How to Improve Strength and Durability with Ethylene Vinyl Acetate?

EVA Enhancement Goals

Ethylene Vinyl Acetate (EVA) enhancement goals focus on improving the material's strength and durability to expand its applications and performance in various industries. The primary objective is to develop EVA formulations that exhibit superior mechanical properties, enhanced resistance to environmental factors, and prolonged service life.

One of the key enhancement goals is to increase the tensile strength of EVA without compromising its flexibility. This involves optimizing the molecular structure and crosslinking density to achieve a balance between rigidity and elasticity. Researchers aim to develop EVA compounds that can withstand higher loads and stresses while maintaining their characteristic resilience.

Improving the impact resistance of EVA is another crucial objective. This involves enhancing the material's ability to absorb and dissipate energy upon impact, reducing the likelihood of fractures or permanent deformation. Achieving this goal would expand EVA's potential in applications requiring high impact resistance, such as protective gear and automotive components.

Enhancing the thermal stability of EVA is essential for broadening its range of applications. Researchers are working on developing EVA formulations that can maintain their structural integrity and mechanical properties at elevated temperatures. This would enable the use of EVA in more demanding environments and increase its suitability for high-temperature applications.

Another important goal is to improve the weathering resistance of EVA. This involves enhancing the material's resistance to UV radiation, moisture, and oxidation. By developing EVA compounds with superior weathering properties, manufacturers can extend the lifespan of products exposed to outdoor conditions, such as solar panel encapsulants and outdoor footwear.

Researchers are also focusing on enhancing the chemical resistance of EVA. The aim is to develop formulations that can withstand exposure to a wider range of chemicals and solvents without degradation. This would expand EVA's potential in industrial applications where chemical resistance is crucial.

Improving the flame retardancy of EVA is another significant enhancement goal. Developing EVA compounds with inherent flame-retardant properties would increase its suitability for applications in construction, electronics, and transportation industries where fire safety is paramount.

Finally, enhancing the processability of EVA while maintaining or improving its mechanical properties is a key objective. This involves optimizing the material's melt flow characteristics and compatibility with various processing techniques, enabling more efficient manufacturing processes and expanding the range of products that can be produced using EVA.

Market Demand Analysis

The market demand for improved strength and durability in materials using Ethylene Vinyl Acetate (EVA) has been steadily growing across various industries. This demand is primarily driven by the need for more resilient and long-lasting products in sectors such as footwear, sports equipment, packaging, and construction materials.

In the footwear industry, there is a significant push for more durable and comfortable shoe soles. EVA's ability to enhance cushioning and impact resistance while maintaining flexibility has made it a sought-after material for athletic and casual footwear. Major sportswear brands are continuously seeking ways to improve the performance of their products, creating a robust market for advanced EVA formulations.

The sports equipment sector also shows a strong demand for EVA-enhanced materials. Tennis rackets, ski boots, and protective gear manufacturers are looking for ways to increase the lifespan and performance of their products. The market for these improved materials is expected to grow as consumers become more conscious of product durability and value for money.

In the packaging industry, there is an increasing need for stronger and more durable materials that can withstand various environmental conditions. EVA's properties make it an excellent candidate for improving the strength of packaging films and containers. This demand is further fueled by the growth of e-commerce and the need for better protection during shipping and handling.

The construction sector presents another significant market opportunity for improved EVA materials. There is a growing demand for more durable and weather-resistant building materials, particularly in regions prone to extreme weather conditions. EVA's potential to enhance the strength and durability of sealants, adhesives, and insulation materials makes it an attractive option for construction applications.

The automotive industry is also showing interest in EVA-enhanced materials for improving the durability of various components, including gaskets, hoses, and interior parts. As vehicles are expected to last longer and perform better under diverse conditions, the demand for more resilient materials continues to rise.

Market trends indicate a shift towards sustainable and eco-friendly materials. This creates an opportunity for developing EVA formulations that not only improve strength and durability but also align with environmental concerns. Manufacturers who can offer such solutions are likely to gain a competitive edge in the market.

The global market for EVA and its enhanced formulations is projected to grow significantly in the coming years. This growth is attributed to the material's versatility and the continuous innovation in improving its properties. As industries seek ways to differentiate their products and meet consumer demands for higher quality and longevity, the market for improved EVA materials is expected to expand across various sectors.

EVA Limitations

While Ethylene Vinyl Acetate (EVA) offers numerous advantages in various applications, it also presents several limitations that can impact its performance and durability. One of the primary challenges with EVA is its susceptibility to degradation under certain environmental conditions. Prolonged exposure to UV radiation can lead to discoloration, embrittlement, and a reduction in mechanical properties. This vulnerability to UV degradation limits its use in outdoor applications without additional protective measures.

Another significant limitation of EVA is its relatively low heat resistance compared to some other polymers. At elevated temperatures, EVA can soften and lose its dimensional stability, which restricts its use in high-temperature environments. This thermal sensitivity can also affect its long-term durability in applications where temperature fluctuations are common.

EVA's moisture absorption tendency is another factor that can compromise its performance. In high-humidity environments or when in contact with water, EVA can absorb moisture, leading to changes in its physical properties and potentially affecting its adhesive capabilities. This characteristic limits its effectiveness in certain moisture-sensitive applications without proper sealing or protection.

The material's limited chemical resistance is also a notable drawback. EVA can be susceptible to degradation when exposed to certain oils, solvents, and chemicals, which narrows its applicability in harsh chemical environments. This vulnerability necessitates careful consideration of the operating conditions and potential chemical exposures in any given application.

Furthermore, EVA exhibits lower tensile strength and tear resistance compared to some other elastomers and thermoplastics. This inherent weakness can limit its use in high-stress applications or environments where superior mechanical properties are required. In such cases, reinforcement or alternative materials may be necessary to meet performance requirements.

Lastly, the processing of EVA can present challenges, particularly in achieving consistent quality across different batches. The material's sensitivity to processing conditions, such as temperature and shear, can lead to variations in final product properties. This variability can complicate manufacturing processes and quality control, potentially impacting the overall strength and durability of EVA-based products.

Current EVA Solutions

01 Composition modifications for improved strength

Enhancing the strength and durability of EVA through composition modifications, such as incorporating additives, fillers, or blending with other polymers. These modifications can improve mechanical properties, impact resistance, and overall performance of EVA-based materials.- Composition modifications for improved strength and durability: EVA properties can be enhanced by modifying its composition. This includes blending with other polymers, adding reinforcing fillers, or adjusting the vinyl acetate content. These modifications can lead to improved tensile strength, impact resistance, and overall durability of the EVA material.

- Crosslinking techniques for EVA: Crosslinking EVA through various methods such as chemical crosslinking, radiation crosslinking, or silane crosslinking can significantly improve its strength and durability. This process creates a more stable network structure, enhancing the material's resistance to heat, chemicals, and mechanical stress.

- EVA foam formulations for enhanced properties: Specialized EVA foam formulations can be developed to improve strength and durability. These formulations may involve the use of specific blowing agents, cell structure control, or density optimization to achieve desired mechanical properties while maintaining lightweight characteristics.

- Surface treatments and coatings for EVA: Applying surface treatments or coatings to EVA products can enhance their durability and resistance to environmental factors. These treatments may include plasma treatment, UV-curable coatings, or specialized chemical treatments that improve adhesion, wear resistance, and weatherability of the EVA material.

- Processing techniques for optimized EVA properties: Advanced processing techniques can be employed to optimize the strength and durability of EVA products. These may include controlled cooling rates, specific extrusion or molding parameters, or post-processing treatments that enhance the material's mechanical properties and long-term performance.

02 Cross-linking techniques for EVA

Utilizing various cross-linking methods to enhance the strength and durability of EVA. This includes chemical cross-linking agents, radiation-induced cross-linking, or other techniques that create stronger bonds between polymer chains, resulting in improved mechanical properties and heat resistance.Expand Specific Solutions03 EVA foam formulations for enhanced durability

Developing specialized EVA foam formulations that offer improved strength and durability. These formulations may include specific blowing agents, cell structure control, or density modifications to create foam materials with enhanced mechanical properties and longevity.Expand Specific Solutions04 Surface treatments and coatings for EVA

Applying surface treatments or coatings to EVA materials to enhance their strength, durability, and resistance to environmental factors. These treatments can improve wear resistance, chemical resistance, and overall longevity of EVA-based products.Expand Specific Solutions05 EVA copolymer design for specific applications

Tailoring EVA copolymer design to meet specific strength and durability requirements for various applications. This involves optimizing the vinyl acetate content, molecular weight distribution, and other polymer characteristics to achieve desired mechanical properties and performance in targeted use cases.Expand Specific Solutions

Key EVA Manufacturers

The market for ethylene vinyl acetate (EVA) technology to improve strength and durability is in a mature growth phase, with a global market size expected to reach $9.7 billion by 2027. The technology's maturity is evident from its widespread adoption across industries like footwear, packaging, and solar panels. Key players such as DuPont, ExxonMobil, and LG Chem have established strong footholds, while companies like Kuraray and Wacker Chemie are innovating with specialized EVA formulations. Chinese firms like Sinopec and Jiangsu Sopo are expanding production capacity, intensifying competition. The industry focus is shifting towards developing eco-friendly EVA variants and enhancing performance for emerging applications in 3D printing and medical devices.

Kuraray Co., Ltd.

Wacker Chemie AG

EVA Innovations

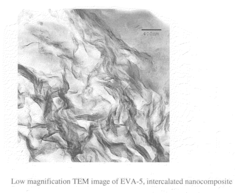

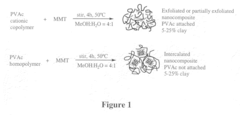

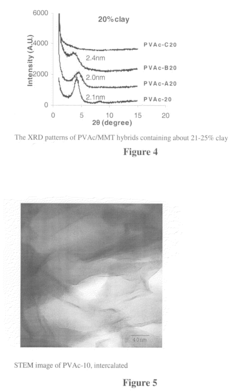

- Solution blending of EVA with a masterbatch of cationic poly(vinyl acetate)/silicate nanocomposite, where the silicate is substantially exfoliated, maintains mechanical properties and prevents loss of exfoliation during heat processing.

- Employing a binder comprising at least 0.25% ethylene-vinyl acetate copolymer, with a vinyl acetate group weight percentage of 10-95%, along with optional additives like polytetrafluoroethylene, silane compounds, and polypropylene fibers, to enhance mechanical properties and adhesion without using polystyrene or butadiene copolymers, on a two-dimensional metallic support.

EVA Regulatory Landscape

The regulatory landscape for Ethylene Vinyl Acetate (EVA) is complex and multifaceted, reflecting the material's widespread use across various industries. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA, particularly in food contact applications. The FDA has approved EVA for use in food packaging and other food-related products, subject to specific limitations and conditions outlined in the Code of Federal Regulations (CFR).

The European Union (EU) has its own set of regulations governing EVA usage. The European Food Safety Authority (EFSA) evaluates the safety of EVA and other materials used in food contact applications. The EU's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation also impacts EVA production and use, requiring manufacturers and importers to register substances and provide safety information.

In the construction industry, EVA is subject to building codes and standards that vary by region. These regulations often focus on fire safety, as EVA is a combustible material. The International Building Code (IBC) and local building codes may specify requirements for flame retardancy and smoke development when EVA is used in construction materials.

The automotive industry has its own set of regulations affecting EVA use. In many countries, automotive safety standards require specific performance characteristics for materials used in vehicle interiors, including EVA-based components. These standards often address issues such as flammability, off-gassing, and durability under various environmental conditions.

Environmental regulations also play a significant role in the EVA landscape. Many countries have implemented restrictions on volatile organic compound (VOC) emissions, which can affect the production and use of EVA in certain applications. Additionally, waste management and recycling regulations impact the end-of-life handling of EVA products.

In the medical device industry, EVA is subject to stringent regulations due to its use in various healthcare applications. The FDA's Center for Devices and Radiological Health (CDRH) oversees the approval process for medical devices containing EVA, ensuring they meet safety and efficacy standards. Similarly, the EU's Medical Device Regulation (MDR) sets requirements for EVA-containing medical devices in European markets.

As sustainability concerns grow, new regulations are emerging that may affect EVA production and use. For example, some jurisdictions are implementing extended producer responsibility (EPR) programs, which could impact manufacturers using EVA in their products. Additionally, circular economy initiatives may lead to new requirements for the recyclability and reusability of EVA-based materials.

Environmental Impact

The environmental impact of using Ethylene Vinyl Acetate (EVA) to improve strength and durability in products is a complex issue that requires careful consideration. EVA, a copolymer of ethylene and vinyl acetate, offers several advantages in terms of performance and durability, but its production and disposal can have significant environmental implications.

From a production standpoint, EVA is derived from petroleum-based sources, which contributes to the depletion of non-renewable resources and generates greenhouse gas emissions during extraction and processing. The manufacturing process of EVA also involves energy-intensive steps, further increasing its carbon footprint. However, compared to some alternative materials, EVA production may have a lower environmental impact due to its relatively simple manufacturing process and the ability to recycle production waste.

In terms of product lifecycle, EVA's durability and strength-enhancing properties can lead to longer-lasting products, potentially reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. This extended product lifespan can contribute positively to sustainability efforts by minimizing the environmental impact associated with manufacturing and disposing of short-lived products.

Recycling and disposal of EVA-enhanced products present both challenges and opportunities. While EVA is technically recyclable, the recycling process can be complex, especially when EVA is combined with other materials in composite products. Proper sorting and specialized recycling facilities are often required, which may not be widely available in all regions. Consequently, many EVA-containing products end up in landfills or incineration facilities.

When incinerated, EVA can release harmful emissions, including volatile organic compounds (VOCs) and potentially toxic fumes. In landfills, EVA does not biodegrade readily, contributing to long-term waste accumulation. However, ongoing research into biodegradable additives and improved recycling technologies offers promising avenues for mitigating these end-of-life environmental concerns.

The use of EVA in certain applications, such as in solar panel encapsulation, can indirectly contribute to positive environmental outcomes by enhancing the efficiency and lifespan of renewable energy technologies. This demonstrates the potential for EVA to play a role in sustainable product design when applied strategically.

To address the environmental challenges associated with EVA, industry efforts are focusing on developing bio-based alternatives, improving recycling processes, and implementing more sustainable manufacturing practices. These initiatives aim to reduce the overall environmental footprint of EVA-enhanced products while maintaining their beneficial strength and durability properties.