How to Optimize Parts for Rapid Prototyping Using Topology Optimization

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization Background and Objectives

Topology optimization has evolved significantly since its inception in the late 1980s, primarily through the seminal work of Bendsøe and Kikuchi who introduced the homogenization method. This mathematical approach to structural design optimization has transformed from an academic concept to an essential industrial tool over the past three decades. The technology enables engineers to determine the most efficient material distribution within a given design space while satisfying specified constraints and performance requirements.

The evolution of topology optimization has been accelerated by advancements in computational power and algorithm efficiency. Early implementations were limited to simple 2D problems due to computational constraints, but modern systems can handle complex 3D geometries with multiple physics considerations. This progression has been particularly important for rapid prototyping applications, where design iteration speed directly impacts product development timelines.

Current trends in topology optimization focus on multi-physics integration, considering not only structural mechanics but also thermal management, fluid dynamics, and electromagnetic performance simultaneously. Machine learning approaches are increasingly being incorporated to enhance optimization algorithms and reduce computational requirements, while preserving or improving solution quality.

The primary objective of topology optimization in rapid prototyping contexts is to create parts that maximize performance while minimizing material usage and manufacturing time. This involves balancing multiple competing factors: structural integrity, weight reduction, thermal characteristics, and manufacturability constraints specific to additive manufacturing processes.

Secondary objectives include reducing post-processing requirements by optimizing support structures and orientation, minimizing build time through efficient material distribution, and ensuring consistent quality across production runs. These objectives align with broader industry goals of sustainable manufacturing and reduced time-to-market.

A critical aspect of modern topology optimization is addressing manufacturing constraints inherent to different rapid prototyping technologies. This includes minimum feature size limitations, overhang angle restrictions, and anisotropic material properties that vary based on build direction. Recent developments have focused on incorporating these constraints directly into the optimization algorithm rather than applying them as post-processing steps.

Looking forward, the field is moving toward democratization of topology optimization tools, making them more accessible to designers without specialized expertise. This trend is supported by the development of more intuitive user interfaces and automated workflows that integrate seamlessly with existing CAD systems and rapid prototyping equipment.

The evolution of topology optimization has been accelerated by advancements in computational power and algorithm efficiency. Early implementations were limited to simple 2D problems due to computational constraints, but modern systems can handle complex 3D geometries with multiple physics considerations. This progression has been particularly important for rapid prototyping applications, where design iteration speed directly impacts product development timelines.

Current trends in topology optimization focus on multi-physics integration, considering not only structural mechanics but also thermal management, fluid dynamics, and electromagnetic performance simultaneously. Machine learning approaches are increasingly being incorporated to enhance optimization algorithms and reduce computational requirements, while preserving or improving solution quality.

The primary objective of topology optimization in rapid prototyping contexts is to create parts that maximize performance while minimizing material usage and manufacturing time. This involves balancing multiple competing factors: structural integrity, weight reduction, thermal characteristics, and manufacturability constraints specific to additive manufacturing processes.

Secondary objectives include reducing post-processing requirements by optimizing support structures and orientation, minimizing build time through efficient material distribution, and ensuring consistent quality across production runs. These objectives align with broader industry goals of sustainable manufacturing and reduced time-to-market.

A critical aspect of modern topology optimization is addressing manufacturing constraints inherent to different rapid prototyping technologies. This includes minimum feature size limitations, overhang angle restrictions, and anisotropic material properties that vary based on build direction. Recent developments have focused on incorporating these constraints directly into the optimization algorithm rather than applying them as post-processing steps.

Looking forward, the field is moving toward democratization of topology optimization tools, making them more accessible to designers without specialized expertise. This trend is supported by the development of more intuitive user interfaces and automated workflows that integrate seamlessly with existing CAD systems and rapid prototyping equipment.

Market Demand Analysis for Rapid Prototyping Solutions

The rapid prototyping market has experienced significant growth over the past decade, driven by increasing demand for faster product development cycles across multiple industries. According to recent market research, the global rapid prototyping market was valued at approximately $2.5 billion in 2022 and is projected to reach $9.7 billion by 2030, growing at a CAGR of 18.6% during the forecast period.

Manufacturing sectors, particularly aerospace, automotive, and medical devices, represent the largest market segments for rapid prototyping solutions. These industries require complex components with optimized performance characteristics while maintaining strict weight and material constraints. The integration of topology optimization into rapid prototyping workflows addresses these specific needs by enabling the creation of lightweight yet structurally sound components.

Customer demand patterns indicate a growing preference for customized solutions that can reduce material waste while maintaining or improving functional performance. A survey of manufacturing executives revealed that 78% consider topology optimization a critical technology for maintaining competitive advantage in product development. Additionally, 65% of respondents reported plans to increase investments in advanced design optimization technologies within the next three years.

The market is witnessing a shift from traditional manufacturing methods toward more agile and efficient processes. Companies are increasingly seeking solutions that can compress development timelines while reducing costs. Topology optimization directly addresses this need by minimizing the number of design iterations required before final production, with users reporting average development time reductions of 30-40%.

Regional analysis shows North America currently leads the market with approximately 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period due to rapid industrialization and increasing adoption of advanced manufacturing technologies in countries like China, Japan, and South Korea.

Industry-specific demand variations are notable, with aerospace demanding solutions focused on weight reduction (typically seeking 40-50% weight savings), automotive prioritizing cost-effective mass production compatibility, and medical device manufacturers emphasizing biocompatibility and patient-specific customization capabilities.

The software segment of the market is growing particularly fast as companies seek integrated solutions that combine topology optimization algorithms with simulation capabilities and direct interfaces to additive manufacturing systems. This integration trend is expected to continue as manufacturers seek to streamline the entire design-to-production workflow.

Manufacturing sectors, particularly aerospace, automotive, and medical devices, represent the largest market segments for rapid prototyping solutions. These industries require complex components with optimized performance characteristics while maintaining strict weight and material constraints. The integration of topology optimization into rapid prototyping workflows addresses these specific needs by enabling the creation of lightweight yet structurally sound components.

Customer demand patterns indicate a growing preference for customized solutions that can reduce material waste while maintaining or improving functional performance. A survey of manufacturing executives revealed that 78% consider topology optimization a critical technology for maintaining competitive advantage in product development. Additionally, 65% of respondents reported plans to increase investments in advanced design optimization technologies within the next three years.

The market is witnessing a shift from traditional manufacturing methods toward more agile and efficient processes. Companies are increasingly seeking solutions that can compress development timelines while reducing costs. Topology optimization directly addresses this need by minimizing the number of design iterations required before final production, with users reporting average development time reductions of 30-40%.

Regional analysis shows North America currently leads the market with approximately 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period due to rapid industrialization and increasing adoption of advanced manufacturing technologies in countries like China, Japan, and South Korea.

Industry-specific demand variations are notable, with aerospace demanding solutions focused on weight reduction (typically seeking 40-50% weight savings), automotive prioritizing cost-effective mass production compatibility, and medical device manufacturers emphasizing biocompatibility and patient-specific customization capabilities.

The software segment of the market is growing particularly fast as companies seek integrated solutions that combine topology optimization algorithms with simulation capabilities and direct interfaces to additive manufacturing systems. This integration trend is expected to continue as manufacturers seek to streamline the entire design-to-production workflow.

Current State and Challenges in Topology Optimization

Topology optimization has emerged as a powerful computational design methodology in engineering, enabling the creation of lightweight yet structurally efficient components. Currently, the field is experiencing rapid advancement with the integration of machine learning algorithms and high-performance computing capabilities. Commercial software solutions such as Altair OptiStruct, ANSYS Mechanical, and Siemens NX have made topology optimization more accessible to engineers across industries, though significant challenges remain.

The primary technical challenge lies in the computational complexity of topology optimization algorithms. For complex parts with multiple load cases and constraints, the optimization process can require substantial computational resources and time, often taking hours or even days to complete. This creates a bottleneck in the rapid prototyping workflow, where quick design iterations are essential.

Manufacturing constraints represent another significant hurdle. While topology optimization can generate geometrically optimal structures, these often include complex organic shapes with internal voids, thin walls, and intricate features that may be difficult to manufacture using traditional methods. Even with additive manufacturing capabilities, considerations such as minimum feature size, support structure requirements, and build orientation significantly constrain the design space.

Multi-physics integration presents additional complexity. Current topology optimization frameworks struggle to simultaneously account for structural, thermal, fluid, and electromagnetic considerations. This limitation often results in sub-optimal designs when multiple physical phenomena are relevant to part performance, requiring engineers to make compromises or perform sequential optimizations.

Material anisotropy and heterogeneity introduce further complications. Most commercial topology optimization tools assume isotropic material properties, yet many additive manufacturing processes produce parts with directional properties. The inability to accurately model and optimize for these material characteristics leads to discrepancies between predicted and actual performance.

Verification and validation methodologies remain underdeveloped. The complex geometries resulting from topology optimization are difficult to inspect and test using conventional methods. This creates uncertainty in quality assurance processes, particularly for critical applications where part failure could have severe consequences.

Geographically, research leadership in topology optimization is concentrated in North America and Europe, with institutions like MIT, Stanford, Technical University of Denmark, and ETH Zurich leading academic advancements. However, industrial implementation is becoming increasingly global, with significant adoption in aerospace and automotive sectors across Asia, particularly in Japan, South Korea, and China.

The primary technical challenge lies in the computational complexity of topology optimization algorithms. For complex parts with multiple load cases and constraints, the optimization process can require substantial computational resources and time, often taking hours or even days to complete. This creates a bottleneck in the rapid prototyping workflow, where quick design iterations are essential.

Manufacturing constraints represent another significant hurdle. While topology optimization can generate geometrically optimal structures, these often include complex organic shapes with internal voids, thin walls, and intricate features that may be difficult to manufacture using traditional methods. Even with additive manufacturing capabilities, considerations such as minimum feature size, support structure requirements, and build orientation significantly constrain the design space.

Multi-physics integration presents additional complexity. Current topology optimization frameworks struggle to simultaneously account for structural, thermal, fluid, and electromagnetic considerations. This limitation often results in sub-optimal designs when multiple physical phenomena are relevant to part performance, requiring engineers to make compromises or perform sequential optimizations.

Material anisotropy and heterogeneity introduce further complications. Most commercial topology optimization tools assume isotropic material properties, yet many additive manufacturing processes produce parts with directional properties. The inability to accurately model and optimize for these material characteristics leads to discrepancies between predicted and actual performance.

Verification and validation methodologies remain underdeveloped. The complex geometries resulting from topology optimization are difficult to inspect and test using conventional methods. This creates uncertainty in quality assurance processes, particularly for critical applications where part failure could have severe consequences.

Geographically, research leadership in topology optimization is concentrated in North America and Europe, with institutions like MIT, Stanford, Technical University of Denmark, and ETH Zurich leading academic advancements. However, industrial implementation is becoming increasingly global, with significant adoption in aerospace and automotive sectors across Asia, particularly in Japan, South Korea, and China.

Current Methodologies for Topology-Optimized Rapid Prototyping

01 Structural optimization methods for mechanical parts

Topology optimization techniques are used to optimize the structure of mechanical parts by redistributing material within a design space to achieve desired performance criteria while minimizing weight. These methods typically involve finite element analysis to evaluate structural performance under various loading conditions. The optimization algorithms iteratively remove material from low-stress regions while maintaining material in high-stress areas, resulting in lightweight yet structurally sound components.- Structural optimization methods for mechanical parts: Topology optimization techniques are used to design mechanical parts with optimal material distribution. These methods involve iterative processes that analyze stress distribution, load paths, and material properties to create lightweight yet strong structures. The optimization algorithms identify areas where material can be removed without compromising structural integrity, resulting in parts with improved performance characteristics and reduced weight.

- Additive manufacturing integration with topology optimization: Topology optimization is increasingly integrated with additive manufacturing technologies to produce complex geometries that would be impossible to create using traditional manufacturing methods. This approach enables the fabrication of parts with internal lattice structures, conformal cooling channels, and organic shapes that maximize performance while minimizing material usage. The optimization process considers manufacturing constraints specific to 3D printing technologies to ensure printability of the optimized designs.

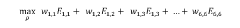

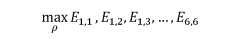

- Multi-objective optimization frameworks for part design: Advanced topology optimization frameworks incorporate multiple design objectives simultaneously, such as structural performance, thermal management, and manufacturing cost. These multi-objective approaches use mathematical algorithms to find optimal trade-offs between competing design goals. The resulting optimization process can balance factors like stiffness, weight, heat dissipation, and production constraints to create parts that perform well across multiple functional requirements.

- Machine learning applications in topology optimization: Machine learning techniques are being applied to enhance topology optimization processes by predicting optimal designs based on training data from previous optimization runs. These AI-driven approaches can significantly reduce computational time by approximating solutions without running full finite element analyses for every iteration. Neural networks and other machine learning models can identify patterns in successful designs and apply them to new optimization problems, accelerating the design process.

- Network architecture optimization using topology principles: Topology optimization principles are being applied beyond mechanical parts to optimize network architectures in telecommunications, computing systems, and electronic circuits. These applications focus on optimizing connection pathways, component placement, and resource allocation to improve performance metrics like latency, throughput, and energy efficiency. The optimization algorithms identify optimal network topologies that minimize resource usage while maintaining or improving system performance.

02 Additive manufacturing integration with topology optimization

Topology optimization is increasingly integrated with additive manufacturing processes to produce complex geometries that would be difficult or impossible to manufacture using traditional methods. This approach enables the creation of parts with internal lattice structures, conformal cooling channels, and other complex features that optimize performance while reducing material usage. The optimization algorithms specifically consider manufacturing constraints of 3D printing technologies to ensure printability of the optimized designs.Expand Specific Solutions03 Multi-objective optimization frameworks for parts design

Advanced topology optimization frameworks incorporate multiple design objectives simultaneously, such as structural performance, thermal management, and fluid flow characteristics. These multi-physics approaches allow engineers to optimize parts for real-world operating conditions where multiple physical phenomena interact. The optimization algorithms balance competing objectives through weighting factors or Pareto optimization techniques to find optimal compromise solutions that satisfy all critical performance requirements.Expand Specific Solutions04 Machine learning enhanced topology optimization

Machine learning techniques are being integrated with topology optimization to accelerate the design process and improve results. Neural networks and other AI methods can predict optimization outcomes, suggest initial design parameters, or replace computationally expensive simulations with trained surrogate models. This approach significantly reduces computational time while maintaining or improving the quality of optimized designs, enabling more design iterations within project timeframes.Expand Specific Solutions05 Network architecture optimization using topology principles

Topology optimization principles are being applied to optimize network architectures in telecommunications, computing systems, and IoT deployments. These methods determine optimal node placement, connection paths, and resource allocation to maximize network performance while minimizing infrastructure costs. The optimization algorithms consider factors such as traffic patterns, latency requirements, and reliability constraints to design robust and efficient network topologies.Expand Specific Solutions

Leading Companies and Research Institutions in the Field

Topology optimization for rapid prototyping is currently in a growth phase, with the market expanding rapidly due to increasing adoption in automotive, aerospace, and medical industries. The global market size for this technology is projected to reach $5-7 billion by 2025, growing at 15-20% annually. Technologically, the field is maturing with advanced solutions from industry leaders like Siemens AG, which offers comprehensive simulation-driven design tools, and Dassault Systèmes, whose SOLIDWORKS platform integrates topology optimization capabilities. Academic institutions including Zhejiang University and Georgia Tech are advancing theoretical frameworks, while manufacturers like Honda Motor and RTX Corp are implementing these technologies in production environments. The collaboration between academic research centers and commercial entities is accelerating practical applications, particularly in lightweight component design and material efficiency optimization.

Siemens AG

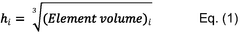

Technical Solution: Siemens has developed a comprehensive topology optimization solution integrated within their NX and Simcenter software suites. Their approach combines parametric CAD modeling with advanced finite element analysis (FEA) to iteratively remove non-essential material while maintaining structural integrity. The system employs mathematical algorithms that analyze stress distribution patterns and material utilization efficiency across the part geometry[1]. Siemens' solution particularly excels in multi-physics optimization, considering not only structural requirements but also thermal, fluid, and electromagnetic factors simultaneously. Their platform incorporates manufacturing constraints directly into the optimization process, ensuring that generated designs remain manufacturable through specific rapid prototyping methods like additive manufacturing or CNC machining[3]. The system also features automated mesh refinement capabilities that adapt element density in critical regions during optimization iterations, improving both accuracy and computational efficiency[5].

Strengths: Seamless integration with existing CAD/CAM workflows; comprehensive multi-physics capabilities; robust manufacturing constraint handling. Weaknesses: Relatively high computational requirements; steep learning curve for new users; optimization algorithms may sometimes produce geometrically complex solutions requiring significant post-processing.

Dassault Systèmes SE

Technical Solution: Dassault Systèmes has pioneered an integrated topology optimization approach within their SOLIDWORKS and CATIA platforms, specifically tailored for rapid prototyping applications. Their technology utilizes non-parametric generative design algorithms that can process design objectives and constraints to produce optimized geometries. The system employs the SIMP (Solid Isotropic Material with Penalization) method, which assigns variable density to elements and iteratively penalizes intermediate densities to drive solutions toward discrete material distributions[2]. Dassault's platform features direct integration with additive manufacturing workflows, automatically generating support structures and optimizing build orientation based on the topology-optimized design. Their solution incorporates lattice structure generation capabilities that can replace solid volumes with weight-optimized internal structures while maintaining mechanical performance[4]. The system also includes automated design validation tools that verify optimized parts against original performance requirements before manufacturing[6].

Strengths: Intuitive user interface with minimal learning curve; excellent integration with additive manufacturing workflows; powerful lattice structure generation capabilities. Weaknesses: Limited multi-physics optimization compared to competitors; optimization algorithms sometimes produce results requiring significant smoothing before manufacturing; computational performance can degrade with very complex models.

Key Algorithms and Software Tools Analysis

Method, system, device for topology optimization, topology optimized component

PatentWO2023061628A1

Innovation

- The method employs a surrogate model that relates unit cell stiffness tensors to average density, using importance weights to optimize the stiffness tensor elements, ensuring that microstructures lie on a Pareto front, allowing for flexible and efficient design optimization without restricting the design space.

Topology optimization with bidirectional mesh adaptation

PatentWO2023133734A1

Innovation

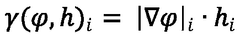

- Bidirectional mesh adaptation technique that dynamically adjusts mesh resolution during topology optimization process, allowing for both refinement and coarsening based on optimization progress.

- Multi-physics topology optimization approach that balances computational efficiency with design detail preservation, particularly for thermal-flow applications like gas turbine components.

- Adaptive meshing methodology that preserves design feature details while using coarser meshes in less critical regions, optimizing computational resource allocation.

Material Considerations for Optimized Parts

Material selection plays a critical role in the success of topology-optimized parts for rapid prototyping. The mechanical properties of the chosen material directly influence the optimization algorithm's effectiveness and the final part performance. Materials with consistent and predictable behavior throughout the manufacturing process enable more accurate topology optimization results, as the algorithm can reliably predict stress distribution and material response.

Different rapid prototyping technologies impose specific material constraints that must be considered during the optimization phase. For instance, powder-based technologies like Selective Laser Sintering (SLS) work effectively with nylon and polyamide powders, while Fused Deposition Modeling (FDM) typically utilizes thermoplastics such as ABS, PLA, and PETG. Stereolithography (SLA) and Digital Light Processing (DLP) employ photopolymer resins with varying mechanical properties. Metal-based additive manufacturing, including Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM), supports aluminum alloys, titanium, and stainless steel.

The anisotropic behavior of materials in additive manufacturing presents significant challenges for topology optimization. Layer-by-layer construction creates inherent directional dependencies in mechanical properties, with parts typically exhibiting greater strength in the XY plane compared to the Z direction. Advanced topology optimization algorithms must account for this anisotropy to produce realistic and manufacturable designs.

Material density-to-strength ratios significantly impact topology optimization outcomes. Lightweight materials with high strength, such as titanium alloys and carbon fiber-reinforced polymers, often yield more efficient optimized structures. These materials allow for greater design freedom in creating complex lattice structures and thin-walled components while maintaining structural integrity.

Post-processing requirements also influence material selection for optimized parts. Some materials necessitate heat treatment to relieve internal stresses, while others may require surface finishing to achieve desired tolerances. These post-processing steps can alter the mechanical properties of the final part and must be factored into the initial optimization parameters.

Emerging composite and multi-material printing technologies are expanding the possibilities for topology optimization. These advancements enable the creation of parts with regionally varied material properties, allowing designers to optimize not only geometry but also material composition throughout the part. This approach, known as multi-material topology optimization, represents the cutting edge of the field and offers promising avenues for creating highly efficient structures with precisely tailored performance characteristics.

Different rapid prototyping technologies impose specific material constraints that must be considered during the optimization phase. For instance, powder-based technologies like Selective Laser Sintering (SLS) work effectively with nylon and polyamide powders, while Fused Deposition Modeling (FDM) typically utilizes thermoplastics such as ABS, PLA, and PETG. Stereolithography (SLA) and Digital Light Processing (DLP) employ photopolymer resins with varying mechanical properties. Metal-based additive manufacturing, including Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM), supports aluminum alloys, titanium, and stainless steel.

The anisotropic behavior of materials in additive manufacturing presents significant challenges for topology optimization. Layer-by-layer construction creates inherent directional dependencies in mechanical properties, with parts typically exhibiting greater strength in the XY plane compared to the Z direction. Advanced topology optimization algorithms must account for this anisotropy to produce realistic and manufacturable designs.

Material density-to-strength ratios significantly impact topology optimization outcomes. Lightweight materials with high strength, such as titanium alloys and carbon fiber-reinforced polymers, often yield more efficient optimized structures. These materials allow for greater design freedom in creating complex lattice structures and thin-walled components while maintaining structural integrity.

Post-processing requirements also influence material selection for optimized parts. Some materials necessitate heat treatment to relieve internal stresses, while others may require surface finishing to achieve desired tolerances. These post-processing steps can alter the mechanical properties of the final part and must be factored into the initial optimization parameters.

Emerging composite and multi-material printing technologies are expanding the possibilities for topology optimization. These advancements enable the creation of parts with regionally varied material properties, allowing designers to optimize not only geometry but also material composition throughout the part. This approach, known as multi-material topology optimization, represents the cutting edge of the field and offers promising avenues for creating highly efficient structures with precisely tailored performance characteristics.

Cost-Benefit Analysis of Topology Optimization Implementation

Implementing topology optimization in manufacturing processes requires careful evaluation of its economic implications. Initial investment costs for topology optimization include software licensing fees ranging from $5,000 to $50,000 depending on capabilities and vendor support packages. Hardware requirements typically involve high-performance computing systems with advanced graphics processing capabilities, adding $3,000-$10,000 to implementation costs. Additionally, organizations must factor in training expenses for engineering staff, which may range from $1,500 to $5,000 per engineer.

Against these investments, significant material savings emerge as a primary benefit. Studies across various industries demonstrate material reduction of 30-60% in optimized parts while maintaining or improving performance characteristics. This translates to direct cost savings in raw materials, particularly valuable when working with expensive alloys or composites where material costs can represent 40-70% of total part expenses.

Manufacturing time reductions represent another substantial economic advantage. Topology-optimized parts typically require less material removal during machining processes, reducing tool wear and machining time by 15-40%. For additive manufacturing applications, optimized designs often reduce build times and support material requirements by 20-50%, directly impacting production costs and throughput capabilities.

Energy consumption during both manufacturing and product lifecycle presents additional cost benefits. Lighter components require less energy during production processes, while weight reduction in transportation applications yields ongoing operational savings. In aerospace applications, each kilogram of weight reduction can translate to approximately $3,000-$5,000 in lifetime fuel savings per aircraft.

Performance improvements from topology optimization frequently deliver indirect economic benefits that exceed direct material and manufacturing savings. Enhanced thermal management, improved structural integrity, and optimized fluid flow characteristics can extend product lifecycles, reduce maintenance requirements, and improve operational efficiency. These benefits, while more challenging to quantify precisely, often represent the most significant long-term economic value.

Return on investment timelines vary significantly based on production volumes and application criticality. High-volume production typically achieves ROI within 6-18 months, while specialized low-volume applications may require 18-36 months to fully recover implementation costs. Organizations implementing topology optimization across multiple product lines generally experience accelerating returns as expertise develops and optimization methodologies become standardized.

Against these investments, significant material savings emerge as a primary benefit. Studies across various industries demonstrate material reduction of 30-60% in optimized parts while maintaining or improving performance characteristics. This translates to direct cost savings in raw materials, particularly valuable when working with expensive alloys or composites where material costs can represent 40-70% of total part expenses.

Manufacturing time reductions represent another substantial economic advantage. Topology-optimized parts typically require less material removal during machining processes, reducing tool wear and machining time by 15-40%. For additive manufacturing applications, optimized designs often reduce build times and support material requirements by 20-50%, directly impacting production costs and throughput capabilities.

Energy consumption during both manufacturing and product lifecycle presents additional cost benefits. Lighter components require less energy during production processes, while weight reduction in transportation applications yields ongoing operational savings. In aerospace applications, each kilogram of weight reduction can translate to approximately $3,000-$5,000 in lifetime fuel savings per aircraft.

Performance improvements from topology optimization frequently deliver indirect economic benefits that exceed direct material and manufacturing savings. Enhanced thermal management, improved structural integrity, and optimized fluid flow characteristics can extend product lifecycles, reduce maintenance requirements, and improve operational efficiency. These benefits, while more challenging to quantify precisely, often represent the most significant long-term economic value.

Return on investment timelines vary significantly based on production volumes and application criticality. High-volume production typically achieves ROI within 6-18 months, while specialized low-volume applications may require 18-36 months to fully recover implementation costs. Organizations implementing topology optimization across multiple product lines generally experience accelerating returns as expertise develops and optimization methodologies become standardized.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!