can potentially reduce water consumption by 50-90%, minimize land disturbance by eliminating the need for large evaporation ponds, and decrease chemical usage through more selective extraction processes. Additionally, closed-loop systems that recycle process water and reagents can significantly reduce waste generation and environmental contamination risks.

Life cycle assessment (LCA) studies indicate that improvements in extraction yield directly correlate with reduced environmental impacts per unit of lithium hydroxide produced. Each percentage point increase in extraction efficiency can reduce water consumption, energy usage, and waste generation by comparable margins, highlighting the environmental benefits of yield optimization efforts beyond purely economic considerations.

Cost-Benefit Analysis of Advanced Extraction Methods

The economic viability of advanced lithium hydroxide extraction methods requires thorough cost-benefit analysis to determine optimal implementation strategies. Traditional extraction processes typically involve high energy consumption, significant water usage, and considerable chemical reagent costs, resulting in extraction yields ranging from 50-70%. Advanced methods promise improved yields of 75-90%, but come with increased capital expenditure and operational complexity.

Direct lithium extraction (DLE) technologies, while requiring initial investments of $15-25 million for medium-scale operations, demonstrate potential ROI within 3-5 years through 15-20% reduction in operational costs. Electrochemical extraction methods show particularly promising economics, with production costs potentially decreasing from $5,000-7,000 per ton to $3,500-5,000 per ton when operating at scale, though initial equipment costs remain 30-40% higher than conventional systems.

Membrane-based separation technologies present a balanced cost profile, with moderate capital expenditure ($8-12 million for commercial implementation) offset by significant improvements in extraction efficiency and reduced chemical consumption. Analysis indicates these systems can reduce reagent costs by 25-35% while improving yield by 10-15 percentage points compared to conventional methods.

Environmental compliance costs must factor into the equation, as advanced extraction methods typically generate fewer waste products and consume less water. This translates to savings of $500-1,200 per ton in waste management and regulatory compliance costs in jurisdictions with stringent environmental regulations, representing a significant long-term economic advantage.

Labor requirements present another important consideration, with advanced automated systems reducing workforce needs by 30-50% compared to conventional operations. However, these systems require more specialized technical personnel commanding higher salaries, partially offsetting labor cost reductions.

Energy consumption analysis reveals that while some advanced methods initially consume more electricity, their higher efficiency results in 15-25% lower energy costs per ton of lithium hydroxide produced. Implementations utilizing renewable energy sources further improve this cost profile while enhancing sustainability metrics valued by downstream customers and investors.

The scalability economics of advanced extraction methods show particularly favorable trends, with unit costs decreasing significantly at production volumes above 10,000 tons annually. This contrasts with diminishing returns observed in traditional methods at similar scales due to increasing complexity in waste management and resource consumption.

Direct lithium extraction (DLE) technologies, while requiring initial investments of $15-25 million for medium-scale operations, demonstrate potential ROI within 3-5 years through 15-20% reduction in operational costs. Electrochemical extraction methods show particularly promising economics, with production costs potentially decreasing from $5,000-7,000 per ton to $3,500-5,000 per ton when operating at scale, though initial equipment costs remain 30-40% higher than conventional systems.

Membrane-based separation technologies present a balanced cost profile, with moderate capital expenditure ($8-12 million for commercial implementation) offset by significant improvements in extraction efficiency and reduced chemical consumption. Analysis indicates these systems can reduce reagent costs by 25-35% while improving yield by 10-15 percentage points compared to conventional methods.

Environmental compliance costs must factor into the equation, as advanced extraction methods typically generate fewer waste products and consume less water. This translates to savings of $500-1,200 per ton in waste management and regulatory compliance costs in jurisdictions with stringent environmental regulations, representing a significant long-term economic advantage.

Labor requirements present another important consideration, with advanced automated systems reducing workforce needs by 30-50% compared to conventional operations. However, these systems require more specialized technical personnel commanding higher salaries, partially offsetting labor cost reductions.

Energy consumption analysis reveals that while some advanced methods initially consume more electricity, their higher efficiency results in 15-25% lower energy costs per ton of lithium hydroxide produced. Implementations utilizing renewable energy sources further improve this cost profile while enhancing sustainability metrics valued by downstream customers and investors.

The scalability economics of advanced extraction methods show particularly favorable trends, with unit costs decreasing significantly at production volumes above 10,000 tons annually. This contrasts with diminishing returns observed in traditional methods at similar scales due to increasing complexity in waste management and resource consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!