How to Minimize Hydrofluoric Acid Environmental Impact

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HF Acid Environmental Impact Background and Objectives

Hydrofluoric acid (HF) has been a critical chemical in various industrial applications since its first commercial production in the early 20th century. Initially utilized primarily in glass etching and metal cleaning, HF has evolved to become an essential component in semiconductor manufacturing, petroleum refining, and numerous chemical synthesis processes. The technological trajectory of HF usage has consistently expanded across industries, creating both economic value and environmental challenges that demand innovative solutions.

The environmental concerns associated with HF have gained significant attention since the 1970s when regulatory frameworks began addressing industrial chemical emissions. HF presents unique environmental hazards due to its high water solubility, persistence in aquatic environments, and potential for both acute and chronic ecological damage. Historical incidents involving HF releases have demonstrated its capacity to cause widespread environmental harm, affecting water bodies, soil quality, and air purity.

Recent technological advancements have focused on minimizing HF's environmental footprint while maintaining its industrial utility. The development of closed-loop systems, recovery technologies, and alternative processes represents the ongoing evolution of HF management practices. However, these improvements have not fully addressed the fundamental environmental challenges posed by this highly reactive acid.

The primary objective of this technical research is to comprehensively evaluate existing and emerging technologies for minimizing HF's environmental impact across its lifecycle—from production and transportation to industrial application and waste management. This investigation aims to identify technological gaps, assess the effectiveness of current mitigation strategies, and explore innovative approaches that could significantly reduce environmental risks associated with HF usage.

Secondary objectives include quantifying the environmental benefits of various HF impact reduction technologies, analyzing their economic feasibility, and establishing performance benchmarks for future technological developments. The research will also examine regulatory trends and their influence on technological innovation in HF management, providing context for strategic decision-making.

This technical assessment seeks to establish a foundation for sustainable HF utilization by mapping the technological landscape, identifying promising research directions, and outlining potential pathways for transformative solutions. By understanding both the historical context and future trajectory of HF environmental impact mitigation, this research aims to contribute to the development of more environmentally responsible industrial practices while maintaining the economic benefits that HF applications provide.

The environmental concerns associated with HF have gained significant attention since the 1970s when regulatory frameworks began addressing industrial chemical emissions. HF presents unique environmental hazards due to its high water solubility, persistence in aquatic environments, and potential for both acute and chronic ecological damage. Historical incidents involving HF releases have demonstrated its capacity to cause widespread environmental harm, affecting water bodies, soil quality, and air purity.

Recent technological advancements have focused on minimizing HF's environmental footprint while maintaining its industrial utility. The development of closed-loop systems, recovery technologies, and alternative processes represents the ongoing evolution of HF management practices. However, these improvements have not fully addressed the fundamental environmental challenges posed by this highly reactive acid.

The primary objective of this technical research is to comprehensively evaluate existing and emerging technologies for minimizing HF's environmental impact across its lifecycle—from production and transportation to industrial application and waste management. This investigation aims to identify technological gaps, assess the effectiveness of current mitigation strategies, and explore innovative approaches that could significantly reduce environmental risks associated with HF usage.

Secondary objectives include quantifying the environmental benefits of various HF impact reduction technologies, analyzing their economic feasibility, and establishing performance benchmarks for future technological developments. The research will also examine regulatory trends and their influence on technological innovation in HF management, providing context for strategic decision-making.

This technical assessment seeks to establish a foundation for sustainable HF utilization by mapping the technological landscape, identifying promising research directions, and outlining potential pathways for transformative solutions. By understanding both the historical context and future trajectory of HF environmental impact mitigation, this research aims to contribute to the development of more environmentally responsible industrial practices while maintaining the economic benefits that HF applications provide.

Market Analysis for Green HF Acid Technologies

The global market for green hydrofluoric acid technologies is experiencing significant growth driven by stringent environmental regulations and increasing corporate sustainability commitments. Currently valued at approximately 3.2 billion USD, this specialized segment of the chemical industry is projected to expand at a compound annual growth rate of 6.8% through 2030, outpacing the broader hydrofluoric acid market which grows at 4.5% annually.

Regional analysis reveals distinct market characteristics across different territories. North America and Europe lead in adoption of green HF technologies, primarily due to strict regulatory frameworks like the EU's REACH regulation and the U.S. EPA's Clean Air Act amendments. The Asia-Pacific region, particularly China, Japan, and South Korea, represents the fastest-growing market with increasing industrial applications coupled with emerging environmental consciousness.

Demand-side analysis indicates that semiconductor manufacturing remains the largest application segment, accounting for 38% of green HF technology implementation. This is followed by the pharmaceutical industry (22%), glass etching (17%), and metal surface treatment (14%), with various other applications comprising the remaining 9%. The semiconductor industry's push toward smaller node sizes and higher purity requirements has particularly accelerated demand for environmentally responsible HF handling solutions.

Customer segmentation reveals three primary buyer categories: large multinational corporations implementing comprehensive environmental management systems, medium-sized specialty manufacturers responding to regulatory pressures, and research institutions developing next-generation green chemistry applications. Each segment demonstrates different price sensitivity and adoption timelines.

Market barriers include significant capital investment requirements for retrofitting existing facilities, technical challenges in maintaining process efficiency while reducing environmental impact, and knowledge gaps regarding implementation best practices. The average return on investment period for green HF technologies ranges from 3-5 years, depending on facility scale and application specifics.

Pricing trends show a premium of 15-25% for green HF technologies compared to conventional approaches, though this gap is narrowing as economies of scale improve and more suppliers enter the market. Early adopters typically accept higher premiums in exchange for regulatory compliance assurance and corporate sustainability achievements.

Distribution channels are evolving from traditional chemical supply chains toward more specialized technical service providers offering integrated solutions combining equipment, chemistry, and ongoing support services. This shift reflects the complex nature of implementing environmentally responsible HF handling systems across diverse industrial applications.

Regional analysis reveals distinct market characteristics across different territories. North America and Europe lead in adoption of green HF technologies, primarily due to strict regulatory frameworks like the EU's REACH regulation and the U.S. EPA's Clean Air Act amendments. The Asia-Pacific region, particularly China, Japan, and South Korea, represents the fastest-growing market with increasing industrial applications coupled with emerging environmental consciousness.

Demand-side analysis indicates that semiconductor manufacturing remains the largest application segment, accounting for 38% of green HF technology implementation. This is followed by the pharmaceutical industry (22%), glass etching (17%), and metal surface treatment (14%), with various other applications comprising the remaining 9%. The semiconductor industry's push toward smaller node sizes and higher purity requirements has particularly accelerated demand for environmentally responsible HF handling solutions.

Customer segmentation reveals three primary buyer categories: large multinational corporations implementing comprehensive environmental management systems, medium-sized specialty manufacturers responding to regulatory pressures, and research institutions developing next-generation green chemistry applications. Each segment demonstrates different price sensitivity and adoption timelines.

Market barriers include significant capital investment requirements for retrofitting existing facilities, technical challenges in maintaining process efficiency while reducing environmental impact, and knowledge gaps regarding implementation best practices. The average return on investment period for green HF technologies ranges from 3-5 years, depending on facility scale and application specifics.

Pricing trends show a premium of 15-25% for green HF technologies compared to conventional approaches, though this gap is narrowing as economies of scale improve and more suppliers enter the market. Early adopters typically accept higher premiums in exchange for regulatory compliance assurance and corporate sustainability achievements.

Distribution channels are evolving from traditional chemical supply chains toward more specialized technical service providers offering integrated solutions combining equipment, chemistry, and ongoing support services. This shift reflects the complex nature of implementing environmentally responsible HF handling systems across diverse industrial applications.

Current HF Acid Management Challenges

Hydrofluoric acid (HF) management presents significant challenges across multiple industrial sectors due to its unique chemical properties and severe hazards. The current landscape of HF acid management is characterized by a complex interplay of technical limitations, regulatory pressures, and economic constraints that collectively impede optimal environmental protection.

The primary challenge in HF management stems from its dual hazard profile - both highly corrosive and systemically toxic. Unlike other acids that cause immediate surface burns, HF penetrates tissues deeply before dissociating, making containment failures particularly dangerous. This property necessitates specialized containment systems that are often costly to implement and maintain, creating economic barriers for smaller operations.

Existing neutralization technologies demonstrate variable effectiveness across different industrial applications. The semiconductor industry, which uses HF for silicon etching, faces particular difficulties in treating high-purity waste streams without introducing additional contaminants. Meanwhile, the petroleum industry struggles with managing large volumes of HF-containing waste from alkylation units, where dilution is often employed but remains environmentally problematic.

Detection and monitoring systems represent another significant challenge. Current technologies for real-time HF detection have limitations in sensitivity, especially at the lower concentration thresholds relevant to environmental protection. This creates blind spots in emission monitoring systems, particularly for fugitive emissions that occur during maintenance operations or from micro-leaks in aging infrastructure.

Regulatory frameworks governing HF management vary substantially across jurisdictions, creating compliance challenges for multinational corporations. The patchwork of regulations leads to inconsistent management practices and potential regulatory arbitrage, where operations might relocate to regions with less stringent environmental controls.

The transportation of HF and HF-containing waste presents additional risks and management challenges. Current containment technologies for transport have improved but remain vulnerable to accidents, while emergency response protocols for HF incidents require specialized training and equipment that is not universally available along transportation routes.

Waste disposal options for HF-containing materials are limited by both technical and regulatory constraints. Deep-well injection, a common disposal method for certain industries, faces increasing scrutiny due to potential groundwater contamination risks. Meanwhile, recycling technologies for HF recovery from waste streams remain energy-intensive and economically viable only at larger scales.

Worker safety protocols for HF handling represent a parallel challenge that directly impacts environmental management. The specialized training and protective equipment required create operational complexities that can lead to compliance gaps, particularly during non-routine operations where most incidents occur.

The primary challenge in HF management stems from its dual hazard profile - both highly corrosive and systemically toxic. Unlike other acids that cause immediate surface burns, HF penetrates tissues deeply before dissociating, making containment failures particularly dangerous. This property necessitates specialized containment systems that are often costly to implement and maintain, creating economic barriers for smaller operations.

Existing neutralization technologies demonstrate variable effectiveness across different industrial applications. The semiconductor industry, which uses HF for silicon etching, faces particular difficulties in treating high-purity waste streams without introducing additional contaminants. Meanwhile, the petroleum industry struggles with managing large volumes of HF-containing waste from alkylation units, where dilution is often employed but remains environmentally problematic.

Detection and monitoring systems represent another significant challenge. Current technologies for real-time HF detection have limitations in sensitivity, especially at the lower concentration thresholds relevant to environmental protection. This creates blind spots in emission monitoring systems, particularly for fugitive emissions that occur during maintenance operations or from micro-leaks in aging infrastructure.

Regulatory frameworks governing HF management vary substantially across jurisdictions, creating compliance challenges for multinational corporations. The patchwork of regulations leads to inconsistent management practices and potential regulatory arbitrage, where operations might relocate to regions with less stringent environmental controls.

The transportation of HF and HF-containing waste presents additional risks and management challenges. Current containment technologies for transport have improved but remain vulnerable to accidents, while emergency response protocols for HF incidents require specialized training and equipment that is not universally available along transportation routes.

Waste disposal options for HF-containing materials are limited by both technical and regulatory constraints. Deep-well injection, a common disposal method for certain industries, faces increasing scrutiny due to potential groundwater contamination risks. Meanwhile, recycling technologies for HF recovery from waste streams remain energy-intensive and economically viable only at larger scales.

Worker safety protocols for HF handling represent a parallel challenge that directly impacts environmental management. The specialized training and protective equipment required create operational complexities that can lead to compliance gaps, particularly during non-routine operations where most incidents occur.

Current HF Acid Mitigation Solutions

01 Wastewater treatment and neutralization methods

Various methods have been developed to treat and neutralize hydrofluoric acid in wastewater to reduce its environmental impact. These methods include chemical precipitation, ion exchange, and neutralization processes that convert the harmful acid into less hazardous compounds. Effective treatment of hydrofluoric acid wastewater is crucial to prevent contamination of water bodies and soil, protecting aquatic ecosystems and groundwater resources.- Wastewater treatment and neutralization methods: Various methods have been developed for treating and neutralizing hydrofluoric acid in wastewater to reduce its environmental impact. These methods include chemical neutralization processes, precipitation techniques, and advanced treatment systems that convert harmful fluoride compounds into less hazardous forms. Such treatments are essential before discharge into the environment to prevent contamination of water bodies and soil.

- Air pollution control and emission reduction: Technologies focused on controlling and reducing hydrofluoric acid emissions to the atmosphere address a significant environmental concern. These include scrubbing systems, filtration technologies, and process modifications that capture or neutralize hydrofluoric acid vapors before they are released. Such measures help prevent air pollution and protect both human health and the surrounding ecosystem from the harmful effects of airborne hydrofluoric acid.

- Recovery and recycling of hydrofluoric acid: Innovative processes for recovering and recycling hydrofluoric acid from industrial waste streams reduce the environmental footprint of operations using this chemical. These technologies enable the capture of hydrofluoric acid for reuse in manufacturing processes, thereby decreasing the demand for new production and minimizing waste discharge. Recovery methods include distillation, membrane separation, and chemical extraction techniques.

- Safer alternatives and substitutes: Research into safer alternatives and substitutes for hydrofluoric acid aims to reduce environmental risks associated with its use. These alternatives include less hazardous acids, modified chemical processes, and novel compounds that can perform similar functions with reduced environmental impact. The development of such substitutes is particularly important in industries where complete elimination of acid-based processes is not feasible.

- Environmental monitoring and impact assessment: Systems and methods for monitoring hydrofluoric acid in the environment and assessing its ecological impact are crucial for environmental protection. These include detection technologies, sampling protocols, and analytical methods that can identify and quantify hydrofluoric acid contamination in various environmental media. Such monitoring enables early detection of leaks or spills and facilitates appropriate remediation measures to minimize long-term environmental damage.

02 Emission control and air pollution prevention

Technologies for controlling hydrofluoric acid emissions from industrial processes help minimize air pollution and associated environmental impacts. These include scrubbing systems, filtration technologies, and process modifications that capture or reduce hydrofluoric acid vapors before they enter the atmosphere. Controlling these emissions is essential as airborne hydrofluoric acid can contribute to acid rain, vegetation damage, and respiratory issues in both humans and wildlife.Expand Specific Solutions03 Recovery and recycling of hydrofluoric acid

Systems and methods for recovering and recycling hydrofluoric acid from industrial processes reduce the need for fresh acid production and minimize waste disposal. These technologies include distillation, membrane separation, and chemical recovery processes that allow the acid to be reused in manufacturing. Recycling hydrofluoric acid decreases the environmental footprint associated with its production and reduces the volume of hazardous waste requiring treatment or disposal.Expand Specific Solutions04 Safer alternatives and substitutes

Development of safer alternatives and substitutes to hydrofluoric acid in various industrial applications helps reduce environmental risks. These alternatives include modified formulations, different chemical approaches, and process redesigns that achieve similar technical outcomes with less hazardous materials. Replacing hydrofluoric acid with environmentally friendlier options can significantly reduce potential ecological damage from accidental releases and routine industrial operations.Expand Specific Solutions05 Containment and spill management technologies

Specialized containment systems and spill management technologies help prevent hydrofluoric acid from entering the environment during accidents or leaks. These include advanced storage designs, leak detection systems, neutralization protocols, and emergency response equipment specifically designed for hydrofluoric acid incidents. Effective containment and rapid response to spills are critical for preventing soil contamination, groundwater pollution, and damage to local ecosystems.Expand Specific Solutions

Leading Organizations in HF Acid Management

The hydrofluoric acid environmental impact minimization market is currently in a growth phase, with increasing regulatory pressure driving innovation. The global market for HF management solutions is estimated at $3-5 billion annually, expanding at 6-8% CAGR as industries seek sustainable alternatives. Leading chemical companies like DuPont, Chemours, and BASF are developing advanced containment systems and neutralization technologies, while specialized firms such as Do-Fluoride New Materials and Stella Chemifa focus on recovery and recycling processes. Academic institutions including Tsinghua University and Shenzhen University are researching novel treatment methods. The technology landscape shows varying maturity levels, with established containment solutions at commercial scale, while emerging technologies like electrochemical degradation (Condias GmbH) and specialized sorbents (Sasakura Engineering) remain in early adoption phases. Industry collaboration between chemical manufacturers and environmental technology providers is accelerating solution development.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced HF recovery and recycling systems that capture over 99% of hydrofluoric acid emissions from industrial processes. Their closed-loop technology integrates specialized scrubber systems with proprietary adsorbent materials that convert gaseous HF into recoverable forms. The company's SafeReturn™ process combines thermal oxidation with wet scrubbing techniques, allowing facilities to neutralize HF waste streams while recovering valuable fluoride compounds for reuse. DuPont's approach emphasizes not only emission reduction but also resource conservation through innovative chemical engineering that transforms hazardous waste into valuable process inputs. Their systems include real-time monitoring capabilities that detect even trace HF concentrations, enabling immediate response to potential leaks or process inefficiencies.

Strengths: Industry-leading capture efficiency exceeding regulatory requirements; creates economic value through resource recovery; comprehensive monitoring systems. Weaknesses: High initial capital investment; requires specialized technical expertise for operation and maintenance; system complexity can increase operational challenges.

BASF Corp.

Technical Solution: BASF has developed the EcoFluor™ system, a comprehensive approach to HF risk mitigation that combines advanced treatment technologies with process optimization. Their solution incorporates specialized calcium-based neutralization agents that form stable, non-leachable fluoride precipitates, reducing environmental mobility by over 90% compared to conventional treatments. BASF's technology includes multi-stage treatment processes with proprietary catalysts that enable lower-temperature operation, reducing energy consumption while maintaining treatment efficacy. The company has also pioneered HF substitution technologies, developing alternative chemistries for industrial processes traditionally dependent on hydrofluoric acid. Their integrated management system includes sophisticated analytics for process optimization, allowing facilities to minimize HF usage while maintaining production quality and efficiency.

Strengths: Comprehensive approach addressing both treatment and source reduction; energy-efficient operation; produces stable end products with minimal environmental mobility. Weaknesses: Substitution technologies may not match HF performance in all applications; requires process modifications; higher operational complexity than single-technology solutions.

Key Innovations in HF Acid Treatment

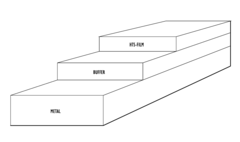

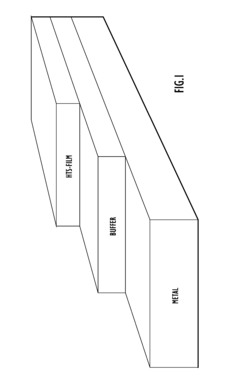

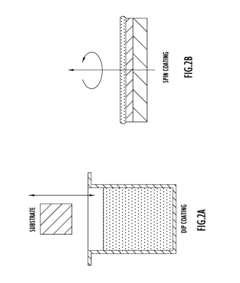

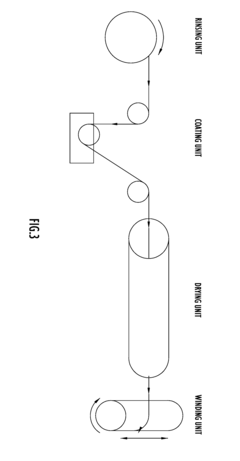

Process for the Production of Highly-Textured, Band-Shaped, High-Temperature Superconductors

PatentInactiveUS20070197397A1

Innovation

- A multi-layered coating process is introduced, where the initial layer has minimal or no fluorine, followed by layers with increasing fluorine content, significantly reducing diffusion paths and by-product emissions, and using a fluorine-free precursor layer to suppress barium carbonate formation, allowing for thicker, textured superconductive layers with improved mechanical properties.

Tetrafluoroborate compounds, compositions and related methods of use

PatentInactiveUS20130178405A1

Innovation

- Development of non-corrosive cleaning compositions using tetrafluoroboric acid in combination with an organic nitrogenous base, such as urea, which forms a tetrafluoroborate salt, offering safer and more effective cleaning without the hazards associated with hydrofluoric acid.

Regulatory Framework for HF Acid Handling

The regulatory landscape governing hydrofluoric acid (HF) handling has evolved significantly over decades, reflecting growing awareness of its severe environmental and health impacts. At the international level, the Basel Convention regulates transboundary movements of hazardous wastes, including HF-containing materials, while the Rotterdam Convention mandates Prior Informed Consent procedures for international trade of hazardous chemicals. The Stockholm Convention, though primarily focused on persistent organic pollutants, establishes principles relevant to managing toxic substances like HF.

In the United States, the Environmental Protection Agency (EPA) regulates HF under multiple frameworks, including the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), which designates HF as a hazardous substance requiring reporting of releases exceeding 100 pounds. The Resource Conservation and Recovery Act (RCRA) governs HF waste management, while the Clean Air Act classifies HF as a Hazardous Air Pollutant, requiring stringent emission controls.

The Occupational Safety and Health Administration (OSHA) has established a Permissible Exposure Limit (PEL) for HF at 3 parts per million (ppm) as an 8-hour time-weighted average. OSHA's Process Safety Management standard applies to facilities using HF above threshold quantities, mandating rigorous risk management protocols and emergency response planning.

European regulations are generally more stringent, with the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) program requiring comprehensive safety data and risk assessments for HF. The Seveso III Directive imposes additional requirements on facilities storing significant quantities of dangerous substances, including detailed safety reports and emergency planning.

In Asia, regulatory approaches vary considerably. Japan's Chemical Substances Control Law and China's Regulations on Safe Management of Hazardous Chemicals provide frameworks similar to Western models, while developing nations often struggle with enforcement despite adopting comparable written standards.

Industry-specific regulations add another layer of complexity. The semiconductor industry faces particularly detailed requirements due to its extensive HF use, with specialized protocols for handling, storage, and disposal. The petroleum refining sector operates under specific regulations addressing alkylation units where HF serves as a catalyst.

Recent regulatory trends show movement toward more preventive approaches, emphasizing inherently safer technologies and substitution principles. Several jurisdictions now require facilities to evaluate alternatives to HF use, particularly in densely populated areas. Reporting requirements have also expanded, with more comprehensive emissions inventories and community right-to-know provisions becoming standard in developed economies.

In the United States, the Environmental Protection Agency (EPA) regulates HF under multiple frameworks, including the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), which designates HF as a hazardous substance requiring reporting of releases exceeding 100 pounds. The Resource Conservation and Recovery Act (RCRA) governs HF waste management, while the Clean Air Act classifies HF as a Hazardous Air Pollutant, requiring stringent emission controls.

The Occupational Safety and Health Administration (OSHA) has established a Permissible Exposure Limit (PEL) for HF at 3 parts per million (ppm) as an 8-hour time-weighted average. OSHA's Process Safety Management standard applies to facilities using HF above threshold quantities, mandating rigorous risk management protocols and emergency response planning.

European regulations are generally more stringent, with the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) program requiring comprehensive safety data and risk assessments for HF. The Seveso III Directive imposes additional requirements on facilities storing significant quantities of dangerous substances, including detailed safety reports and emergency planning.

In Asia, regulatory approaches vary considerably. Japan's Chemical Substances Control Law and China's Regulations on Safe Management of Hazardous Chemicals provide frameworks similar to Western models, while developing nations often struggle with enforcement despite adopting comparable written standards.

Industry-specific regulations add another layer of complexity. The semiconductor industry faces particularly detailed requirements due to its extensive HF use, with specialized protocols for handling, storage, and disposal. The petroleum refining sector operates under specific regulations addressing alkylation units where HF serves as a catalyst.

Recent regulatory trends show movement toward more preventive approaches, emphasizing inherently safer technologies and substitution principles. Several jurisdictions now require facilities to evaluate alternatives to HF use, particularly in densely populated areas. Reporting requirements have also expanded, with more comprehensive emissions inventories and community right-to-know provisions becoming standard in developed economies.

Life Cycle Assessment of HF Acid Technologies

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of hydrofluoric acid (HF) throughout its entire lifecycle. Current LCA studies reveal that HF production generates significant environmental burdens, primarily through energy-intensive processes and potential emissions at multiple stages. The extraction of fluorite minerals, the primary raw material for HF production, causes substantial land disturbance, habitat destruction, and water contamination in mining regions.

Manufacturing processes contribute heavily to the environmental footprint through high energy consumption, primarily from fossil fuel sources, resulting in greenhouse gas emissions and air pollutants. The Fluorspar-Sulfuric Acid process, while economically efficient, produces considerable sulfur dioxide emissions and calcium sulfate waste. Alternative production methods, such as the Fluorosilicic Acid Recovery process, demonstrate reduced primary resource requirements but face efficiency challenges.

Transportation and storage phases present significant environmental risks due to HF's corrosive nature and toxicity. Specialized containment systems, while necessary for safety, increase the carbon footprint of distribution networks. Monitoring data indicates that even minor leaks during transport can cause localized environmental damage requiring extensive remediation efforts.

Application phases in semiconductor manufacturing, petroleum refining, and glass etching each present unique environmental challenges. Semiconductor applications typically implement closed-loop systems with recovery rates approaching 80%, while petroleum refining operations show more variable environmental performance depending on facility age and technology implementation.

End-of-life management represents a critical phase where significant improvements are possible. Advanced neutralization techniques using calcium compounds achieve 99.9% conversion of waste HF to less hazardous calcium fluoride, though this process remains energy-intensive. Emerging recovery technologies demonstrate promising results in laboratory settings, with potential recovery rates of 85-95% for high-purity applications.

Comparative LCA studies indicate that alternative technologies, particularly those employing ionic liquids or supercritical CO2 as substitutes in specific applications, can reduce lifecycle environmental impacts by 40-60%. However, these alternatives currently face economic barriers to widespread adoption and may introduce new environmental considerations that require further assessment.

Manufacturing processes contribute heavily to the environmental footprint through high energy consumption, primarily from fossil fuel sources, resulting in greenhouse gas emissions and air pollutants. The Fluorspar-Sulfuric Acid process, while economically efficient, produces considerable sulfur dioxide emissions and calcium sulfate waste. Alternative production methods, such as the Fluorosilicic Acid Recovery process, demonstrate reduced primary resource requirements but face efficiency challenges.

Transportation and storage phases present significant environmental risks due to HF's corrosive nature and toxicity. Specialized containment systems, while necessary for safety, increase the carbon footprint of distribution networks. Monitoring data indicates that even minor leaks during transport can cause localized environmental damage requiring extensive remediation efforts.

Application phases in semiconductor manufacturing, petroleum refining, and glass etching each present unique environmental challenges. Semiconductor applications typically implement closed-loop systems with recovery rates approaching 80%, while petroleum refining operations show more variable environmental performance depending on facility age and technology implementation.

End-of-life management represents a critical phase where significant improvements are possible. Advanced neutralization techniques using calcium compounds achieve 99.9% conversion of waste HF to less hazardous calcium fluoride, though this process remains energy-intensive. Emerging recovery technologies demonstrate promising results in laboratory settings, with potential recovery rates of 85-95% for high-purity applications.

Comparative LCA studies indicate that alternative technologies, particularly those employing ionic liquids or supercritical CO2 as substitutes in specific applications, can reduce lifecycle environmental impacts by 40-60%. However, these alternatives currently face economic barriers to widespread adoption and may introduce new environmental considerations that require further assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!