How to Optimize ICP-MS Instrumentation Settings

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ICP-MS Technology Background and Objectives

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has evolved significantly since its commercial introduction in the early 1980s. This analytical technique combines the high-temperature ICP source with a mass spectrometer to detect and quantify trace elements at concentrations as low as one part per trillion. The technology emerged from earlier atomic emission spectroscopy methods but offered superior detection limits and analytical capabilities for elemental analysis.

The evolution of ICP-MS technology has been characterized by continuous improvements in sensitivity, precision, and interference reduction. Early systems faced challenges with matrix effects, polyatomic interferences, and limited dynamic range. Over time, innovations such as collision/reaction cells, high-resolution mass analyzers, and improved sample introduction systems have addressed many of these limitations, expanding the technique's applicability across diverse scientific fields.

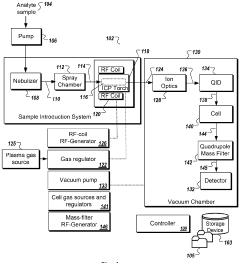

Current ICP-MS instrumentation represents a sophisticated integration of plasma generation technology, ion optics, mass analyzers, and detection systems. Modern systems incorporate advanced features like triple quadrupole configurations, time-of-flight mass analyzers, and multicollector systems that enable isotope ratio measurements with unprecedented precision. These developments have positioned ICP-MS as an indispensable tool in environmental monitoring, clinical diagnostics, pharmaceutical analysis, and materials science.

The optimization of ICP-MS instrumentation settings remains a critical aspect of achieving reliable analytical results. This process involves fine-tuning numerous parameters including plasma power, gas flows, ion lens voltages, and detector settings to maximize sensitivity while minimizing interferences. The complexity of these interactions necessitates a systematic approach to optimization that considers both the specific analytical requirements and the physical principles governing plasma behavior and ion transport.

The primary technical objectives in ICP-MS optimization include enhancing detection limits, improving signal stability, reducing matrix effects, minimizing spectral interferences, and extending linear dynamic range. These goals must be balanced against practical considerations such as sample throughput, argon consumption, and instrument longevity. As applications of ICP-MS continue to expand into new fields like single-cell analysis, nanoparticle characterization, and laser ablation imaging, the demands for specialized optimization strategies have grown accordingly.

Looking forward, the trajectory of ICP-MS technology points toward greater automation of optimization processes, integration with artificial intelligence for method development, and enhanced compatibility with specialized sample introduction techniques. The ultimate goal remains consistent: to provide accurate, precise elemental analysis across an expanding range of sample types and concentrations while simplifying the user experience and reducing the expertise required for optimal instrument operation.

The evolution of ICP-MS technology has been characterized by continuous improvements in sensitivity, precision, and interference reduction. Early systems faced challenges with matrix effects, polyatomic interferences, and limited dynamic range. Over time, innovations such as collision/reaction cells, high-resolution mass analyzers, and improved sample introduction systems have addressed many of these limitations, expanding the technique's applicability across diverse scientific fields.

Current ICP-MS instrumentation represents a sophisticated integration of plasma generation technology, ion optics, mass analyzers, and detection systems. Modern systems incorporate advanced features like triple quadrupole configurations, time-of-flight mass analyzers, and multicollector systems that enable isotope ratio measurements with unprecedented precision. These developments have positioned ICP-MS as an indispensable tool in environmental monitoring, clinical diagnostics, pharmaceutical analysis, and materials science.

The optimization of ICP-MS instrumentation settings remains a critical aspect of achieving reliable analytical results. This process involves fine-tuning numerous parameters including plasma power, gas flows, ion lens voltages, and detector settings to maximize sensitivity while minimizing interferences. The complexity of these interactions necessitates a systematic approach to optimization that considers both the specific analytical requirements and the physical principles governing plasma behavior and ion transport.

The primary technical objectives in ICP-MS optimization include enhancing detection limits, improving signal stability, reducing matrix effects, minimizing spectral interferences, and extending linear dynamic range. These goals must be balanced against practical considerations such as sample throughput, argon consumption, and instrument longevity. As applications of ICP-MS continue to expand into new fields like single-cell analysis, nanoparticle characterization, and laser ablation imaging, the demands for specialized optimization strategies have grown accordingly.

Looking forward, the trajectory of ICP-MS technology points toward greater automation of optimization processes, integration with artificial intelligence for method development, and enhanced compatibility with specialized sample introduction techniques. The ultimate goal remains consistent: to provide accurate, precise elemental analysis across an expanding range of sample types and concentrations while simplifying the user experience and reducing the expertise required for optimal instrument operation.

Market Demand Analysis for Advanced ICP-MS Solutions

The global market for ICP-MS (Inductively Coupled Plasma Mass Spectrometry) instrumentation continues to experience robust growth, driven by increasing demands across multiple sectors including environmental monitoring, pharmaceutical research, food safety testing, and clinical diagnostics. Current market valuations place the ICP-MS sector at approximately 1.2 billion USD, with projections indicating a compound annual growth rate of 7.8% through 2028.

Environmental regulatory compliance represents a primary market driver, with governmental agencies worldwide implementing stricter monitoring protocols for heavy metals and trace elements in water, soil, and air. The EPA, EU Water Framework Directive, and similar regulatory frameworks in Asia-Pacific regions have established increasingly stringent detection limits, necessitating more sensitive and precise instrumentation settings.

The pharmaceutical and biomedical research sectors demonstrate particularly strong demand growth, with requirements for enhanced sensitivity in biomarker discovery, drug metabolism studies, and metallomics research. These applications require optimized ICP-MS settings capable of detecting ultra-trace elements in complex biological matrices while minimizing interferences.

Food safety testing constitutes another significant market segment, with growing consumer awareness regarding heavy metal contamination in food products. Regulatory bodies including the FDA and EFSA have implemented comprehensive testing requirements, creating demand for ICP-MS systems with optimized settings for high-throughput analysis of diverse food matrices.

Clinical diagnostics represents an emerging high-growth segment, with ICP-MS increasingly utilized for trace element analysis in biological fluids for disease diagnosis and monitoring. This application demands specialized optimization settings to handle high-salt matrices while maintaining sensitivity and precision.

Market research indicates that end-users increasingly prioritize instruments with automated optimization capabilities, intelligent interference management, and intuitive software interfaces that simplify the complex process of method development and parameter adjustment. Laboratories face persistent challenges in maintaining analytical expertise amid workforce shortages, creating demand for systems with built-in optimization intelligence.

Regional analysis reveals the North American and European markets currently dominate ICP-MS instrumentation adoption, though Asia-Pacific regions—particularly China, Japan, and South Korea—demonstrate the highest growth rates. This geographic shift reflects increasing industrialization, strengthening regulatory frameworks, and growing research infrastructure in these regions.

Customer feedback consistently highlights optimization challenges as a significant pain point, with laboratories seeking solutions that reduce method development time, minimize maintenance requirements, and provide consistent performance across diverse sample types. This creates substantial market opportunity for advanced optimization technologies that address these specific needs.

Environmental regulatory compliance represents a primary market driver, with governmental agencies worldwide implementing stricter monitoring protocols for heavy metals and trace elements in water, soil, and air. The EPA, EU Water Framework Directive, and similar regulatory frameworks in Asia-Pacific regions have established increasingly stringent detection limits, necessitating more sensitive and precise instrumentation settings.

The pharmaceutical and biomedical research sectors demonstrate particularly strong demand growth, with requirements for enhanced sensitivity in biomarker discovery, drug metabolism studies, and metallomics research. These applications require optimized ICP-MS settings capable of detecting ultra-trace elements in complex biological matrices while minimizing interferences.

Food safety testing constitutes another significant market segment, with growing consumer awareness regarding heavy metal contamination in food products. Regulatory bodies including the FDA and EFSA have implemented comprehensive testing requirements, creating demand for ICP-MS systems with optimized settings for high-throughput analysis of diverse food matrices.

Clinical diagnostics represents an emerging high-growth segment, with ICP-MS increasingly utilized for trace element analysis in biological fluids for disease diagnosis and monitoring. This application demands specialized optimization settings to handle high-salt matrices while maintaining sensitivity and precision.

Market research indicates that end-users increasingly prioritize instruments with automated optimization capabilities, intelligent interference management, and intuitive software interfaces that simplify the complex process of method development and parameter adjustment. Laboratories face persistent challenges in maintaining analytical expertise amid workforce shortages, creating demand for systems with built-in optimization intelligence.

Regional analysis reveals the North American and European markets currently dominate ICP-MS instrumentation adoption, though Asia-Pacific regions—particularly China, Japan, and South Korea—demonstrate the highest growth rates. This geographic shift reflects increasing industrialization, strengthening regulatory frameworks, and growing research infrastructure in these regions.

Customer feedback consistently highlights optimization challenges as a significant pain point, with laboratories seeking solutions that reduce method development time, minimize maintenance requirements, and provide consistent performance across diverse sample types. This creates substantial market opportunity for advanced optimization technologies that address these specific needs.

Current Status and Technical Challenges in ICP-MS Optimization

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has evolved significantly over the past three decades, becoming a cornerstone analytical technique for elemental analysis. Currently, the global ICP-MS market is dominated by several key manufacturers including Agilent Technologies, PerkinElmer, Thermo Fisher Scientific, and Shimadzu, who continuously refine their instrumentation to address analytical challenges.

The current state of ICP-MS technology represents a balance between sensitivity, precision, and interference management. Modern instruments typically achieve detection limits in the parts-per-trillion (ppt) range for most elements, with some capable of parts-per-quadrillion (ppq) detection for select elements. However, despite these impressive capabilities, several significant technical challenges persist in optimizing ICP-MS performance.

One primary challenge involves plasma stability and robustness. Fluctuations in plasma conditions can significantly impact measurement precision and accuracy. Current systems employ various approaches to stabilize plasma conditions, including improved RF generators and gas flow controllers, but maintaining consistent plasma characteristics remains problematic when analyzing complex matrices.

Sample introduction systems present another critical challenge area. Conventional nebulizers and spray chambers typically deliver only 1-2% of the sample to the plasma, resulting in significant sample waste and reduced sensitivity. While ultrasonic nebulizers and desolvation systems have improved efficiency, they introduce additional complexity and potential for contamination.

Interface design between the plasma and mass analyzer continues to challenge engineers. The pressure reduction from atmospheric pressure to high vacuum must be achieved while maintaining ion transmission efficiency. Current cone designs and vacuum systems have improved but still suffer from clogging and signal drift during extended analytical runs with complex matrices.

Polyatomic and isobaric interferences remain perhaps the most persistent challenge in ICP-MS analysis. While collision/reaction cell technologies have revolutionized interference management, optimizing cell conditions for multi-element analysis requires complex compromises. The latest instruments incorporate sophisticated cell designs with multiple gases and operation modes, but universal elimination of all interferences remains elusive.

Mass analyzers present their own optimization challenges. Quadrupole systems offer simplicity and speed but limited resolution, while high-resolution magnetic sector instruments provide superior interference separation but at significantly higher cost and complexity. Time-of-flight and triple-quadrupole systems represent emerging alternatives with their own optimization challenges.

Data processing and calibration strategies also present significant optimization hurdles. Modern instruments generate massive datasets requiring sophisticated algorithms for signal processing, interference correction, and drift compensation. Machine learning approaches are beginning to emerge but remain in early development stages for routine applications.

The current state of ICP-MS technology represents a balance between sensitivity, precision, and interference management. Modern instruments typically achieve detection limits in the parts-per-trillion (ppt) range for most elements, with some capable of parts-per-quadrillion (ppq) detection for select elements. However, despite these impressive capabilities, several significant technical challenges persist in optimizing ICP-MS performance.

One primary challenge involves plasma stability and robustness. Fluctuations in plasma conditions can significantly impact measurement precision and accuracy. Current systems employ various approaches to stabilize plasma conditions, including improved RF generators and gas flow controllers, but maintaining consistent plasma characteristics remains problematic when analyzing complex matrices.

Sample introduction systems present another critical challenge area. Conventional nebulizers and spray chambers typically deliver only 1-2% of the sample to the plasma, resulting in significant sample waste and reduced sensitivity. While ultrasonic nebulizers and desolvation systems have improved efficiency, they introduce additional complexity and potential for contamination.

Interface design between the plasma and mass analyzer continues to challenge engineers. The pressure reduction from atmospheric pressure to high vacuum must be achieved while maintaining ion transmission efficiency. Current cone designs and vacuum systems have improved but still suffer from clogging and signal drift during extended analytical runs with complex matrices.

Polyatomic and isobaric interferences remain perhaps the most persistent challenge in ICP-MS analysis. While collision/reaction cell technologies have revolutionized interference management, optimizing cell conditions for multi-element analysis requires complex compromises. The latest instruments incorporate sophisticated cell designs with multiple gases and operation modes, but universal elimination of all interferences remains elusive.

Mass analyzers present their own optimization challenges. Quadrupole systems offer simplicity and speed but limited resolution, while high-resolution magnetic sector instruments provide superior interference separation but at significantly higher cost and complexity. Time-of-flight and triple-quadrupole systems represent emerging alternatives with their own optimization challenges.

Data processing and calibration strategies also present significant optimization hurdles. Modern instruments generate massive datasets requiring sophisticated algorithms for signal processing, interference correction, and drift compensation. Machine learning approaches are beginning to emerge but remain in early development stages for routine applications.

Current Optimization Approaches for ICP-MS Settings

01 Plasma generation and ion source optimization

Optimization of the plasma generation system and ion source is critical for ICP-MS performance. This includes adjustments to RF power settings, plasma gas flow rates, and torch position to ensure stable plasma formation and efficient ionization. The design of the ion source interface, including sampler and skimmer cones, affects ion transmission efficiency and instrument sensitivity. Advanced designs incorporate improved cooling systems and geometries to enhance plasma stability and reduce matrix effects.- Plasma source and ion generation optimization: Optimization of the plasma source and ion generation process is critical for ICP-MS performance. This includes adjustments to RF power settings, plasma gas flow rates, and torch design to enhance ionization efficiency. Proper configuration of these parameters ensures stable plasma conditions and optimal ion production, which directly impacts sensitivity and detection limits. Advanced designs incorporate improved ion optics and plasma containment systems to maximize ion extraction and transmission.

- Interface and ion transmission systems: The interface region between the plasma source and mass analyzer requires specific settings to efficiently transmit ions while maintaining vacuum conditions. This includes optimization of sampler and skimmer cone geometries, spacing, and voltages. Ion lens configurations, extraction voltages, and focusing parameters significantly affect transmission efficiency. Advanced systems incorporate collision/reaction cells with specific gas flows and voltages to reduce interferences and improve selectivity.

- Mass analyzer configuration and detection parameters: Mass analyzer settings are crucial for achieving desired resolution, mass range, and scanning speed in ICP-MS. This includes quadrupole bias voltages, resolution settings for sector-field instruments, or timing parameters for time-of-flight analyzers. Detector configurations involve voltage settings, pulse/analog mode switching points, and dead time corrections. Optimization of these parameters balances sensitivity, precision, and dynamic range requirements for specific analytical applications.

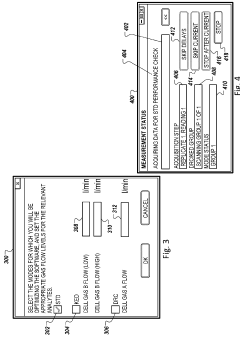

- Sample introduction and aerosol generation systems: Sample introduction systems require specific settings for nebulizer gas flow rates, spray chamber temperatures, and peristaltic pump speeds to optimize aerosol generation and transport. These parameters affect droplet size distribution, transport efficiency, and signal stability. Advanced systems incorporate desolvation units, membrane separators, or laser ablation systems with specific power, spot size, and repetition rate settings to enhance sensitivity and reduce matrix effects.

- Calibration and interference management techniques: Proper calibration and interference management settings are essential for accurate ICP-MS analysis. This includes tuning procedures for mass calibration, abundance sensitivity, and oxide/doubly-charged ion formation. Specific settings for collision/reaction cell technologies involve gas types, flow rates, and cell voltages to reduce polyatomic interferences. Mathematical correction models and internal standardization approaches require specific configuration to compensate for matrix effects and instrument drift during analysis.

02 Mass analyzer configuration and tuning

The mass analyzer component requires specific settings for optimal ion separation and detection. This includes quadrupole, time-of-flight, or magnetic sector analyzers with parameters such as resolution settings, scan speeds, and mass calibration. Proper tuning of lens voltages, pole bias, and axis offset is essential for achieving high resolution and sensitivity. Advanced systems incorporate collision/reaction cells with specific gas flows and cell voltages to reduce interferences and improve detection limits for challenging elements.Expand Specific Solutions03 Sample introduction system optimization

The sample introduction system significantly impacts measurement stability and sensitivity. Key parameters include nebulizer gas flow rates, spray chamber temperature, and peristaltic pump speeds. Specialized nebulizers and spray chambers are designed for different sample types, with adjustable settings to accommodate varying viscosities and dissolved solid content. Automated sample introduction systems incorporate washout protocols and internal standard addition to improve precision and accuracy across diverse sample matrices.Expand Specific Solutions04 Detector configuration and signal processing

Detector settings are crucial for accurate quantification across a wide dynamic range. This includes pulse/analog mode switching thresholds, detector voltage, and dead time correction factors. Signal processing parameters such as dwell time, integration time, and number of sweeps affect precision and detection limits. Advanced systems incorporate dual-mode detection with automatic cross-calibration between pulse-counting and analog modes to extend the linear dynamic range across multiple orders of magnitude.Expand Specific Solutions05 Interference management and calibration techniques

Specialized settings for interference management include collision/reaction cell parameters, kinetic energy discrimination values, and mathematical correction equations. Calibration approaches involve selection of appropriate standards, internal standardization methods, and quality control procedures. Advanced systems utilize intelligent software for automatic optimization of interference removal settings based on sample composition. Isotope ratio measurement applications require specific mass bias correction factors and detector dead time settings to achieve high precision isotopic analysis.Expand Specific Solutions

Key Industry Players and Manufacturers in ICP-MS Technology

The ICP-MS instrumentation optimization landscape is currently in a mature growth phase, with a global market size exceeding $1.5 billion and projected annual growth of 6-8%. Leading players include Agilent Technologies, Thermo Fisher Scientific, and PerkinElmer, who dominate with comprehensive solutions and advanced software integration. Emerging competitors like Kimia Analytics and Ruilaipu are disrupting the market with innovative torch designs and specialized applications. The technology has reached high maturity in environmental and pharmaceutical sectors, while newer applications in semiconductor manufacturing and clinical diagnostics are driving innovation. Companies like Shimadzu and Nu Instruments are focusing on enhancing sensitivity and reducing interference, while academic partnerships with institutions like ETH Zurich are advancing fundamental research in plasma physics and ion detection methodologies.

Agilent Technologies, Inc.

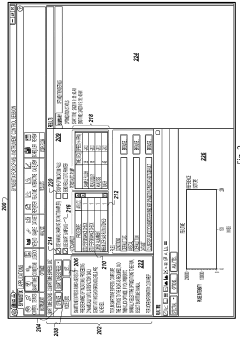

Technical Solution: Agilent's ICP-MS optimization approach centers on their patented High Matrix Introduction (HMI) technology, which dilutes plasma with argon to reduce matrix effects without physical sample dilution. Their instruments feature Octopole Reaction System (ORS) technology that operates in helium collision mode to remove polyatomic interferences through kinetic energy discrimination. Agilent's ICP-MS MassHunter software provides automated optimization routines including plasma conditions, ion lens voltages, and mass calibration. Their instruments incorporate intelligent autotuning capabilities that optimize nebulizer gas flow, torch position, and lens voltages based on specific application requirements. Agilent has also developed the Ultra High Matrix Introduction (UHMI) system that extends the total dissolved solids tolerance up to 25%, significantly improving analysis of challenging environmental and industrial samples[1][2].

Strengths: Superior matrix tolerance through HMI/UHMI technology; excellent interference removal with ORS collision/reaction cell; comprehensive automated optimization tools. Weaknesses: Higher initial investment cost compared to some competitors; optimization routines may require more specialized training for new users; some advanced features may be underutilized in routine laboratories.

Thermo Fisher Scientific (Bremen) GmbH

Technical Solution: Thermo Fisher's approach to ICP-MS optimization centers on their proprietary Triple Quadrupole (TQ-ICP-MS) technology, which provides enhanced interference removal through controlled reaction chemistry. Their instruments feature the QCell collision/reaction cell with flatapole design that maintains transmission efficiency while removing interferences. Thermo's Qtegra Intelligent Scientific Data Solution software includes automated performance optimization routines that adjust plasma conditions, ion optics, and detector parameters simultaneously. Their kinetic energy discrimination (KED) mode optimizes collision gas flow rates to effectively remove polyatomic interferences while maintaining sensitivity. Thermo Fisher has also developed the high-sensitivity interface that optimizes ion extraction from plasma through precisely engineered sample and skimmer cones, achieving detection limits in the sub-ppt range for most elements[3][4].

Strengths: Superior interference removal with triple quadrupole technology; comprehensive software automation for optimization; excellent sensitivity through optimized interface design. Weaknesses: Higher complexity in method development for reaction chemistry approaches; premium pricing structure; optimization of triple quadrupole methods requires deeper technical expertise.

Critical Technical Innovations in ICP-MS Parameter Control

Systems and methods for automated optimization of a multi-mode inductively coupled plasma mass spectrometer

PatentActiveCA2938675C

Innovation

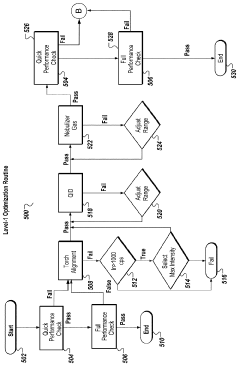

- An automated optimization system for multi-mode ICP-MS that allows for 'single click' operation, using a processor and non-transitory computer-readable medium to execute user inputs for automated tuning routines, including performance assessments and dynamic range optimization, to adjust settings such as torch alignment, quadrupole ion deflector calibration, and nebulizer gas flow, ensuring optimal instrument performance across various modes.

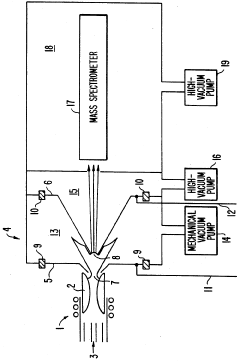

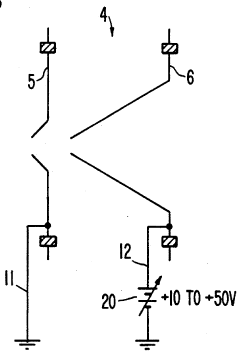

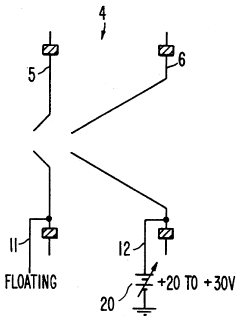

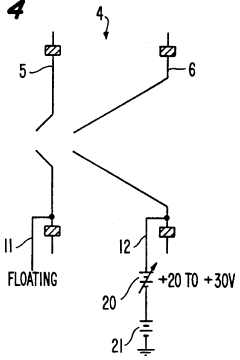

Plasma sampling interface for inductively coupled plasma-mass spectrometry (ICP-MS)

PatentInactiveUS5218204A

Innovation

- A plasma sampling interface with insulating spacers and an adjustable DC bias voltage source applying a DC bias voltage of 10 to 50 V to the skimmer, allowing the sampler to float or grounding it, enhances ion transmission by using a DC offset voltage for mass spectrometers requiring higher initial ion energy.

Validation and Quality Assurance Methodologies

Validation and quality assurance methodologies form a critical foundation for reliable ICP-MS analysis. Robust validation protocols must be established to ensure that optimized instrument settings consistently deliver accurate and precise results across various sample matrices. Method validation should include assessment of linearity, detection limits, quantification limits, accuracy, precision, and robustness under the selected instrumental parameters.

Performance verification procedures should be implemented on a regular schedule, including daily system suitability tests that monitor key performance indicators such as sensitivity, oxide formation rates, and doubly-charged ion ratios. These tests provide early warning of potential instrumental drift or degradation that could compromise analytical quality. Certified reference materials (CRMs) that match the matrix of analytical samples should be analyzed regularly to verify calibration accuracy and method performance under the optimized conditions.

Quality control charts represent an essential tool for monitoring long-term instrument stability and method performance. Control charts tracking instrumental sensitivity, background levels, and internal standard recovery rates can reveal subtle shifts in performance that might otherwise go undetected. Statistical process control principles should be applied to establish appropriate warning and action limits based on method validation data.

Uncertainty estimation is another crucial aspect of quality assurance in ICP-MS analysis. A comprehensive uncertainty budget should account for contributions from sample preparation, calibration, instrumental drift, and matrix effects. This enables meaningful interpretation of results and appropriate decision-making based on analytical data generated using the optimized instrument settings.

Proficiency testing participation provides external validation of the laboratory's analytical capabilities using the optimized ICP-MS methods. Regular participation in interlaboratory comparison programs helps identify any systematic biases that may not be apparent through internal quality control procedures alone. Results from these exercises should be used to refine optimization strategies if necessary.

Documentation systems must be established to record all aspects of instrument optimization, validation, and ongoing quality control. This includes detailed standard operating procedures (SOPs) for instrument setup, tuning protocols, calibration procedures, and maintenance schedules. Electronic laboratory information management systems (LIMS) can facilitate comprehensive data tracking and trend analysis to support continuous improvement of analytical methods.

Finally, staff training and competency assessment programs ensure that personnel can consistently implement the optimized methods and correctly interpret quality control data. Regular retraining and performance evaluation help maintain analytical excellence and ensure that the benefits of instrument optimization are fully realized in routine laboratory operations.

Performance verification procedures should be implemented on a regular schedule, including daily system suitability tests that monitor key performance indicators such as sensitivity, oxide formation rates, and doubly-charged ion ratios. These tests provide early warning of potential instrumental drift or degradation that could compromise analytical quality. Certified reference materials (CRMs) that match the matrix of analytical samples should be analyzed regularly to verify calibration accuracy and method performance under the optimized conditions.

Quality control charts represent an essential tool for monitoring long-term instrument stability and method performance. Control charts tracking instrumental sensitivity, background levels, and internal standard recovery rates can reveal subtle shifts in performance that might otherwise go undetected. Statistical process control principles should be applied to establish appropriate warning and action limits based on method validation data.

Uncertainty estimation is another crucial aspect of quality assurance in ICP-MS analysis. A comprehensive uncertainty budget should account for contributions from sample preparation, calibration, instrumental drift, and matrix effects. This enables meaningful interpretation of results and appropriate decision-making based on analytical data generated using the optimized instrument settings.

Proficiency testing participation provides external validation of the laboratory's analytical capabilities using the optimized ICP-MS methods. Regular participation in interlaboratory comparison programs helps identify any systematic biases that may not be apparent through internal quality control procedures alone. Results from these exercises should be used to refine optimization strategies if necessary.

Documentation systems must be established to record all aspects of instrument optimization, validation, and ongoing quality control. This includes detailed standard operating procedures (SOPs) for instrument setup, tuning protocols, calibration procedures, and maintenance schedules. Electronic laboratory information management systems (LIMS) can facilitate comprehensive data tracking and trend analysis to support continuous improvement of analytical methods.

Finally, staff training and competency assessment programs ensure that personnel can consistently implement the optimized methods and correctly interpret quality control data. Regular retraining and performance evaluation help maintain analytical excellence and ensure that the benefits of instrument optimization are fully realized in routine laboratory operations.

Environmental and Safety Considerations in ICP-MS Operation

The operation of ICP-MS systems presents significant environmental and safety considerations that must be addressed to ensure both regulatory compliance and personnel protection. These instruments utilize high-temperature plasma (6,000-10,000K) and potentially hazardous materials, necessitating comprehensive safety protocols. Laboratory ventilation systems must be designed to effectively remove waste heat, argon gas, and any potentially toxic vapors generated during analysis, with a minimum exhaust capacity of 200-300 cubic feet per minute.

Proper management of waste streams is essential in ICP-MS operations. Liquid waste containing heavy metals and other toxic elements requires specialized disposal procedures in accordance with local environmental regulations. Many facilities implement waste collection systems that separate different types of analytical waste, particularly those containing mercury, arsenic, and other highly regulated elements, to facilitate proper treatment before disposal.

Gas cylinder safety represents another critical consideration, as ICP-MS systems typically utilize high-pressure argon. Cylinders must be properly secured with appropriate restraints, stored away from heat sources, and equipped with functioning pressure regulators. Standard operating procedures should include regular inspection of gas lines for leaks and proper cylinder exchange protocols to minimize risk of injury from high-pressure releases.

Electromagnetic radiation and RF exposure risks must also be mitigated through proper shielding and interlocks. Modern ICP-MS instruments incorporate safety features that prevent operation when access panels are removed, but regular maintenance of these systems is essential to ensure continued protection. Operators should be trained to recognize warning signs of RF leakage and understand emergency shutdown procedures.

Chemical hazards associated with sample preparation represent a significant safety concern. The acids commonly used (nitric, hydrochloric, hydrofluoric) require specialized handling procedures, including appropriate personal protective equipment and fume hood operation. Particular attention must be paid to hydrofluoric acid protocols, including availability of calcium gluconate gel for immediate treatment of exposures.

Comprehensive training programs for all ICP-MS operators should cover not only analytical procedures but also emergency response protocols for various scenarios including plasma quenching, gas leaks, chemical spills, and electrical hazards. Documentation of this training and regular safety refresher courses are increasingly required by regulatory agencies and institutional safety committees.

Proper management of waste streams is essential in ICP-MS operations. Liquid waste containing heavy metals and other toxic elements requires specialized disposal procedures in accordance with local environmental regulations. Many facilities implement waste collection systems that separate different types of analytical waste, particularly those containing mercury, arsenic, and other highly regulated elements, to facilitate proper treatment before disposal.

Gas cylinder safety represents another critical consideration, as ICP-MS systems typically utilize high-pressure argon. Cylinders must be properly secured with appropriate restraints, stored away from heat sources, and equipped with functioning pressure regulators. Standard operating procedures should include regular inspection of gas lines for leaks and proper cylinder exchange protocols to minimize risk of injury from high-pressure releases.

Electromagnetic radiation and RF exposure risks must also be mitigated through proper shielding and interlocks. Modern ICP-MS instruments incorporate safety features that prevent operation when access panels are removed, but regular maintenance of these systems is essential to ensure continued protection. Operators should be trained to recognize warning signs of RF leakage and understand emergency shutdown procedures.

Chemical hazards associated with sample preparation represent a significant safety concern. The acids commonly used (nitric, hydrochloric, hydrofluoric) require specialized handling procedures, including appropriate personal protective equipment and fume hood operation. Particular attention must be paid to hydrofluoric acid protocols, including availability of calcium gluconate gel for immediate treatment of exposures.

Comprehensive training programs for all ICP-MS operators should cover not only analytical procedures but also emergency response protocols for various scenarios including plasma quenching, gas leaks, chemical spills, and electrical hazards. Documentation of this training and regular safety refresher courses are increasingly required by regulatory agencies and institutional safety committees.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!