How to Optimize Zirconia for Optical Clarity?

Zirconia Optical Clarity Background and Objectives

Zirconia, a versatile ceramic material, has gained significant attention in the field of optics due to its unique properties. The quest for optimizing zirconia for optical clarity has been a focus of research and development for several decades. This pursuit stems from the material's potential to revolutionize various optical applications, ranging from high-performance lenses to advanced display technologies.

The journey of zirconia in optics began in the mid-20th century when researchers first recognized its potential for optical applications. Initially, the primary challenge was to overcome the inherent opacity of zirconia in its natural state. As technology progressed, scientists and engineers developed various methods to enhance the optical clarity of zirconia, marking the beginning of a new era in ceramic optics.

The evolution of zirconia for optical applications has been driven by the increasing demand for materials that can withstand harsh environments while maintaining excellent optical properties. This demand has been particularly strong in industries such as aerospace, defense, and medical imaging, where traditional glass-based optics often fall short in terms of durability and performance under extreme conditions.

One of the key milestones in the development of optically clear zirconia was the introduction of yttria-stabilized zirconia (YSZ) in the 1970s. This breakthrough significantly improved the material's transparency and mechanical properties, opening up new possibilities for its use in optical systems. Since then, researchers have been continuously refining the composition and processing techniques to further enhance the optical clarity of zirconia.

The current technological landscape presents both challenges and opportunities in the optimization of zirconia for optical clarity. On one hand, advancements in nanotechnology and materials science have provided new tools and approaches for manipulating the structure of zirconia at the atomic level. On the other hand, the increasing complexity of optical systems and the demand for higher performance in extreme environments continue to push the boundaries of what is possible with zirconia-based optics.

Looking ahead, the objectives for optimizing zirconia for optical clarity are multifaceted. These include improving transparency across a broader spectrum of wavelengths, enhancing resistance to thermal shock and radiation, and developing more efficient and cost-effective manufacturing processes. Additionally, there is a growing interest in exploring the potential of zirconia-based composites and hybrid materials that could offer even better optical and mechanical properties than pure zirconia.

Market Analysis for Optically Clear Zirconia

The market for optically clear zirconia is experiencing significant growth, driven by increasing demand across various industries. The global zirconia market, which includes optically clear zirconia, was valued at approximately $4.8 billion in 2020 and is projected to reach $8.2 billion by 2027, growing at a CAGR of 7.8% during the forecast period. This growth is primarily attributed to the expanding applications of zirconia in sectors such as healthcare, electronics, and optics.

In the healthcare industry, optically clear zirconia is gaining traction in dental applications, particularly for dental crowns and implants. The material's biocompatibility, durability, and aesthetic properties make it an attractive alternative to traditional materials. The global dental zirconia market is expected to grow at a CAGR of 9.5% from 2021 to 2028, indicating a strong demand for optically clear zirconia in this sector.

The electronics industry is another key driver for the optically clear zirconia market. With the increasing adoption of advanced display technologies, such as OLED and micro-LED, there is a growing need for high-performance optical materials. Optically clear zirconia is being explored for use in display substrates and optical coatings, offering improved light transmission and durability compared to conventional materials.

In the optics sector, optically clear zirconia is finding applications in high-performance lenses, optical filters, and precision optical components. The global optical components market is expected to grow at a CAGR of 7.2% from 2021 to 2026, presenting significant opportunities for optically clear zirconia manufacturers.

Geographically, Asia-Pacific is expected to dominate the zirconia market, including the optically clear segment, due to rapid industrialization and increasing investments in research and development. North America and Europe are also significant markets, driven by advancements in healthcare and electronics industries.

However, the market for optically clear zirconia faces challenges, including high production costs and competition from alternative materials such as sapphire and high-purity alumina. Manufacturers are focusing on developing cost-effective production methods and improving the optical properties of zirconia to address these challenges and expand market share.

In conclusion, the market for optically clear zirconia shows promising growth potential across multiple industries. As research and development efforts continue to optimize zirconia for optical clarity, new applications and market opportunities are likely to emerge, further driving demand for this versatile material.

Current Challenges in Zirconia Optical Clarity

Despite significant advancements in zirconia technology, achieving optimal optical clarity remains a persistent challenge in the field. One of the primary obstacles is the inherent opacity of zirconia in its natural state. The material's crystalline structure and high refractive index contribute to light scattering, which compromises transparency. This characteristic makes it difficult to produce zirconia components with the level of clarity required for advanced optical applications.

Another major challenge lies in controlling the grain size and distribution during the sintering process. As zirconia undergoes densification at high temperatures, the grains tend to grow, leading to increased light scattering at grain boundaries. Achieving a fine-grained microstructure with uniform distribution is crucial for enhancing optical clarity, but it requires precise control over sintering parameters, which can be technically demanding and costly.

The presence of impurities and defects in zirconia also significantly impacts its optical properties. Even minute amounts of contaminants or structural defects can act as scattering centers, reducing overall transparency. Ensuring ultra-high purity of raw materials and maintaining stringent process controls throughout manufacturing are essential but challenging aspects of producing optically clear zirconia.

Porosity is another critical factor affecting zirconia's optical clarity. Residual pores, even at the nanoscale, can dramatically increase light scattering and reduce transparency. Achieving full densification without compromising the material's other desirable properties, such as strength and toughness, presents a significant technical challenge.

The stabilization of zirconia's crystal structure also poses difficulties in optimizing optical clarity. Different crystal phases of zirconia exhibit varying optical properties, and phase transformations can lead to changes in transparency. Maintaining a stable crystal structure that promotes optical clarity while preserving mechanical properties requires careful balancing of dopants and processing conditions.

Furthermore, the surface quality of zirconia components plays a crucial role in their optical performance. Achieving and maintaining an ultra-smooth surface finish is challenging due to zirconia's hardness and the potential for surface defects during processing. Advanced polishing techniques are necessary but can be time-consuming and expensive.

Lastly, the trade-off between optical clarity and other material properties presents an ongoing challenge. Efforts to enhance transparency often come at the expense of mechanical strength, toughness, or chemical stability. Finding the optimal balance that meets both optical and structural requirements remains a key focus of research and development in the field of zirconia optimization for optical applications.

Existing Methods for Zirconia Clarity Enhancement

01 Composition and processing for improved optical clarity

Zirconia's optical clarity can be enhanced through specific compositions and processing methods. This includes controlling the grain size, using specific dopants, and optimizing sintering conditions to reduce light scattering and increase transparency. Advanced processing techniques like hot isostatic pressing may be employed to achieve higher density and improved optical properties.- Composition and processing for improved optical clarity: Zirconia's optical clarity can be enhanced through careful control of composition and processing methods. This includes optimizing the grain size, reducing porosity, and controlling the phase composition. Advanced sintering techniques and the addition of specific dopants can contribute to achieving higher transparency in zirconia ceramics.

- Surface treatment and polishing techniques: Various surface treatment and polishing techniques can significantly improve the optical clarity of zirconia. These methods may include chemical etching, mechanical polishing, and laser treatment. The goal is to reduce surface roughness and eliminate defects that can scatter light, thereby enhancing transparency and overall optical performance.

- Nanostructured zirconia for optical applications: Developing nanostructured zirconia materials can lead to improved optical clarity. By controlling the size and distribution of nanoparticles or creating nanocomposites, it's possible to reduce light scattering and increase transparency. This approach is particularly useful in creating optically clear zirconia for advanced applications in optics and photonics.

- Doping and alloying for enhanced transparency: Introducing specific dopants or alloying elements into zirconia can significantly improve its optical properties. Careful selection and precise control of these additives can modify the crystal structure, reduce defects, and enhance light transmission. This method is crucial for developing highly transparent zirconia materials for various optical applications.

- Characterization and measurement of optical clarity: Advanced techniques for characterizing and measuring the optical clarity of zirconia are essential for quality control and product development. These may include spectrophotometry, interferometry, and other optical testing methods. Accurate measurement and analysis of optical properties are crucial for optimizing the production process and ensuring consistent high-quality transparent zirconia materials.

02 Surface treatments for optical clarity

Various surface treatments can be applied to zirconia to improve its optical clarity. These may include polishing techniques, application of coatings, or chemical treatments that modify the surface properties. Such treatments can reduce surface roughness, minimize light scattering, and enhance the overall transparency of zirconia components.Expand Specific Solutions03 Zirconia in optical applications

Zirconia with high optical clarity is utilized in various optical applications. This includes its use in lenses, optical windows, and other components in imaging systems, sensors, and scientific instruments. The material's durability combined with optical transparency makes it suitable for demanding environments where both optical performance and mechanical strength are required.Expand Specific Solutions04 Nanostructured zirconia for optical clarity

Nanostructured zirconia materials are being developed to achieve superior optical clarity. By controlling the material at the nanoscale, it's possible to reduce grain boundaries and defects that cause light scattering. This approach can lead to zirconia with exceptional transparency and optical properties suitable for advanced applications.Expand Specific Solutions05 Characterization and measurement of zirconia optical clarity

Accurate characterization and measurement of zirconia's optical clarity are crucial for quality control and development. This involves using specialized equipment and techniques to assess properties such as transmittance, refractive index, and scattering. Advanced imaging and spectroscopic methods may be employed to analyze the material's optical performance across different wavelengths.Expand Specific Solutions

Key Players in Zirconia Optics Industry

The optimization of zirconia for optical clarity is a rapidly evolving field in the advanced materials industry. The market is in a growth phase, driven by increasing demand for high-performance optical components in various sectors. The global market size for optically clear zirconia is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like 3M Innovative Properties Co., Tosoh Corp., and Kuraray Noritake Dental, Inc. leading the way in research and development. These firms are focusing on improving synthesis methods, doping techniques, and surface treatments to enhance zirconia's optical properties. Academic institutions such as Shanghai University and Yangzhou University are also contributing to the technological advancements, bridging the gap between fundamental research and industrial applications.

Tosoh Corp.

Kuraray Noritake Dental, Inc.

Innovative Approaches to Zirconia Transparency

- The development of colloidal, crystalline, and substantially non-associated zirconia particles with specific size and crystal structure, produced through a process involving two hydrothermal treatments, are dispersed in an organic matrix to create composite materials with high refractive index and x-ray opacity while maintaining optical transmission.

- A method involving hydrothermal treatment of a mixture of zirconium oxychloride and an alkali metal halide at temperatures above 150°C, followed by desalting without peptization, to produce a colloidal suspension of zirconia with a monoclinic crystalline phase and high redispersibility, enhancing crystallinity and stability.

Material Characterization Techniques for Zirconia

Material characterization techniques play a crucial role in optimizing zirconia for optical clarity. These techniques provide essential insights into the material's structure, composition, and properties, enabling researchers and engineers to fine-tune the manufacturing process and enhance the optical performance of zirconia.

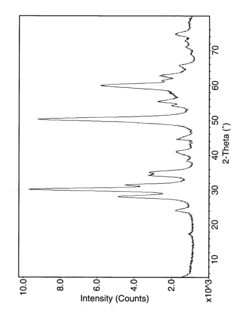

X-ray diffraction (XRD) is a fundamental technique used to analyze the crystal structure of zirconia. By examining the diffraction patterns, researchers can identify the crystalline phases present in the material, such as tetragonal, monoclinic, or cubic zirconia. This information is vital for understanding how different phases affect optical clarity and for developing strategies to control phase transformations during processing.

Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) are powerful tools for investigating the microstructure of zirconia samples. SEM provides high-resolution images of the surface morphology, revealing grain size, porosity, and defects that can impact optical clarity. TEM, on the other hand, allows for the examination of internal structures at the nanoscale, providing valuable information about grain boundaries, dislocations, and other structural features that influence light transmission.

Spectroscopic techniques, such as Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR), are employed to study the vibrational modes of zirconia. These methods can detect impurities, structural defects, and phase transitions that may affect optical properties. By analyzing spectral data, researchers can identify and quantify factors that contribute to light scattering or absorption in zirconia samples.

Optical characterization techniques, including UV-Vis spectrophotometry and ellipsometry, are essential for directly measuring the optical properties of zirconia. UV-Vis spectrophotometry provides information on light transmission and absorption across different wavelengths, while ellipsometry allows for precise measurements of refractive index and thickness of thin zirconia films. These techniques are invaluable for assessing the optical clarity of zirconia samples and optimizing processing parameters.

Thermal analysis methods, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are used to study the thermal behavior of zirconia. These techniques can reveal phase transitions, decomposition temperatures, and other thermal events that may impact the material's optical properties during processing or in high-temperature applications.

Surface analysis techniques, including X-ray photoelectron spectroscopy (XPS) and atomic force microscopy (AFM), provide detailed information about the surface chemistry and topography of zirconia samples. XPS can detect surface contaminants and chemical states that may affect optical clarity, while AFM offers nanoscale resolution of surface roughness and morphology, which are critical factors in light scattering and reflection.

By employing these advanced characterization techniques, researchers can gain a comprehensive understanding of the factors influencing zirconia's optical clarity. This knowledge enables the development of optimized processing methods, composition adjustments, and surface treatments to enhance the material's transparency and overall optical performance.

Environmental Impact of Zirconia Production

The production of zirconia for optical applications has significant environmental implications that warrant careful consideration. The extraction and processing of zirconium minerals, primarily zircon sand, involve energy-intensive operations that contribute to greenhouse gas emissions. Mining activities can lead to habitat disruption and soil erosion, particularly in sensitive ecosystems. The refining process requires substantial water usage, potentially straining local water resources in arid regions.

Chemical treatments used in zirconia production, such as acid leaching and alkali fusion, generate hazardous waste streams that necessitate proper management and disposal. These processes may release toxic compounds into the environment if not adequately controlled, posing risks to both aquatic and terrestrial ecosystems. Additionally, the high-temperature calcination and sintering stages consume considerable energy, often derived from fossil fuels, further exacerbating the carbon footprint of zirconia manufacturing.

The pursuit of optical clarity in zirconia production introduces additional environmental challenges. Advanced purification techniques, such as chemical vapor deposition or sol-gel methods, may involve the use of volatile organic compounds or other environmentally persistent chemicals. The stringent quality control measures required for optical-grade zirconia can result in higher rejection rates, leading to increased material waste and resource inefficiency.

However, recent advancements in green chemistry and sustainable manufacturing practices offer promising avenues for mitigating the environmental impact of zirconia production. Closed-loop water recycling systems and more efficient filtration technologies can significantly reduce water consumption and minimize wastewater discharge. The implementation of cleaner energy sources, such as solar or wind power, for high-temperature processes can substantially lower carbon emissions associated with zirconia manufacturing.

Furthermore, the development of novel synthesis routes, including low-temperature sol-gel techniques and microwave-assisted processing, presents opportunities for reducing energy requirements and minimizing chemical waste. These innovative approaches not only contribute to environmental sustainability but also have the potential to enhance the optical properties of zirconia, aligning environmental stewardship with product quality improvement.

As the demand for high-performance optical materials continues to grow, the zirconia industry faces increasing pressure to adopt more sustainable practices. Lifecycle assessment studies and environmental impact evaluations are becoming crucial tools for identifying and addressing the most significant environmental challenges in zirconia production. By integrating these considerations into the optimization process for optical clarity, manufacturers can work towards developing eco-friendly production methods that balance performance requirements with environmental responsibility.