How to Optimize Conductivity Paths in Flexible Electronics Solutions

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Conductivity Evolution and Objectives

Flexible electronics has evolved significantly over the past three decades, transitioning from rudimentary proof-of-concept designs to sophisticated systems that integrate seamlessly with various applications. The journey began in the 1990s with the development of basic flexible substrates, primarily focusing on polymer-based materials that could maintain electrical properties while being subjected to mechanical deformation. By the early 2000s, researchers had established fundamental techniques for creating conductive pathways on these flexible substrates, though conductivity remained significantly lower than traditional rigid electronics.

The mid-2000s marked a pivotal shift with the discovery of graphene and subsequent exploration of other 2D materials, opening new possibilities for highly conductive yet flexible pathways. This period also witnessed the emergence of silver nanowire networks and conductive polymers as viable alternatives for flexible conductivity solutions. The 2010s brought significant advancements in manufacturing techniques, including roll-to-roll processing and direct-write technologies, enabling more precise and scalable production of conductive paths.

Current technical objectives in flexible electronics conductivity center around five key areas. First, achieving conductivity values comparable to rigid electronics while maintaining flexibility through multiple deformation cycles remains a primary goal. Research indicates that hybrid materials combining nanomaterials with traditional conductors show promising results, potentially reaching up to 80% of rigid counterpart performance. Second, developing stretchable conductors that can withstand not just bending but significant elongation (>50%) without performance degradation represents a frontier challenge.

Third, the industry aims to create self-healing conductive pathways that can automatically restore electrical connections after mechanical damage, with current technologies demonstrating recovery of up to 90% original conductivity. Fourth, improving the environmental stability of conductive materials against oxidation, humidity, and temperature fluctuations is crucial for real-world applications. Finally, developing manufacturing techniques that enable high-precision, high-throughput production of complex conductive patterns on flexible substrates at reduced costs remains a significant objective.

The ultimate goal is to enable a new generation of flexible electronic devices that can conform to non-planar surfaces, withstand repeated mechanical stress, and deliver performance comparable to conventional electronics. This would revolutionize applications ranging from wearable health monitors and flexible displays to soft robotics and bioelectronic interfaces, potentially creating a market valued at over $30 billion by 2030 according to industry projections.

The mid-2000s marked a pivotal shift with the discovery of graphene and subsequent exploration of other 2D materials, opening new possibilities for highly conductive yet flexible pathways. This period also witnessed the emergence of silver nanowire networks and conductive polymers as viable alternatives for flexible conductivity solutions. The 2010s brought significant advancements in manufacturing techniques, including roll-to-roll processing and direct-write technologies, enabling more precise and scalable production of conductive paths.

Current technical objectives in flexible electronics conductivity center around five key areas. First, achieving conductivity values comparable to rigid electronics while maintaining flexibility through multiple deformation cycles remains a primary goal. Research indicates that hybrid materials combining nanomaterials with traditional conductors show promising results, potentially reaching up to 80% of rigid counterpart performance. Second, developing stretchable conductors that can withstand not just bending but significant elongation (>50%) without performance degradation represents a frontier challenge.

Third, the industry aims to create self-healing conductive pathways that can automatically restore electrical connections after mechanical damage, with current technologies demonstrating recovery of up to 90% original conductivity. Fourth, improving the environmental stability of conductive materials against oxidation, humidity, and temperature fluctuations is crucial for real-world applications. Finally, developing manufacturing techniques that enable high-precision, high-throughput production of complex conductive patterns on flexible substrates at reduced costs remains a significant objective.

The ultimate goal is to enable a new generation of flexible electronic devices that can conform to non-planar surfaces, withstand repeated mechanical stress, and deliver performance comparable to conventional electronics. This would revolutionize applications ranging from wearable health monitors and flexible displays to soft robotics and bioelectronic interfaces, potentially creating a market valued at over $30 billion by 2030 according to industry projections.

Market Analysis for Flexible Conductive Materials

The flexible conductive materials market is experiencing robust growth, driven by the expanding applications of flexible electronics across multiple industries. Current market valuations place this sector at approximately $3.2 billion as of 2023, with projections indicating a compound annual growth rate (CAGR) of 8.5% through 2030, potentially reaching $5.7 billion by the end of the forecast period.

Consumer electronics remains the dominant application segment, accounting for roughly 40% of the total market share. This dominance stems from the increasing consumer demand for wearable devices, foldable smartphones, and other flexible display technologies that require advanced conductive materials capable of withstanding repeated bending and stretching while maintaining electrical performance.

Healthcare applications represent the fastest-growing segment, with an estimated growth rate of 12% annually. The integration of flexible electronics in medical devices, biosensors, and patient monitoring systems is creating substantial demand for biocompatible conductive materials that can conform to human body contours while delivering reliable electrical conductivity.

Regional analysis reveals Asia-Pacific as the market leader, holding approximately 45% of the global market share. This dominance is attributed to the concentration of electronics manufacturing facilities in countries like China, South Korea, and Taiwan. North America follows with about 30% market share, driven by significant investments in research and development of next-generation flexible electronics.

Material-wise, silver-based conductive inks and pastes currently dominate with approximately 35% market share due to their superior conductivity properties. However, carbon-based materials, particularly graphene and carbon nanotubes, are gaining traction with an estimated annual growth rate of 15%, owing to their exceptional mechanical flexibility and potential for cost reduction at scale.

Key market challenges include the high cost of advanced conductive materials, which can be 5-10 times more expensive than traditional rigid counterparts, and technical limitations related to conductivity degradation after repeated mechanical stress. These challenges are creating market opportunities for innovative solutions that can optimize conductivity paths while maintaining flexibility and reducing production costs.

Industry experts anticipate that emerging applications in automotive (flexible sensors and displays), smart textiles, and energy harvesting devices will create new market segments, potentially adding $1.2 billion to the overall market size by 2028. This expansion will likely accelerate the development of hybrid conductive materials that combine the advantages of different material types to achieve optimal performance-to-cost ratios.

Consumer electronics remains the dominant application segment, accounting for roughly 40% of the total market share. This dominance stems from the increasing consumer demand for wearable devices, foldable smartphones, and other flexible display technologies that require advanced conductive materials capable of withstanding repeated bending and stretching while maintaining electrical performance.

Healthcare applications represent the fastest-growing segment, with an estimated growth rate of 12% annually. The integration of flexible electronics in medical devices, biosensors, and patient monitoring systems is creating substantial demand for biocompatible conductive materials that can conform to human body contours while delivering reliable electrical conductivity.

Regional analysis reveals Asia-Pacific as the market leader, holding approximately 45% of the global market share. This dominance is attributed to the concentration of electronics manufacturing facilities in countries like China, South Korea, and Taiwan. North America follows with about 30% market share, driven by significant investments in research and development of next-generation flexible electronics.

Material-wise, silver-based conductive inks and pastes currently dominate with approximately 35% market share due to their superior conductivity properties. However, carbon-based materials, particularly graphene and carbon nanotubes, are gaining traction with an estimated annual growth rate of 15%, owing to their exceptional mechanical flexibility and potential for cost reduction at scale.

Key market challenges include the high cost of advanced conductive materials, which can be 5-10 times more expensive than traditional rigid counterparts, and technical limitations related to conductivity degradation after repeated mechanical stress. These challenges are creating market opportunities for innovative solutions that can optimize conductivity paths while maintaining flexibility and reducing production costs.

Industry experts anticipate that emerging applications in automotive (flexible sensors and displays), smart textiles, and energy harvesting devices will create new market segments, potentially adding $1.2 billion to the overall market size by 2028. This expansion will likely accelerate the development of hybrid conductive materials that combine the advantages of different material types to achieve optimal performance-to-cost ratios.

Technical Barriers in Flexible Conductivity Pathways

Despite significant advancements in flexible electronics, several critical technical barriers continue to impede the optimization of conductivity paths. The foremost challenge lies in material limitations, as traditional conductive materials like copper and silver exhibit inherent rigidity that contradicts the fundamental requirements of flexibility. When these materials are subjected to repeated bending and stretching, they develop microcracks that progressively degrade conductivity performance and ultimately lead to complete failure.

Dimensional constraints present another significant barrier. As flexible electronics trend toward increasingly miniaturized form factors, the width and thickness of conductive paths must be reduced accordingly. This miniaturization intensifies the technical difficulties in maintaining consistent electrical performance across varying mechanical states, particularly when devices transition between flat and bent configurations.

Interface stability between different materials represents a persistent challenge. Flexible electronics typically incorporate multiple material layers with disparate mechanical properties. The adhesion between conductive paths and substrate materials often weakens during flexing operations, creating delamination issues that compromise both mechanical integrity and electrical performance. This problem becomes particularly acute at connection points and intersections where stress concentrations naturally occur.

Environmental susceptibility further complicates conductivity path optimization. Unlike rigid electronics that can be hermetically sealed, flexible devices are frequently exposed to moisture, oxygen, and temperature fluctuations. These environmental factors accelerate oxidation processes and other degradation mechanisms that directly impact conductivity. The development of effective barrier layers that maintain flexibility while providing environmental protection remains technically challenging.

Manufacturing scalability constitutes a significant barrier to widespread implementation. Current production techniques for creating high-performance flexible conductivity paths often involve complex, multi-step processes that are difficult to scale economically. Techniques like photolithography, which work well for rigid electronics, require substantial modification for flexible substrates and frequently yield inconsistent results when applied to non-planar surfaces.

The integration of multi-functionality into conductivity paths presents additional complications. Modern flexible electronics increasingly demand that conductive elements serve multiple purposes simultaneously—carrying electrical signals while also providing structural support, heat dissipation, or sensing capabilities. Optimizing for these competing requirements often involves design compromises that limit overall performance.

Dimensional constraints present another significant barrier. As flexible electronics trend toward increasingly miniaturized form factors, the width and thickness of conductive paths must be reduced accordingly. This miniaturization intensifies the technical difficulties in maintaining consistent electrical performance across varying mechanical states, particularly when devices transition between flat and bent configurations.

Interface stability between different materials represents a persistent challenge. Flexible electronics typically incorporate multiple material layers with disparate mechanical properties. The adhesion between conductive paths and substrate materials often weakens during flexing operations, creating delamination issues that compromise both mechanical integrity and electrical performance. This problem becomes particularly acute at connection points and intersections where stress concentrations naturally occur.

Environmental susceptibility further complicates conductivity path optimization. Unlike rigid electronics that can be hermetically sealed, flexible devices are frequently exposed to moisture, oxygen, and temperature fluctuations. These environmental factors accelerate oxidation processes and other degradation mechanisms that directly impact conductivity. The development of effective barrier layers that maintain flexibility while providing environmental protection remains technically challenging.

Manufacturing scalability constitutes a significant barrier to widespread implementation. Current production techniques for creating high-performance flexible conductivity paths often involve complex, multi-step processes that are difficult to scale economically. Techniques like photolithography, which work well for rigid electronics, require substantial modification for flexible substrates and frequently yield inconsistent results when applied to non-planar surfaces.

The integration of multi-functionality into conductivity paths presents additional complications. Modern flexible electronics increasingly demand that conductive elements serve multiple purposes simultaneously—carrying electrical signals while also providing structural support, heat dissipation, or sensing capabilities. Optimizing for these competing requirements often involves design compromises that limit overall performance.

Current Approaches to Optimize Conductivity Paths

01 Semiconductor device conductivity paths

Semiconductor devices utilize specific conductivity paths to control electrical flow. These paths are created through doped regions, conductive layers, or specialized structures within the semiconductor material. The design of these paths affects the device's performance characteristics, including current capacity, resistance, and switching speed. Advanced semiconductor designs incorporate optimized conductivity paths to enhance efficiency and functionality in integrated circuits.- Semiconductor conductivity path designs: Various designs of conductivity paths in semiconductor devices to enhance electrical performance. These include specialized layouts for transistors, integrated circuits, and other semiconductor components where the conductivity path configuration directly impacts device efficiency and functionality. The designs focus on optimizing electron flow through strategic placement of conductive materials and junctions to reduce resistance and improve signal integrity.

- Measurement and testing of conductivity paths: Methods and apparatus for measuring and testing the conductivity of various materials and components. These include techniques for evaluating electrical pathways, detecting defects in conductive paths, and characterizing conductivity properties. Advanced sensing technologies are employed to provide accurate measurements of conductivity parameters under different environmental conditions, enabling quality control and performance verification.

- Thermal conductivity path optimization: Techniques for optimizing thermal conductivity paths in various applications to improve heat dissipation and thermal management. These approaches focus on materials and structures that efficiently conduct heat away from critical components, preventing overheating and enhancing overall system reliability. The designs incorporate specialized thermal interfaces and heat-conducting elements arranged in optimal configurations.

- Conductive path formation in electronic devices: Methods for creating and enhancing conductivity paths in electronic devices and circuits. These include techniques for forming conductive traces, vias, and interconnects in printed circuit boards and integrated circuits. Advanced manufacturing processes are employed to create reliable electrical connections with minimal resistance, ensuring signal integrity and power delivery efficiency across complex electronic systems.

- Novel materials for enhanced conductivity paths: Development and application of innovative materials to create superior conductivity paths with enhanced electrical or thermal properties. These materials include specialized alloys, composites, and engineered structures designed to provide optimal conductivity characteristics while meeting other requirements such as flexibility, durability, or compatibility with specific manufacturing processes. The materials enable the creation of conductivity paths with improved performance in challenging environments.

02 Measurement and testing of conductivity

Various methods and devices are used for measuring electrical conductivity in materials and systems. These include probe-based techniques, impedance analyzers, and specialized sensors that can detect changes in conductivity under different conditions. Testing equipment may utilize direct or alternating current to evaluate conductivity properties, with applications ranging from quality control in manufacturing to scientific research in material characterization.Expand Specific Solutions03 Thermal conductivity paths and management

Thermal conductivity paths are designed to efficiently transfer heat away from critical components. These paths may consist of specialized materials with high thermal conductivity, heat pipes, or other thermal management structures. Effective thermal conductivity path design is crucial in electronic devices to prevent overheating and ensure optimal performance. Various approaches include the use of metal heat spreaders, thermal interface materials, and engineered cooling structures.Expand Specific Solutions04 Conductive materials and composites

Specialized materials and composites are developed to provide enhanced electrical conductivity for various applications. These may include metal alloys, conductive polymers, carbon-based materials like graphene, or composite structures combining different conductive elements. The development of these materials focuses on optimizing conductivity while maintaining other desirable properties such as flexibility, durability, or cost-effectiveness.Expand Specific Solutions05 Conductivity control in electronic devices

Methods and systems for controlling conductivity in electronic devices involve techniques such as gating, doping, or applying external fields to modulate the conductivity of materials. These approaches allow for dynamic control of electrical pathways, enabling functions like switching, amplification, or signal modulation. Advanced electronic devices incorporate sophisticated conductivity control mechanisms to achieve specific performance characteristics and functionality.Expand Specific Solutions

Industry Leaders in Flexible Electronics Solutions

The flexible electronics market is currently in a growth phase, characterized by increasing adoption across consumer electronics, healthcare, and automotive sectors. The global market size is projected to reach significant expansion due to rising demand for wearable devices and IoT applications. Technologically, the field is advancing rapidly with companies at different maturity levels. Industry leaders like Samsung Electronics, Infineon Technologies, and Taiwan Semiconductor Manufacturing are driving innovation in conductive materials and manufacturing processes. Sumitomo Electric Industries and Siemens AG are focusing on specialized applications in automotive and industrial sectors. Research institutions like Fraunhofer-Gesellschaft and Northwestern University are contributing fundamental advancements in flexible conductive paths, while companies like Google and Sony are exploring consumer applications, creating a competitive yet collaborative ecosystem.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed proprietary metal nanowire technology for flexible electronics conductivity paths. Their approach involves silver nanowire networks embedded in polymer substrates that maintain conductivity even under extreme bending conditions (radius <1mm). The company's SUMI-FLEX™ technology incorporates a unique self-healing mechanism where nanowires can reconnect after deformation, maintaining electrical performance through stretching cycles. Their manufacturing process includes specialized coating techniques that create uniform nanowire distribution, critical for consistent conductivity across flexible surfaces. Sumitomo has also pioneered hybrid systems combining metal nanowires with conductive polymers to enhance durability while maintaining flexibility, achieving sheet resistance values below 10 ohms/square with over 90% optical transparency.

Strengths: Superior flexibility while maintaining high conductivity; self-healing properties that extend product lifespan; excellent transparency for display applications. Weaknesses: Higher production costs compared to traditional rigid conductors; potential for oxidation in certain environmental conditions requiring additional protective layers.

Siemens AG

Technical Solution: Siemens has developed an advanced flexible electronics platform called SILFLEX that optimizes conductivity paths through a multi-layer architecture. Their technology employs sintered silver nanoparticle inks deposited via precision digital printing techniques, creating stretchable interconnects that maintain conductivity at strains exceeding 100%. The company's proprietary serpentine geometry design allows for mechanical stress distribution across the entire conductive path rather than concentrating at specific points. Siemens has also pioneered a thermal annealing process that enhances particle-to-particle contact within the conductive traces while maintaining substrate integrity. Their system incorporates real-time impedance monitoring that allows for dynamic adjustment of current pathways based on mechanical deformation, ensuring consistent performance even under variable stress conditions.

Strengths: Exceptional stretchability while maintaining electrical performance; advanced manufacturing techniques allowing complex circuit designs; comprehensive testing protocols ensuring reliability. Weaknesses: Higher initial implementation costs; requires specialized equipment for manufacturing and quality control; limited compatibility with some substrate materials.

Key Patents in Flexible Conductive Materials

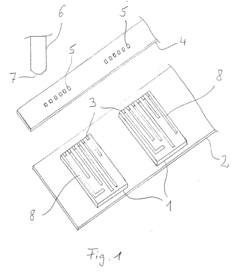

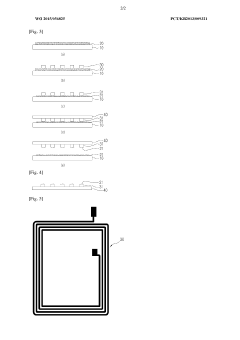

Process for improving the electrical conductivity and the corrosion and wear resistance of a flexible circuit

PatentInactiveEP1365638A2

Innovation

- The method involves selectively coating connection areas of conductor tracks with electrically conductive particles using a stencil and kinetic spraying, allowing for precise application without heating the circuit, thus saving material and enhancing conductivity and resistance without affecting non-contact areas.

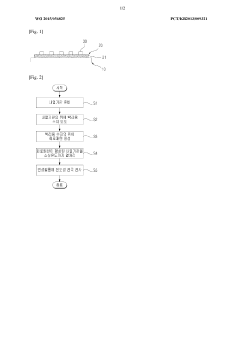

Method for manufacturing flexible printed circuit board through high-temperature heat treatment on heat-resistant substrate and flexible printed circuit board thereof

PatentWO2015056825A1

Innovation

- A method involving high-temperature heat treatment of a conductive paste on a heat-resistant substrate to form a conductive electrode, which is then transferred to a flexible film using a resin for exfoliation, allowing for the use of non-ferrous metals and noble metals, and enabling the formation of thin films with superior electrical conductivity.

Manufacturing Scalability Challenges

Scaling up the manufacturing of flexible electronics with optimized conductivity paths presents significant challenges that must be addressed for commercial viability. Current production methods often rely on laboratory-scale techniques that cannot easily transition to high-volume manufacturing environments. Photolithography processes, while precise for creating intricate conductive patterns, require substantial capital investment and face limitations when applied to flexible substrates at industrial scales. The delicate nature of flexible materials introduces variability in production outcomes, with substrate deformation during processing leading to misalignment issues and inconsistent electrical performance.

Material compatibility represents another critical challenge, as conductive inks and pastes must maintain consistent viscosity and particle distribution throughout extended production runs. Variations in material properties can lead to inconsistent conductivity paths, affecting product reliability and performance. Additionally, the curing processes for conductive materials must be optimized for speed without compromising the integrity of heat-sensitive flexible substrates, creating a delicate balance between throughput and quality.

Roll-to-roll (R2R) manufacturing offers promising solutions for scalability but introduces unique challenges for maintaining precise registration of multiple layers across large production volumes. The dynamic tension and environmental factors during continuous processing can affect the dimensional stability of flexible substrates, potentially compromising the integrity of conductive paths. Current R2R systems also struggle with in-line quality control for conductivity verification, often relying on sampling methods that may miss defects in continuous production.

Cost considerations further complicate manufacturing scale-up, as the economics of flexible electronics production must compete with established rigid electronics manufacturing. The higher material costs for specialized conductive inks and flexible substrates, combined with potentially lower yields during early production scaling, create significant barriers to market entry. Equipment modifications required for handling flexible materials add further capital expenses that must be amortized across production volumes.

Integration of automated inspection systems presents another scalability hurdle, as traditional vision systems designed for rigid electronics may struggle with the variable surface topography of flexible substrates. Developing robust, high-speed inspection protocols capable of detecting subtle conductivity path defects remains an ongoing challenge. Furthermore, the environmental sensitivity of many flexible electronics materials necessitates controlled manufacturing environments, adding operational complexity and cost to large-scale production facilities.

Material compatibility represents another critical challenge, as conductive inks and pastes must maintain consistent viscosity and particle distribution throughout extended production runs. Variations in material properties can lead to inconsistent conductivity paths, affecting product reliability and performance. Additionally, the curing processes for conductive materials must be optimized for speed without compromising the integrity of heat-sensitive flexible substrates, creating a delicate balance between throughput and quality.

Roll-to-roll (R2R) manufacturing offers promising solutions for scalability but introduces unique challenges for maintaining precise registration of multiple layers across large production volumes. The dynamic tension and environmental factors during continuous processing can affect the dimensional stability of flexible substrates, potentially compromising the integrity of conductive paths. Current R2R systems also struggle with in-line quality control for conductivity verification, often relying on sampling methods that may miss defects in continuous production.

Cost considerations further complicate manufacturing scale-up, as the economics of flexible electronics production must compete with established rigid electronics manufacturing. The higher material costs for specialized conductive inks and flexible substrates, combined with potentially lower yields during early production scaling, create significant barriers to market entry. Equipment modifications required for handling flexible materials add further capital expenses that must be amortized across production volumes.

Integration of automated inspection systems presents another scalability hurdle, as traditional vision systems designed for rigid electronics may struggle with the variable surface topography of flexible substrates. Developing robust, high-speed inspection protocols capable of detecting subtle conductivity path defects remains an ongoing challenge. Furthermore, the environmental sensitivity of many flexible electronics materials necessitates controlled manufacturing environments, adding operational complexity and cost to large-scale production facilities.

Environmental Impact of Flexible Electronics Materials

The environmental impact of flexible electronics materials represents a critical consideration in the sustainable development of this emerging technology sector. Traditional electronics manufacturing processes involve significant use of toxic chemicals, heavy metals, and energy-intensive production methods. Flexible electronics, while offering numerous advantages in terms of functionality, present both challenges and opportunities from an environmental perspective.

Materials used in flexible electronics conductivity paths, such as silver nanoparticles, carbon nanotubes, and conductive polymers, have varying environmental footprints. Silver nanoparticle inks, commonly used for their excellent conductivity, raise concerns regarding resource depletion and potential ecological toxicity when improperly disposed. The mining and processing of silver generates substantial environmental burdens, including habitat destruction and water pollution.

Carbon-based conductive materials offer a potentially more sustainable alternative. Graphene and carbon nanotubes can be produced from renewable carbon sources and typically require less energy-intensive manufacturing processes. However, the long-term environmental fate and potential toxicity of these nanomaterials remain subjects of ongoing research, particularly regarding their persistence in ecosystems.

The substrate materials supporting conductivity paths also contribute significantly to the environmental profile of flexible electronics. Petroleum-based polymers like polyethylene terephthalate (PET) and polyimide dominate the market but present end-of-life disposal challenges. Biodegradable alternatives such as cellulose-based substrates and bio-derived polymers are emerging as environmentally preferable options, though they often face performance limitations in terms of moisture resistance and thermal stability.

Manufacturing processes for optimizing conductivity paths also carry environmental implications. Additive manufacturing techniques like inkjet printing and screen printing generally produce less waste compared to traditional subtractive methods. However, they may require specialized inks containing volatile organic compounds or require multiple curing steps that consume significant energy.

End-of-life considerations present perhaps the greatest environmental challenge for flexible electronics. The intimate integration of different materials in thin, flexible formats makes recycling particularly difficult. Current recycling infrastructure is poorly equipped to handle these composite materials, resulting in most flexible electronics being landfilled or incinerated at end-of-life, wasting valuable resources and potentially releasing harmful substances.

Emerging design approaches that consider environmental impact include designing for disassembly, using monomaterial systems where possible, and developing water-soluble or thermally degradable temporary substrates that facilitate material recovery. Life cycle assessment studies indicate that optimizing conductivity paths using environmentally benign materials and energy-efficient deposition methods can significantly reduce the overall environmental footprint of flexible electronic devices.

Materials used in flexible electronics conductivity paths, such as silver nanoparticles, carbon nanotubes, and conductive polymers, have varying environmental footprints. Silver nanoparticle inks, commonly used for their excellent conductivity, raise concerns regarding resource depletion and potential ecological toxicity when improperly disposed. The mining and processing of silver generates substantial environmental burdens, including habitat destruction and water pollution.

Carbon-based conductive materials offer a potentially more sustainable alternative. Graphene and carbon nanotubes can be produced from renewable carbon sources and typically require less energy-intensive manufacturing processes. However, the long-term environmental fate and potential toxicity of these nanomaterials remain subjects of ongoing research, particularly regarding their persistence in ecosystems.

The substrate materials supporting conductivity paths also contribute significantly to the environmental profile of flexible electronics. Petroleum-based polymers like polyethylene terephthalate (PET) and polyimide dominate the market but present end-of-life disposal challenges. Biodegradable alternatives such as cellulose-based substrates and bio-derived polymers are emerging as environmentally preferable options, though they often face performance limitations in terms of moisture resistance and thermal stability.

Manufacturing processes for optimizing conductivity paths also carry environmental implications. Additive manufacturing techniques like inkjet printing and screen printing generally produce less waste compared to traditional subtractive methods. However, they may require specialized inks containing volatile organic compounds or require multiple curing steps that consume significant energy.

End-of-life considerations present perhaps the greatest environmental challenge for flexible electronics. The intimate integration of different materials in thin, flexible formats makes recycling particularly difficult. Current recycling infrastructure is poorly equipped to handle these composite materials, resulting in most flexible electronics being landfilled or incinerated at end-of-life, wasting valuable resources and potentially releasing harmful substances.

Emerging design approaches that consider environmental impact include designing for disassembly, using monomaterial systems where possible, and developing water-soluble or thermally degradable temporary substrates that facilitate material recovery. Life cycle assessment studies indicate that optimizing conductivity paths using environmentally benign materials and energy-efficient deposition methods can significantly reduce the overall environmental footprint of flexible electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!